Patents

Literature

48results about How to "Shorten sealing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

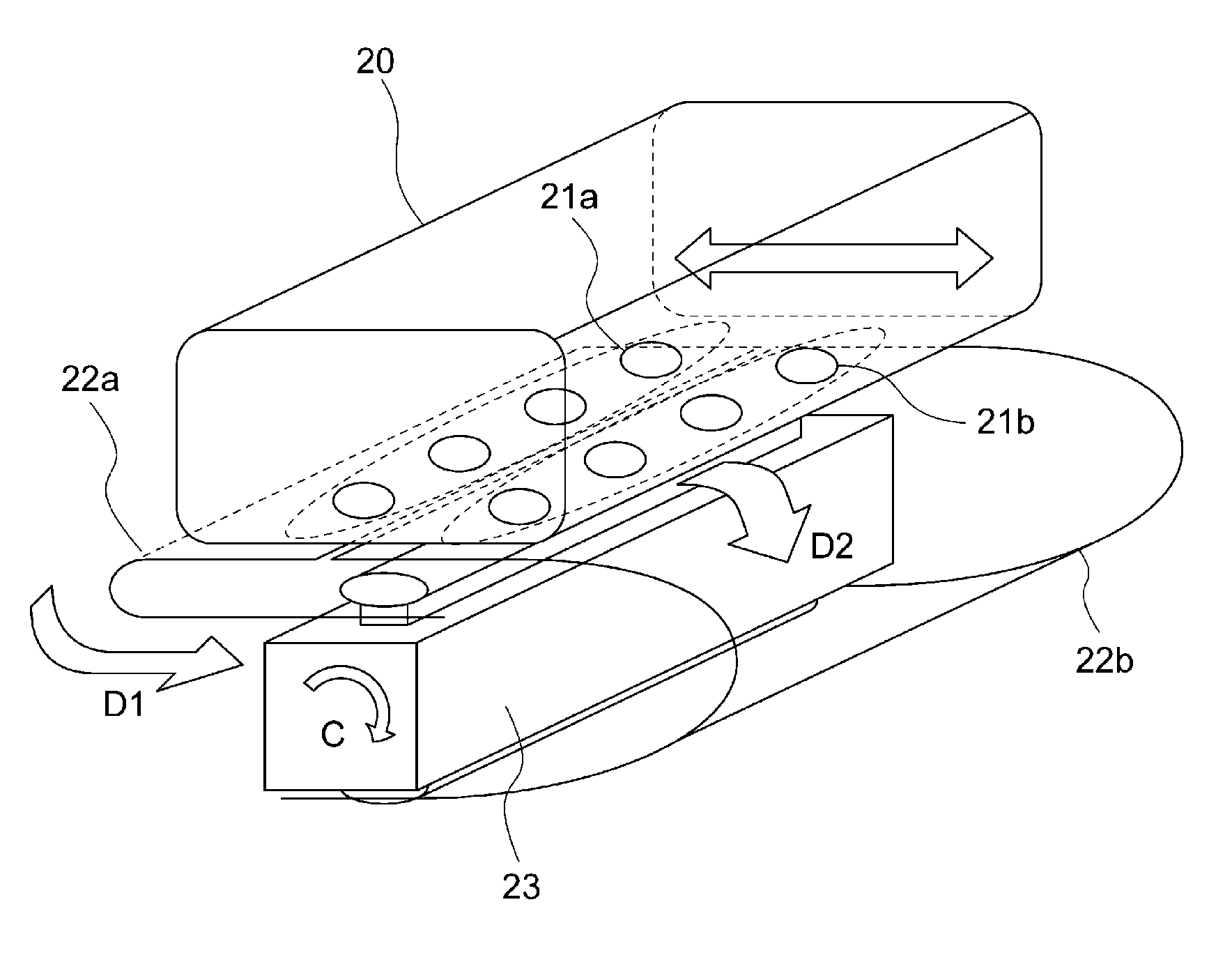

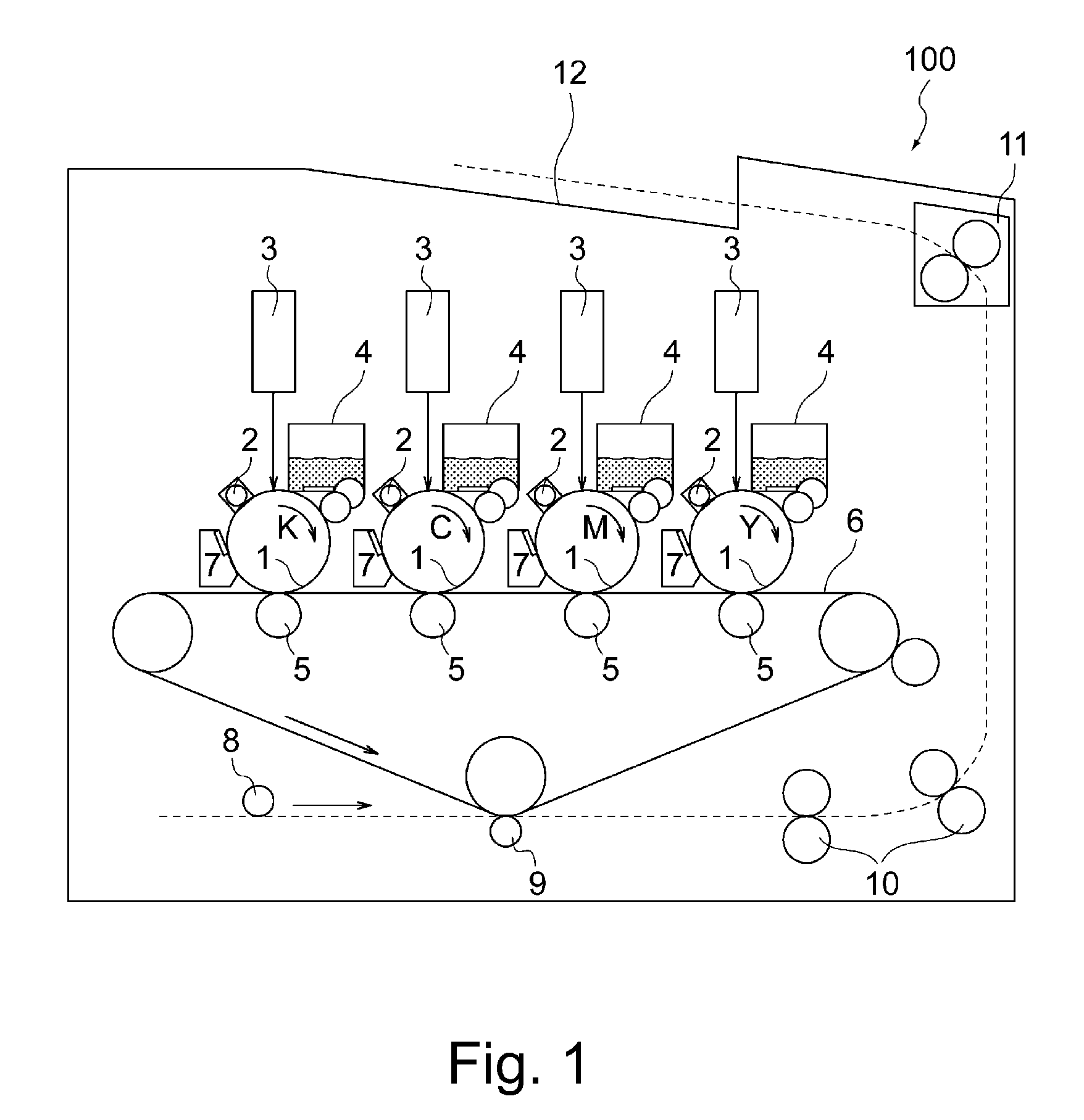

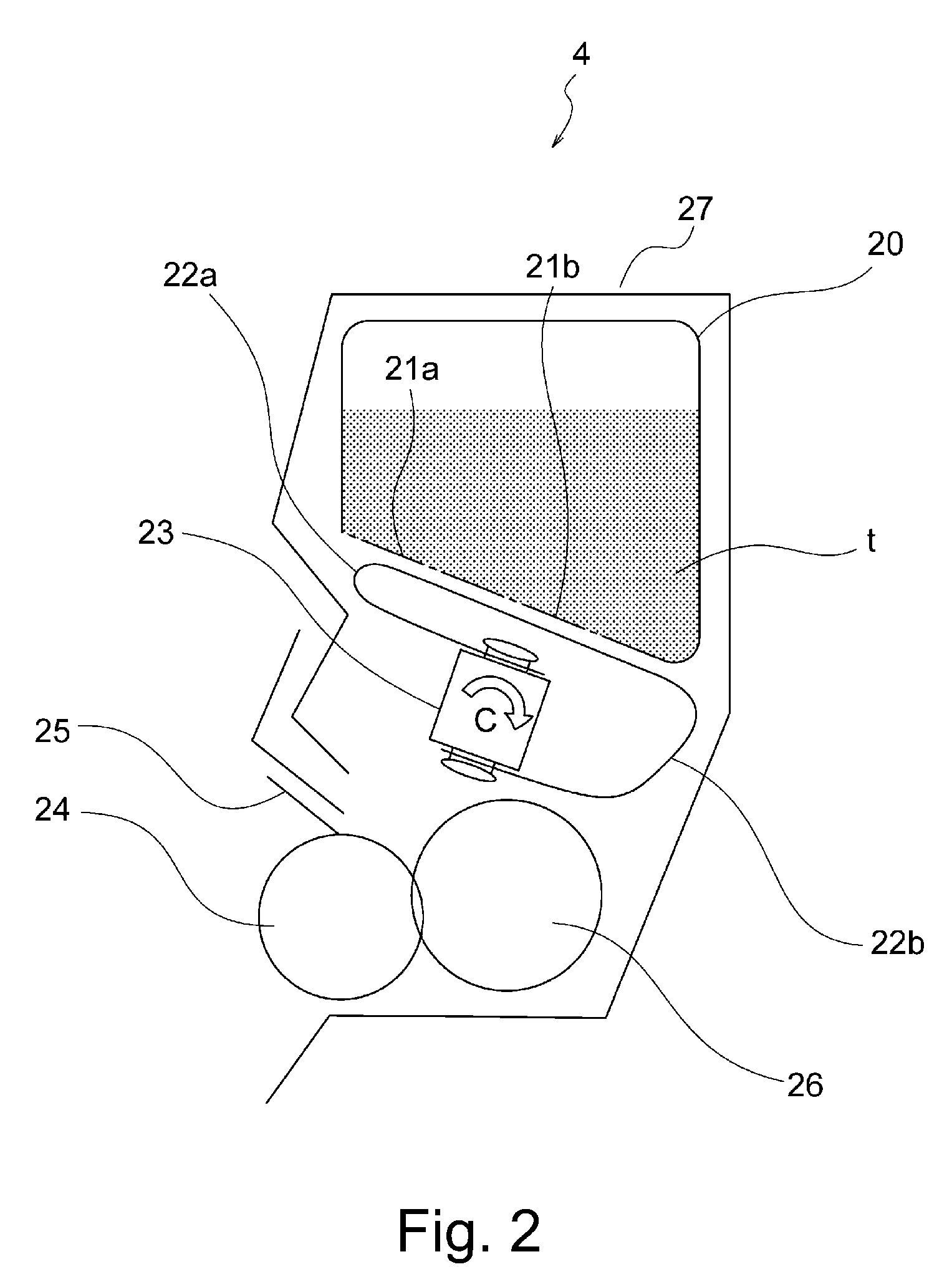

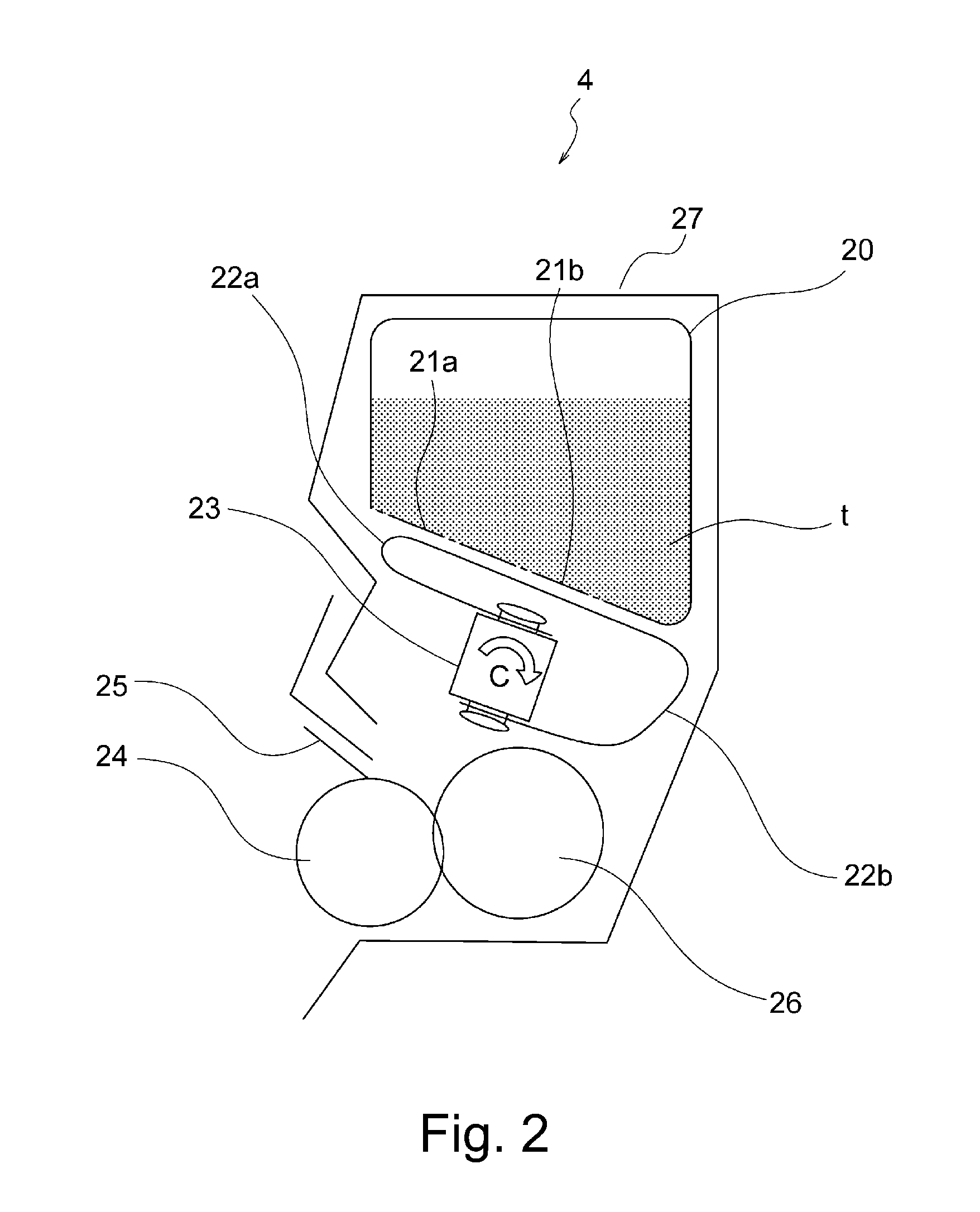

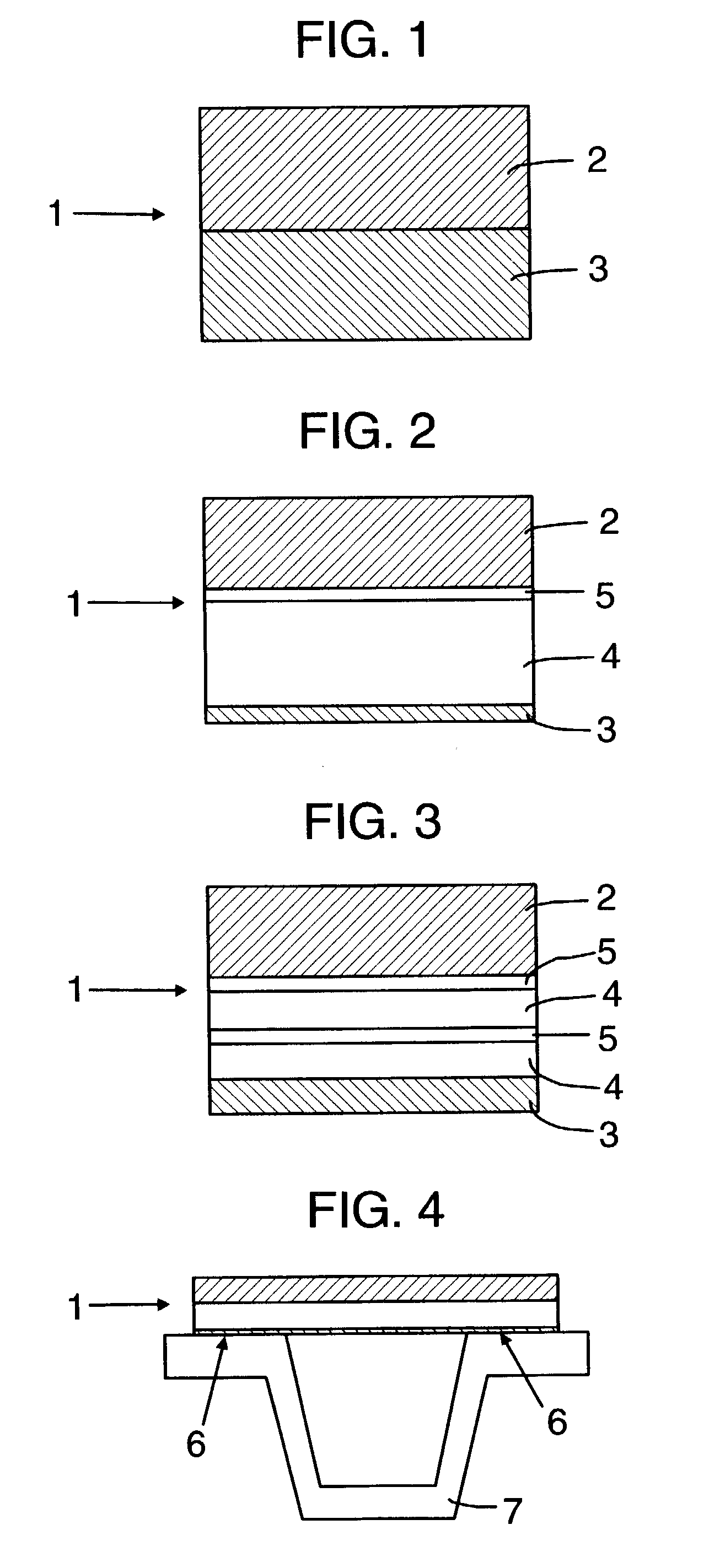

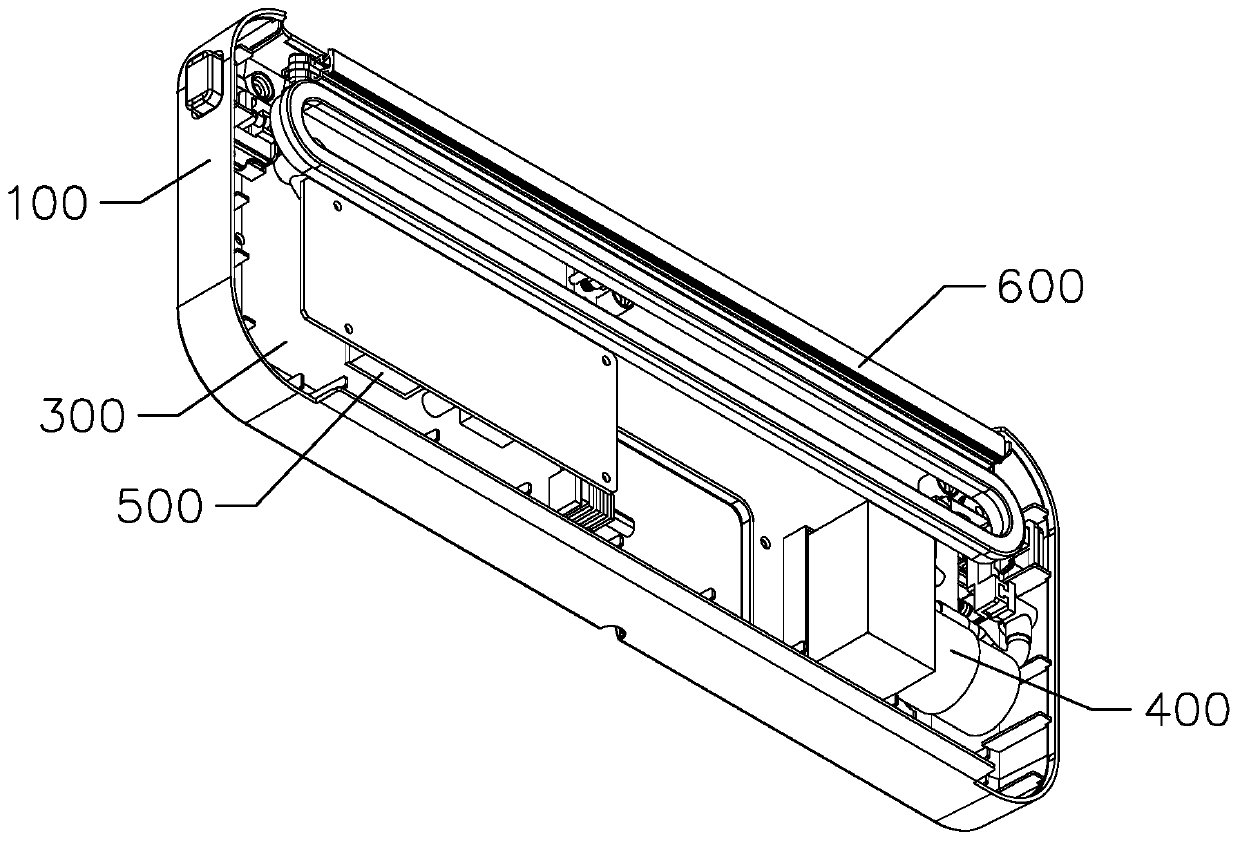

Developer accommodating unit, developing device, process cartridge and image forming apparatus

ActiveUS9207581B2Shorten sealing timeImprove openabilityElectrographic process apparatusEngineeringImaging equipment

