Multi-cabin prefabricated jacking pipe manufacturing method

A manufacturing method and technology of pipe joints, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of poor working environment, slow progress, difficult quality assurance, etc., and achieve the effect of convenient production and flexible separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

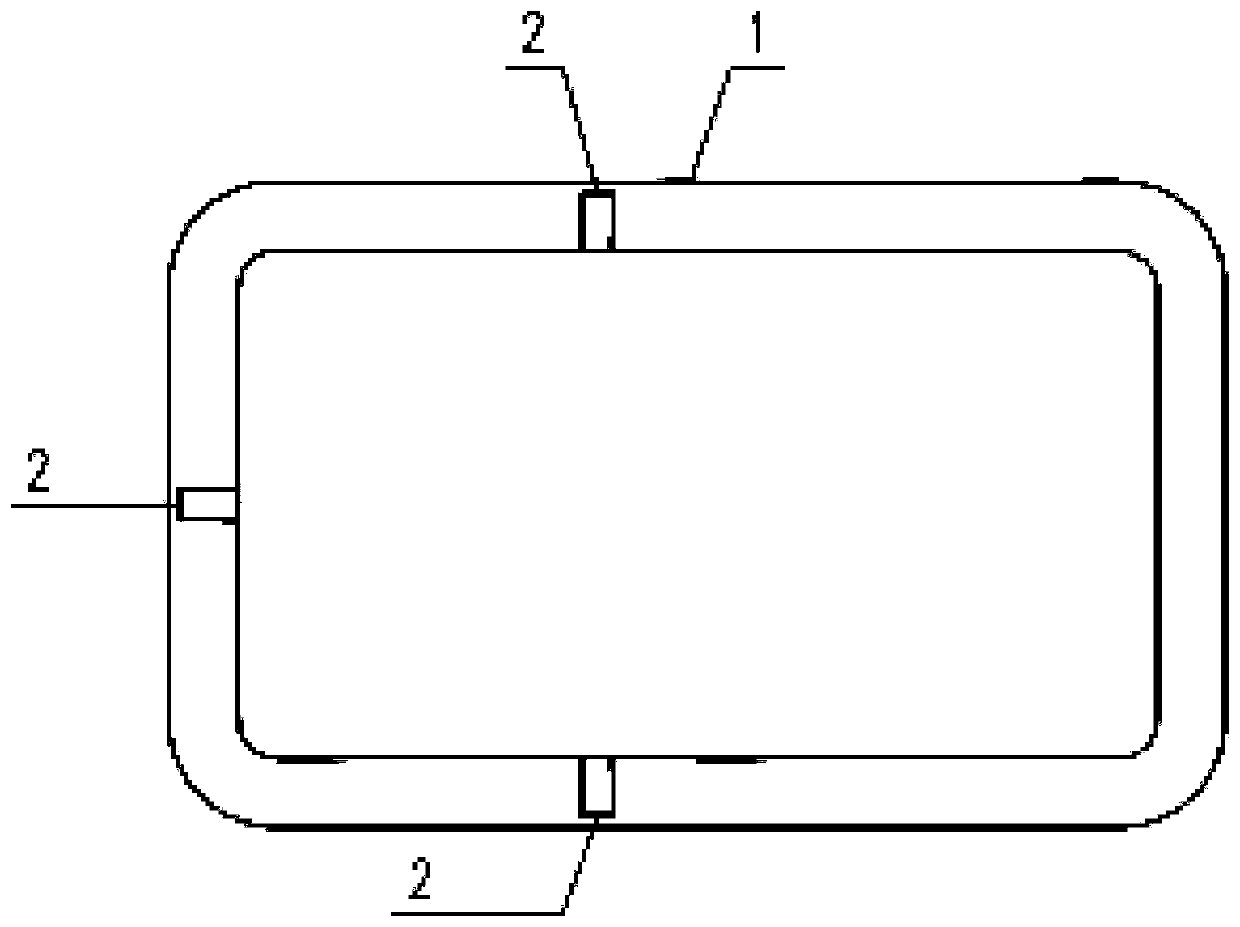

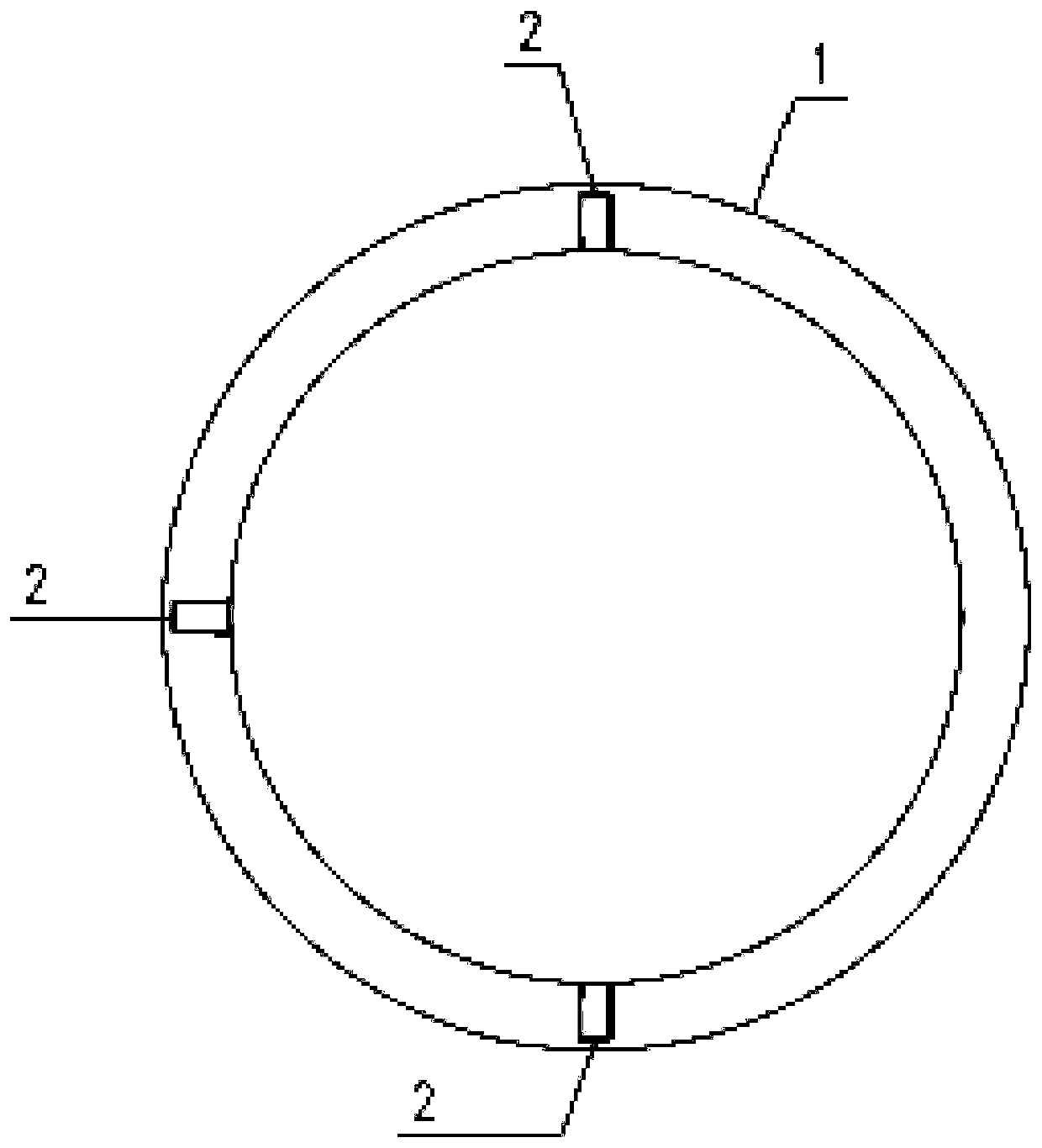

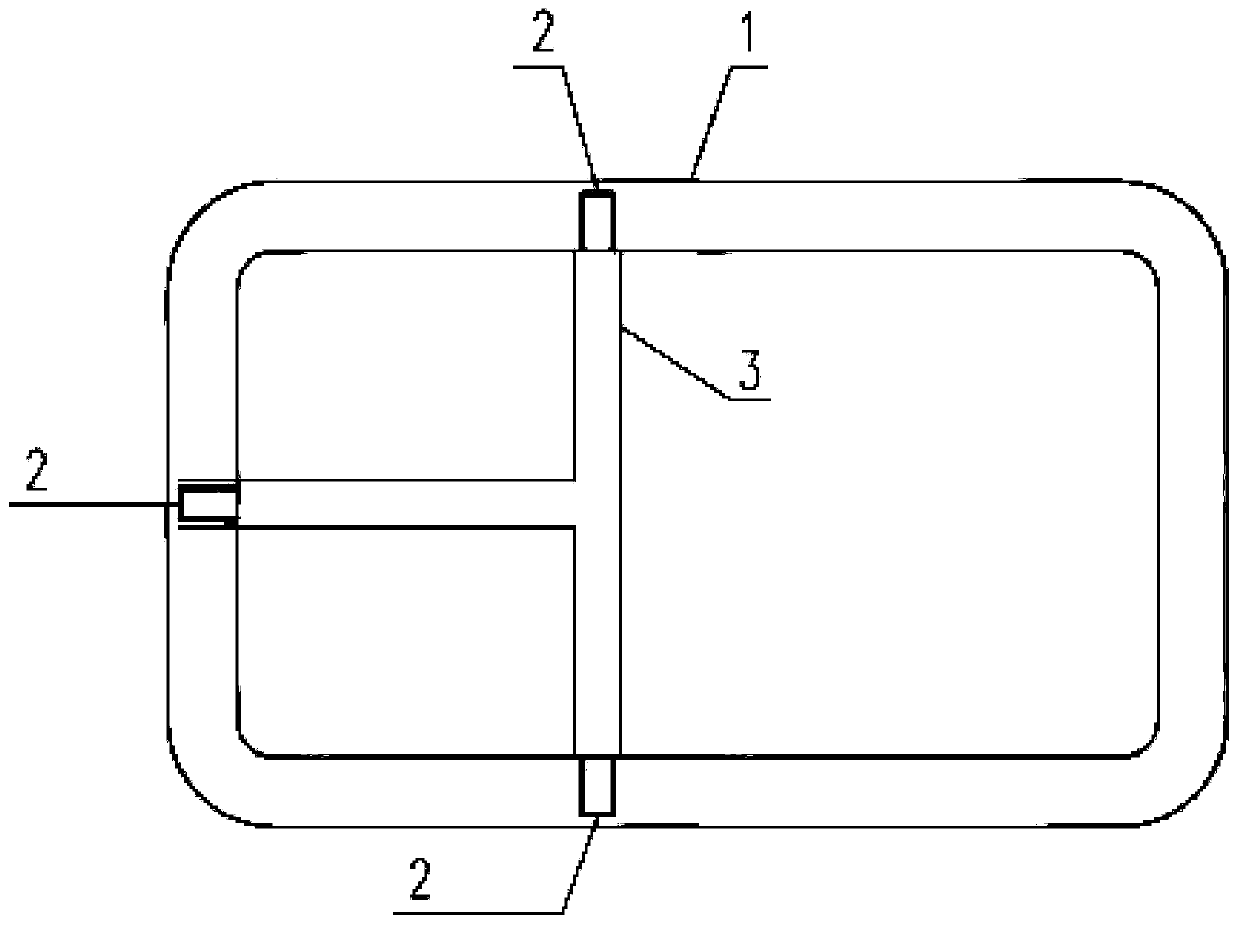

[0022] Such as figure 1 and image 3 ,or figure 2 and Figure 4 As shown, the multi-chamber prefabricated pipe jacking manufacturing method includes a concrete pipe jacking joint 1, a reserved steel bar connector 2 and a post-cast concrete wall 3 arranged in the concrete pipe jacking joint 1, and the specific steps are as follows:

[0023] Step 1: Use a general mold to make the concrete pipe jacking joint 1, and set a reserved steel bar connector 2 in the concrete pipe jacking joint 1 during pouring;

[0024] Step 2: After the concrete pipe jacking joint 1 is demoulded, lie down the pipe joint, and pour the post-cast concrete wall 3 in the concrete pipe jacking joint 1; the steel bars of the post-cast concrete wall 3 are connected with the reserved steel bars Connector 2.

[0025] The principle of the present invention is that the concrete pipe jacking joint 1 and the post-cast concrete wall 3 are successively produced in the factory, no custom-made molds are required dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com