Liquid-level sealed connector and method for connecting signal transmission and gas conduction under water

A connector and liquid level technology, which is applied in the connection/disconnection, connection, and two-part connection device of the connecting device, etc., can solve the problem that the general connector cannot effectively seal the special cable for the liquid level transmitter, and affects the liquid level transmitter. Use range and accuracy, inability to communicate with the reference atmosphere, etc., to achieve the effect of being conducive to repeated use, good sealing, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

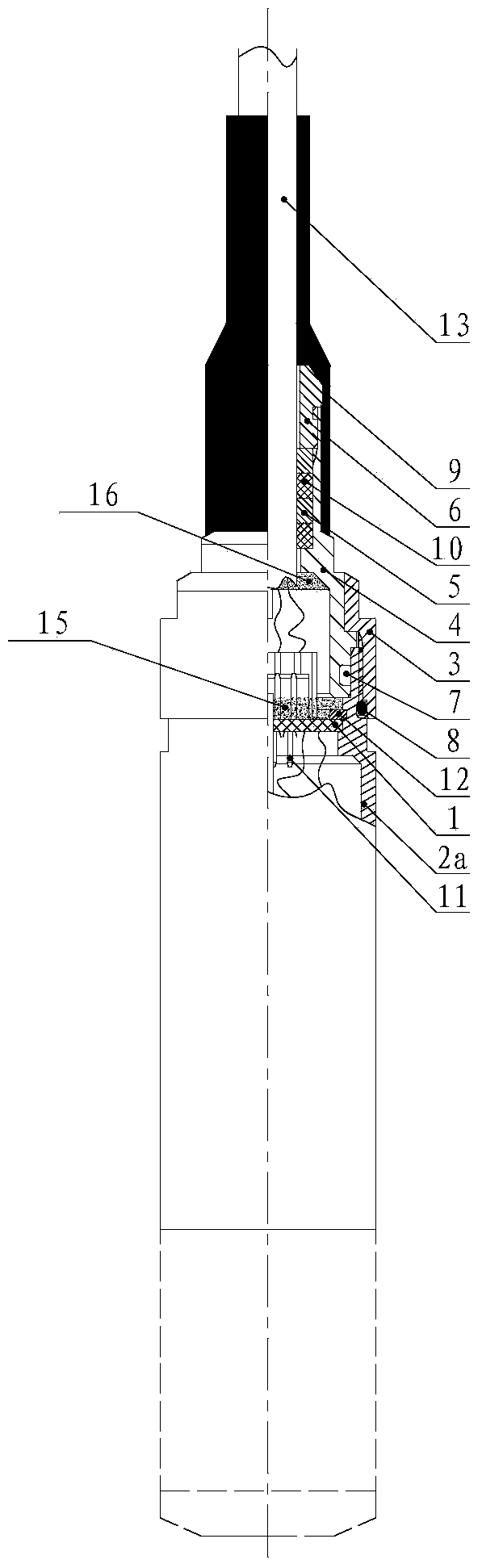

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

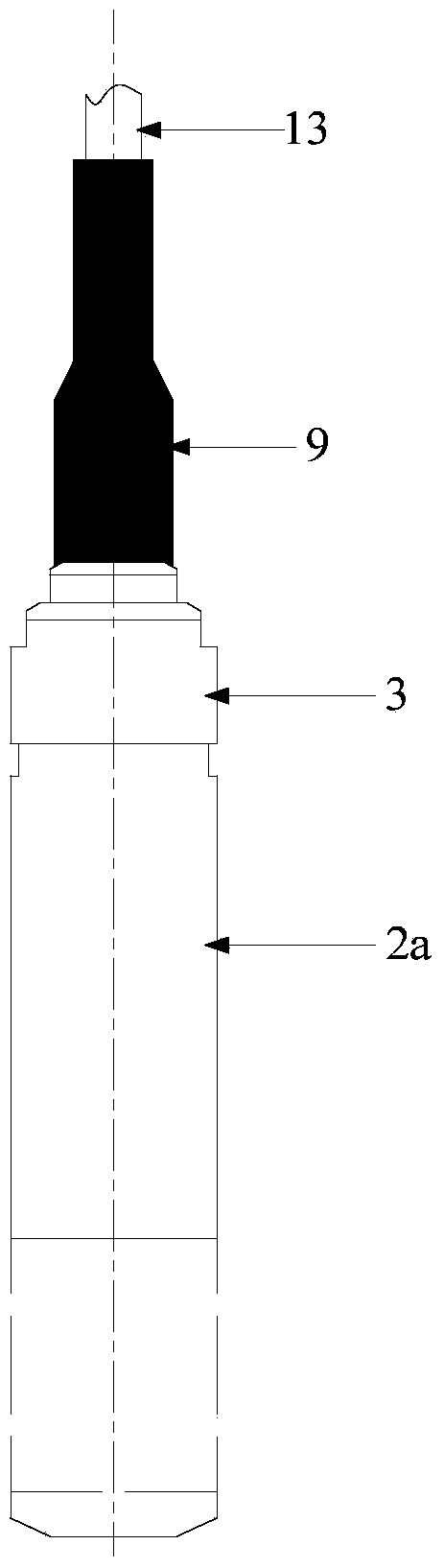

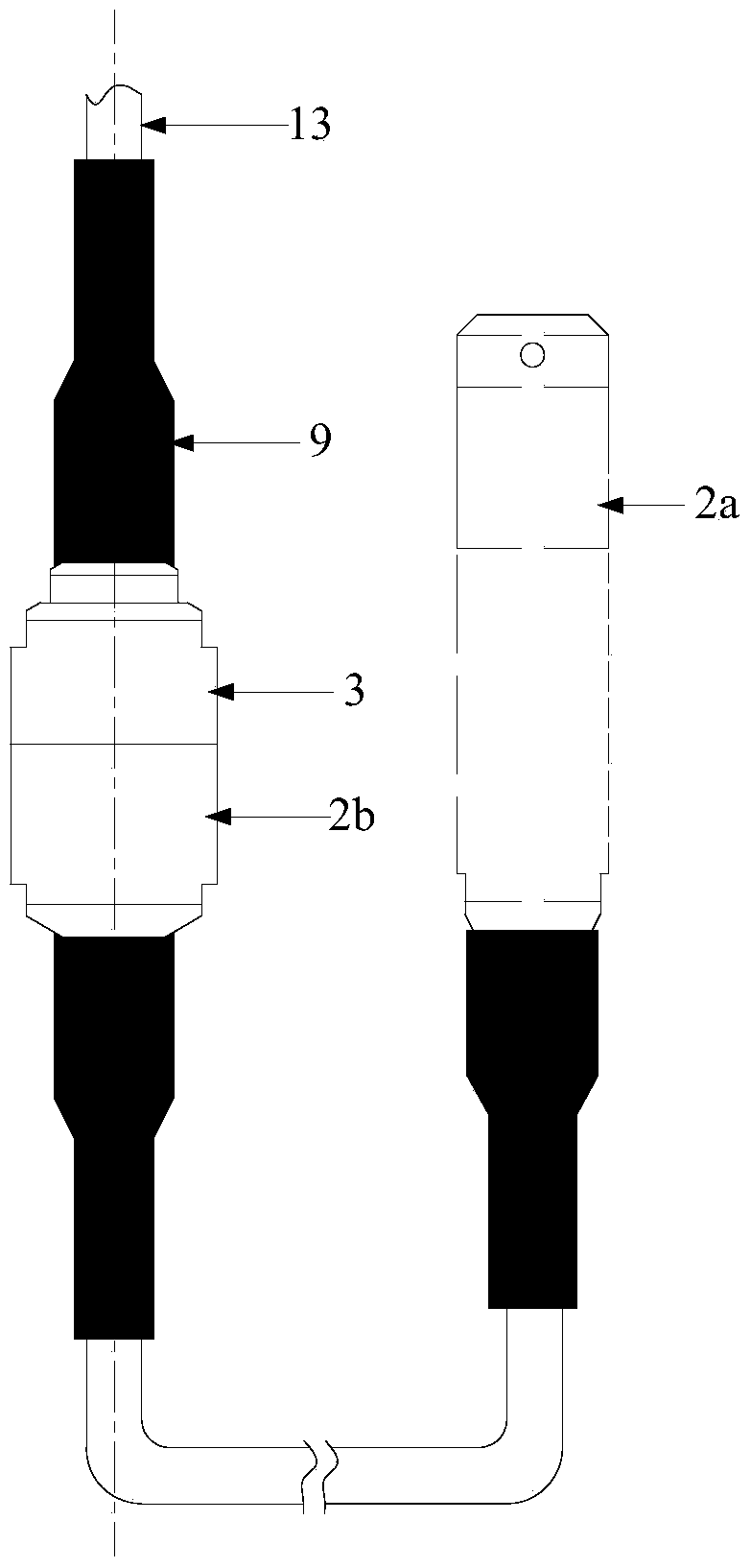

[0039] see Figure 1 to Figure 4 , The connector of the present invention includes two structures, one-piece and two-piece. Both the one-piece connector structure and the two-piece connector structure include a cable 13 and a shell cap; the two-piece connector structure also includes a connector shell.

[0040] Wherein in the one-piece connector structure, the sensor part of the transmitter can be connected with the shell cap part of the present invention, and the shell cap part can be directly connected to the signal receiving device and the power supply through the cable 13; in the split connector structure, the transmitter sensor The sense part is connected with the first shell cap part, the first shell cap part is connected with the connector shell part through the transmitter signal line, the connector shell part is connected with the second shell cap pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com