Owner:CANON KK

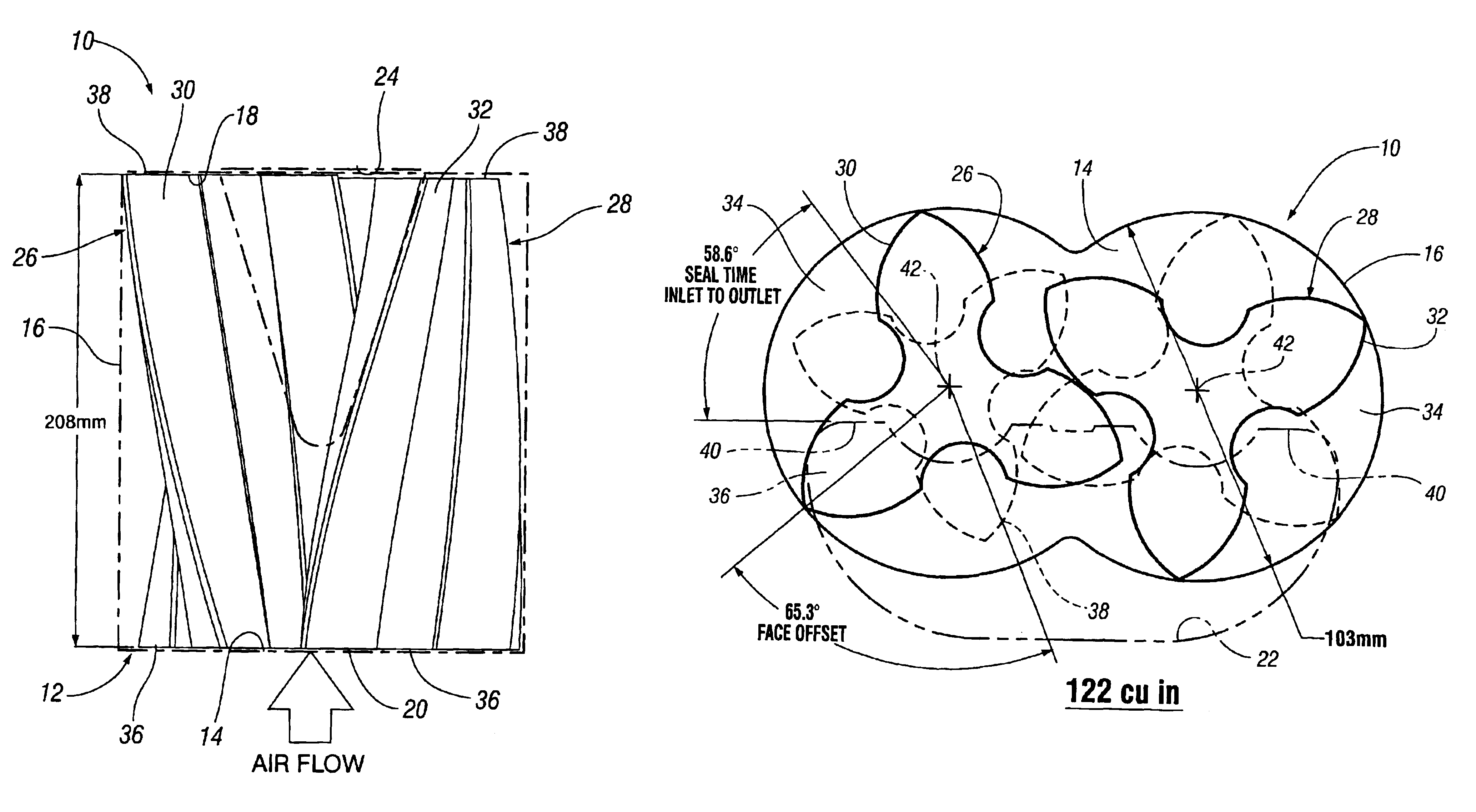

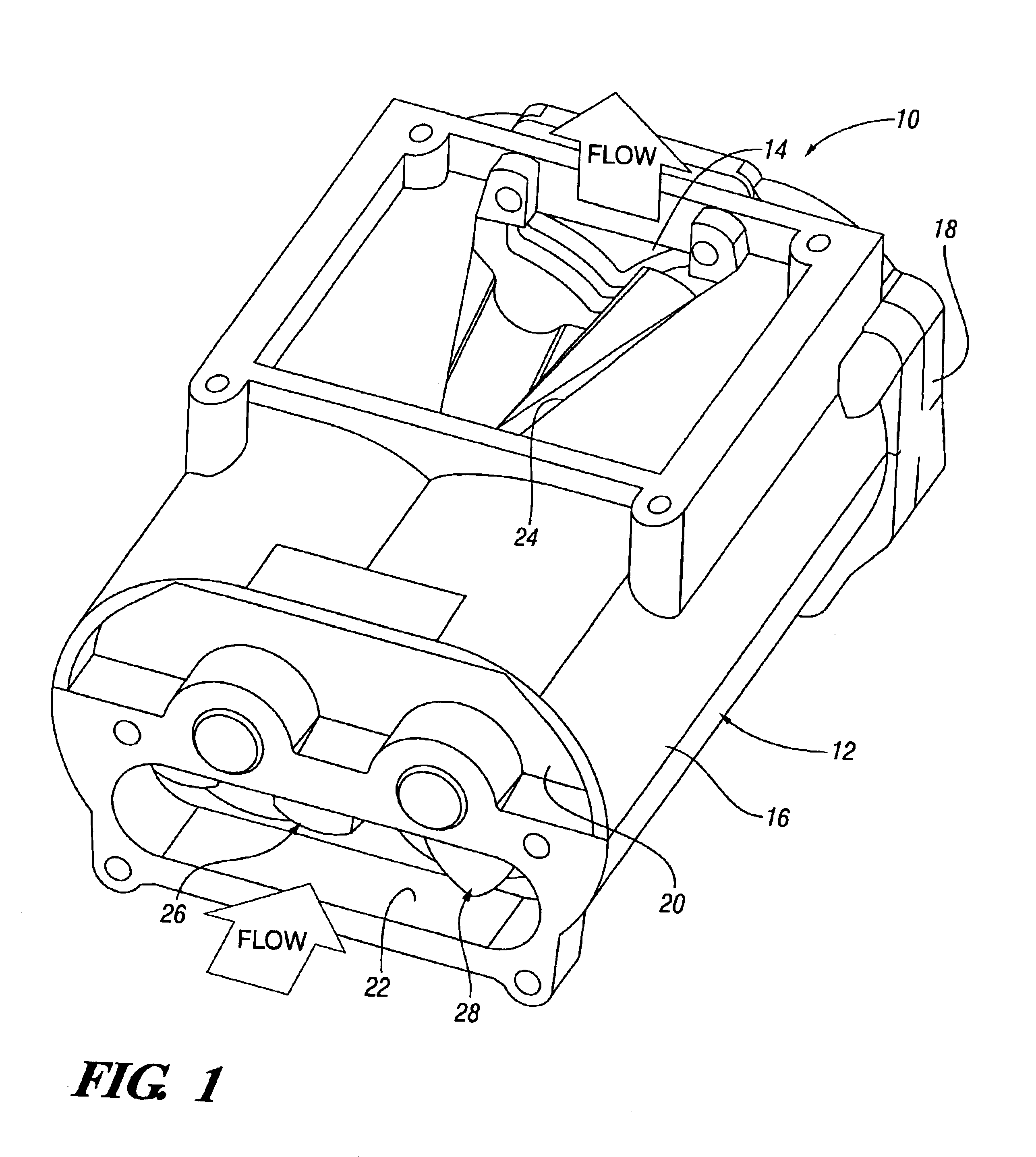

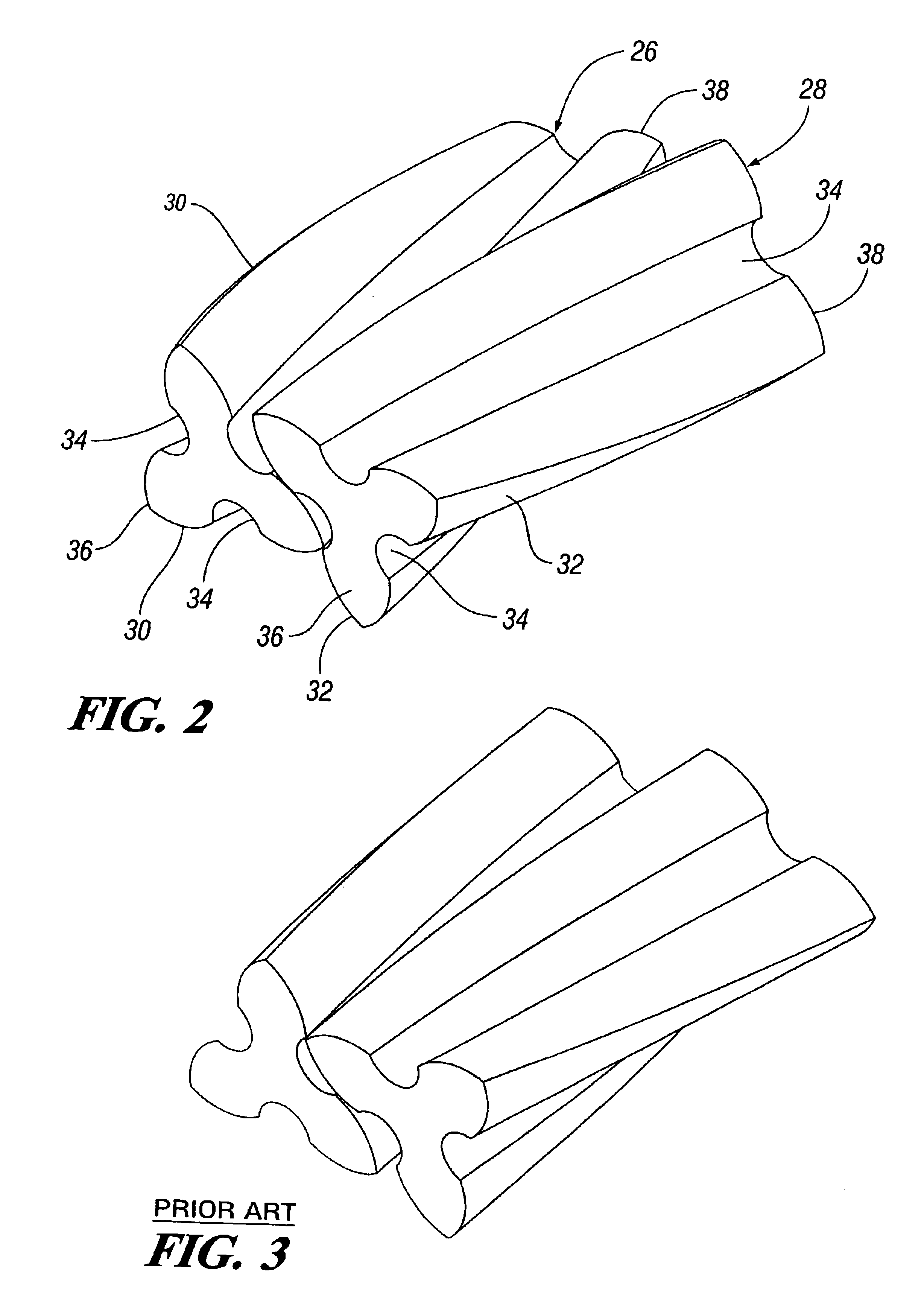

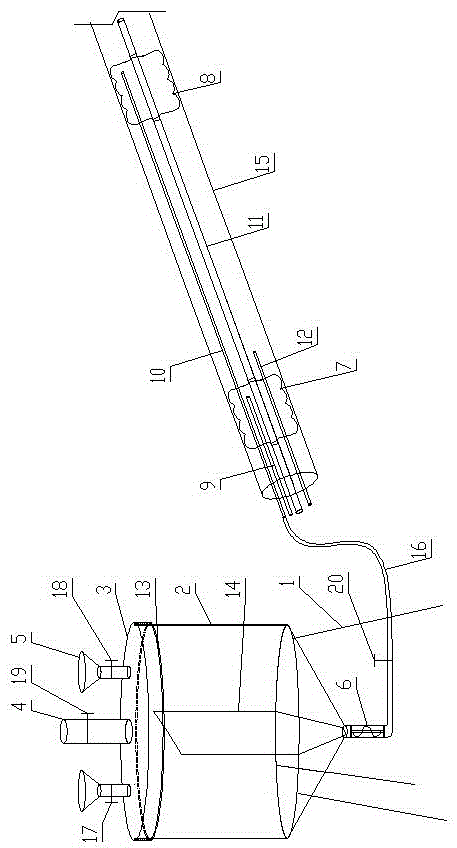

Roots supercharger with extended length helical rotors

InactiveUS6884050B2Improve efficiencyLow temperature changeOscillating piston enginesEngine of counter-engagement typeEngineeringHelix angle

A Roots supercharger has an extended cavity with 103 mm diameter rotors having chambers defined by interleaved helical lobes with equal angular face offsets exceeding 60 degrees from inlet to outlet end faces angled in directions opposite to directions of rotor rotation. The chambers have angular seal times of less than 67 degrees of rotation. A preferred embodiment has a displacement of 122 cu mm / revolution, rotor length of 208 mm, face offsets of 65.3 degrees and seal time of 58.6 degrees. The rotor lobe helix angle is essentially 0.314 deg / mm, equal to the helix angle of a prior art supercharger with rotors of common diameter, displacement of 112 cubic inch / revolution, rotor length of 191 mm, previously considered maximum, 60 degree face offset, previously considered optimum, and seal time of 67 degrees. Both flow volumes and efficiency of the new configuration are improved from the prior art wherein the 60 degree face offset was considered optimum.

Owner:GM GLOBAL TECH OPERATIONS LLC

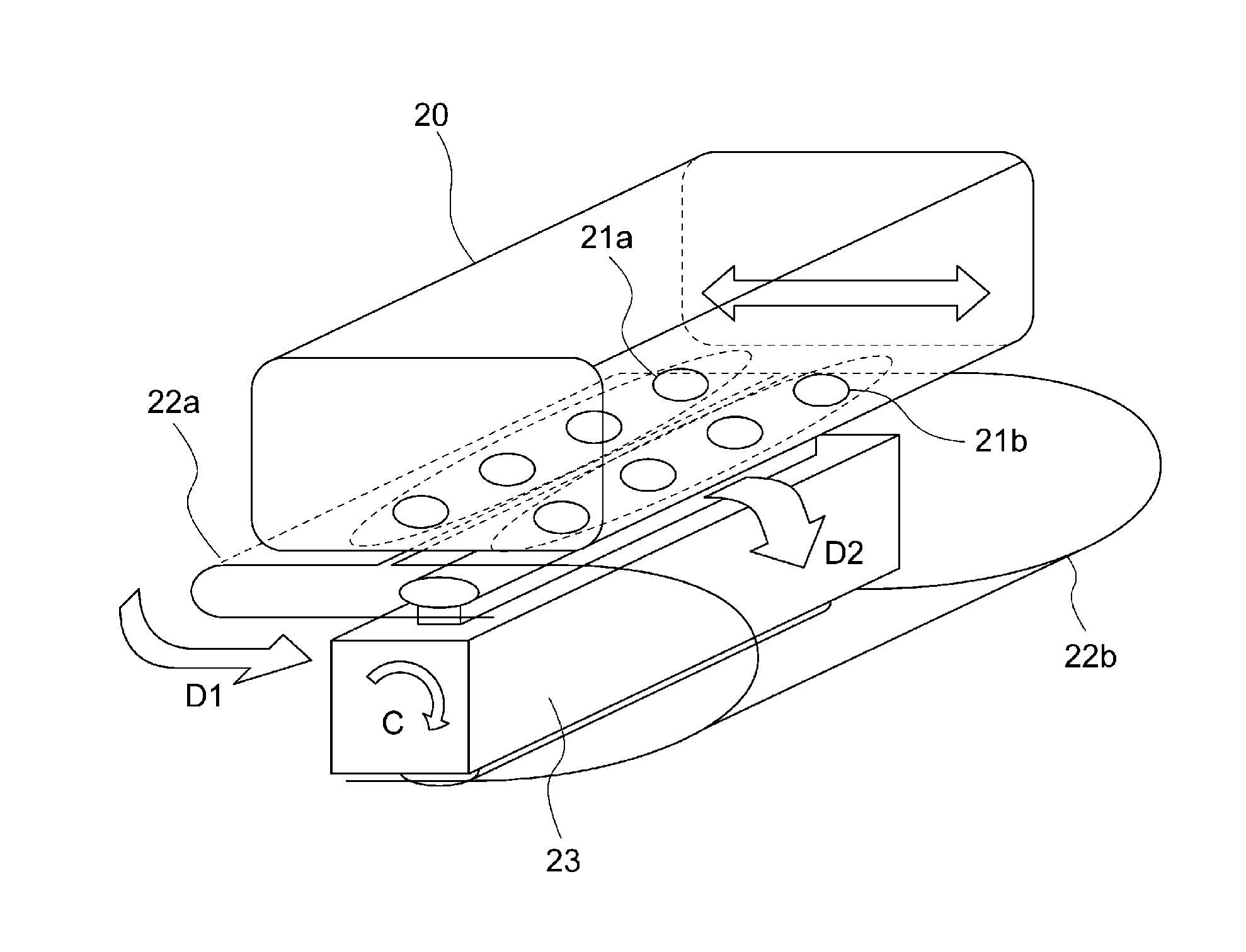

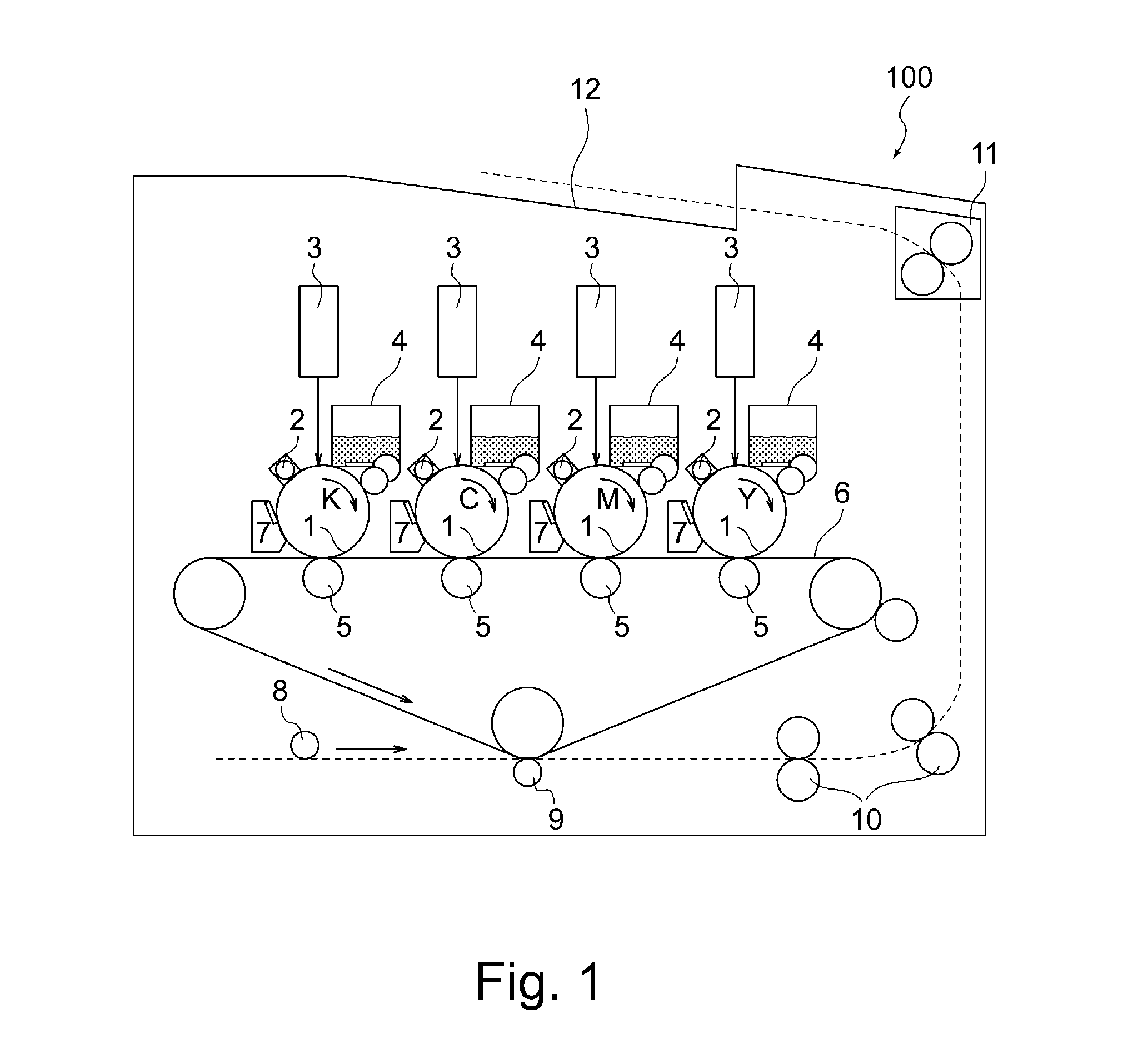

Developer accommodating unit, developing device, process cartridge and image forming apparatus

ActiveUS20140363196A1Shorten sealing timeImprove openabilityElectrographic process apparatusImaging equipmentMechanical engineering

Owner:CANON KK

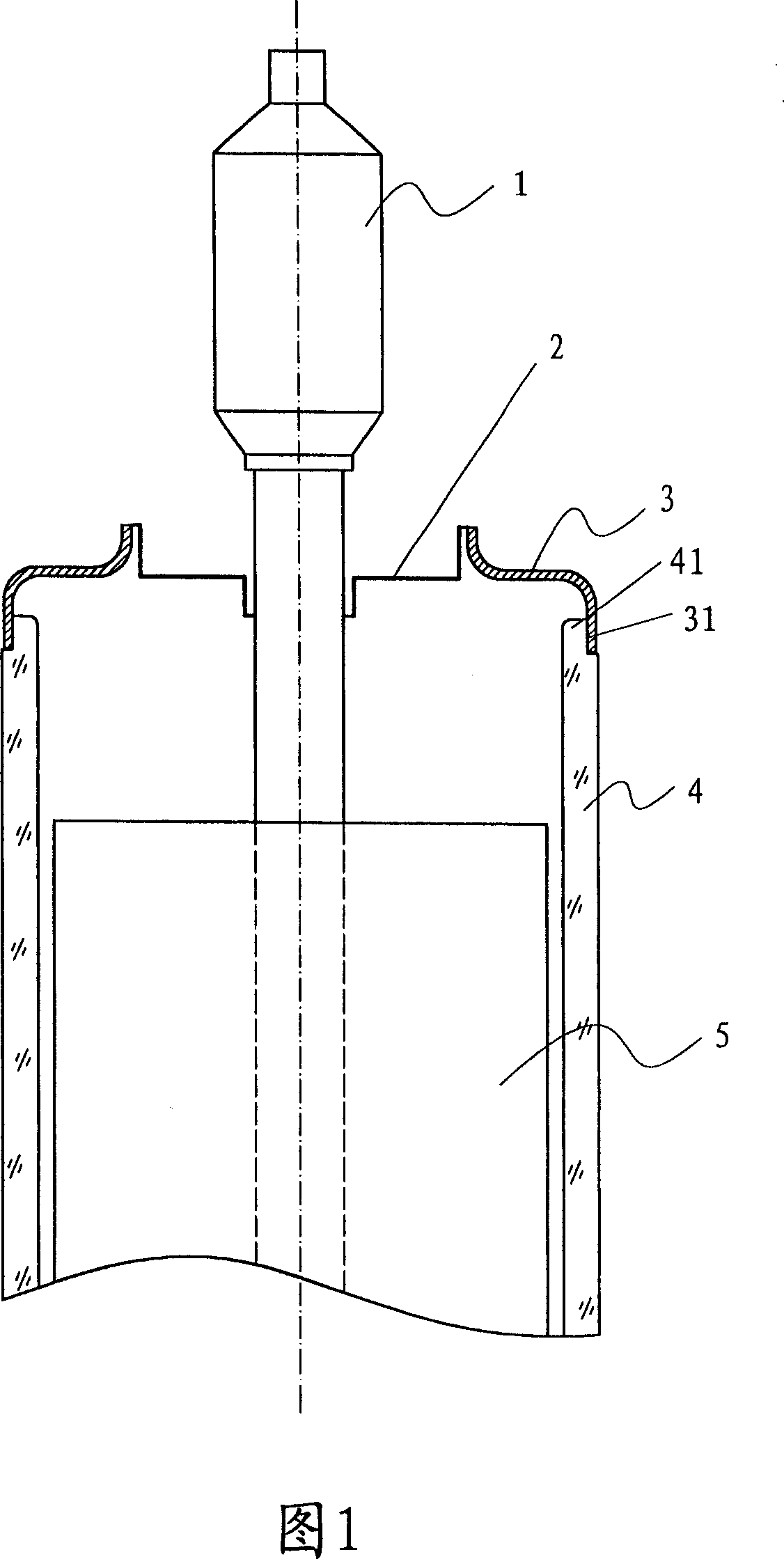

Glass-metal sealing process for vacuum heat collecting tube

The glass-metal sealing process for vacuum heat collecting tube includes the following steps: pre-oxidizing the part of the sealing metal workpiece, pre-vitrifying the part of the sealing metal workpiece, and sealing the glass and the pre-vitrified part of the sealing metal workpiece through heating. The glass-metal sealing process of the present invention has greatly lowered sealing temperature, greatly shortened sealing time, raised sealing quality, simplified sealing equipment and lowered production cost.

