Device and method for the flexible classification of polycrystalline silicon fragments

A polysilicon and fragmentation technology, applied in chemical instruments and methods, grading, solid separation, etc., can solve problems such as adjustment methods that do not describe the results of grading, photoelectric separation of polysilicon fragments, interference with image recognition of larger fragments, etc. The effect of short time, less blockage and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Polysilicon is deposited in rod form by the Siemens method. The sticks were removed from the Siemens reactor and broken into coarse polysilicon fragments according to methods known in the art (for example by hand crushing). These coarse-grained chips, with a side length of 0 to 250 mm, are discharged by means of a feed device, preferably a hopper, onto a chute which conveys the material to the device according to the invention.

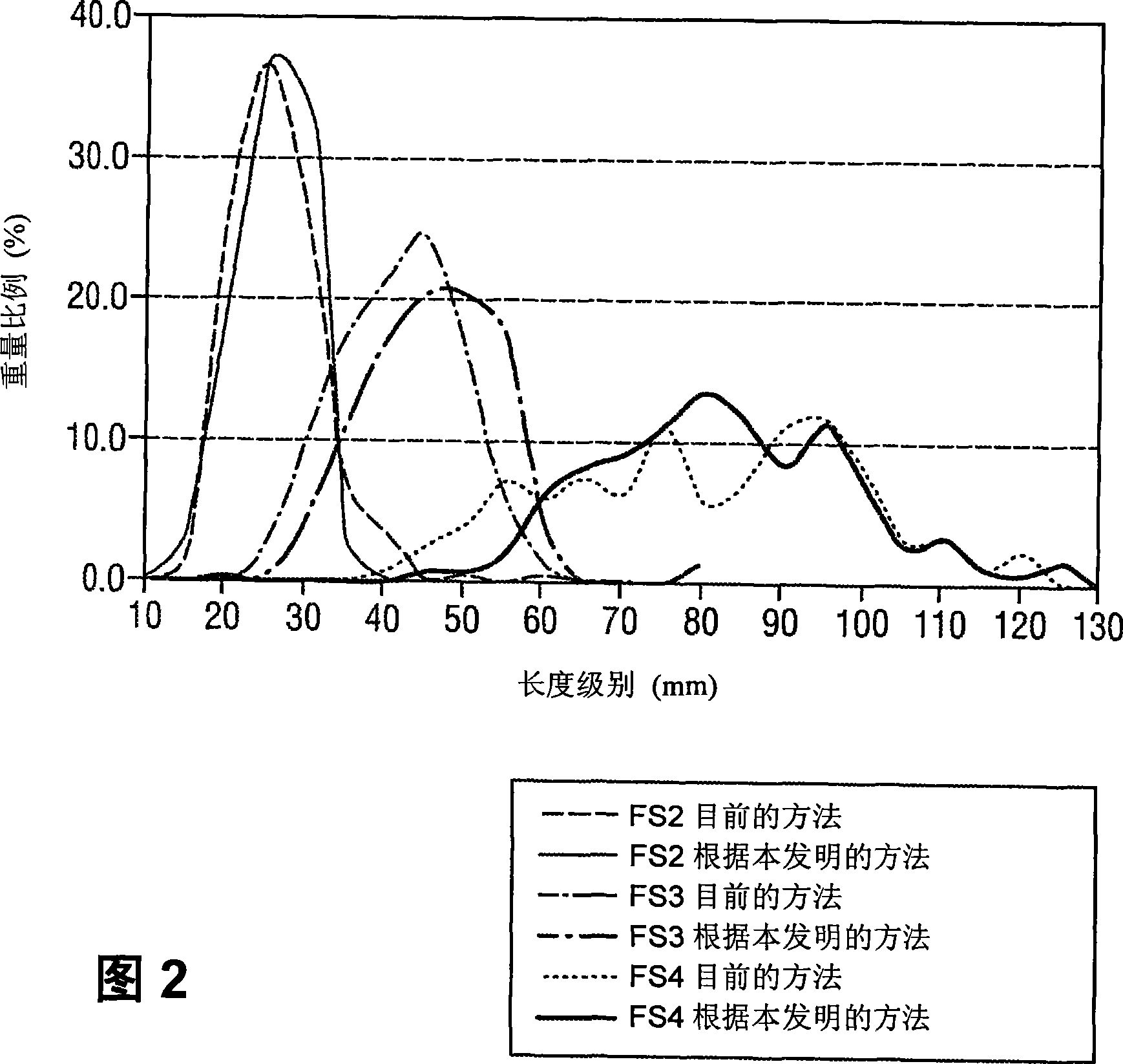

[0063] The parameters of the granule group to be prepared are input to a superordinate measuring and control device. Since the respective desired particle size distributions in the different particle groups are predetermined by the respective further use of the fragments to be prepared, this particle group is usually stored as a formula in a superordinate measuring and control device and correspondingly choose. In this example, the device was used to prepare 6 different particle sets (FSO, FS1, FS2, FS3, FS4 and FS5). All parameters of the o...

