CO2 trapping absorbent with secondary phase change function and application method

An application method and absorbent technology, which is applied in the field of CO2 capture absorbent, can solve problems such as increase in total capture cost, environmental hazards, and changes in absorbent concentration, so as to solve water balance problems, ensure capture effect, and reduce evaporation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

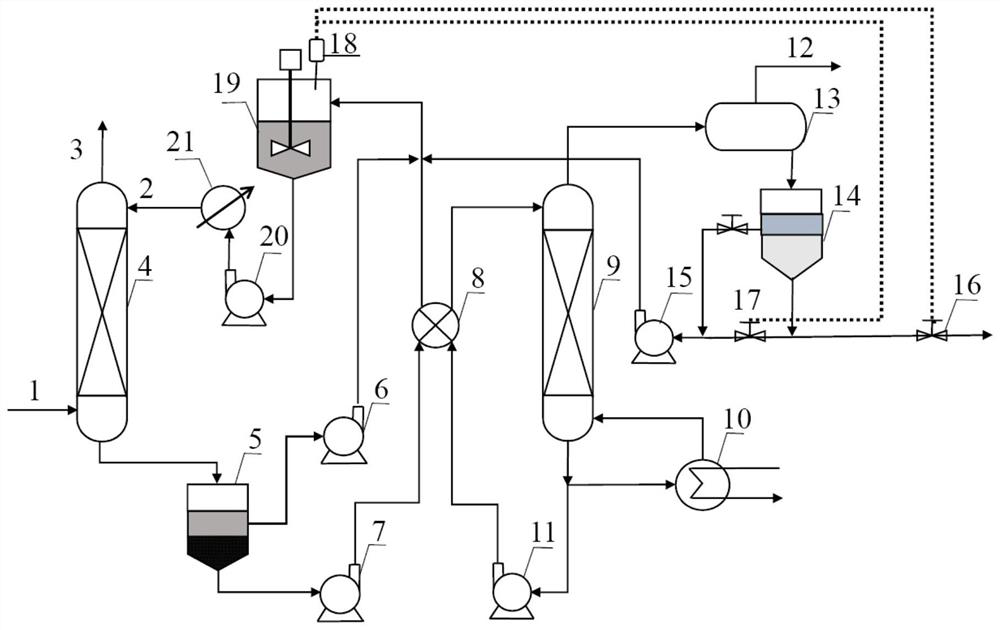

Image

Examples

Embodiment 1

[0035] This embodiment provides a CO trap with secondary phase change function 2 Absorbent, the absorbent is prepared by the following method: by mass percentage, weigh 25% of 2-aminoethanol, 65% of diethylene glycol monobutyl ether, 10% of water, mix the components After homogenization, obtain described two-phase change absorbent solution; At 40 ℃, wet mixed gas (volume fraction meter, 15%CO 2 , 3%H 2 O, the rest are N 2 ) into the reactor with 150 grams of absorbent and turn on the magnetic stirring to start the absorption process. 2 The concentration is measured by a non-dispersive infrared gas analyzer, when the outlet CO 2 When the concentration reaches more than 95% of the imported concentration, stop absorbing. After standing still for 10 min, a liquid-liquid two-phase system was obtained, in which the volume ratio of the upper and lower phases was about 2, CO 2 The loads were 0.3 mol / kg and 4.5 mol / kg, respectively. After separating the lower phase, heat the lowe...

Embodiment 2

[0037] In terms of mass percentage, weigh the following components: 40% 2-(methylamino)ethanol, 45% ethylene glycol monohexyl ether, 12% water, 3% tert-butanol, and mix the components After homogenization, obtain described absorbent solution with secondary phase change function; At 50 ℃, wet mixed gas (volume fraction meter, 35%CO 2 , 5%H 2 O, the rest are N 2 ) into the reactor of 150 grams of absorbent and turn on the magnetic stirring to start the absorption process. 2 When the concentration reaches more than 95% of the imported concentration, stop absorbing. After standing still for 10 minutes, a liquid-liquid two-phase system was obtained, in which the volume ratio of the upper phase and the lower phase was about 1.5, and the CO 2 The loads were 0.6 mol / kg and 3.9 mol / kg, respectively. After separating the lower phase, heat the lower phase solution to 110°C for desorption, condense the outlet vapor phase to obtain a condensate, and obtain a liquid-liquid two-phase sys...

Embodiment 3

[0039] In terms of mass percentage, the following components are weighed: 65% of 2-(butylamino)ethanol, 25% of ethylene glycol phenyl ether, 1% of potassium metavanadate, 9% of water, each group After the parts are mixed evenly, the absorbent is obtained; at 40°C, the wet mixed gas (volume fraction, 25% CO 2 , 2%H 2 O, the rest are N 2 ) into the reactor with 350 grams of absorbent and turn on the magnetic stirring to start the absorption process. 2 When the concentration reaches more than 90% of the imported concentration, stop absorbing. After standing still, a liquid-liquid two-phase system is obtained. After the lower phase is separated, the lower phase solution is heated to 120°C for desorption, and the outlet vapor phase is condensed to obtain a condensate at about 25°C. After standing still, a liquid-liquid two-phase system is obtained again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com