Patents

Literature

35results about How to "No recycling value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dioscin and extraction method of diosgenin

The method for extracting dioscin and diosgenin includes the following steps: pulverizing rhizome of Chinese yam plant by adding water, fermentation by using lipolytic enzyme, separating cellulose and lignin, recovering supernatant, suspension and starch, mixing recovered liquors and filtering residue, boiling and filtering, repeating for several times, filtering residue for stand-by, combining filtrates and concentrating, using ethyl alcohol to make reflux extraction, cooling and filtering, decompressing and concentrating filtrate, adsorbing, evaporating, ethyl alcohol extracting, adding ethyl ether, cooling to room temp. and separating out tetrasaccharide saponin, recovering ethyl alcohol and ethyl ether from supernatant, precipitating out saponin, drying, adding water in starch and filter residue, regulating pH, adding alpha-amylase.

Owner:张万举 +3

Method for manufacturing manhole cover or water grate cover

InactiveCN101818504ALight weightImprove carrying capacityArtificial islandsSewerage structuresRebarQuartz

The invention discloses a method for manufacturing a cement concrete manhole cover or a water grate cover by using an autoclaving process, belongs to the technical field of building materials and relates to the method, which comprises the following steps of: taking cement, sand, stones, additives, admixtures, steel fibers, water, lime and grammite as main raw materials, wherein the admixtures are one or more of slag powder, fly ash, quartz sand powder, steel slag and other levigated silicon-containing industrial solid wastes or tailings powder; uniformly mixing the cement, sand, stones, additives, admixtures, steel fibers, water, lime and grammite in certain proportion; placing a reinforcement cage into a mould of the manhole cover or the water grate cover; pouring the concrete mixture into the mould for molding, maintaining the mould at the normal temperature or under the condition of steam for 0.5 hour to 28 days; and autoclaving the mould at the constant temperature under an autoclaving condition (steam pressure is 0.5 to 1.5 MPa) for 0.5 to 16 hours to manufacture the manhole cover or the water grate cover. The autoclaved manhole cover or water grate cover produced by the method has the characteristics of high strength, little deformation and high durability; and the method has the advantages of making good use of solid wastes and achieving remarkable economic effect and social effect.