Embodiment 2

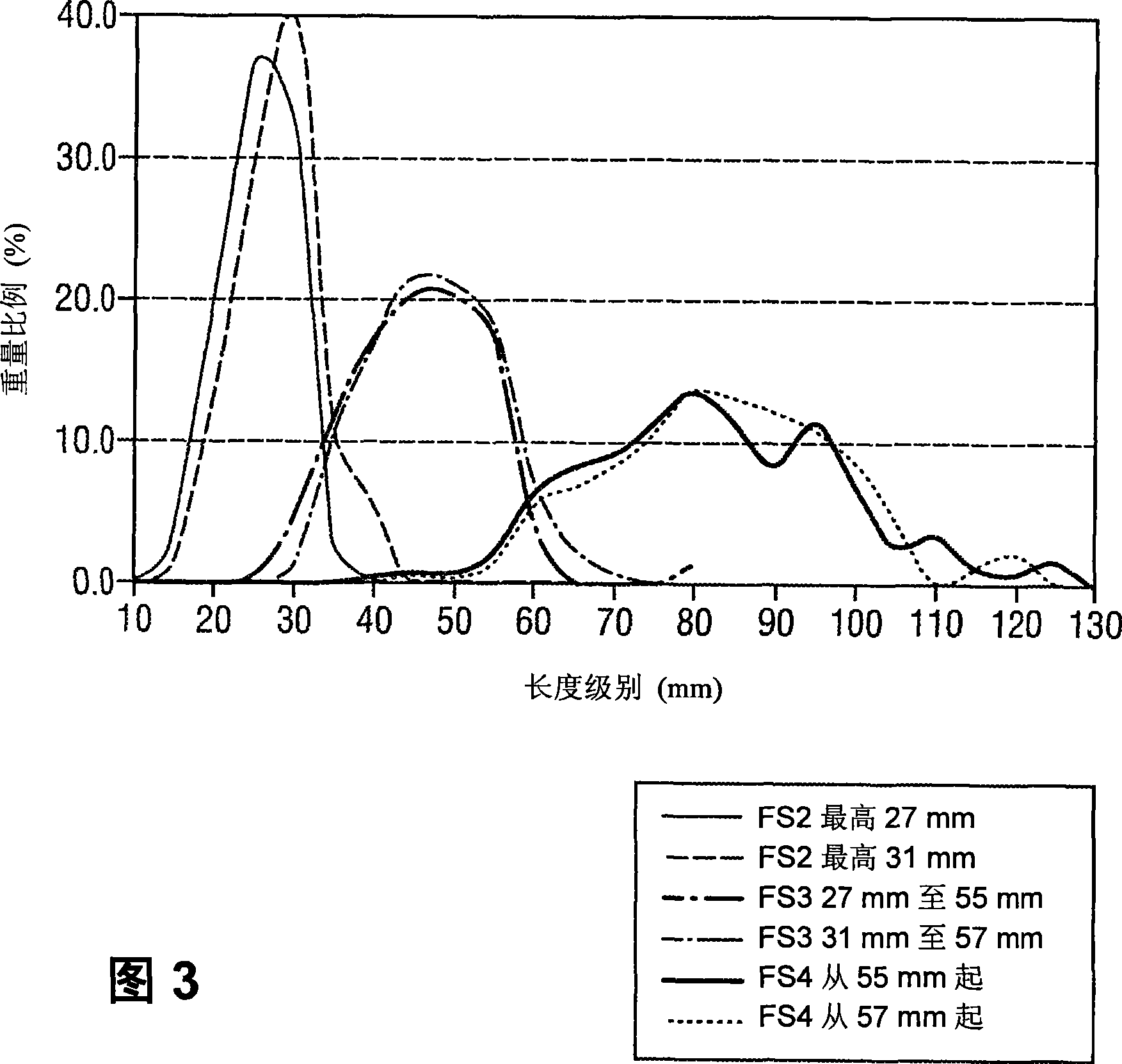

[0071]The software parameters in terms of the separation limit of the individual fractions were changed slightly to stabilize the desired yield. In the formula used to control the photoelectric separation system, the maximum or minimum fragment length value allowed in each particle group varies by several millimeters (see FIG. 3 ). Thus, the blown separation limit varied from 27mm to 31mm between FS2 and FS3, and from 55mm to 57mm between FS3 and FS4. This process parameter variation of only a few millimeters is already evident in the product properties (e.g. length distribution), i.e. the separation limit between the individual particle groups can be flexibly adjusted to the respective specification with high precision by simple formula selection, Or it can be considered within the scope of online adjustment to achieve the desired theoretical value.