Owner:江希年 +2

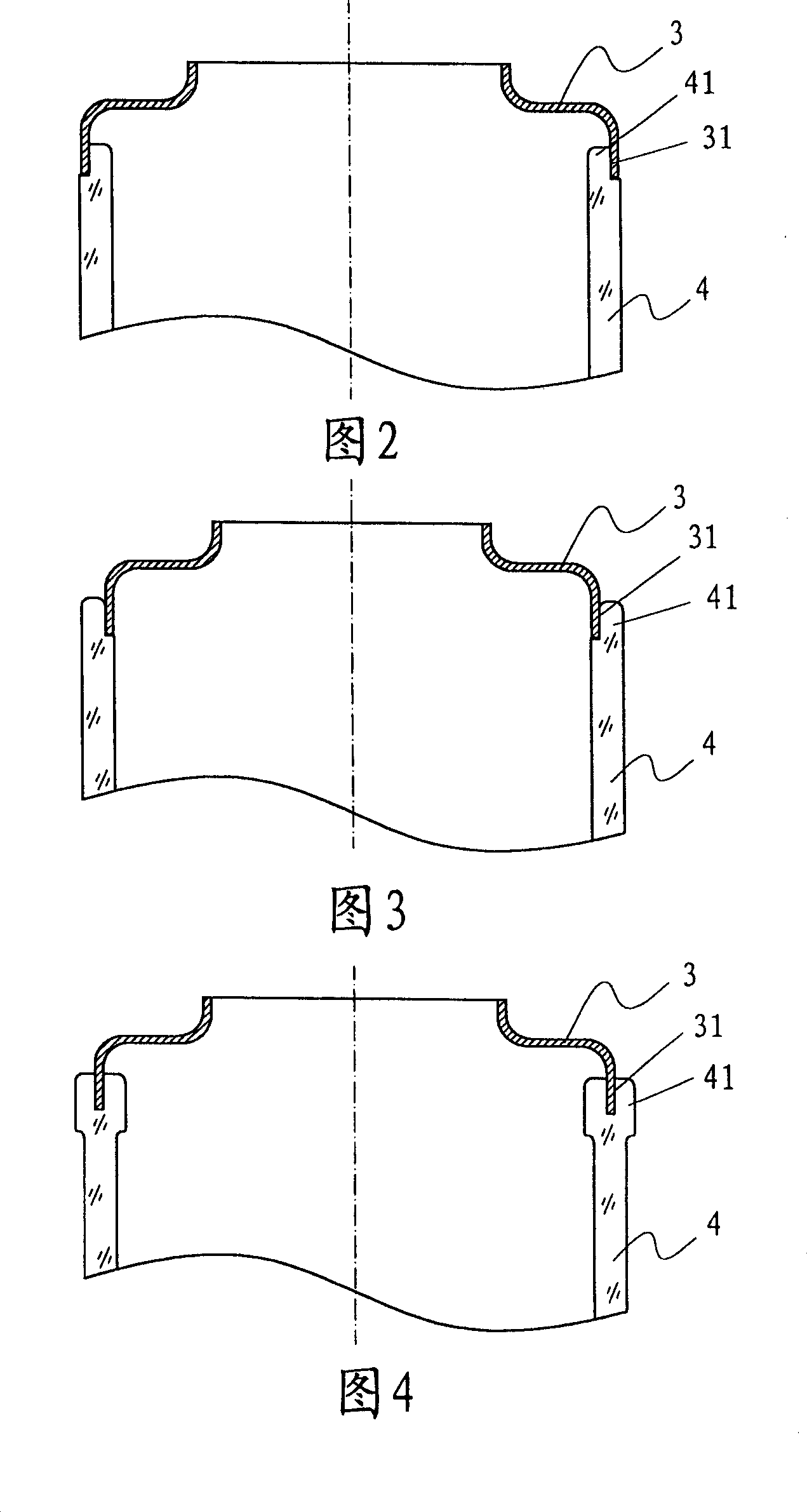

Automatic sealing method of three-phase electric energy meter

ActiveCN103226161AReduce mechanical linksShorten sealing timeTime integral measurementElectricity meterElectric energy

The invention relates to an automatic sealing method of a three-phase electric energy meter, which comprises the following steps that A, an electric meter manufacturer mounts a sealing base on the electric meter before the electric meter leaves a factory; B, the electric meter is conveyed to a sealing stamping device through an automation verification line to be fixed; C, stamping is performed through the sealing stamping device; D, a sealing bar code is scanned by a bar code scanning device; E, the scanned sealing bar code is transmitted to an asset management system through computer software where the sealing bar code is located, so that binding between a sealing serial number and an electric energy meter asset is achieved; and F, automatic sealing is completed, and the fixed electric meter is released. The automatic sealing method of the three-phase electric energy meter is reasonable in design, simple to operate, simple in flow and high in automation degree; the whole efficiency and reliability of the automation verification flow line can be improved after the method is used; and the method is suitable for popularization and application in the fields of metering automation detection, three-phase electric meter automation detection and the like.

Owner:STATE GRID CORP OF CHINA +1

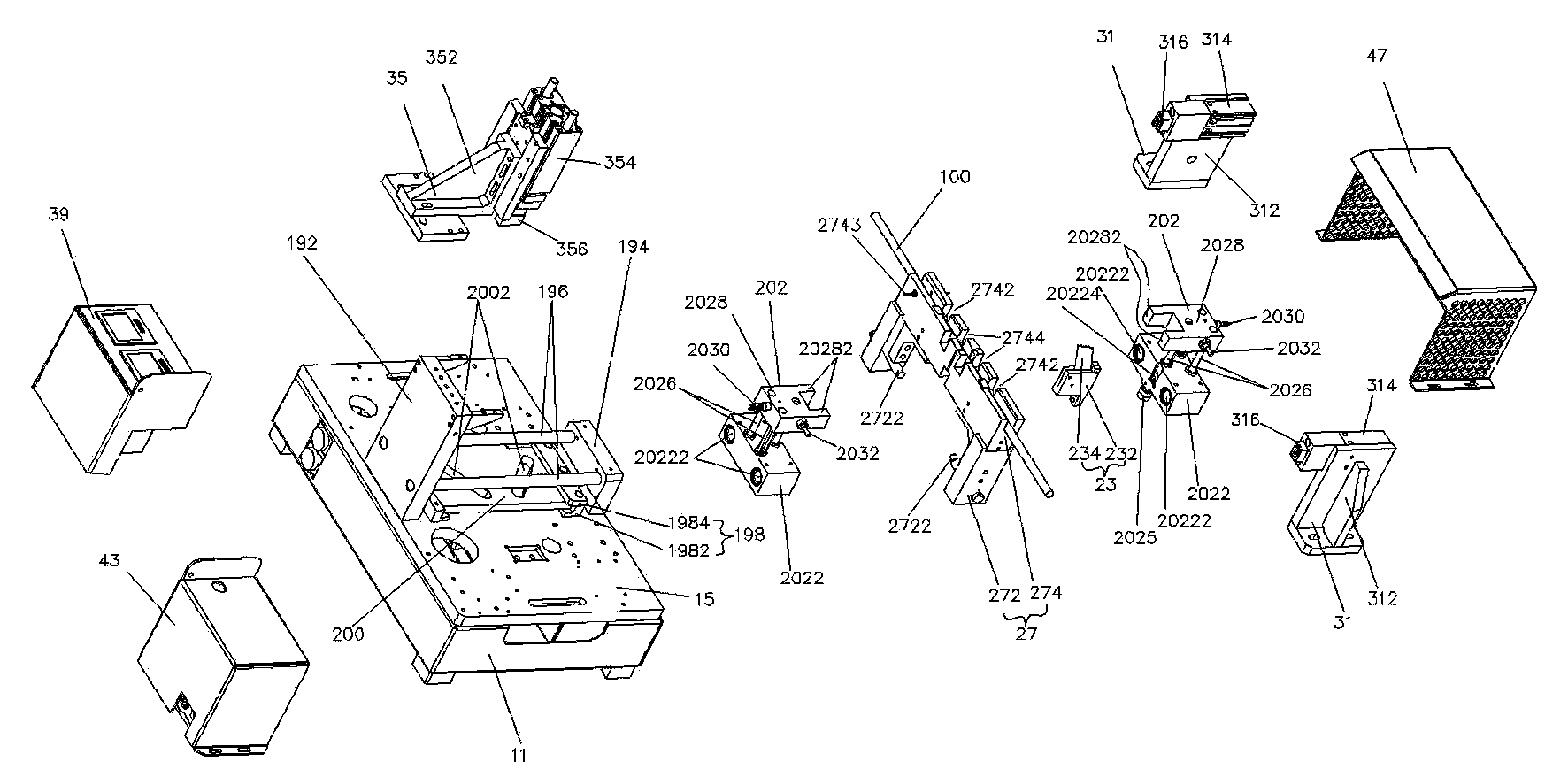

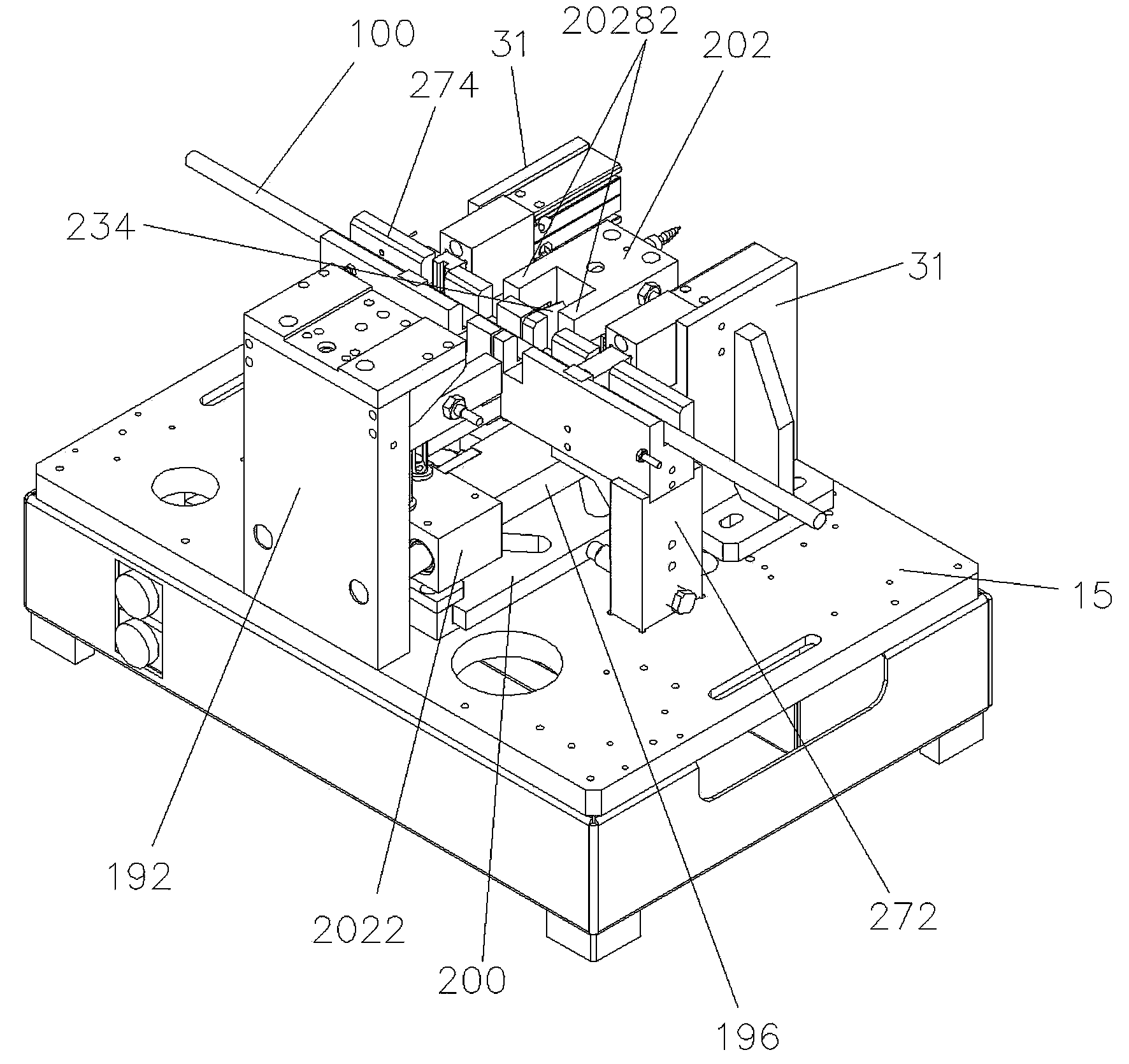

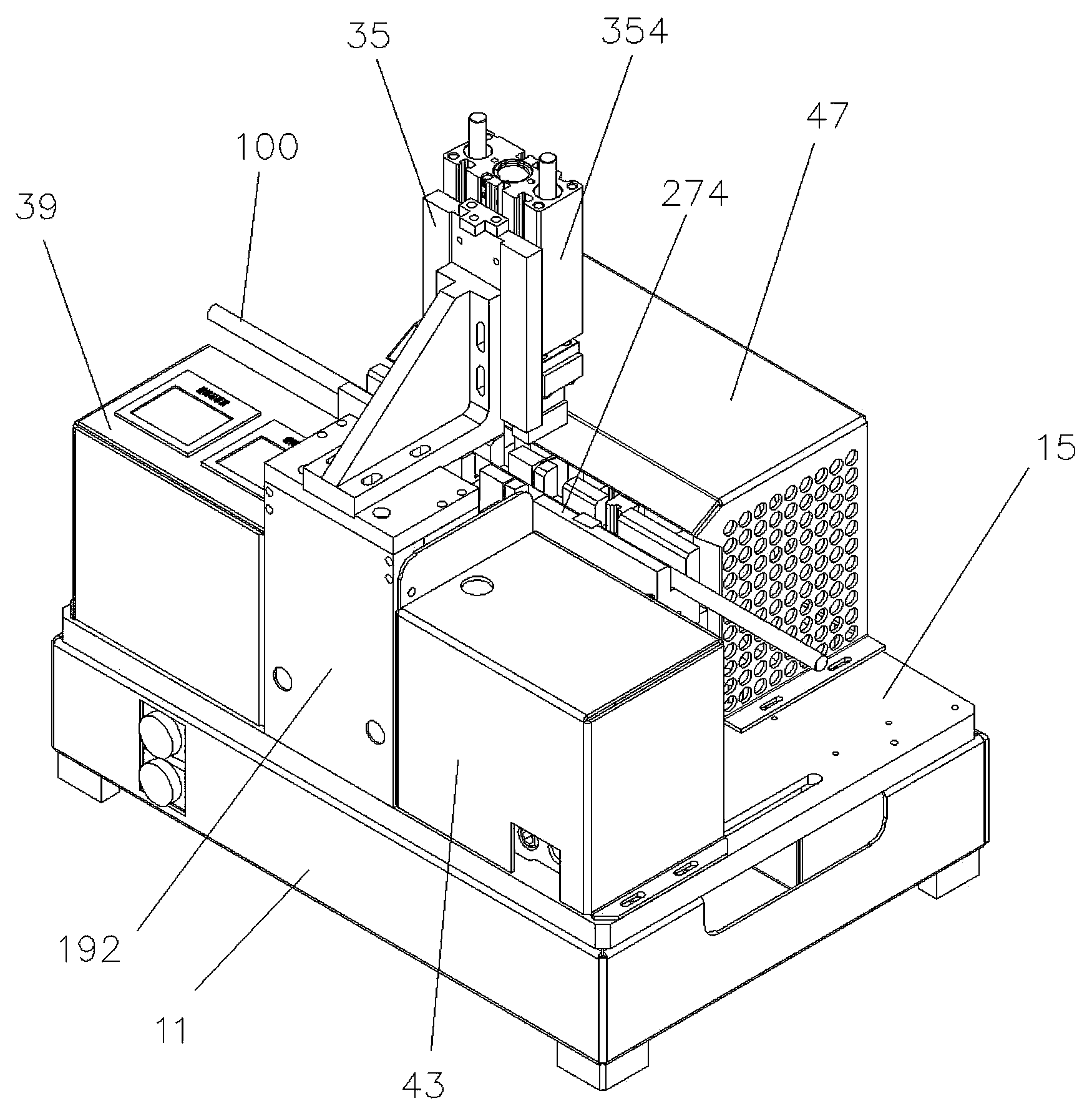

Automatic break sealing machine for heat shrinking tube

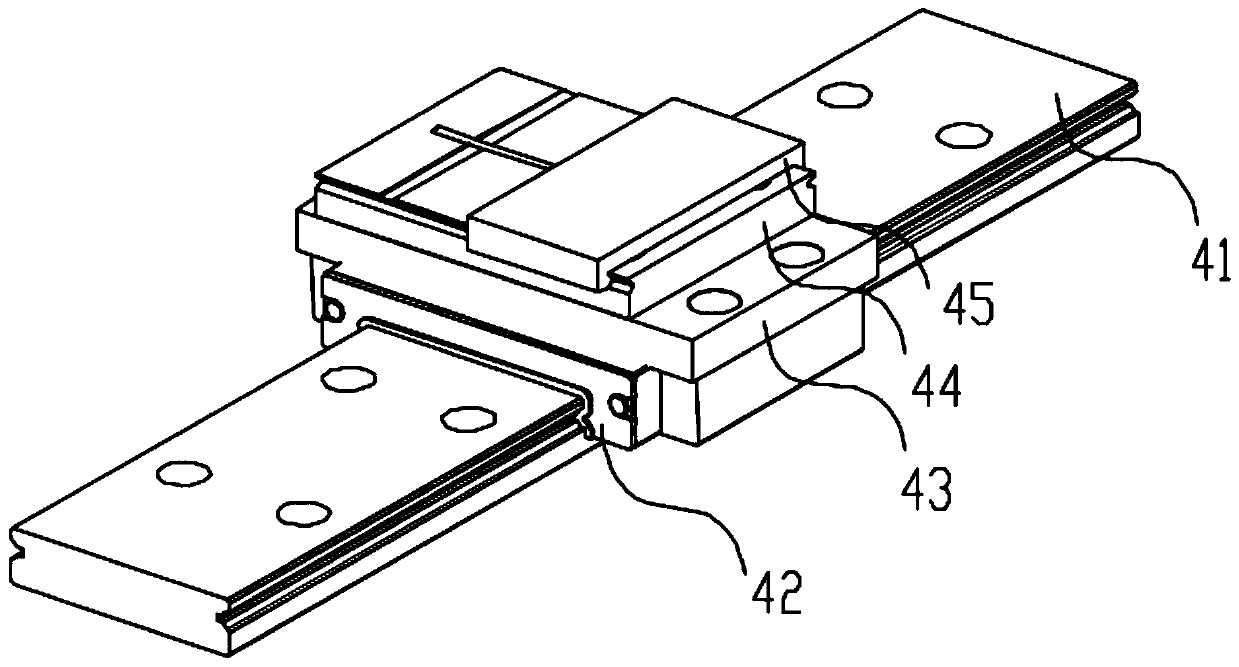

ActiveCN103723310AReduce wasteReduce labor intensityWrapper twisting/gatheringEngineeringSlide plate

An automatic break sealing machine for a heat shrinking tube comprises a mounting bottom plate, a heating mechanism, a cutting mechanism, a flow channel mechanism and an air compressing mechanism. The heating mechanism comprises a plurality of sliding rods, sliding groove assemblies, a stroke control sliding plate and heating assemblies. A sliding groove is formed between the two sliding groove assemblies, and the stroke control sliding plate is inserted into the sliding groove and slides in the lateral direction of the sliding groove. Two stroke control grooves are formed in the stroke control sliding plate, each heating assembly comprises a supporting sliding block, a bottom shaft and a heating block, the bottom shaft is arranged at the bottom of the supporting sliding block, a rolling bearing is arranged on the bottom shaft, the two heating assemblies are arranged on a plurality of sliding rods and can slide along the sliding rods, and the rolling bearings are correspondingly inserted in the stroke control grooves. The flow channel mechanism comprises two sliding channel vertical columns and a flow channel, and the flow channel is arranged on the two flow channel vertical columns and cross the sliding rods from above. The automatic break sealing machine for the heat shrinking tube effectively reduces seal time, improves seal efficiency, improves seal quality, and reduces material waste.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

