Optical cavity sealing method

A technology of optical cavity and optical mirror, which is applied in the direction of optics, optical components, installation, etc., can solve the problems that the inner layer of silica gel is difficult to completely cure, the sealing effect of the cavity is poor, and shrinkage gaps are easy to appear, so as to shorten the sealing time and sealing time Short, achieves a firm bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The optical cavity sealing method of this embodiment, the specific operation steps are:

[0021] 1) Install the lens base of the optical cavity on the glue-filling tool to ensure that the glue-filling surface is level;

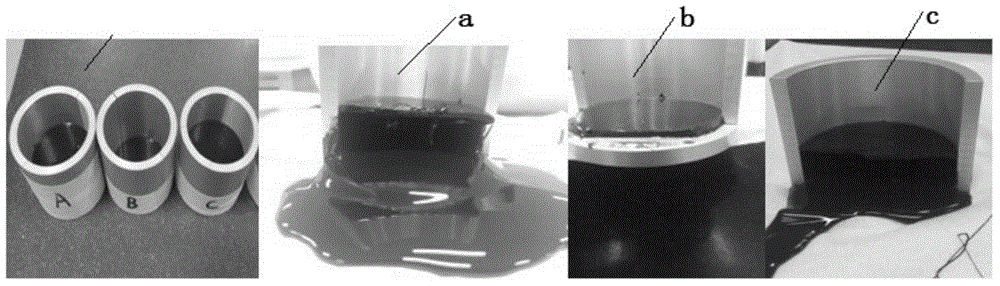

[0022] 2) Install the optical lens, use a dispenser to spray the first layer of non-anaerobic silicone rubber at the joint between the side of the combined glass and the mirror base, with a thickness of 4mm, and after standing for 5 minutes, the surface of the adhesive layer will condense to form an optical cavity Put the lens holder with the optical lens on the body into a vacuum drying oven, and heat it at 60°C for 4 hours;

[0023] 3) Carry out a sealing and nitrogen filling detection test on the optical cavity to check that the cavity is completely sealed;

[0024] 4) Use a dispenser to spray a second layer of non-anaerobic silicone rubber at the joint between the side of the combined glass and the mirror base, with a thickness of 10mm. Put the mir...

Embodiment 2

[0027] The optical cavity sealing method of this embodiment, the specific operation steps are:

[0028] 1) Install the lens base of the optical cavity on the glue-filling tool to ensure that the glue-filling surface is level;

[0029] 2) Install the optical lens, use a dispenser to spray the first layer of non-anaerobic silicone rubber at the joint between the side of the combined glass and the mirror base, with a thickness of 4mm, and after standing for 5 minutes, the surface of the adhesive layer will condense to form an optical cavity Put the lens holder with the optical lens installed on the body into a vacuum drying oven, and heat it at 60°C for 5 hours;

[0030] 3) Carry out a sealing and nitrogen filling detection test on the optical cavity to check that the cavity is completely sealed;

[0031] 4) Use a dispenser to spray a second layer of non-anaerobic silicone rubber at the joint between the side of the combined glass and the mirror base, with a thickness of 15 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com