Owner:YANGTZE UNIVERSITY

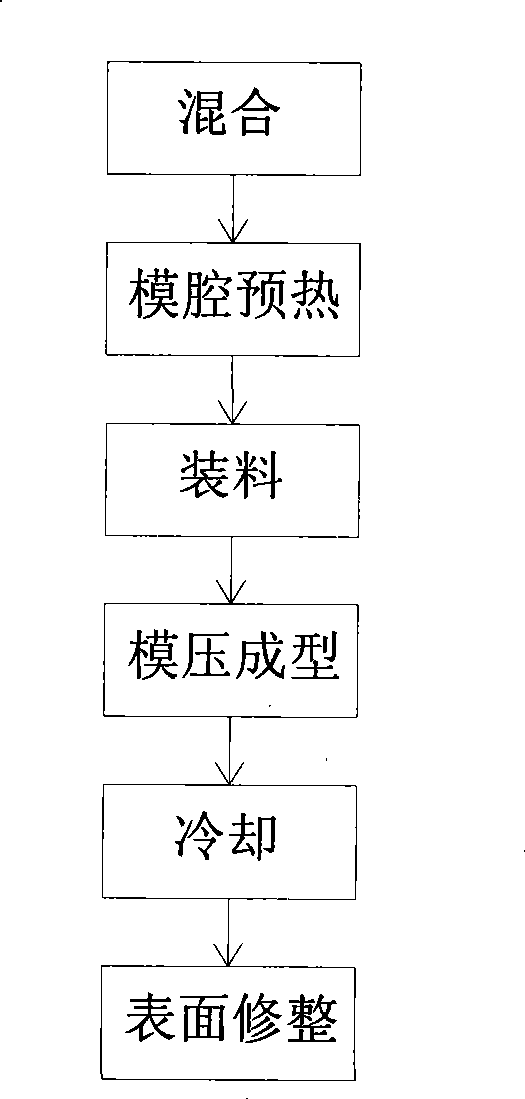

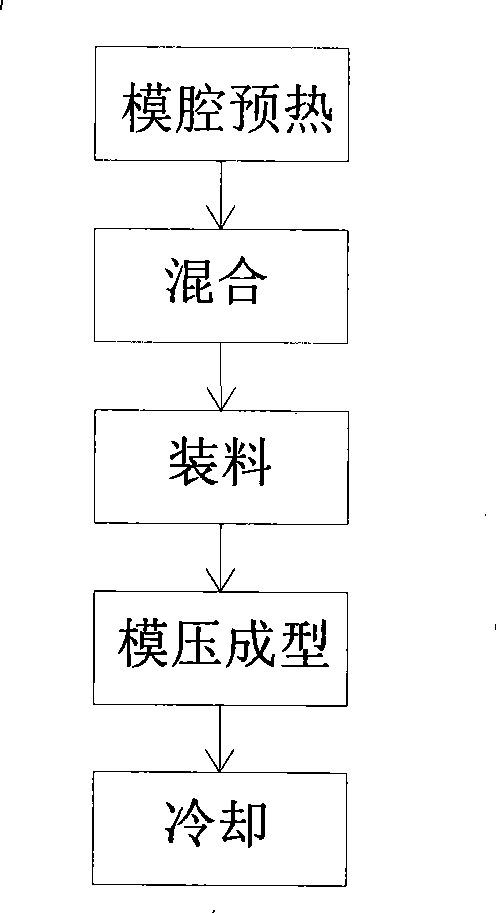

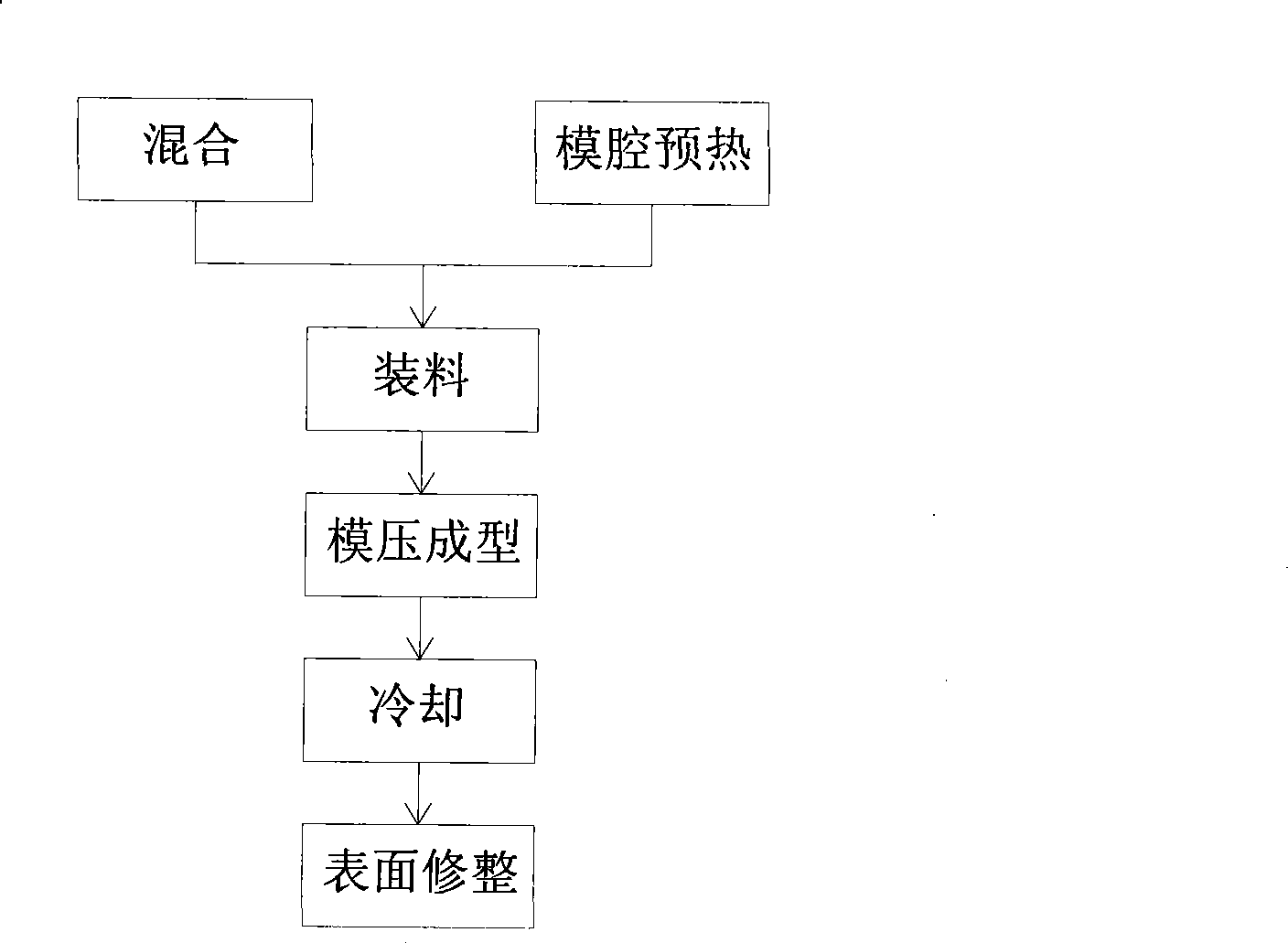

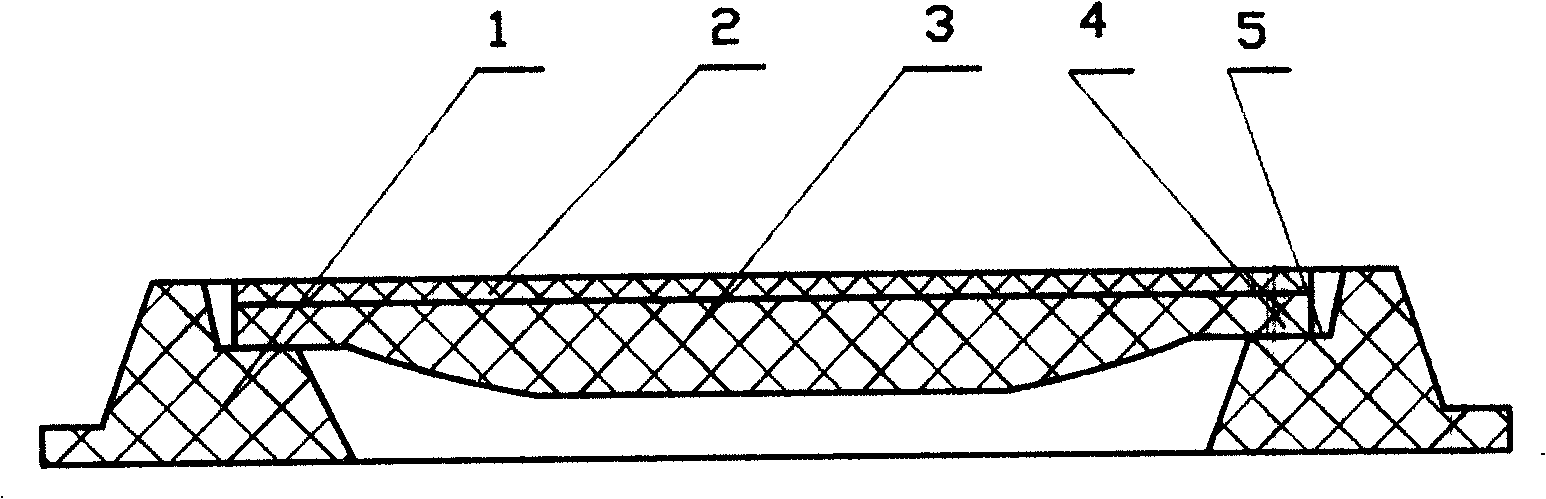

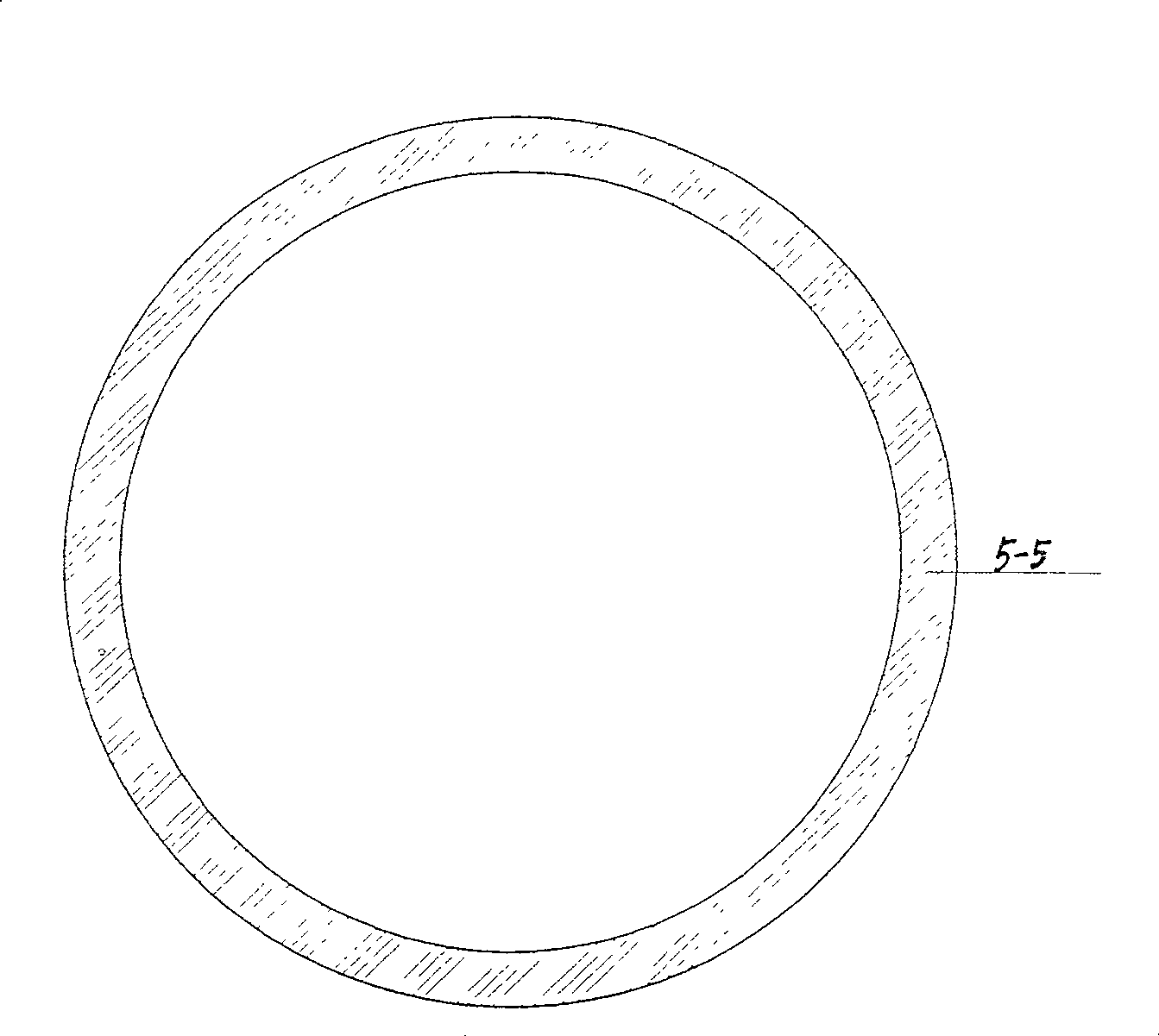

Process for manufacturing manhole cover

InactiveCN101367259ANo recycling valueShort holding timeDomestic articlesCompression moldingSheet moulding compound

The invention relates to a process for manufacturing inspection well covers. The method comprises the following: a step of mixing, which is to match and mix sheet molding compounds accounting for 1 to 99 percent of total weight, scattered molding compounds accounting for 1 to 99 percent of total weight and bulk molding compounds accounting for 1 to 99 percent of total weight; a step of preheating a mold cavity which is to preheat the mold cavity of a hydraulic press to be between 100 and 150 DEG C for 1 to 3 hours; a step of charging which is to put the mixed material into the mold cavity or lay profiles and then the residual mixed material; a step of carrying out compression molding which is to carry out compression molding under the pressure between 1,000 and 10,000 KN at the temperature between 100 and 150 DEG C, maintain pressure and preserve heat for 5 to 60 minutes; and a step of cooling. As the inspection well covers are made from sheet molding compounds and scattered molding compounds or bulk molding compounds through compression molding, the inspection well covers have the advantages of high strength, good anti-fracture toughness and the like. In addition, during manufacture, the time of compression molding and heat preservation is short, so as to save energy. As the inspection well covers have no recycling value, the possibility for stealing the inspection well covers is certainly reduced.