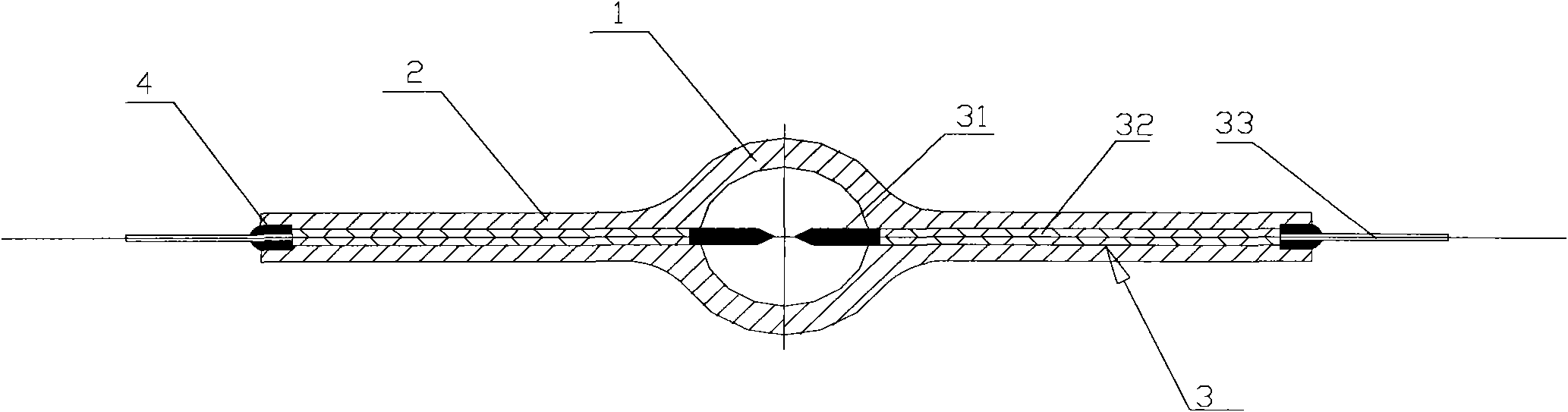

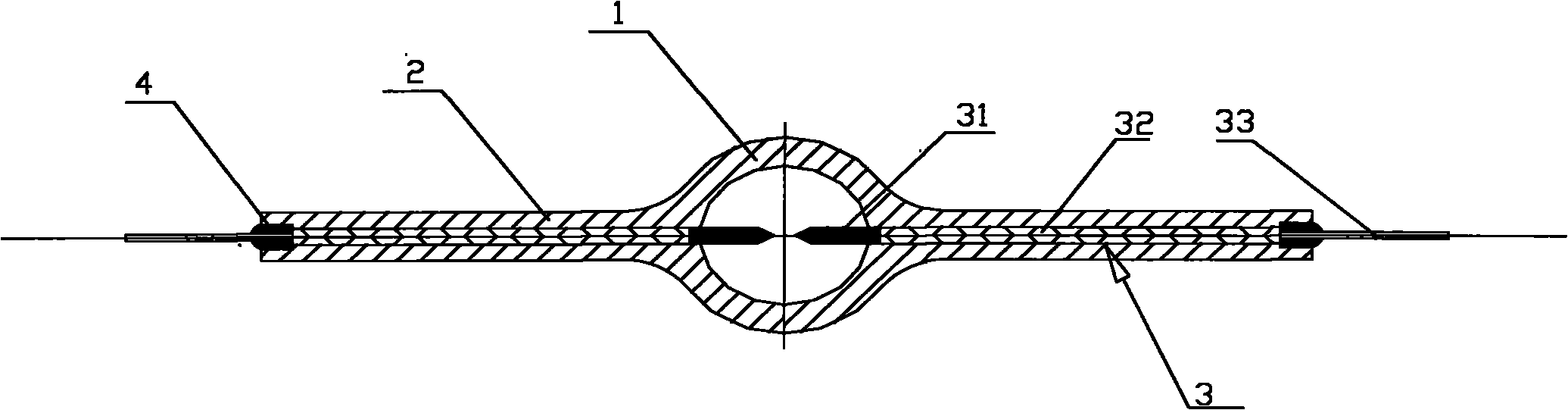

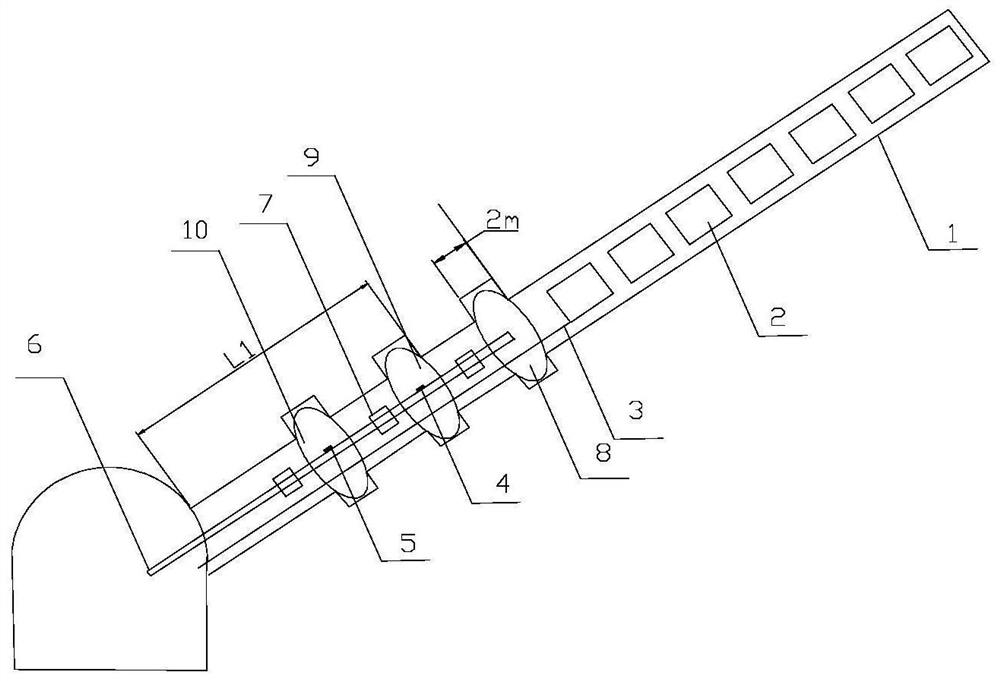

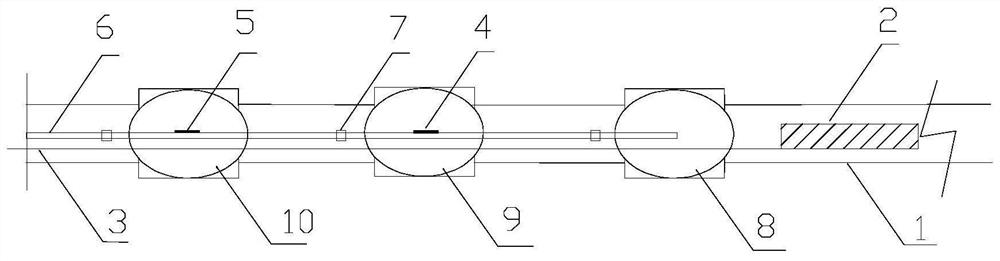

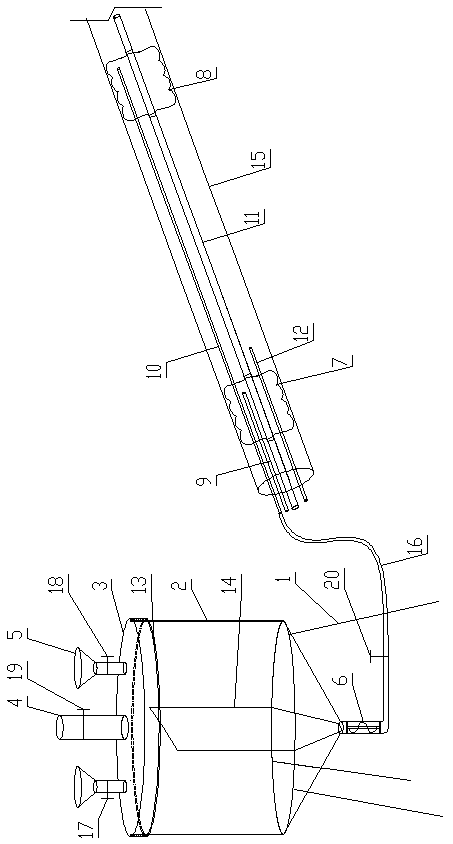

Polyurethane long-distance rapid fixed-point hole sealing device and method for underground drilling of coal mine

The invention provides a polyurethane long-distance rapid fixed-point hole sealing device for underground drilling of a coal mine. The polyurethane long-distance rapid fixed-point hole sealing device comprises supporting legs, a material injection barrel, a barrel cover, a pressure air connection pipe, feeding funnels, a powerless pipeline mixer, a first polyurethane foaming bag, a second polyurethane foaming bag, a pressure measuring or extraction pipe, a first material injection pipe, a second material injection pipe and a slurry injection pipe, wherein the barrel cover is horizontally arranged at the top of the material injection barrel; the material injection barrel is internally vertically provided with a separation plate for separating the inner part of the material injection barrel into a material storage chamber a and a material storage chamber b; the pressure air connection pipe and the two feeding funnels are arranged on the barrel cover; the upper end of the powerless pipeline mixer is arranged at the center of the bottom of the material injection barrel; and an inlet of the powerless pipeline mixer is communicated with the material storage chamber a and the material storage chamber b. The invention further discloses a hole sealing method. With the adoption of the polyurethane long-distance rapid fixed-point hole sealing device provided by the invention, the labor intensity of workers can be greatly alleviated; the polyurethane long-distance rapid fixed-point hole sealing device has the advantages of light weight, convenience for carrying, simplicity in operation and the like; after hole sealing work is finished, a plastic thin film in the material injection barrel is removed to finish the work, so that the procedure of washing the material injection barrel is avoided and the device is convenient and rapid.

Owner:HENAN POLYTECHNIC UNIV

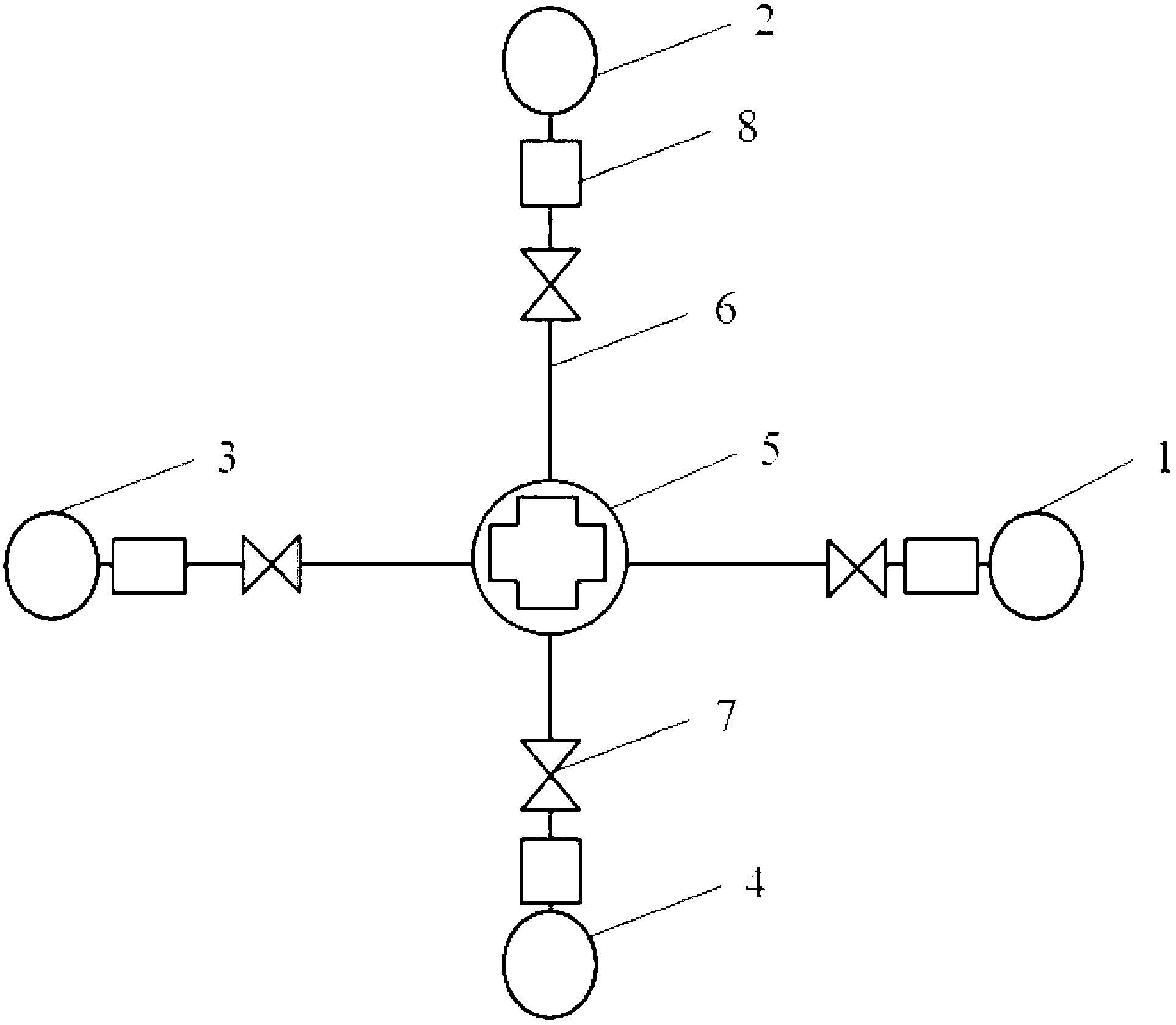

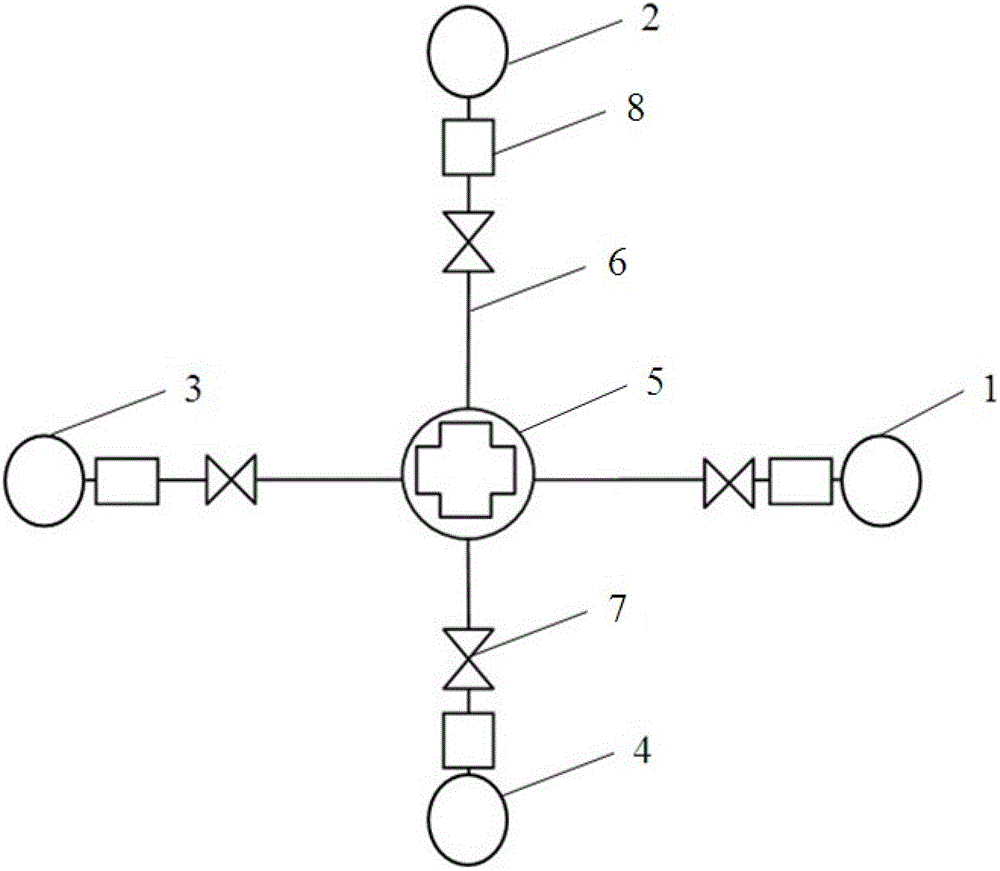

System for pumping and inflating SF6 for gas insulated switchgear

ActiveCN103322408ASave time switching devicesGuaranteed versatilitySwitchgear arrangementsContainer filling methodsEngineeringInternal pressure

The invention discloses a system for pumping and inflating SF6 for a gas insulated switchgear (GIS), comprising an SF6 recovery device, a vacuum pump, an SF6 storage device, a vacuum gauge and a connection pipeline, wherein the connection pipeline is combination pipes with four pipes which are communicated with each other, a moveable connector matched to a connection device is respectively on each of four ports of the connection pipeline, any pipe of the combination pipes can individually be opened or closed, three ports of the combination pipes are respectively connected with a GIS main body, the SF6 recovery device and the vacuum pump, and the other port is respectively connected with the vacuum gauge and the SF6 storage device in order. The system for pumping and inflating SF6 can greatly save time for pumping and inflating SF6 for the GIS, and has good internal pressure endurance and sealing reliability. In addition, the system for pumping and inflating SF6 has versatility.

Owner:STATE GRID CORP OF CHINA +1

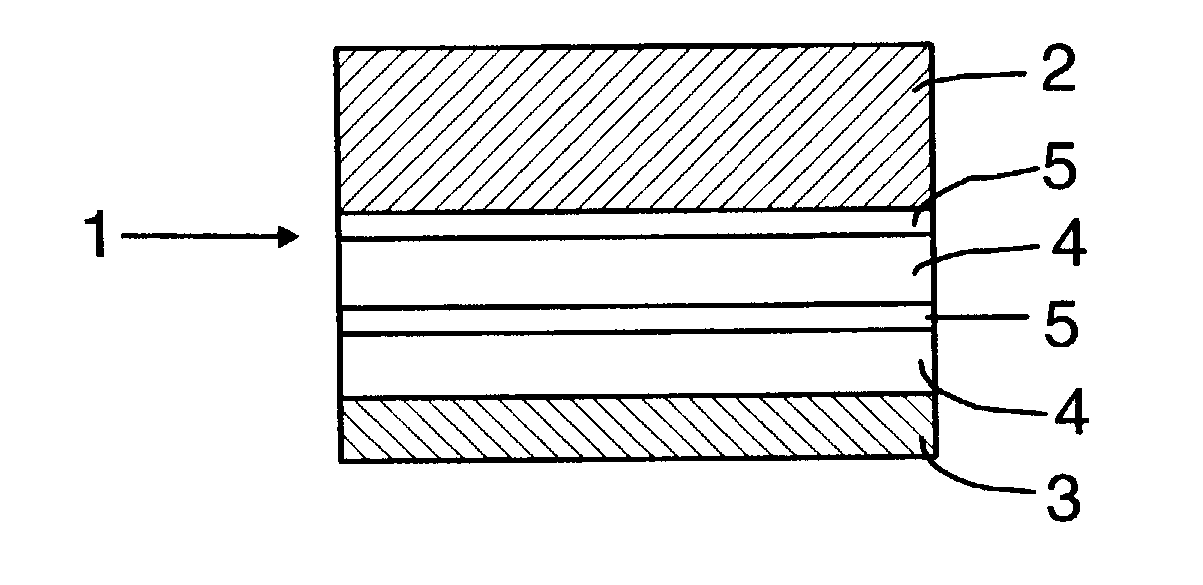

Radio frequency sealable film, sealed film structure and method of making the same

InactiveUS20120128907A1Reduce seal cycle timeHigh clarityLamination ancillary operationsFilm/foil adhesivesRadio frequencyPolypropylene

Radio frequency sealable films and sealed film structures are disclosed where the film comprises an outer seal layer and a substantially adjacent radio frequency receptive layer, wherein the outer seal layer consists essentially of a substantially isotactic polypropylene composition and the radio frequency receptive layer comprises a radio frequency receptive material.

Owner:DOW GLOBAL TECH LLC

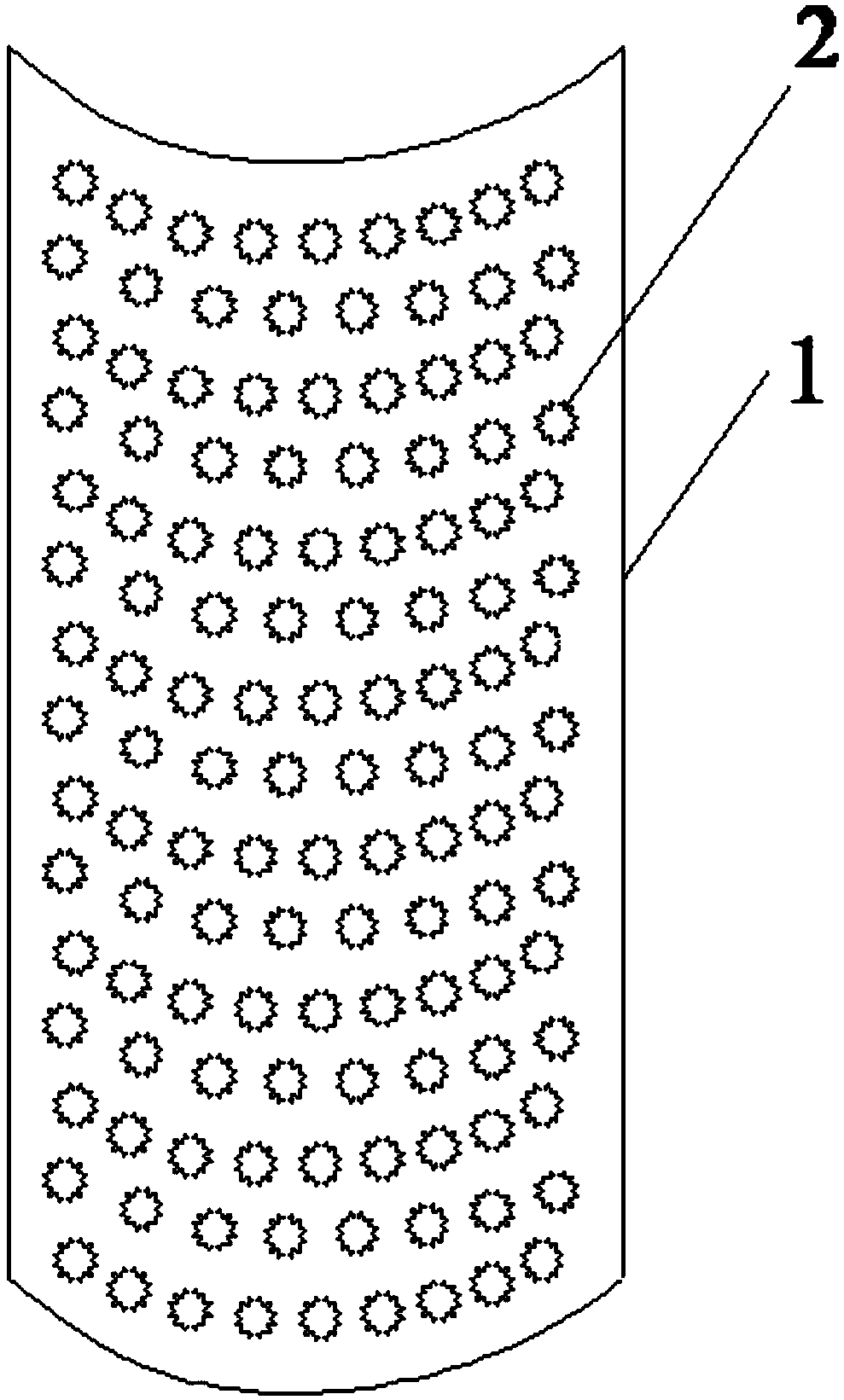

Cover tape for packaging electronic elements

InactiveUS20030127726A1Good transparencyReduce sealing timeFlexible coversWrappersElectrically conductiveBisphenol-A-polycarbonate

Owner:SUMITOMO BAKELITE CO LTD

Mucus type sealing agent doped with graded particles and preparation and using method thereof

ActiveCN109370515AWide variety of sourcesLow priceOther chemical processesSealing/packingCelluloseSlurry

The invention discloses a mucus type sealing agent doped with graded particles and a preparation and using method thereof. The sealing agent is prepared from the following components in parts by weight: 4-7 parts of cellulose thickening agents, 1-2 parts of sodium polyacrylate, 2-3 parts of gelatin, 7-9 parts of graded particles, 0.04-0.05 part of nonionic surfactant and 140-180 parts of water, wherein the grain mass ratio of the graded particles is (5-3)mm:(3-1)mm:(1-0.4)mm:less than 0.4mm is (2.4-3.3):(5-5.3):(6-6.3):(5.4-6.3). The sealing agent is wide in raw material source, non-toxic, harmless and low in price, and can be used for effectively blocking off multi-dimensional developing fissures of drilled surrounding rocks and new fissures under the influence of mining decompression. Compared with cement base and other solid sealing material, the mucus type sealing agent has the advantages that the drill hole sealing performance and extraction cycle stability can be improved, the sealing quality of extraction drill holes can be improved, secondary slurry filling can be carried out if fissures are well developed after 40 days, the gas extraction effect can be remarkably improved,and the extraction period of drill hole gas can be prolonged.

