Recycling-friendly packaging laminate with improved thermal stability during sealing

A packaging layer, sealing layer technology, applied in the field of recyclable packaging laminates with improved heat resistance during sealing, can solve problems such as increasing the cost of deep drawable laminates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

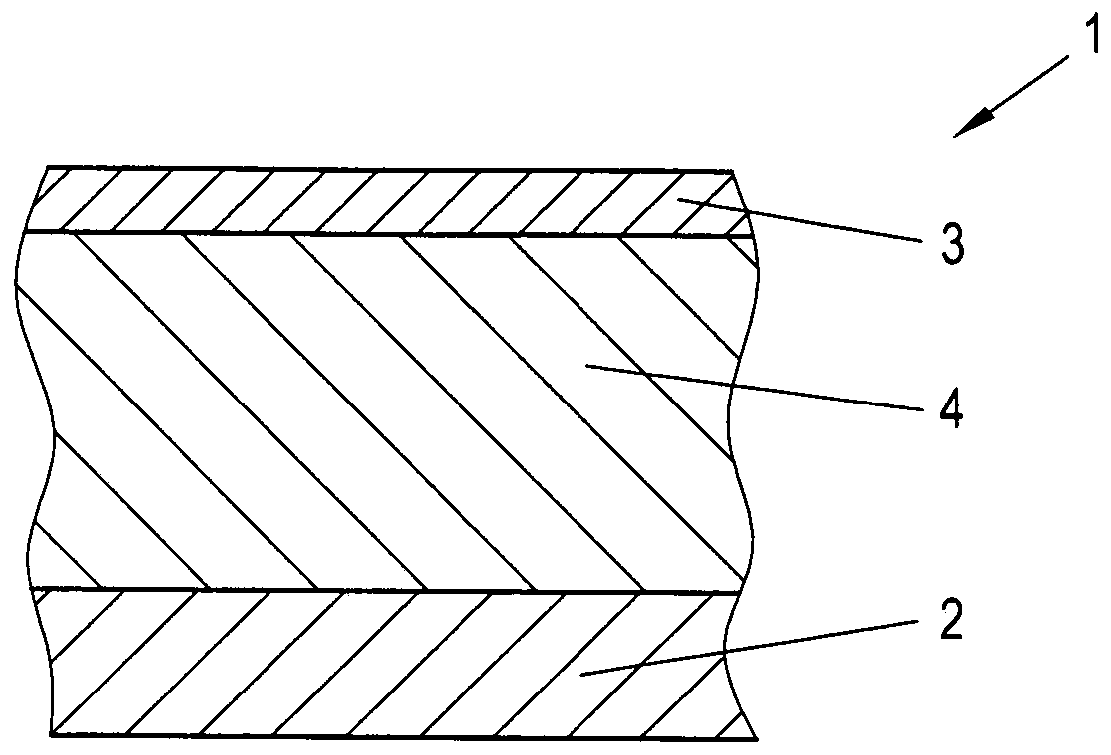

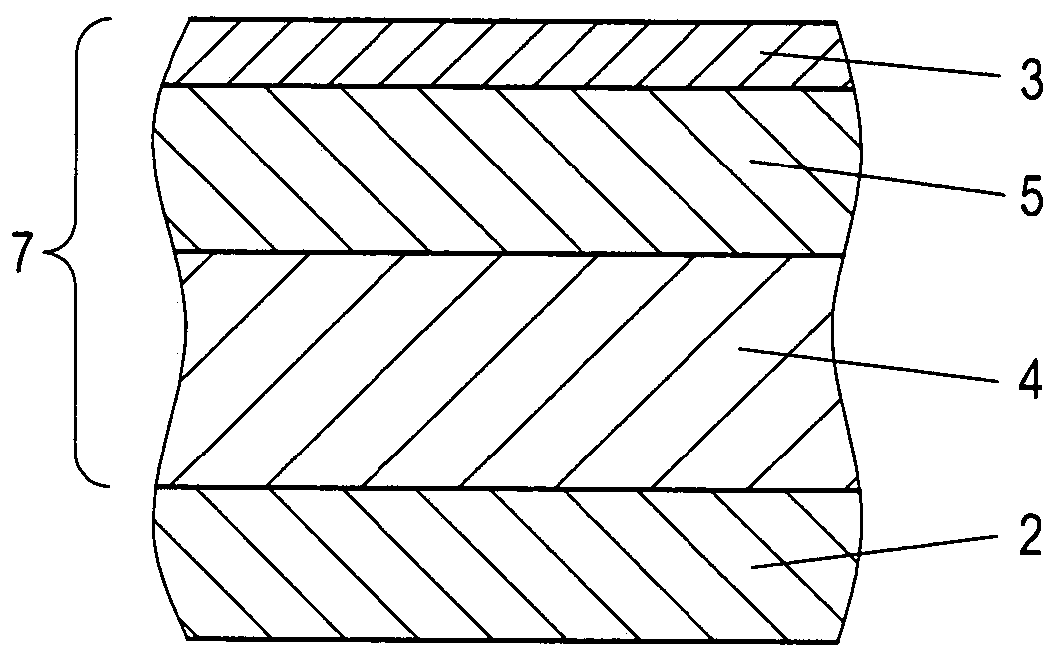

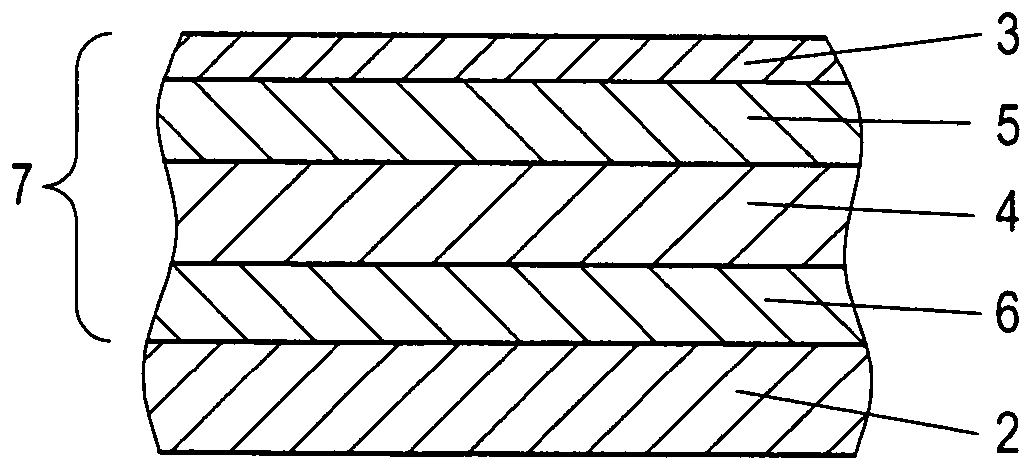

[0021] figure 1 A packaging laminate 1 according to the invention is shown having two outer layers, namely a sealing layer 2 and a thermal stabilization layer 3 , and a matrix layer 4 arranged between them.

[0022] The matrix layer 4 consists essentially of polyethylene (PE) and thus a compatible material with regard to recyclability. Advantageously, the matrix layer 4 has a PE fraction, advantageously high-density (HDPE) polyethylene (PE), of at least 60% by volume, preferably at least 70% by volume, and particularly preferably at least 80% by volume. PE share. The PE fraction here can reach approximately 100% by volume, wherein a PE fraction of 100% by volume is generally never reached due to customary additives in the packaging laminate 1 (eg slip additives, antiblocking additives, dyes, fillers, etc.). The rest (besides possible additives) are compatible polyolefin materials that do not impair recyclability. As compatible polyolefin material basically any type of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com