Atomospheric pressure glow discharge plasma reactor possessing rotary relix electrode

A glow discharge and plasma technology, applied in the direction of condensation hydrocarbon production with dehydrogenated hydrocarbons, chemical/physical/physicochemical processes using energy, etc., can solve problems such as uneven electric field distribution and no axial electric field, etc. Achieve great social and economic benefits, speed up the flow, and achieve the effect of large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

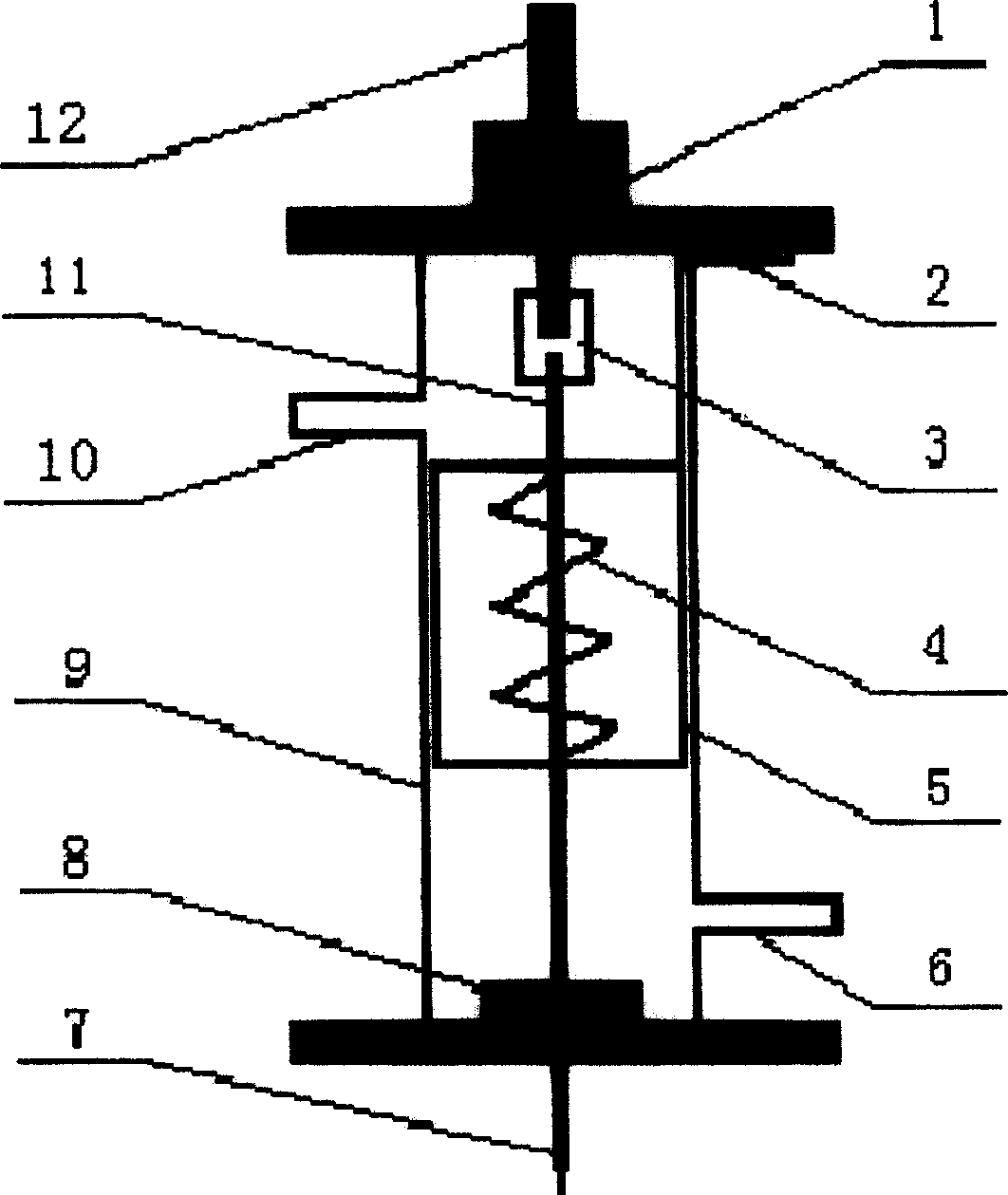

[0023] The specific implementation of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0024] In the figure, the reaction gas methane and hydrogen are divided into two paths through the mass flow meter and then mixed from the raw material gas inlet 10 into the insulating cylindrical reactor 9. The metal cylinder 11 with the helical metal belt 4 in the reactor passes through the insulating joint 3 and The magnetic fluid sealing device 1 is connected, and then connected to the driving device through the lead-out end 12 of the magnetic fluid sealing device; the other end of the rotating electrode is connected to the metal groove base 8 through a rolling bearing, and high voltage is introduced from the metal groove base extension 7. A circular metal barrel 5 as a fixed electrode is placed at the spiral electrode and kept concentric with it, and the lead-out end 2 of the fixed electrode is connected to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com