Owner:CHINA UNIV OF MINING & TECH

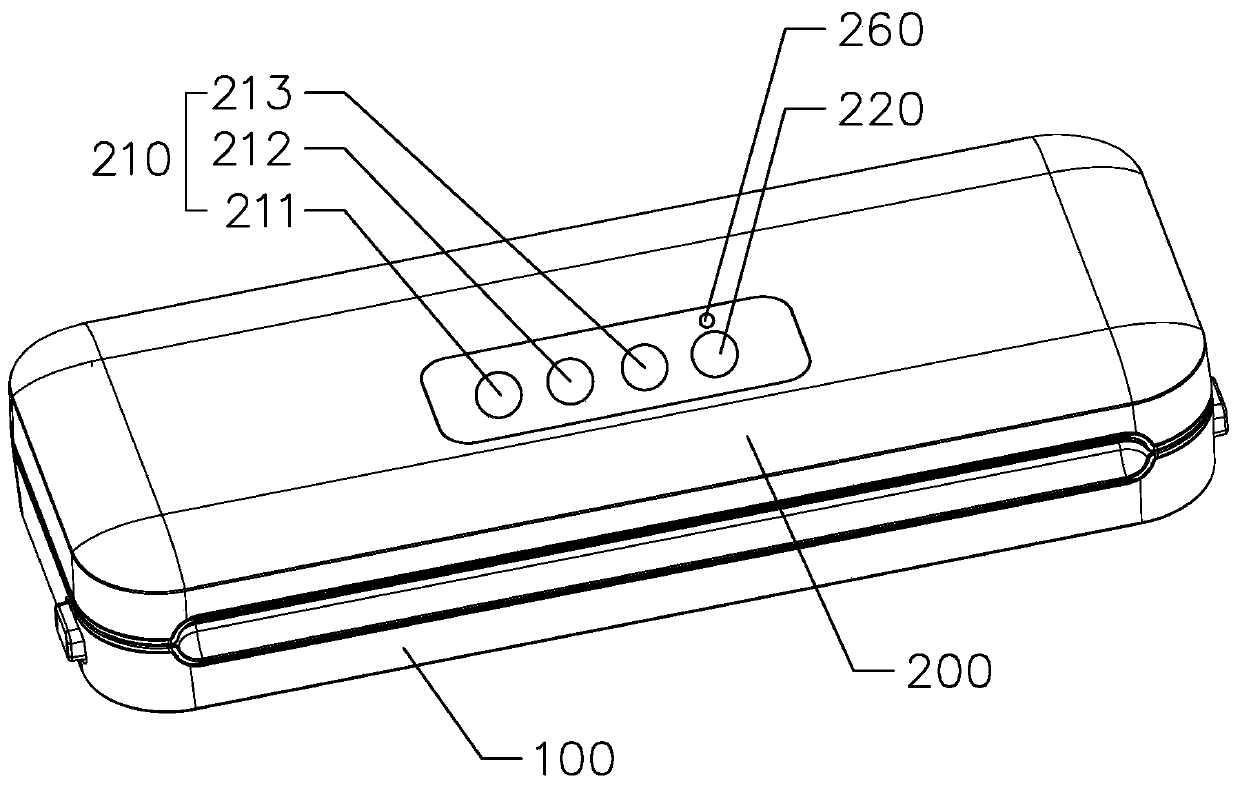

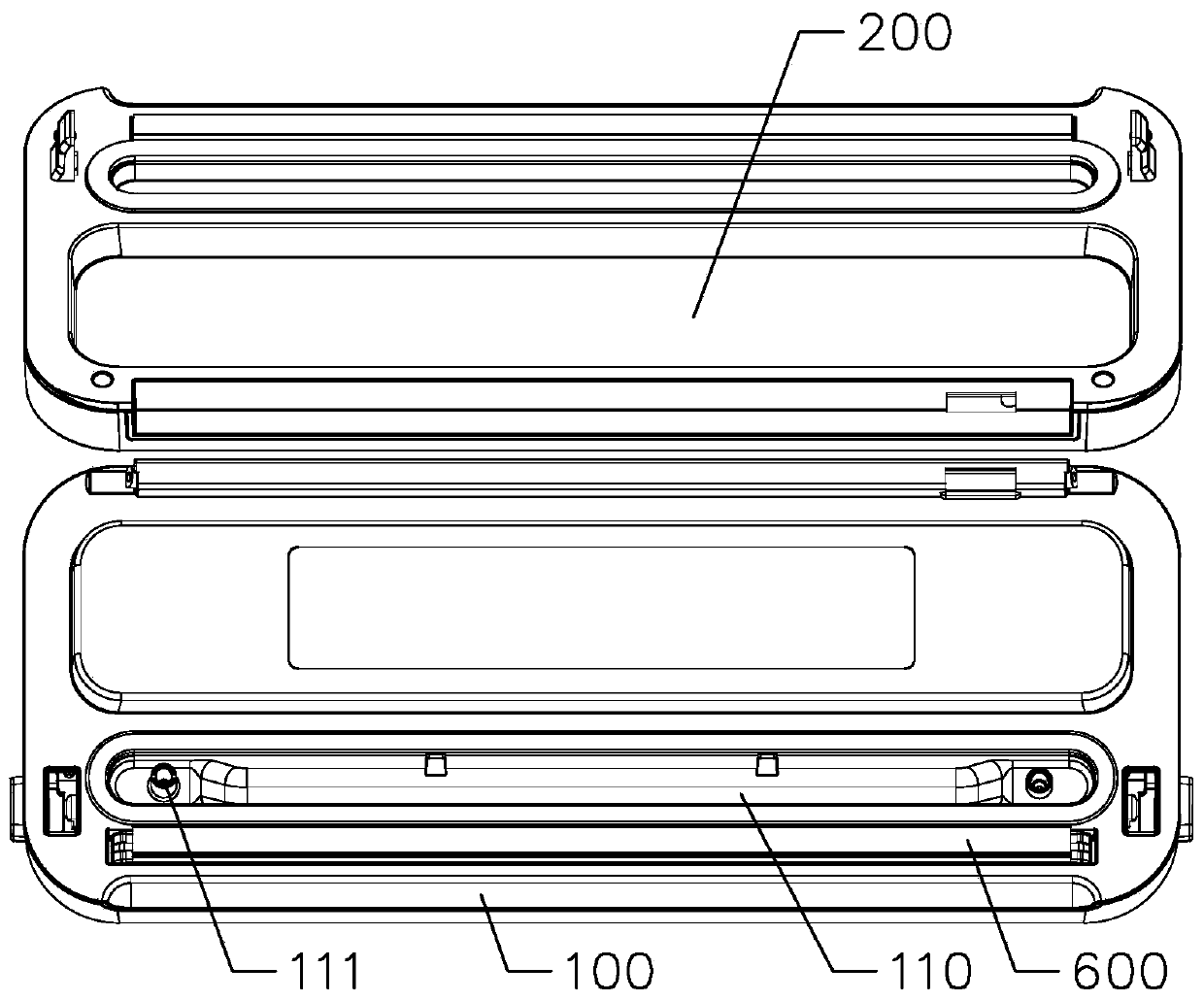

Vacuum packaging machine and use method thereof

InactiveCN110356625AVarious operating modesMeet different usage needsPackaging by pressurising/gasifyingWrapper twisting/gatheringOperation modeVacuum pump

The invention provides a vacuum packaging machine and a use method thereof. The vacuum packaging machine comprises a machine body, a gland rotatably connected to the machine body, a control plate, a vacuum pump, a pressure switch, a vacuumizing groove and a sealing device, wherein the pressure switch and the vacuum pump respectively communicate with the vacuumizing groove; the pressure switch, thevacuum pump and the sealing device are respectively electrically connected with the control plate; a function switching key and mode switching key are arranged on the gland; the function switching key is capable of switching among vacuum sealing function, vacuumizing function and sealing function according to needs to diversify operating modes of the vacuum packaging machine; the mode switching key is capable of switching between wet mode and dry mode according to the dry and wet states inside the package; and the mode switching key is electrically connected with the control plate and the working parameters of the vacuum pump and the sealing device are controlled through the control plate, so that the application range of the vacuum packaging machine is wider to meet different requirements of users. According to the vacuum packaging machine and the use method, different packages can be packaged, the application range is wider, and the operation is simple and convenient.

Owner:杭州青晓白科技有限公司

Ceramic projection lamp

InactiveCN101882558AReduced electrode heatingRaise the cold junction temperatureProjectorsHigh-pressure discharge lampsMaterials scienceElectrode

The invention discloses a ceramic projection lamp, which comprises a discharge chamber, electrode pipes placed at two ends of the discharge chamber and electrode components entering the discharge chamber through the electrode pipes, wherein the discharge chamber and the electrode pipes are made of a transparent material; the electrode components and the electrode pipes are airtightly sealed by solder; and mercury is filled in the discharge chamber; each electrode pipe comprises an inner pipe section and a welded groove, which are connected; the inner pipe section is close to the discharge chamber, the welded groove is positioned at the position of the end face, the inside diameter of the welded groove is greater than that of the inner pipe section, and the welded groove and the discharge chamber are airtightly sealed by the solder. The ceramic projection lamp has high illumination efficiency and good sealing effect.

Owner:CHAOZHOU ORILITE LIGHTING

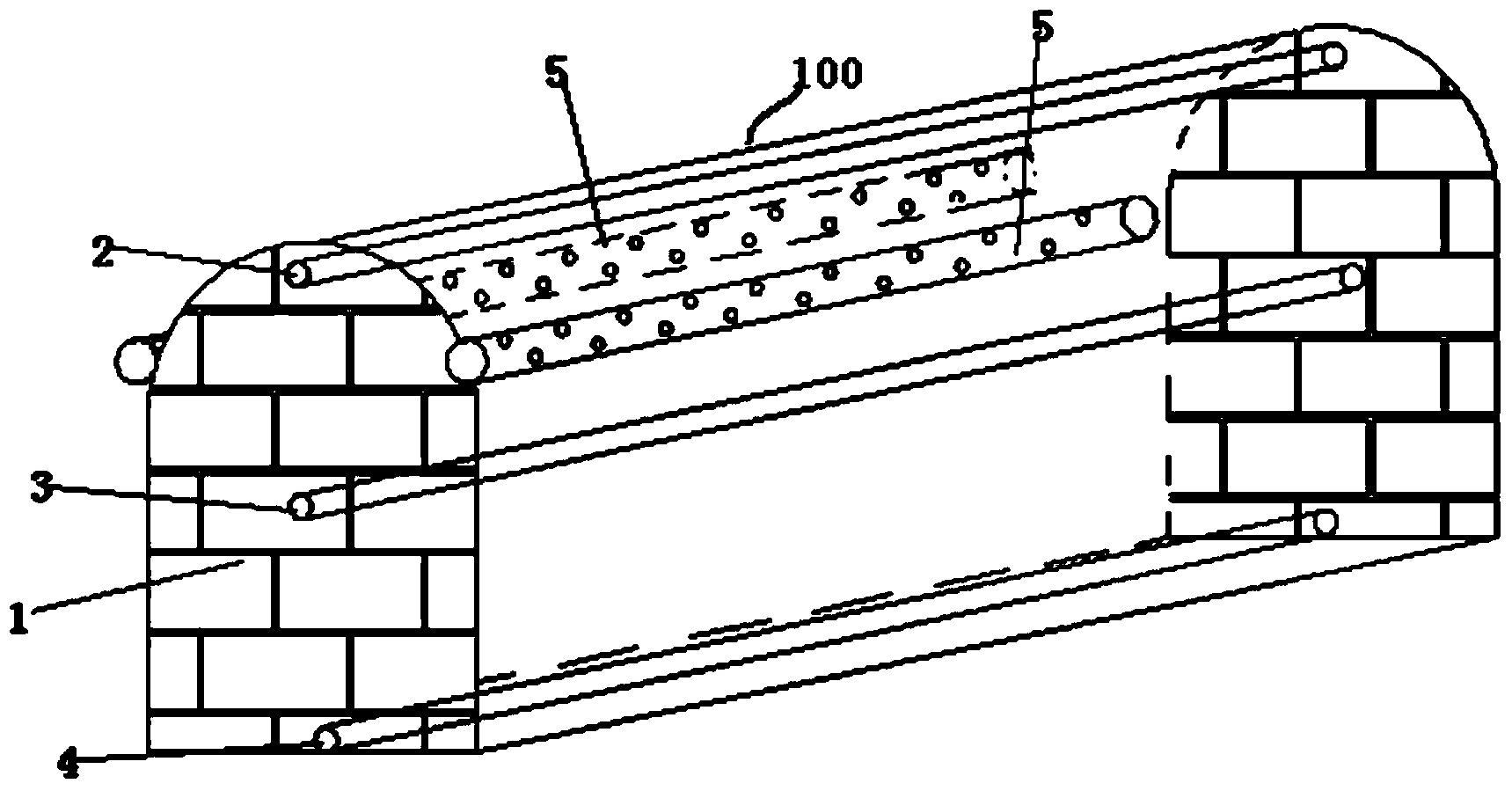

Method for remote filling of explosion-proof compression-resistant closing of coal mine

InactiveCN103726875APrevent leakageGuarantee the safety of lifeMining devicesFilling materialsEngineering

The invention relates to a method for remote filling of explosion-proof compression-resistant closing of a coal mine. The method comprises the steps of (1) piling up a fire dam on each of two sides in a closed section roadway with outbreak of fire; (2) arranging a plurality of guide pipes between the fire dam on the side far away from a fire area and the side wall of the roadway, putting one end of each guide pipe into the roadway between the two fire dams, and connecting the other end of each guide pipe with a conveying pipeline directly communicated with the outside of a mine; and (3) injecting a filling material into the conveying pipeline which is arranged outside the mine to ensure that the filling material flows into the roadway through the guide pipes, and filling and closing the roadway between the two fire dams after the filling material is solidified. By adopting the method, the life safety of closing workers can be effectively guaranteed. By adopting foamed cement with strong fluidity as the filling material, the filling material can infiltrate into every gap of the closed space to ensure that the finished fire dams have the advantage of difficulty in air leakage. The foamed cement is strong in anti-explosion capacity and compression resistance, so that the fire dams do not need to be very thick, the closing engineering quantity and sealing time are effectively reduced, and the deformation of surrounding roadways in the closed space can be resisted conveniently. The method disclosed by the invention can be widely applied to the field of underground closing filling of mines.

Owner:NORTH CHINA INST OF SCI & TECH

A continuous anodizing process for aluminum strip

ActiveCN105603486BAvoid unevennessOvercoming polarization voltageAnodisationElectrodesEngineeringElectrolyte

Owner:ZHEJIANG DILONG NEW MATERIAL

Sealing technique for element of PCM board

InactiveCN105170415AShorten production timeIncrease production speedLiquid surface applicatorsCoatingsMechanical engineeringSealant

The invention discloses a sealing technique for an element of a PCM board. The sealing technique for the element of the PCM board comprises the following steps that firstly, sealant is placed in a sealant tank of a sealant smelting machine to be dissolved; secondly, the PCM board welded with the element is placed in a jig; and finally, the sealant dissolved through the sealant smelting machine is injected into the jig through a gun body, and cooling and forming are conducted. According to the sealing technique, a traditional sealing technique is changed, the PCM board is placed in the jig, and cooling and forming are achieved after the sealant is injected into the jig, and the quality of sealed PCM boards produced through the same jig can be effectively monitored; the sealing time is shortened to be 20 s at present from the traditional four hours, production time is shortened greatly, the production speed is increased, and production efficiency is improved; meanwhile, the sealed PCM board produced through the technical scheme further has the advantages that coating is uniform, and seams are avoided; the quality and reliability of produced products are improved, and accordingly both production efficiency and product quality are improved, and the competitiveness of enterprises is improved.

Owner:HUIZHOU BLUEWAY ELECTRONICS

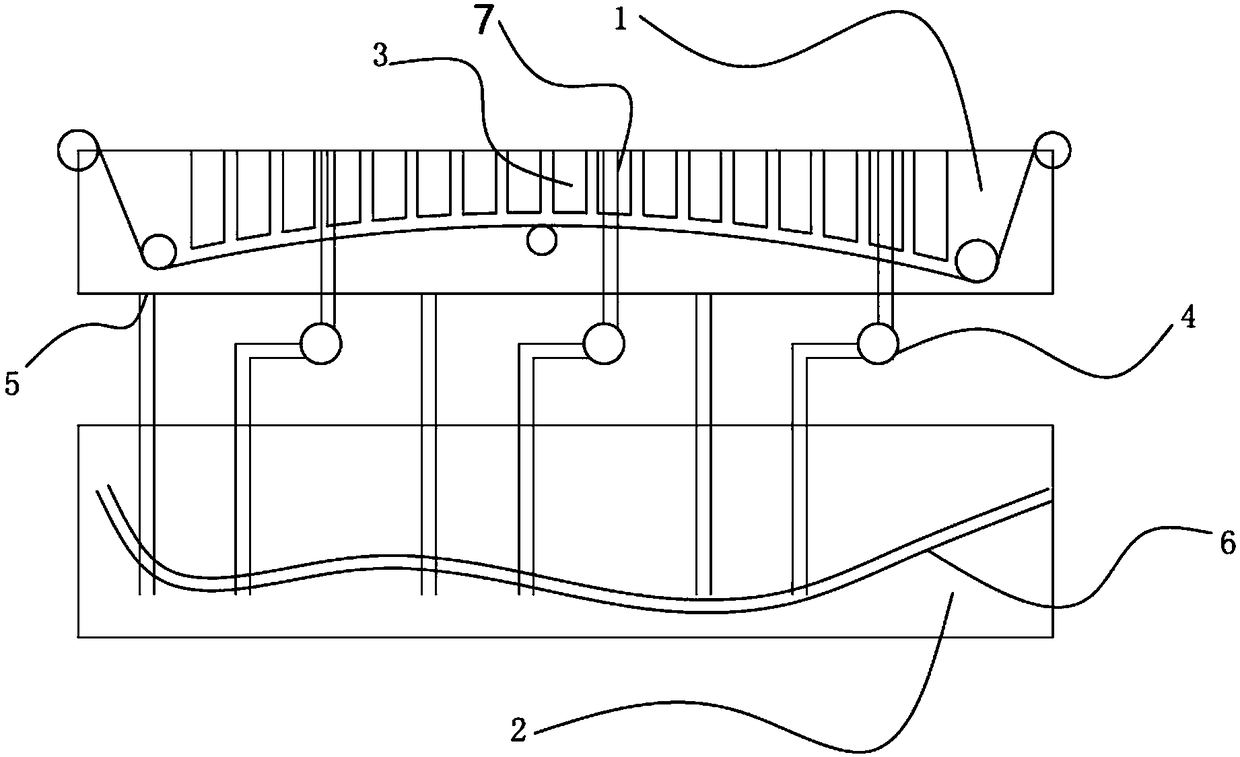

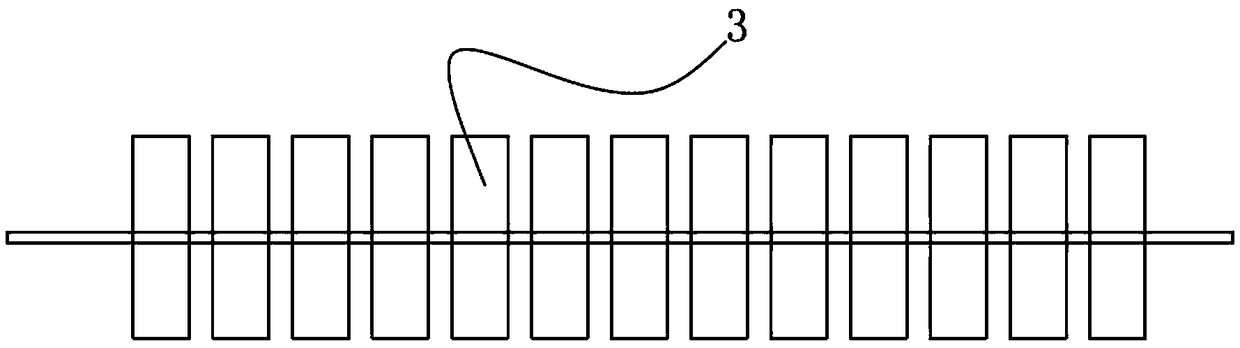

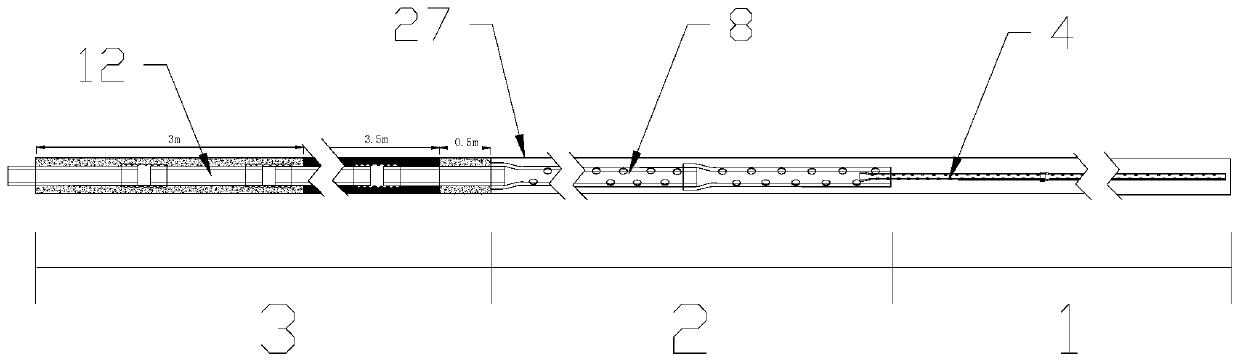

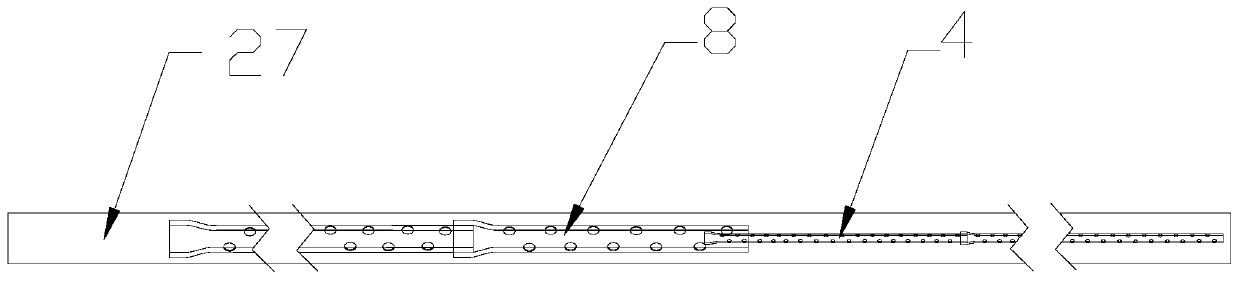

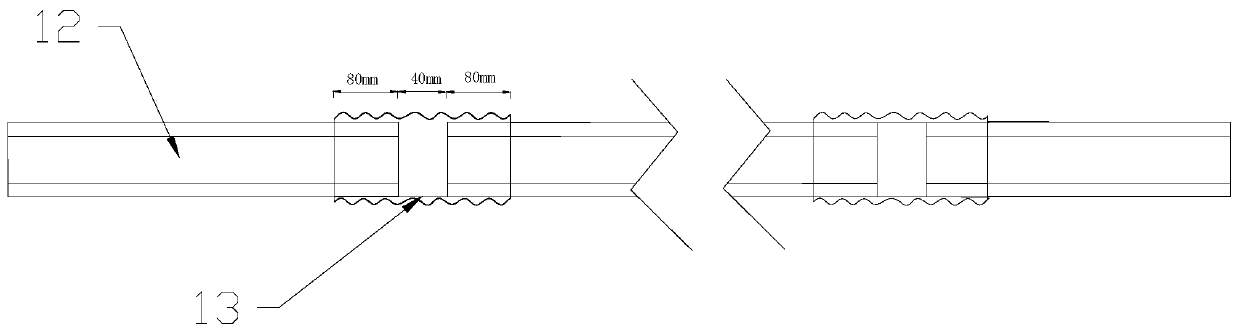

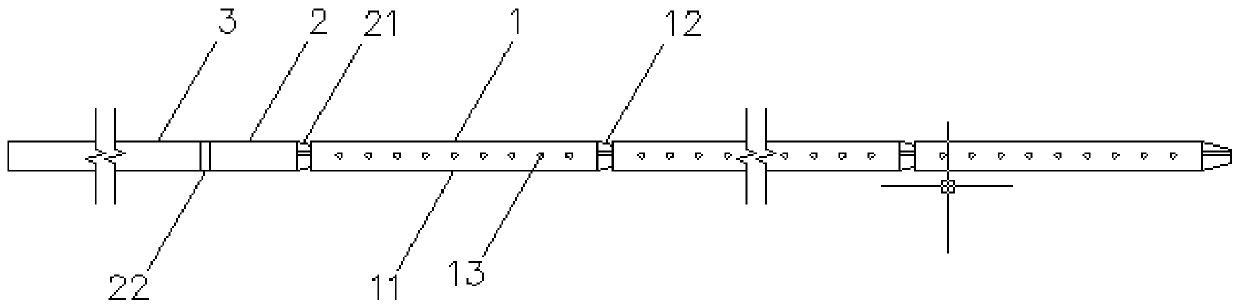

All hole depth different-diameter hole protecting and hole sealing system and method for deep-buried soft coal seam

ActiveCN110778356AImprove extraction efficiencySimple processDrilling rodsGas removalMining engineeringStructural engineering

The invention provides an all hole depth different-diameter hole protecting and hole sealing system and method for a deep-buried soft coal seam. The system involves a small floral tube hole protectingsection, a large floral tube hole protecting section and a hole sealing section which are sequentially arranged form a hole bottom part to a hole opening of a drilled hole, wherein the small floral tube hole protecting section is provided with a plurality of small floral tubes which are sequentially connected, the large floral tube hole protecting section is provided with a plurality of large floral tubes which are sequentially connected, the tube diameter of the small floral tubes is smaller than the tube diameter of the large floral tubes, and the end parts of the small floral tubes adjacent to the large floral tubes are arranged in the large floral tubes; and the hole sealing section comprises a plurality of short connecting tubes which are sequentially connected, the end parts of every adjacent short connecting pipes are connected with each other through a soft connecting buried wire tubes, the end parts of the short connecting tubes adjacent to the large floral tubes communicatewith the large floral tubes, and plugging materials are arranged between the short connecting tubes and the inner wall of the drilled hole. The all hole depth different-diameter hole protecting and hole sealing system has the advantages that the process is simple, the construction is convenient, the hole sealing time is shortened, the labor efficiency is improved, all hole depth hole protecting ofgas extraction drilling is realized, and the drilling gas extraction efficiency is improved.

