Operation method for forward movement of rudder blade sealing plate

A technology of sealing plates and rudder blades, which is applied in the direction of load hanging components, transportation and packaging, ships, etc., can solve problems such as declining operation quality, high risk factor, and safety threats, and achieve reduced operation time, simple and safe operation methods The effect of increasing the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

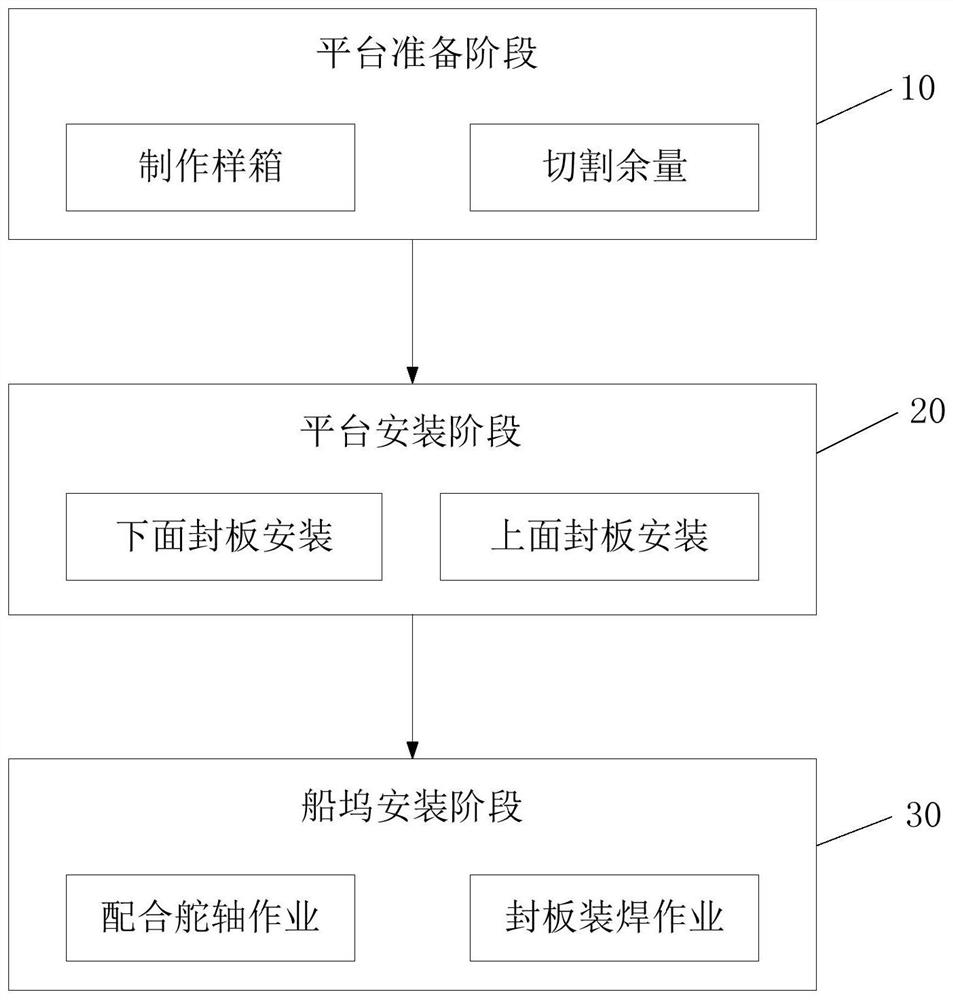

[0028] see Figure 1-8 , the operation method that the rudder blade sealing plate of the present invention moves forward comprises the following steps:

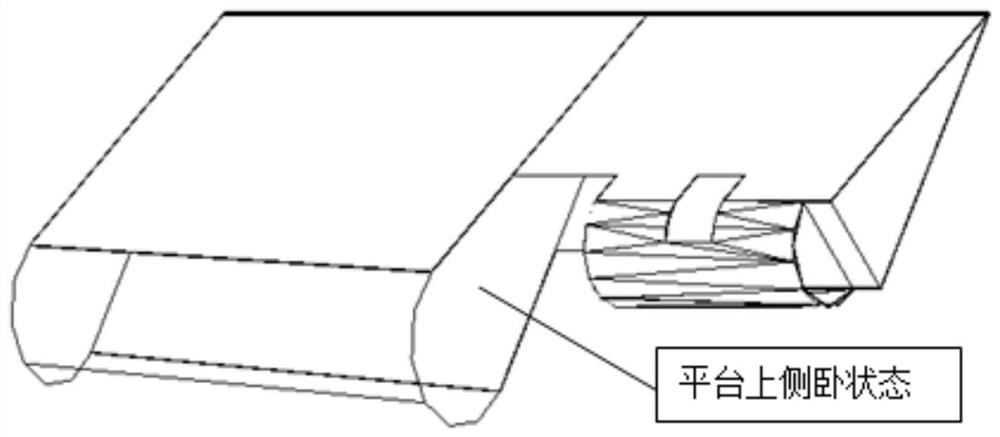

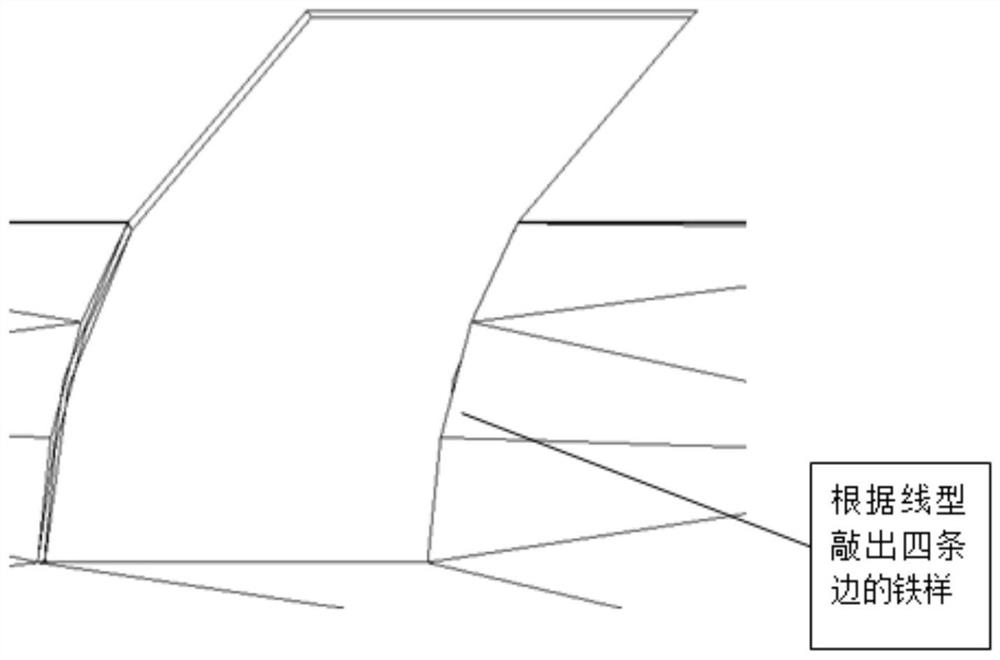

[0029] 1) Platform preparation stage: Make a sample box, place the sample box at the position of each rudder blade sealing plate to check its line shape until it matches completely, and cut the margin. Specifically, use a small flat iron of 4mm*15mm to knock out splines according to the line shape of the rudder blade sealing plate, and then weld the splines on the four sides to form a sample box. Such as figure 2 , 3 shown. Then put the sample box at the position of the rudder blade sealing plate to check its line shape, until it is completely matched, draw the margin line and cut, bevel, and polish. Finally, install iron hinges on the sealing plate as needed. Moved a lot of work forward.

[0030] Each rudder blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com