Casing for borehole gas drainage

A gas extraction and casing technology, applied in drilling pipe, casing, gas discharge and other directions, can solve the problem that the continuity and maximization of gas extraction cannot be achieved, work efficiency and safety are reduced, and the extraction volume of a single hole is reduced. and other problems to achieve the effect of improving work efficiency and safety, reducing sealing time, and ensuring maximum effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

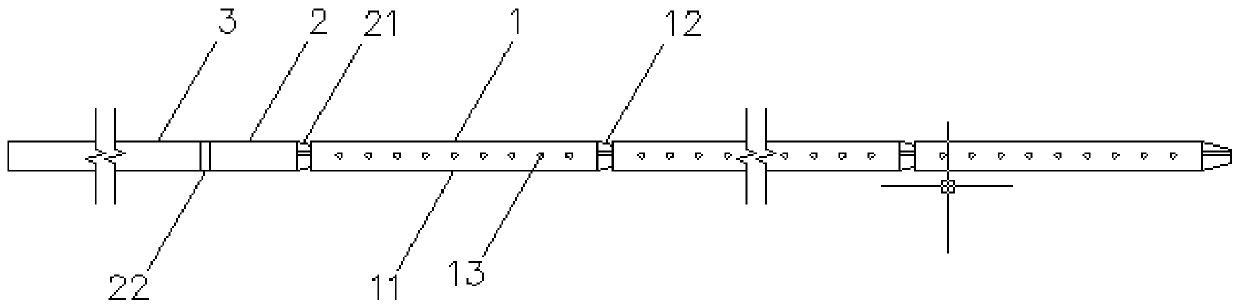

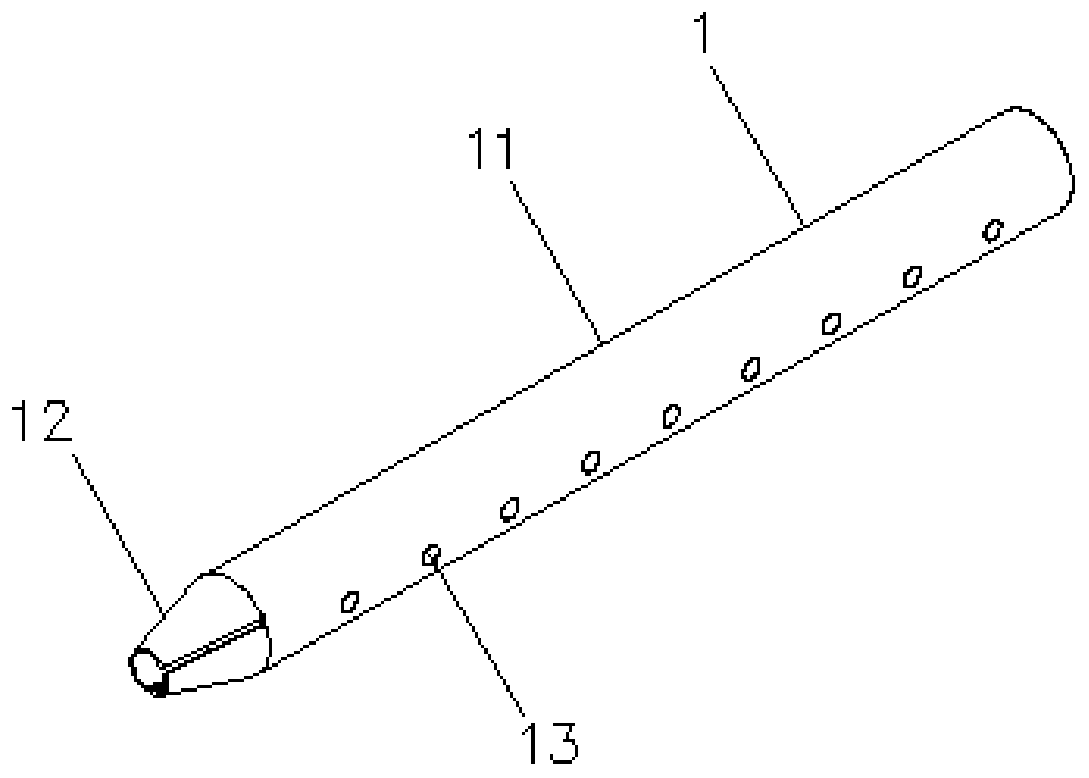

[0021] like Figure 1-4 As shown, the casing used for drilling gas drainage includes an insertion pipe 1 , a connecting variable head 2 , and a core pipe 3 .

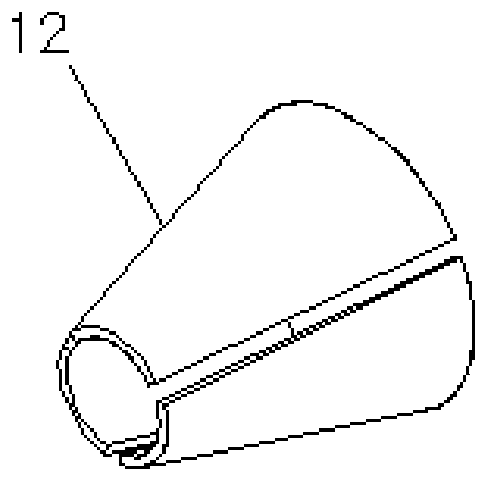

[0022] The plug-in pipe 1 includes a pipe body 11 and a plug-in joint 12, and the pipe body 11 is provided with a plurality of flow holes 13.

[0023] The pipe body 11 and the plug joint 12 are integrally structured, and one end of the plug joint 12 is connected to one end of the pipe body 11. The length of the pipe body 11 is 1200 mm, and the length of the plug joint 12 is 80 mm.

[0024] The tube body 11 is a round tube; the plug-in joint 12 is in the shape of a round platform, the bottom surface of the round platform is connected to one end of the tube body 11 and its diameter is equal to the diameter of the tube body 11, and the diameter of the top surface of the round platform is smaller than the diameter of the bottom surface; The angle between the extension line and the extension line of the central axis is 20°....

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is:

[0036] The length of the pipe body 11 is 1500mm, and the length of the plug joint 12 is 120mm.

[0037] The angle between the extension line of the plug connector 12 round table busbar and the extension line of the central axis is 30°

[0038] The interval between adjacent flow holes 13 is 110 mm, and the diameter of the flow holes 13 is 22 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com