Owner:HENAN INST OF ENG +1

Segmented rapid hole sealing method for coal mine broken roof blasting drilling

The invention relates to a blasting drilling hole sealing method, in particular to a segmented rapid hole sealing method for coal mine broken roof blasting drilling. The segmented rapid hole sealing method comprises the following steps that local chambering is carried out on a drilled hole, and a chambering section is blocked by adopting a filter accumulation type bag, so that a sugar-coated haw-shaped cement column is formed. Blasting pressure generated by explosive explosion is difficult to break through the sugar-coated haw-shaped cement column, water can flow out of the bag after cement mortar enters the filter accumulation type bag, and high-concentration quick-setting cement can be stored in the bag, so that simple, quick and safe hole sealing of coal mine broken roof blasting drilling is realized. By using the segmented rapid hole sealing method for coal mine broken roof blasting drilling, on-duty (within 6 hours) blasting can be achieved, and the potential safety hazard that ashot line is exposed can be eliminated.

Owner:ANHUI UNIV OF SCI & TECH

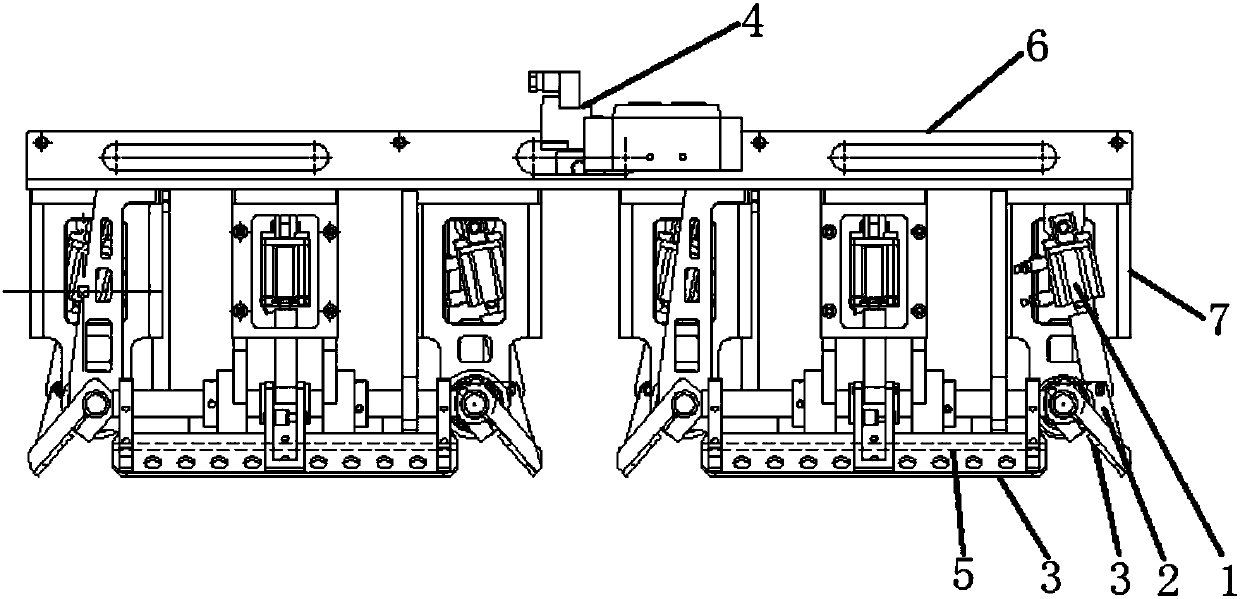

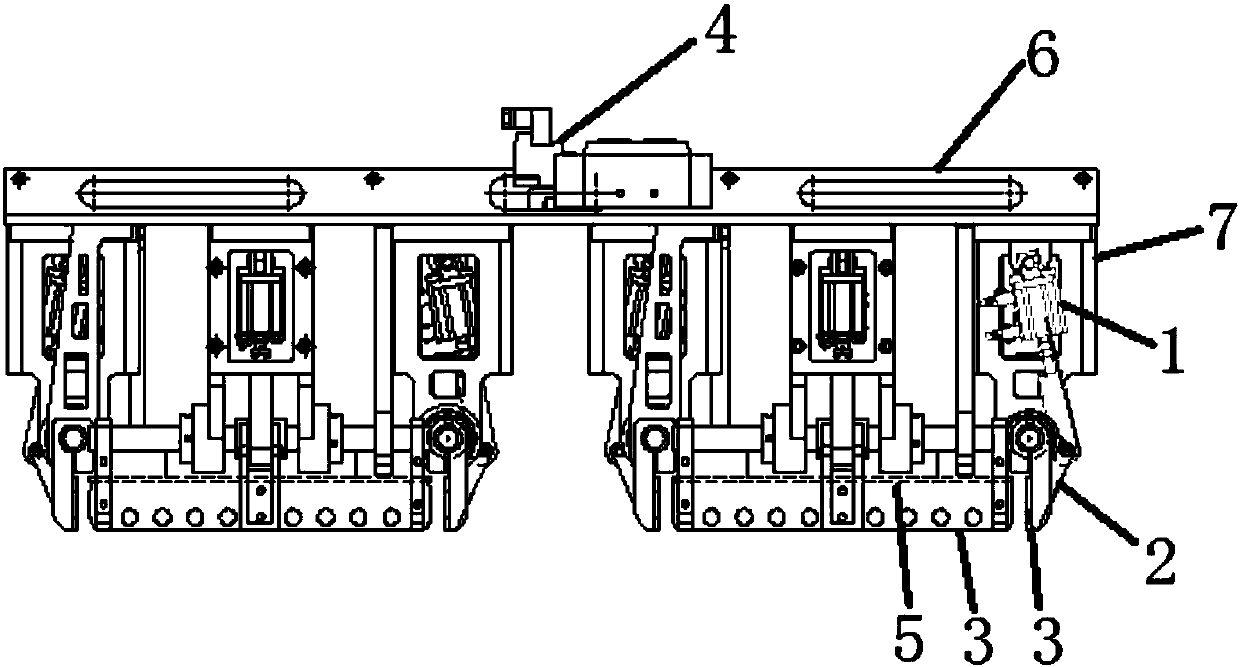

Automatic box sealing gripper for robot

The invention relates to an automatic box sealing gripper for a robot. The gripper is arranged at the end of a robot arm and comprises a gripper connecting frame arranged at the end of the robot arm and four-face box sealing units arranged at the bottom of the gripper connecting frame. The four-face box sealing units seal the front faces, the rear faces, the left faces and the right faces of paperboxes at the same time. Compared with the prior art, totally eight air cylinders of the two four-face box sealing units in the automatic box sealing gripper work at the same time, the two paper boxescan be sealed at a time, the box sealing time is greatly shortened, the production efficiency is improved, and fast box sealing is achieved; and the space occupied by a device is saved, and the production cost is reduced.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

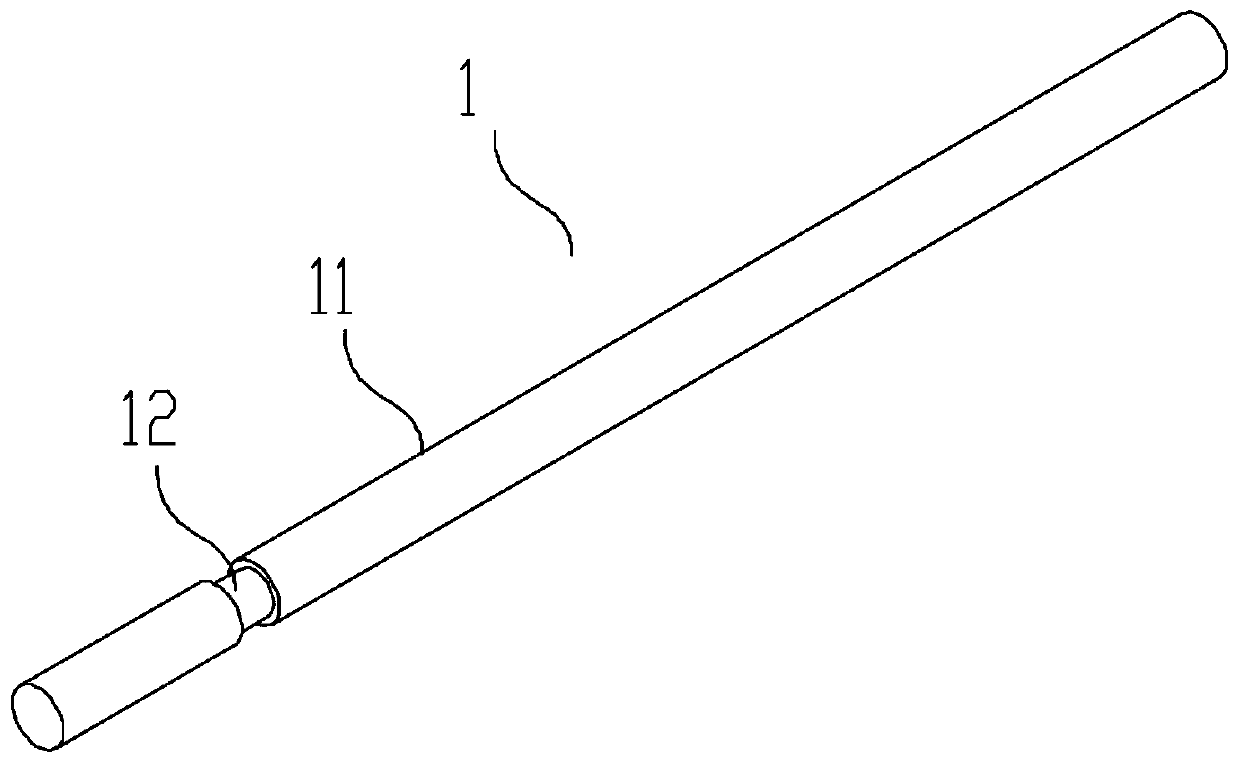

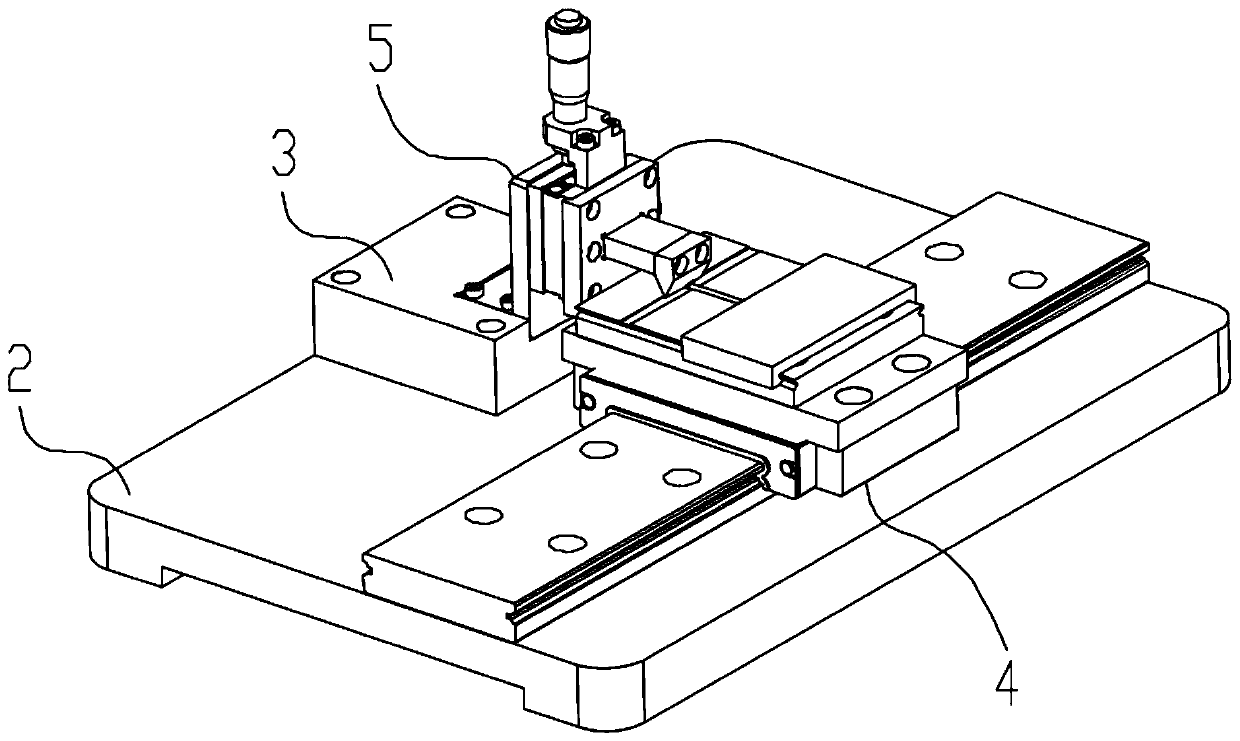

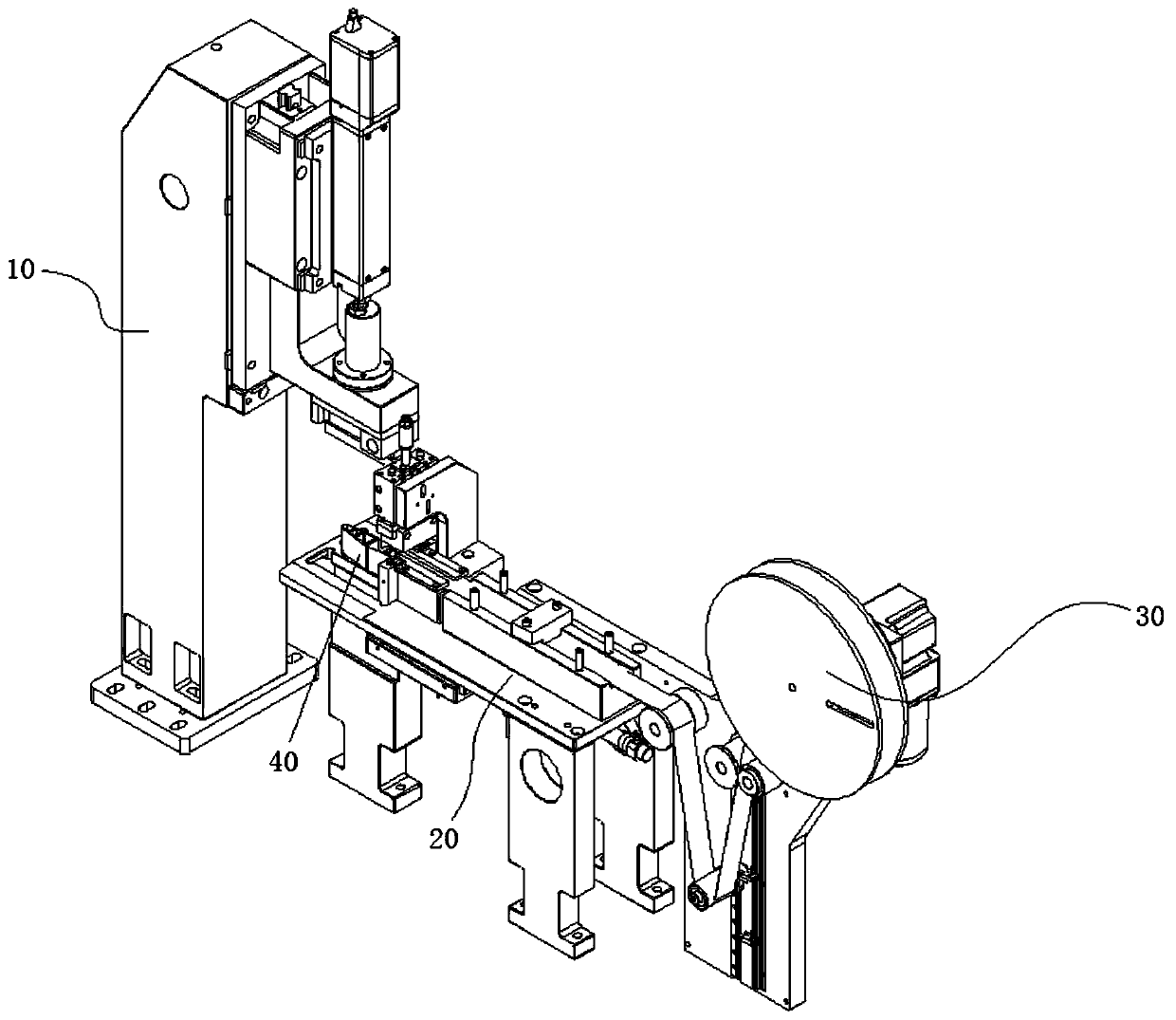

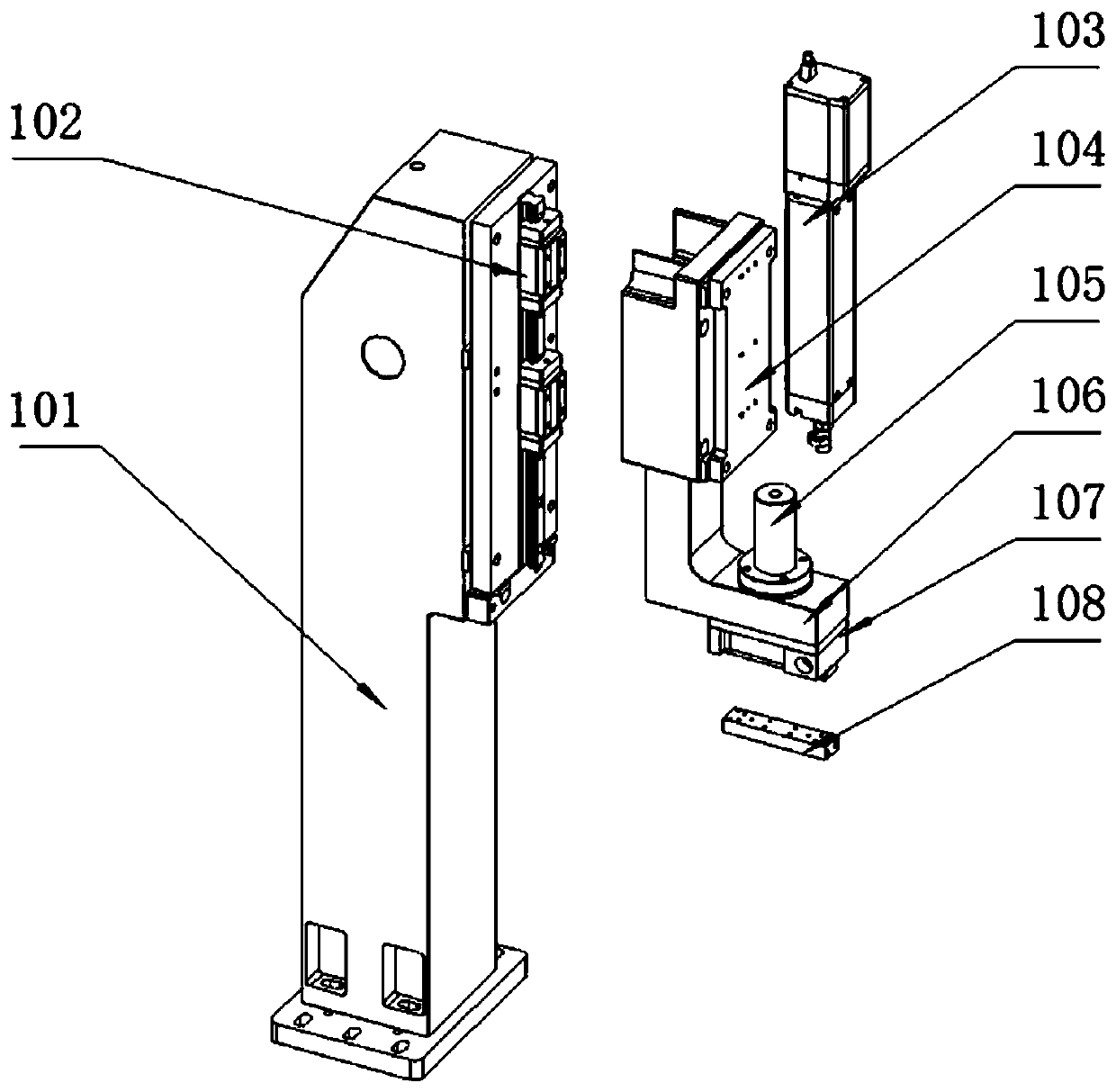

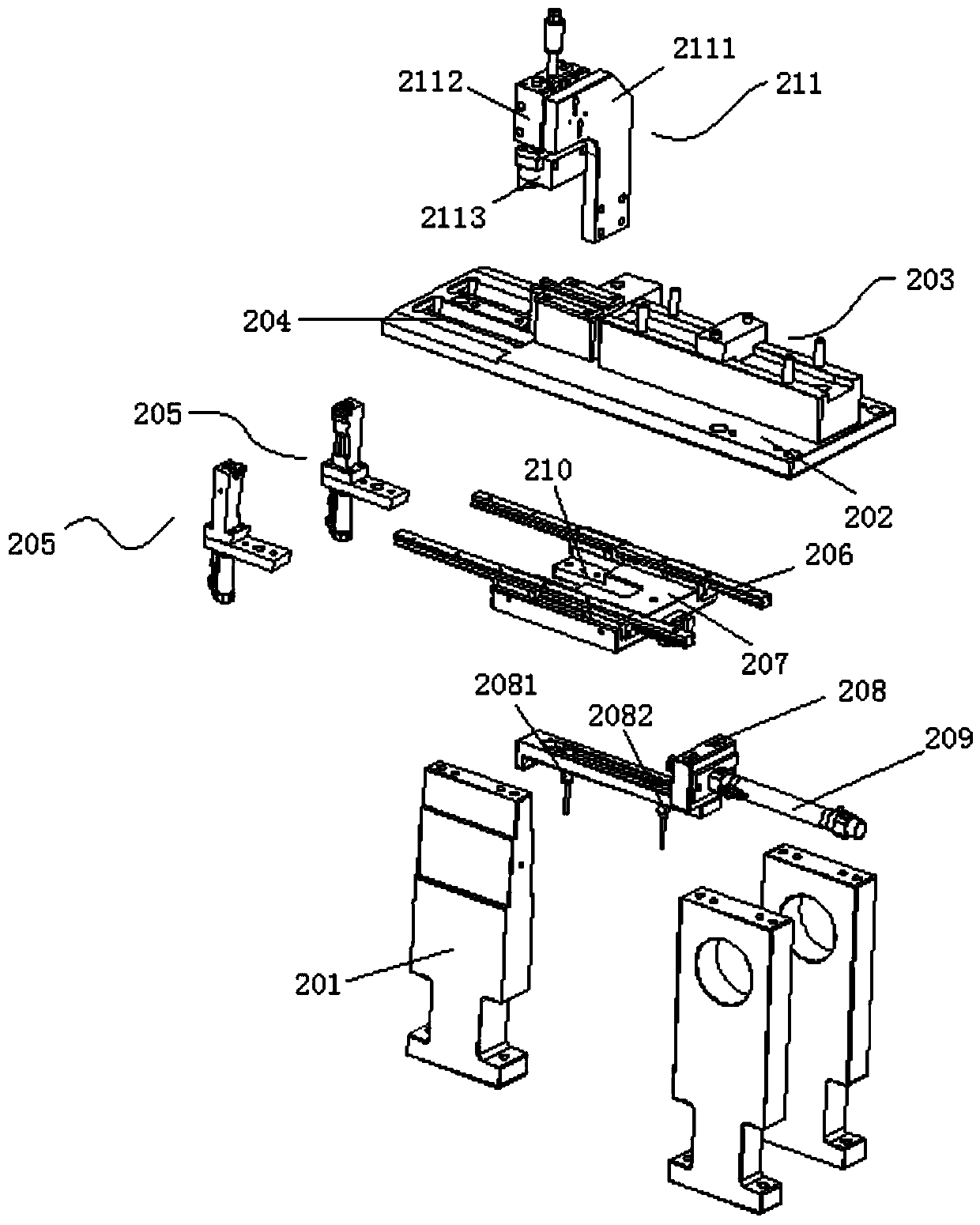

Semiautomatic sealing machine for miniature spring-type probe

The invention discloses a semiautomatic sealing machine for a miniature spring-type probe. The semiautomatic sealing machine includes a base, a connection block A, an X-axis sliding component, and a Z-axis fine-tuning component. The connection block A and the X-axis sliding component are arranged on a base. The Y-axis fine-tuning component is disposed on the connecting block A. The X-axis slidingcomponent includes: a fixed slide, an X-axis slide table, a connection plate C, a probe fixing base and a probe fixing block. The X-axis slide table is arranged on the fixed slide and can slide alongthe fixed slide. The connection plate C is disposed on the X-axis slide table. The probe fixing base is disposed on the connection plate C for holding a probe. The probe fixing block is arranged on the probe fixing base for pressing the probe. The semiautomatic sealing machine can solve the poor accuracy and the low efficiency of a traditional manual sealing machine.