Embodiment 3

[0073] Polycrystalline fragments of different particle size distributions are classified by means of the device according to the invention.

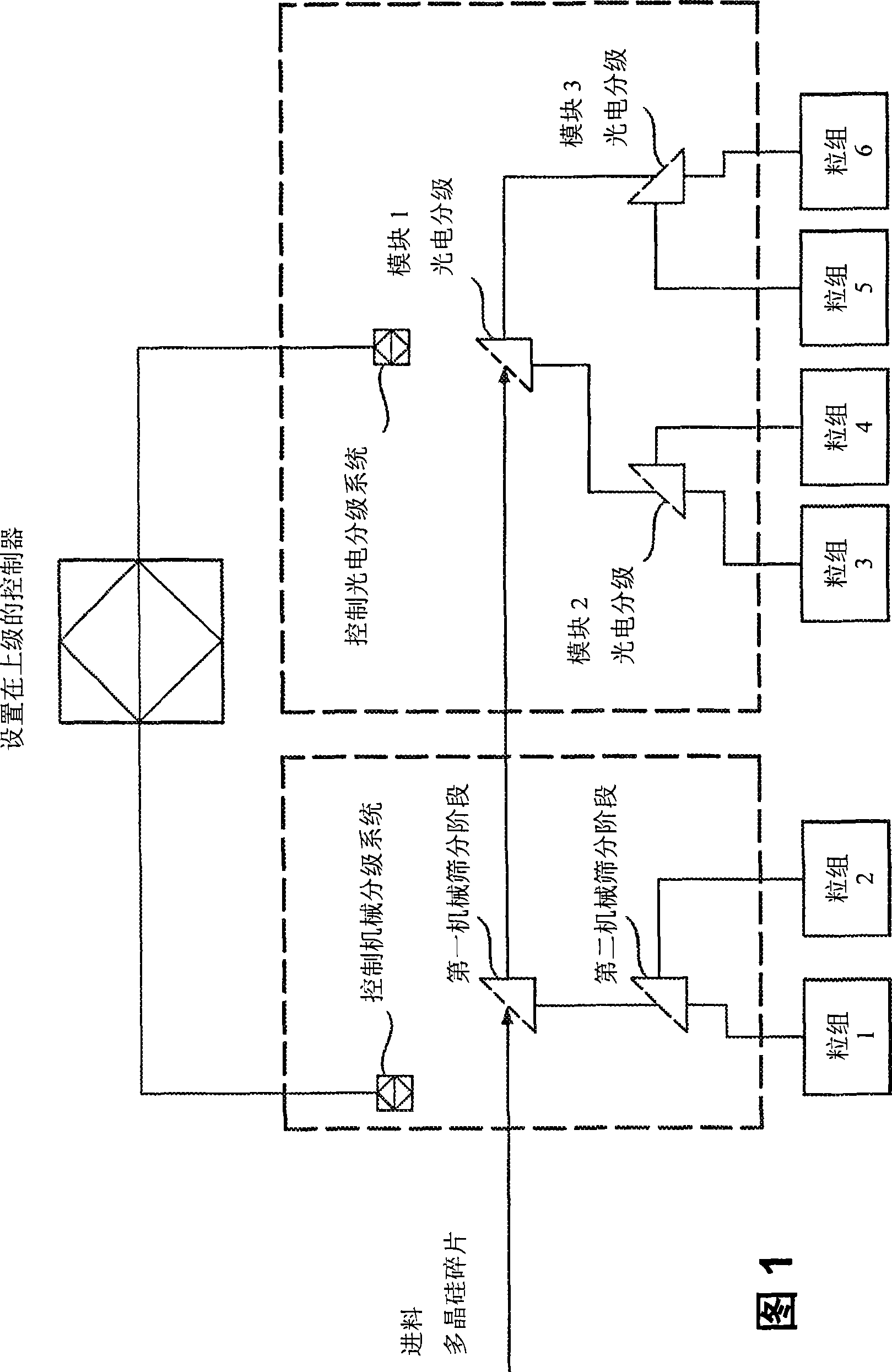

[0074] a) Classify polycrystalline fragments with a main grain size larger than 100 mm into 6 grain groups (eg FS0 to FS5). The fine fraction (less than 12 mm, ie FS0+FS1) is first separated from the coarse fraction by means of a mechanical sieve. The separated fractions are further separated into fractions FS0 and FS1 by a subsequent second mechanical sieve. The coarse-grained components (≥FS2) are sent to the photoelectric classification system, and are separated into larger (≥FS4) and smaller (≤FS3) particles in the first separation stage (module 1, the first tree plane) group (separation limit FS3 / FS4 between ~50 and 70 mm). In the second tree plane, these two grain groups are sent to another separation stage (module 2 and module 3), and are separated into two grain groups in turn (separation limit FS2 / FS3 is about 25 to 45mm, whil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com