Owner:苏州英世米半导体技术有限公司

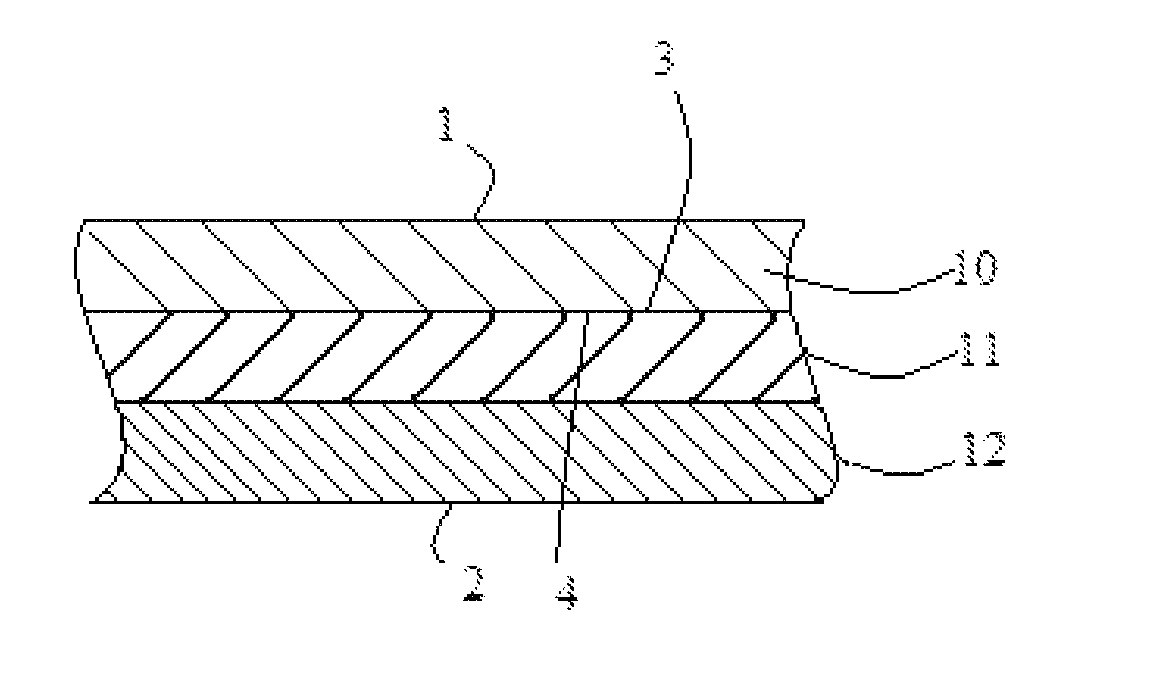

Easily-recycled high-barrier low-temperature heat-sealing packaging composite film and production method thereof

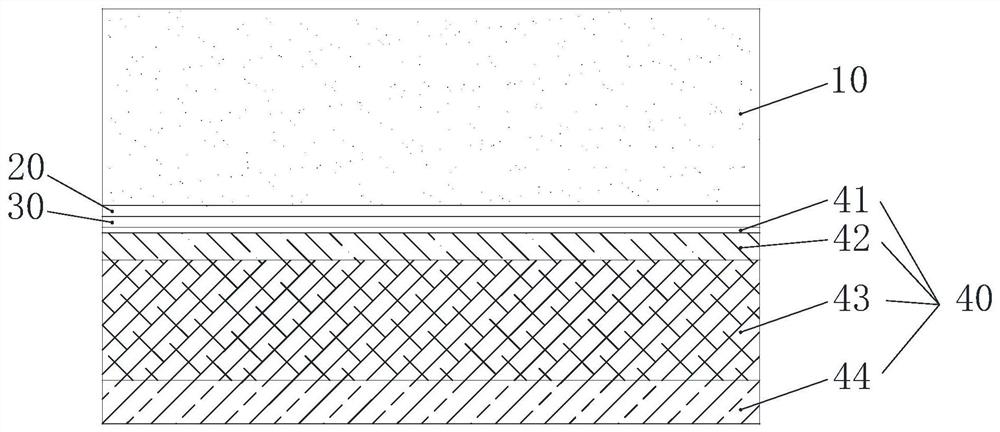

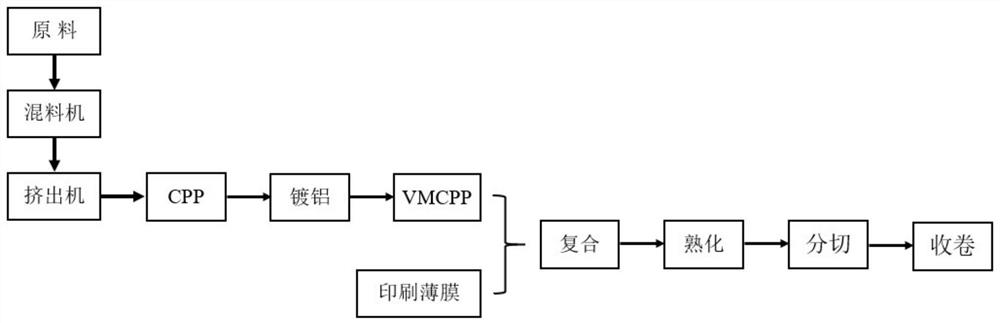

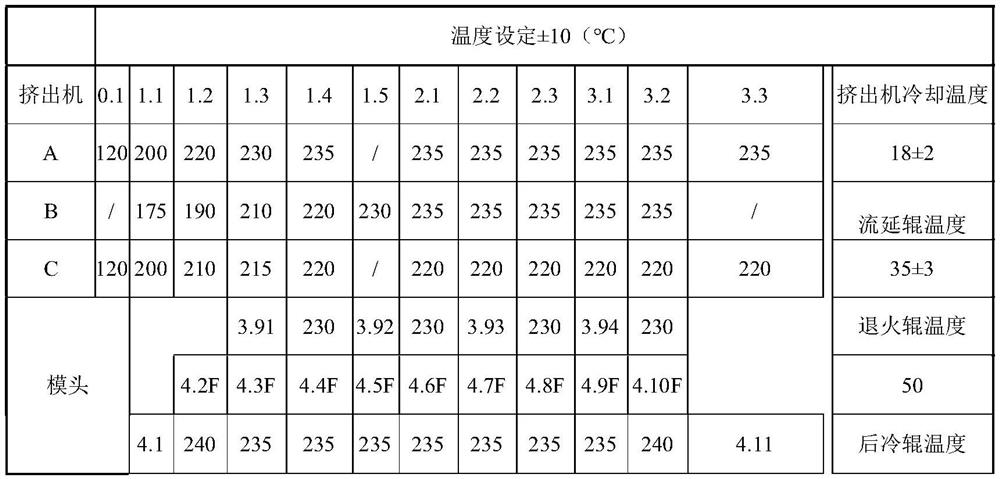

PendingCN113815280ANo recycling valueLow heat seal strengthPackage recyclingFlexible coversPolymer sciencePolyolefin

The invention relates to the field of packaging, in particular to an easily-recycled high-barrier low-temperature heat-sealing packaging composite film and a production method thereof. The composite film is formed by compounding a printing film and an aluminum-plated casting polypropylene film VMCPP, the aluminum-plated casting polypropylene film VMCPP is of a four-layer structure, the first layer is an aluminum layer, and the printing film is compounded on the surface of the aluminum layer; the second layer is a composite layer and is composed of copolymerized PP resin and maleic anhydride grafted POE; the third layer is a middle layer and is made of homo-polypropylene resin; and the fourth layer is a heat sealing layer and is composed of a metallocene-based polypropylene random copolymer, a butenyl polymer and an anti-blocking agent. The composite film is a single polyolefin material composite film, is easy to melt and recycle, has high recovery value, has the advantages of high barrier property, low-temperature heat sealing and high heat sealing strength, and can well meet the requirements of high barrier and high-speed packaging.

Owner:HUANGSHAN NOVEL

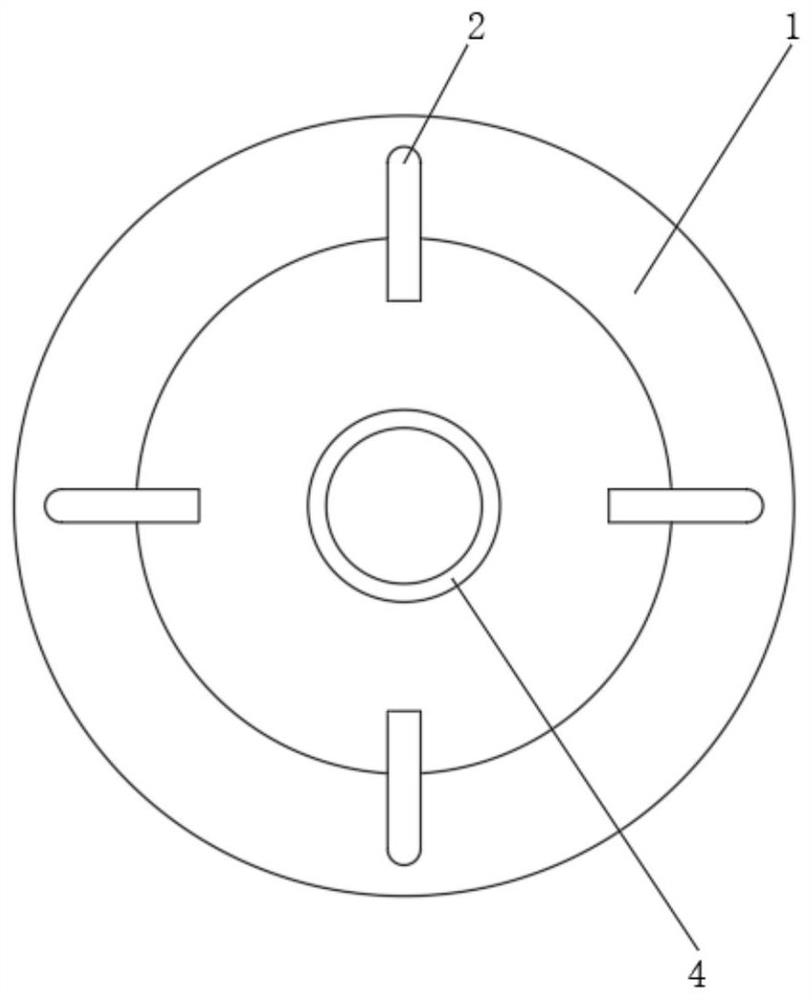

Polyurethane long-distance fast fixed-point sealing device and method for underground drilling in coal mine

The invention provides a polyurethane long-distance rapid fixed-point hole sealing device for underground drilling of a coal mine. The polyurethane long-distance rapid fixed-point hole sealing device comprises supporting legs, a material injection barrel, a barrel cover, a pressure air connection pipe, feeding funnels, a powerless pipeline mixer, a first polyurethane foaming bag, a second polyurethane foaming bag, a pressure measuring or extraction pipe, a first material injection pipe, a second material injection pipe and a slurry injection pipe, wherein the barrel cover is horizontally arranged at the top of the material injection barrel; the material injection barrel is internally vertically provided with a separation plate for separating the inner part of the material injection barrel into a material storage chamber a and a material storage chamber b; the pressure air connection pipe and the two feeding funnels are arranged on the barrel cover; the upper end of the powerless pipeline mixer is arranged at the center of the bottom of the material injection barrel; and an inlet of the powerless pipeline mixer is communicated with the material storage chamber a and the material storage chamber b. The invention further discloses a hole sealing method. With the adoption of the polyurethane long-distance rapid fixed-point hole sealing device provided by the invention, the labor intensity of workers can be greatly alleviated; the polyurethane long-distance rapid fixed-point hole sealing device has the advantages of light weight, convenience for carrying, simplicity in operation and the like; after hole sealing work is finished, a plastic thin film in the material injection barrel is removed to finish the work, so that the procedure of washing the material injection barrel is avoided and the device is convenient and rapid.

Owner:HENAN POLYTECHNIC UNIV

On-line heat sealing device

PendingCN111071565AControl altitudeControl seal pressureWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses an on-line heat sealing device. A hot pressing mechanism and a film releasing mechanism are arranged at the two ends of a film pulling and cutting mechanism; a support is provided with a fixing mounting plate; the fixing mounting plate is provided with a material channel; two displacement through grooves are formed in the front part of the fixing mounting plate; the two sides of the front end of the material channel are each provided with a film clamping mechanism correspondingly; a second linear guide rail is arranged at the bottom of the fixing mounting plate and is movably connected with a movable plate; a film pulling mounting seat is arranged at the bottom of the fixing mounting plate as well and is movably connected with a film pulling cylinder piston rod; a free end of the film pulling cylinder piston rod is connected with a rear end of the movable plate; two film clamping mounting grooves are formed in the front end of the movable plate and are connectedwith a film clamping cylinder seat; a film clamping cylinder is fixed on the film clamping cylinder seat; and a film cutting mechanism is arranged at the front end of the material channel. The designof the on-line heat sealing device achieves the purposes of being in low cost and controllable in sealing pressure; and the on-line heat sealing device is easy to integrate with equipment and is convenient to maintain.

Owner:烽禾升医疗设备(昆山)有限公司

Optical cavity sealing method

The invention discloses an optical cavity sealing method, and belongs to the technical field of sealing glue filling. According to the optical cavity sealing method, the mode of combining layered solidifying and heating drying is adopted, complete sealing of an optical cavity is achieved by spraying a first silica gel layer, the needed silica gel thickness is obtained through many times of layered spraying, heating drying and solidifying, and the firm bonding of a mirror base and an optical mirror is achieved. According to the optimal cavity sealing method, the inner silica gel layer (the first silica gel layer) is completely solidified, sealing of the optimal cavity is completely achieved, and the fixing and bonding effects of the mirror base and the optical mirror can be achieved without complete solidifying of the rest of silica gel layers, and the sealing time is shortened through the heating drying and solidifying mode. According to the optical cavity sealing method, operation is easy and convenient, the inner silica gel layer is solidified completely, the sealing quality is high, the solidifying speed of each silica gel layer is high, and the sealing time is short.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Operation method for forward movement of rudder blade sealing plate

PendingCN113581409AShorten working timeImprove securityWaterborne vesselsLoad-engaging elementsSafety coefficientOperation safety

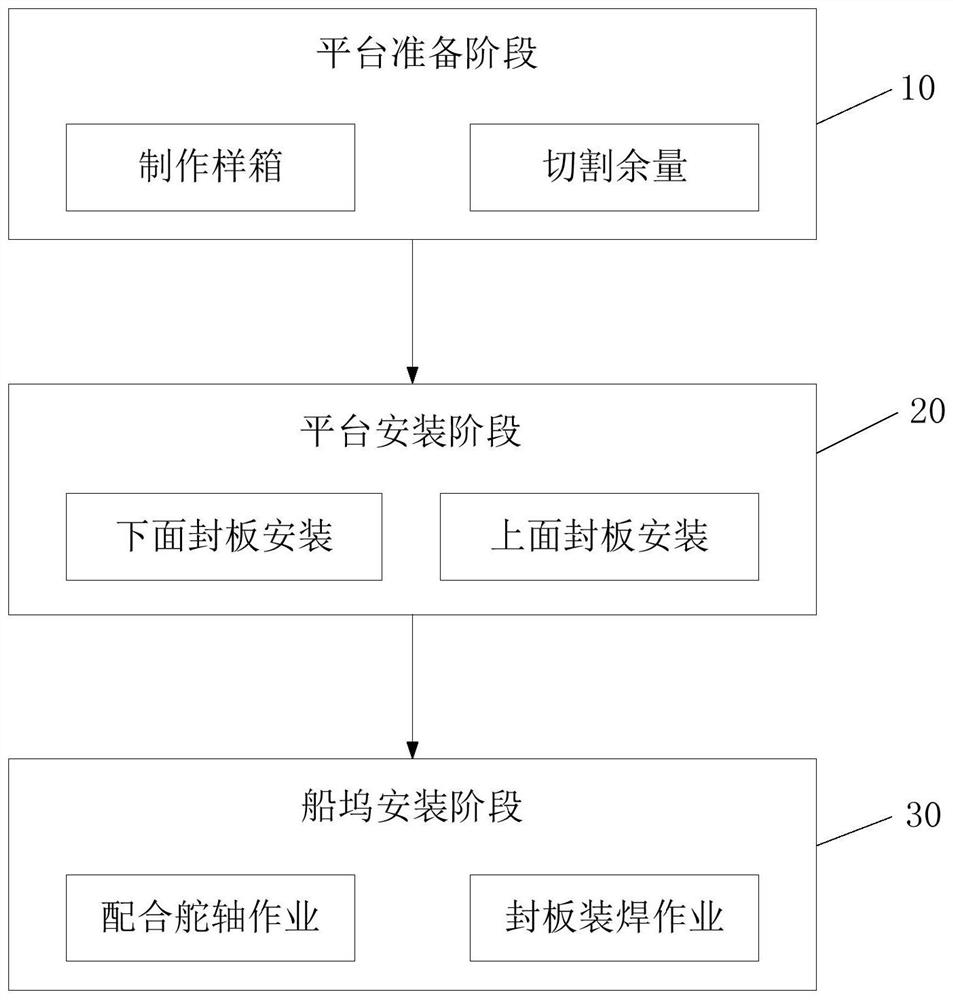

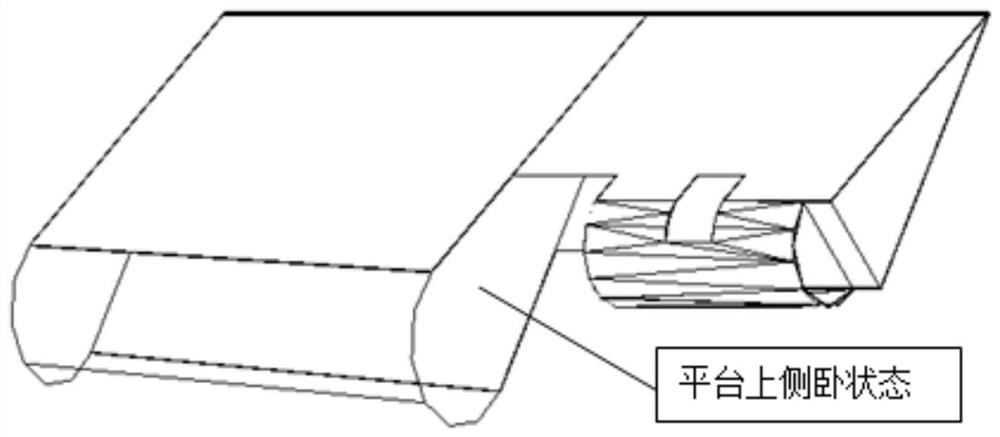

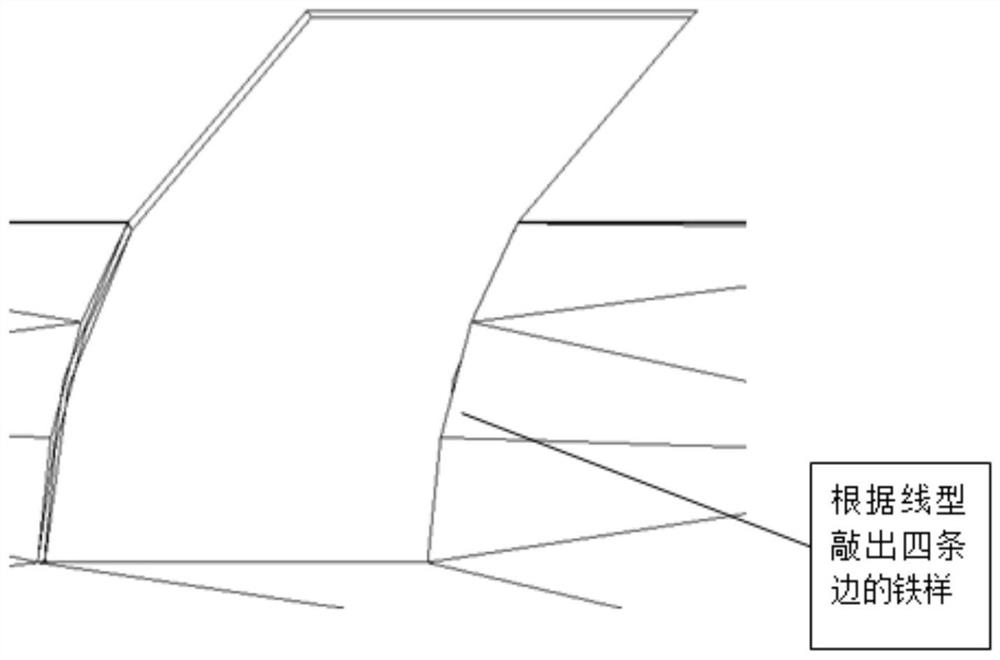

The invention discloses an operation method for forward movement of a rudder blade sealing plate. The method comprises the following steps: a platform preparation stage: manufacturing sample boxes, placing the sample boxes at the positions of the rudder blade sealing plates to inspect the line types of the rudder blade sealing plates until the sample boxes are completely matched with the rudder blade sealing plates, and cutting allowance, wherein each rudder blade sealing plate is divided into a middle sealing plate, two lower sealing plates and two upper sealing plates; a platform installation stag:installing the middle sealing plate firstly, then installing the two lower sealing plates through hinges, and then installing the two upper sealing plates through hinges; and a dock installation stage: opening a required rudder blade sealing plate, performing rudder shaft operation, and performing sealing plate assembling and welding operation. The operation safety coefficient on the platform is obviously improved, and a large amount of assembly operation is completed in advance in the platform stage.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

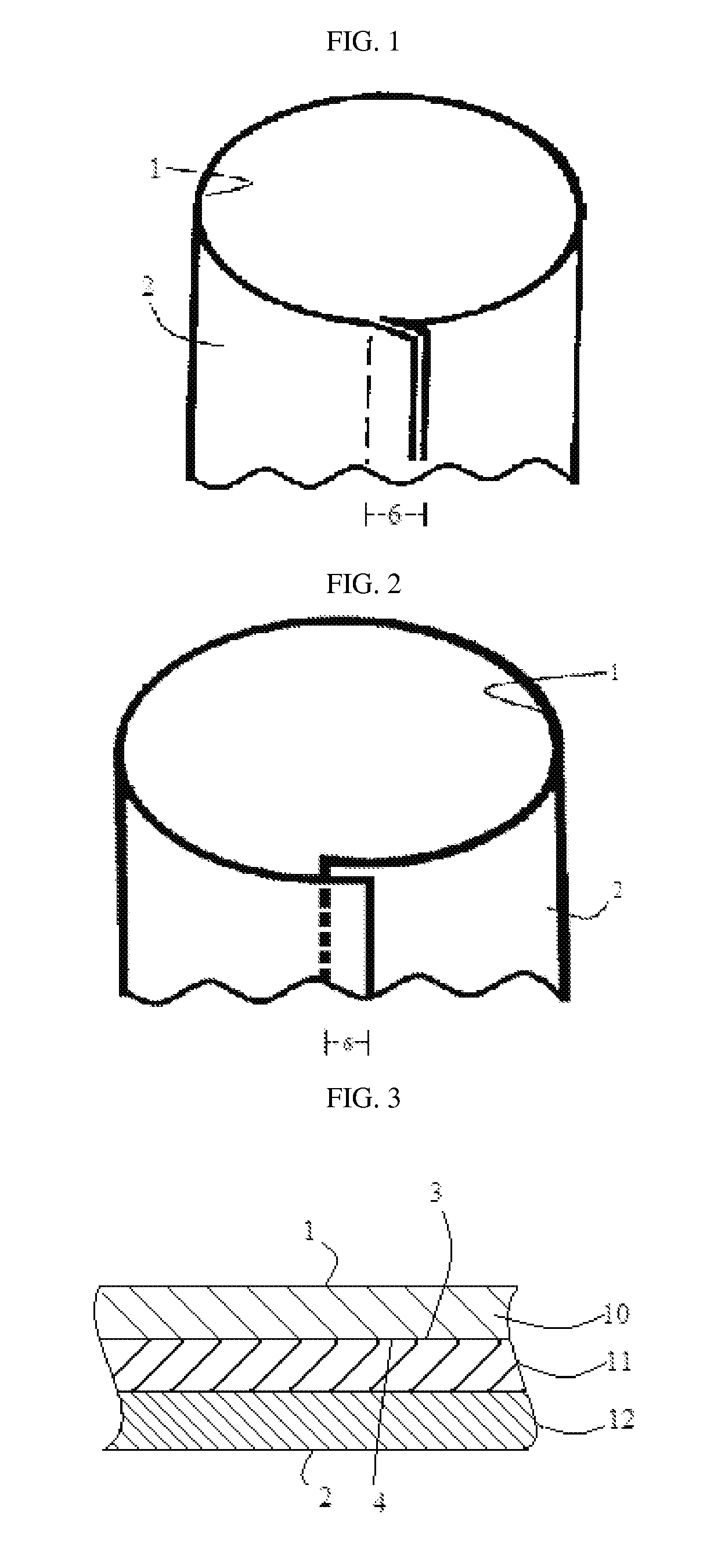

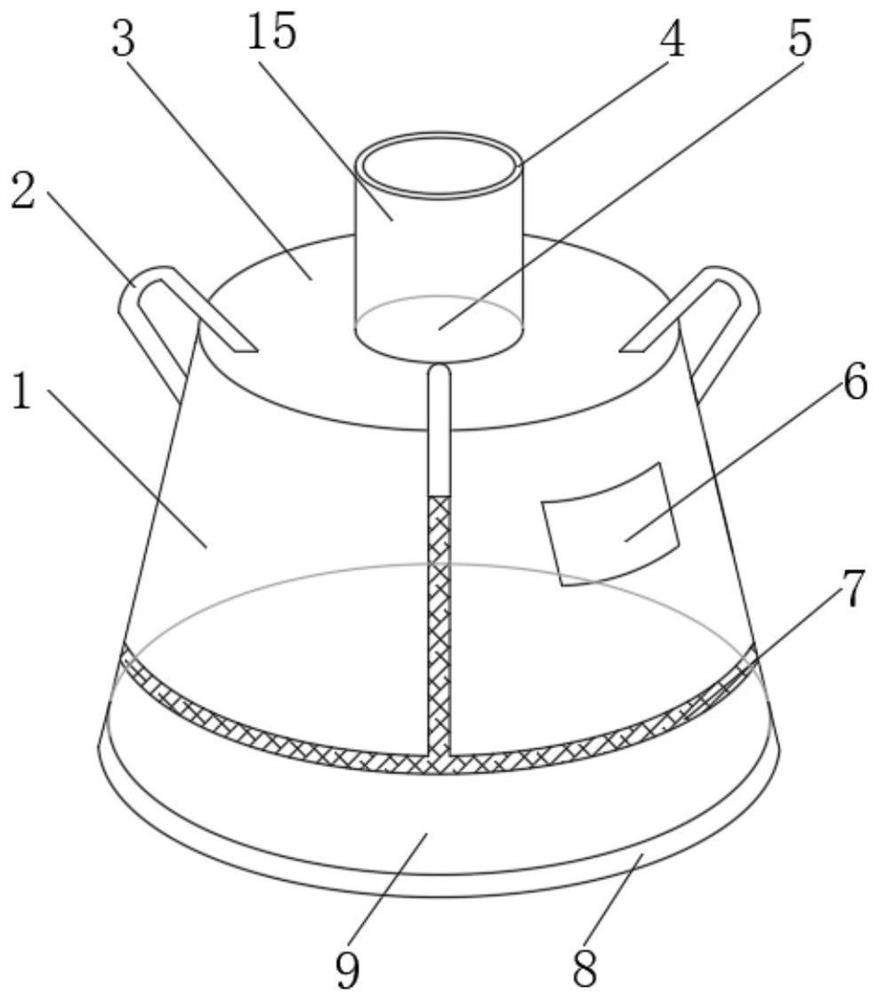

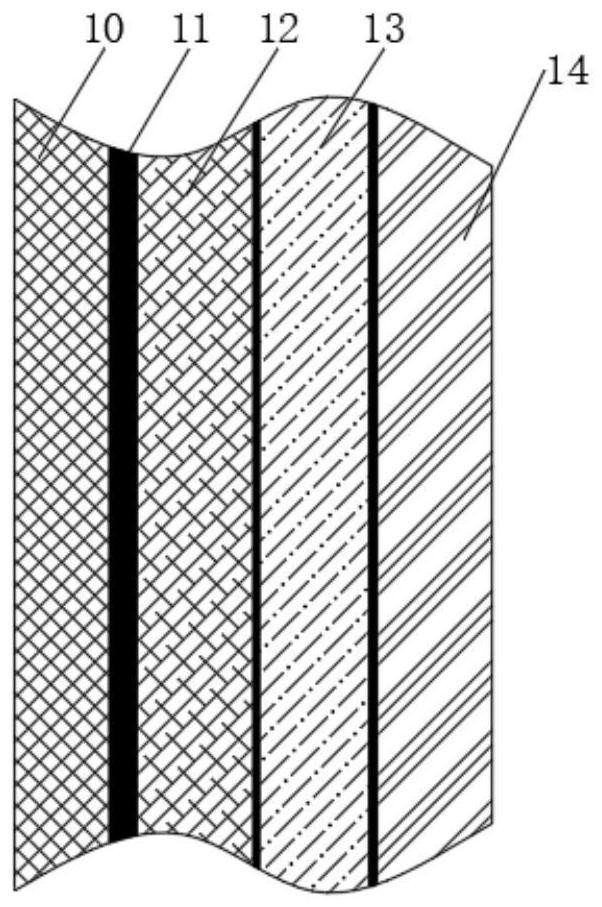

A flexible packaging container for extremely low radioactive contamination soil

ActiveCN111599503BShorten sealing timeReduce radiation doseLandfill technologiesShieldingPollution soilAdhesive

The invention discloses a flexible packaging container for soil with extremely low radioactive contamination, which comprises a bag body, a reinforcing rib is arranged inside the bag body, a bag cover is arranged on one side of the bag body, and the bag cover is connected with the bag cover. The bag body is fixedly connected, the bag cover is provided with a feeding port, one side of the feeding port is provided with a feeding pipe, one end of the feeding pipe is fixedly connected with the bag cover, and the other end of the feeding pipe A quick seal is provided, and the quick seal is fixedly connected with the feeding pipe. One side of the bag body is provided with a bag bottom, and the bag bottom is fixedly connected with the bag body. The bag body, bag cover, bag bottom and inlet The material used for the material tube includes waterproof plastic film and flexible high-strength adhesive. The present invention provides a flexible packaging container for extremely low radioactive soil, which can solve the problem that existing common container bags cannot meet the extremely low radioactive level. High safety performance requirements for soil during temporary storage, transportation and disposal.

Owner:63653 FORCES PLA

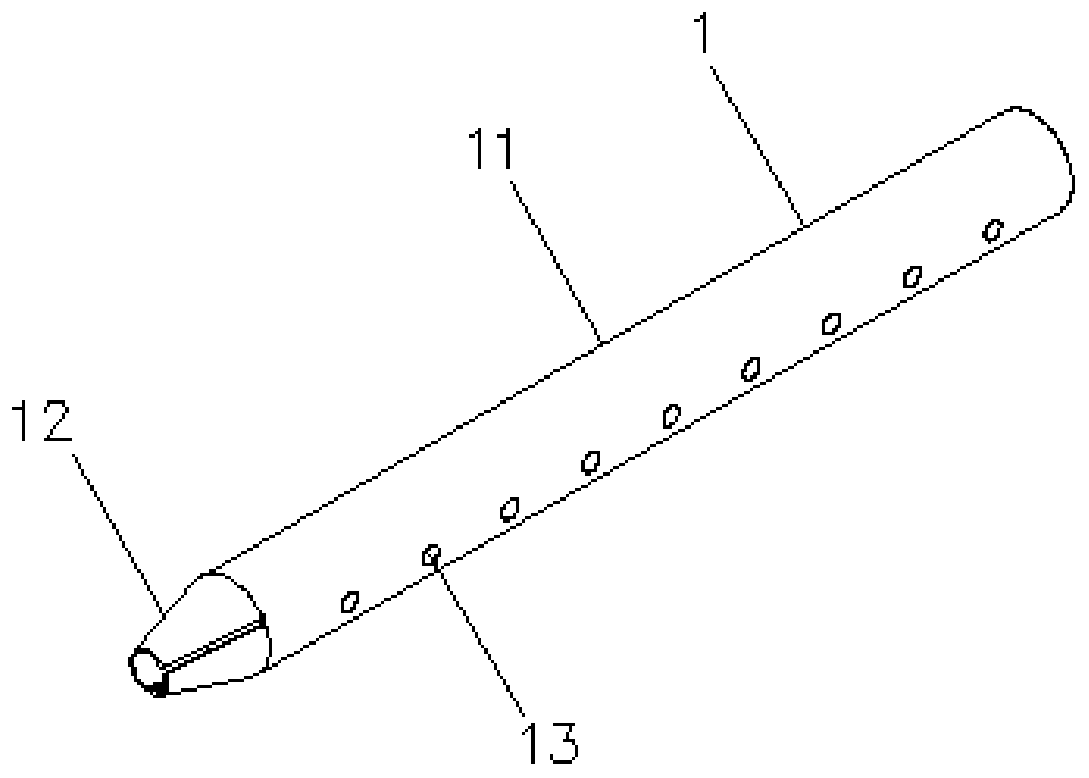

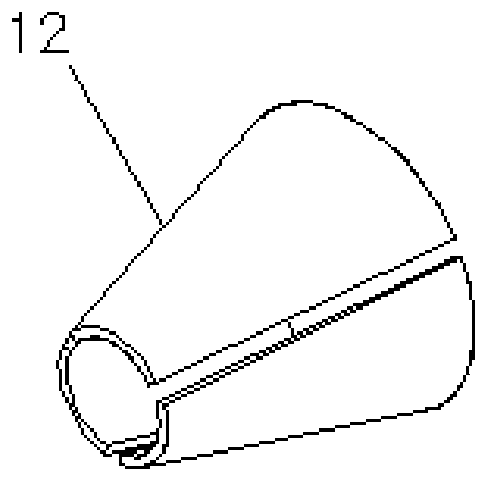

Casing for borehole gas drainage

ActiveCN109899005BAvoid cloggingGuaranteed continuityDrilling rodsGas removalThermodynamicsEngineering

The invention discloses a casing for drilling gas extraction, and relates to the field of coal mine underground drilling. The casing includes inserting pipes, each inserting pipe includes a pipe bodyand an inserting joint, and the pipe bodies are provided with a plurality of flow holes; the pipe bodies and the inserting joints are of an integral structure, one ends of the inserting joints are connected with one ends of the pipe bodies, a plurality of gaps are formed in the pipe walls of the inserting joints, the multiple inserting joints are connected end to end, and the inserting joint of the latter inserting pipe is inserted into the end of the pipe body of the former inserting pipe; and the front half part of each inserting joint is inserted into the corresponding pipe body, the secondhalf part of the inserting joint is exposed, and the gap of the inserting joint extends to the second half part and is exposed with the second half part. The casing for drilling gas extraction has the advantages that the phenomenon of casing blockage during gas extraction is avoided, and a gas extraction passage is maintained to be smooth.

Owner:HUAINAN MINING IND GRP

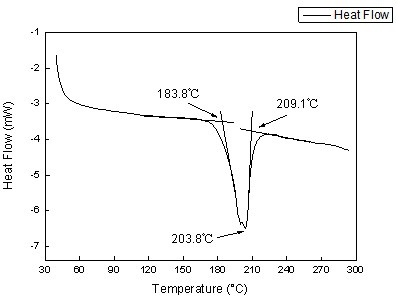

Lead-free solder for sealing tempered vacuum glass in atmospheric environment and pressure brazing sealing method thereof

ActiveCN112247394BImprove mechanical propertiesReduce oxidationWelding/cutting media/materialsSoldering mediaToughened glassMelting temperature

The invention relates to a lead-free solder used for sealing toughened vacuum glass in an atmospheric environment and a pressurized brazing sealing method thereof. The toughened vacuum glass is prefabricated with a metal layer in a region to be sealed. In the lead-free solder, In accounts for 5.0%-15.0% by weight of the solder, Ag accounts for 0.5%-5.0% by weight of the solder, Ga accounts for 0.05%-2.0% by weight of the solder, and the rest is Sn, an unavoidable impurity The content is less than 0.2%. The solder contains few components, has a low melting temperature and good wettability, and meets the requirements for low-temperature sealing of tempered vacuum glass. At the same time, the pressurized brazing technology is used for sealing in the atmospheric environment. The solder can form a good sealing joint with the prefabricated tempered glass substrate with a metal layer, which meets the production and use requirements. The invention overcomes the defects of high sealing temperature, complicated process and harsh sealing conditions in the traditional sealing method, improves the sealing quality and production efficiency of the tempered vacuum glass, and is suitable for popularization and application.

Owner:HENAN POLYTECHNIC UNIV +1

Sulfur hexafluoride gas pumping and filling system for gis

ActiveCN103322408BGood internal pressure toleranceShorten the timeSwitchgear arrangementsContainer filling methodsInternal pressureEngineering

The invention discloses a system for pumping and inflating SF6 for a gas insulated switchgear (GIS), comprising an SF6 recovery device, a vacuum pump, an SF6 storage device, a vacuum gauge and a connection pipeline, wherein the connection pipeline is combination pipes with four pipes which are communicated with each other, a moveable connector matched to a connection device is respectively on each of four ports of the connection pipeline, any pipe of the combination pipes can individually be opened or closed, three ports of the combination pipes are respectively connected with a GIS main body, the SF6 recovery device and the vacuum pump, and the other port is respectively connected with the vacuum gauge and the SF6 storage device in order. The system for pumping and inflating SF6 can greatly save time for pumping and inflating SF6 for the GIS, and has good internal pressure endurance and sealing reliability. In addition, the system for pumping and inflating SF6 has versatility.

Owner:STATE GRID CORP OF CHINA +1

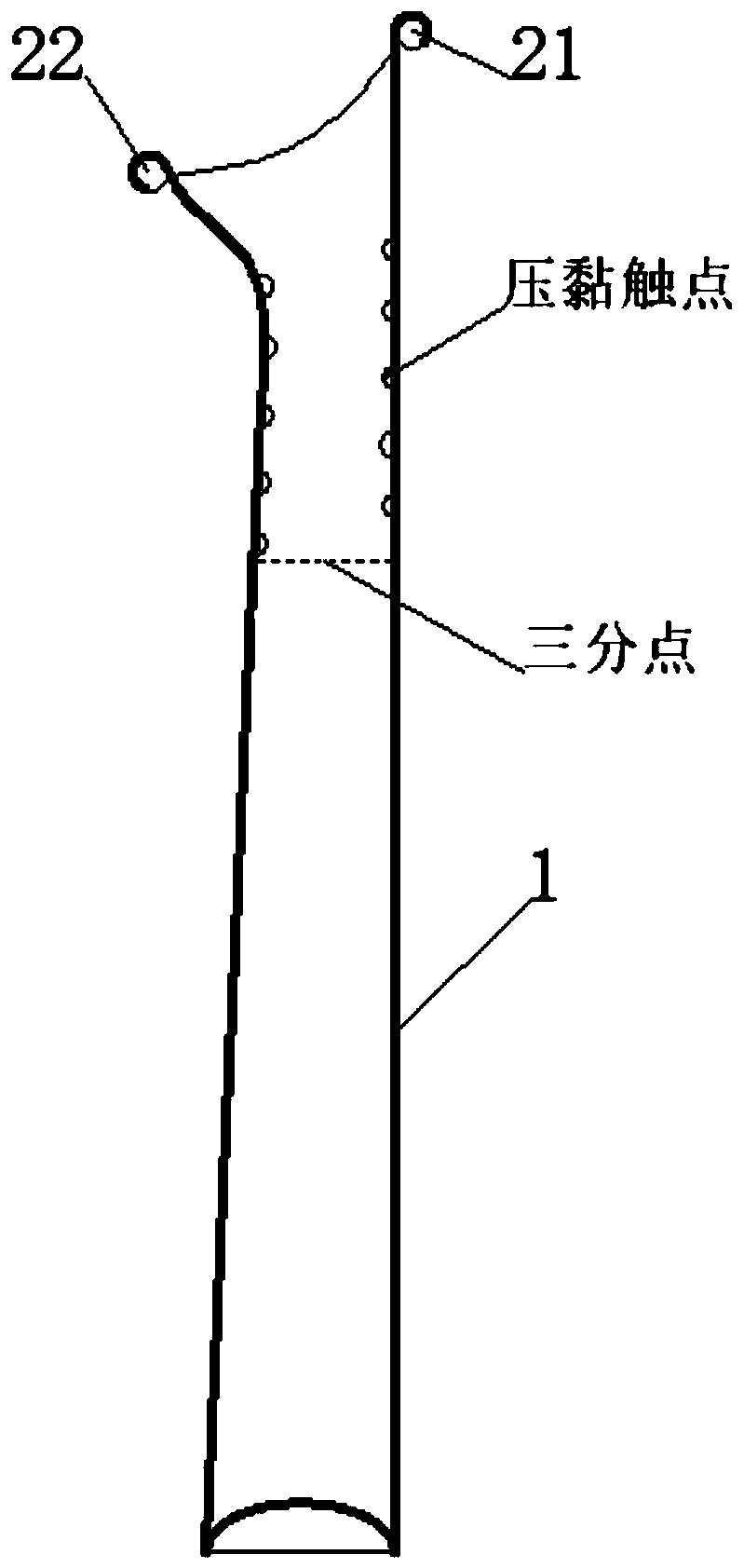

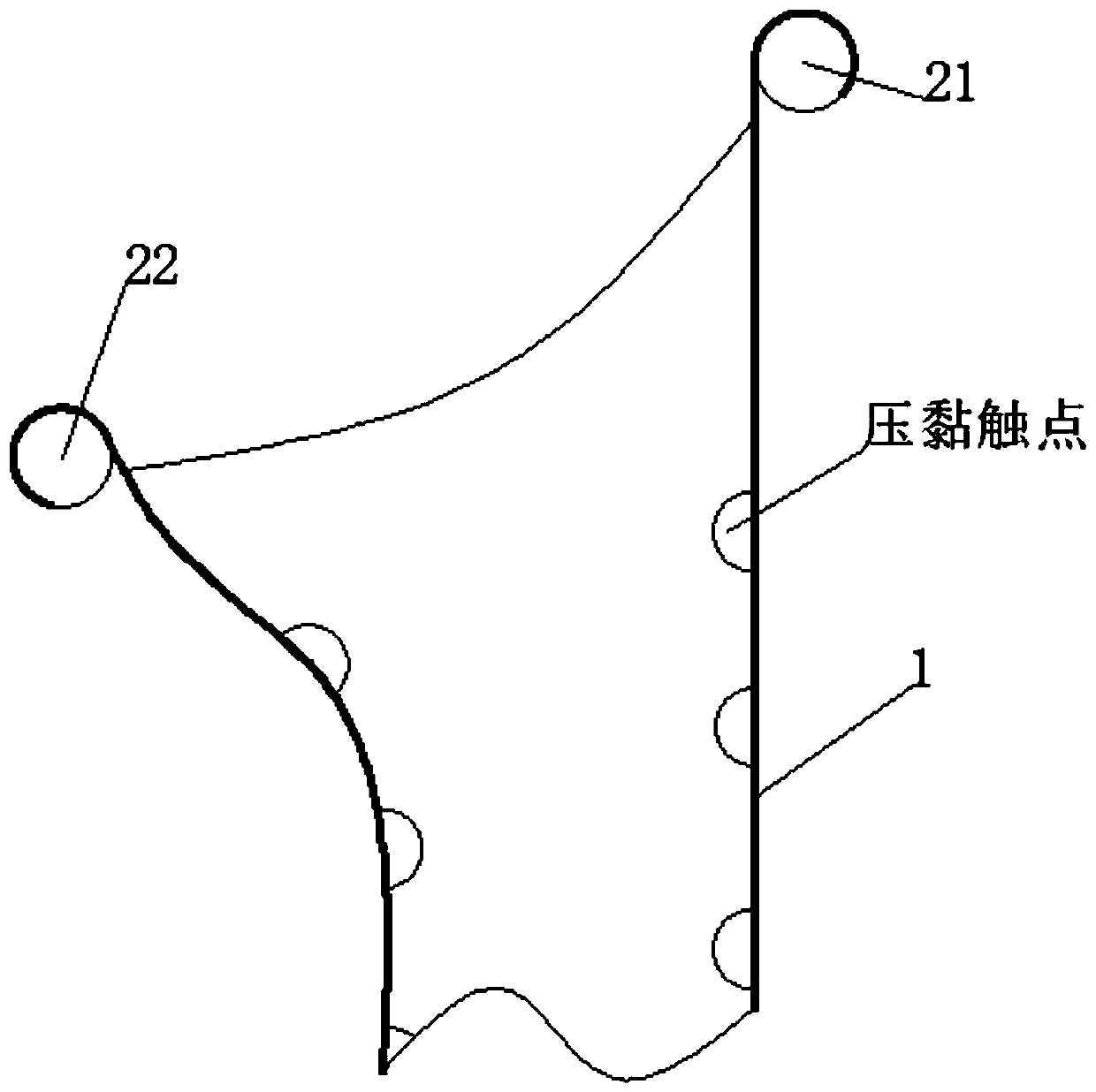

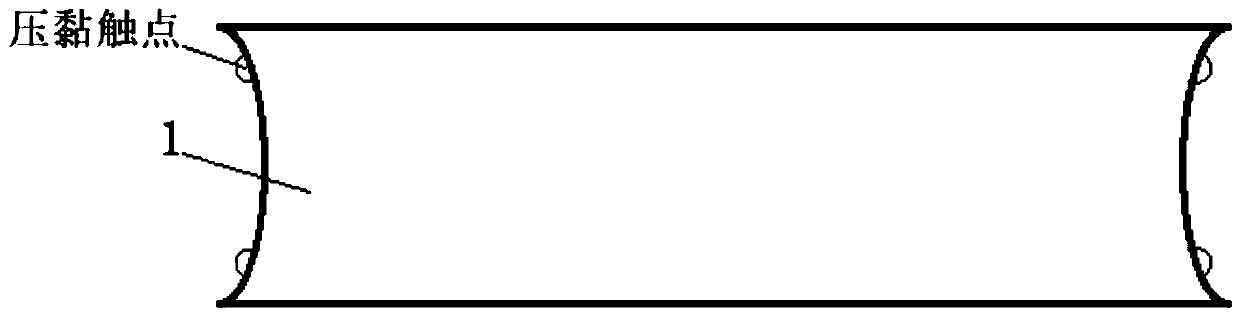

Quick sealing type food bag and using method thereof

ActiveCN110482001AInhibit sheddingFlush adsorption surfaceFlexible container closureEngineeringOperating time

The invention discloses a quick sealing type food bag and a using method thereof, and belongs to the field of food bags. According to the quick sealing type food bag and the using method thereof, through a long pressing rod and a short pressing rod arranged at the edges of the two sides of a bag opening, the bag opening can be turned and folded; the bag opening is turned repeatedly and folded, andthe connectivity with the outside is blocked many times, so that the sealing effect is better; at the same time, under the matching action of an embedded locking rod and an attraction magnet, the turned and folded bag opening can be fixed; in combination with the action of pressing and adhering contacts, the sealing performance and stability after sealing can be effectively improved, the probability of accidental opening of the bag opening can be reduced, and the time for finding a tool to seal the bag opening can be effectively reduced; and meanwhile, compared with clamping sealing, the positioning difficulty and the too much operation time are effectively avoided, and the convenience and the operation efficiency for sealing the packaging bags are effectively improved.

Owner:上海新川崎食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com