Owner:HANGZHOU JINMENG ROAD ESTAB CO LTD

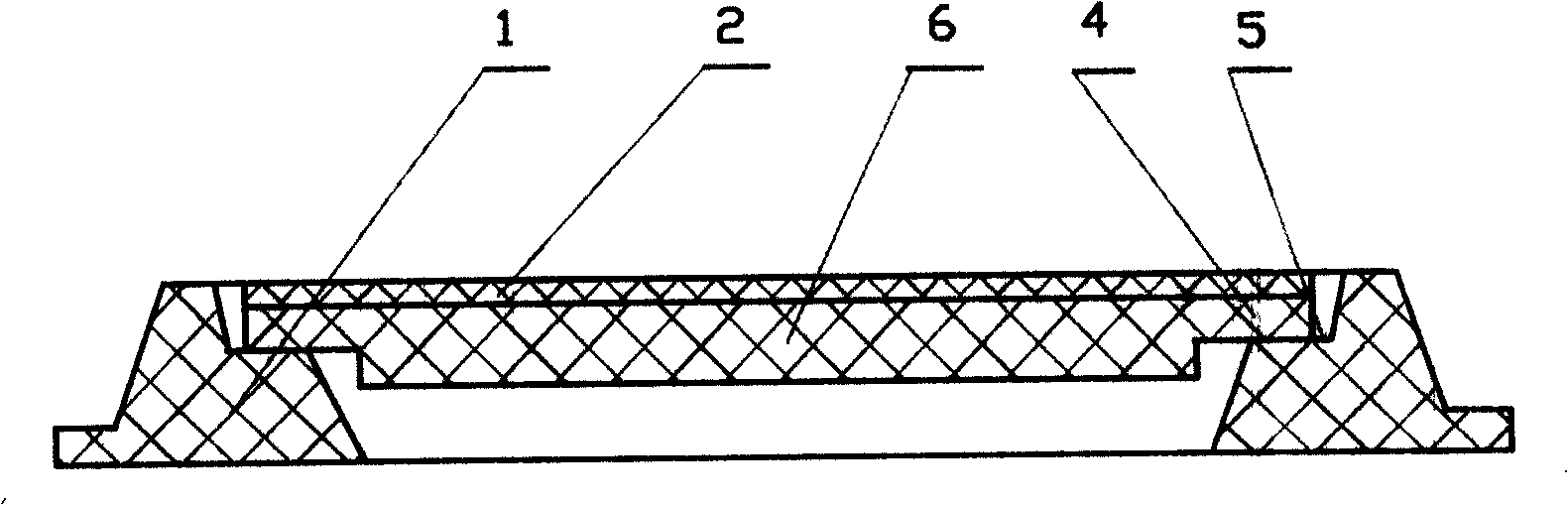

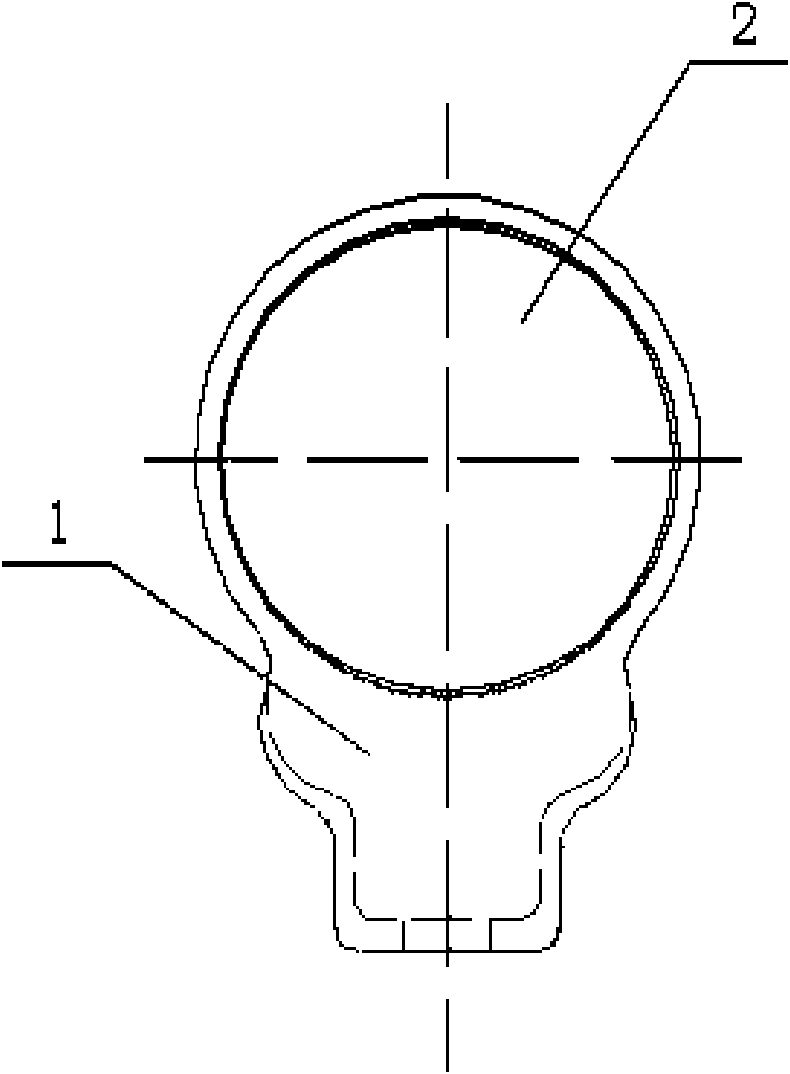

Compound resin hole cover and its manufacture method

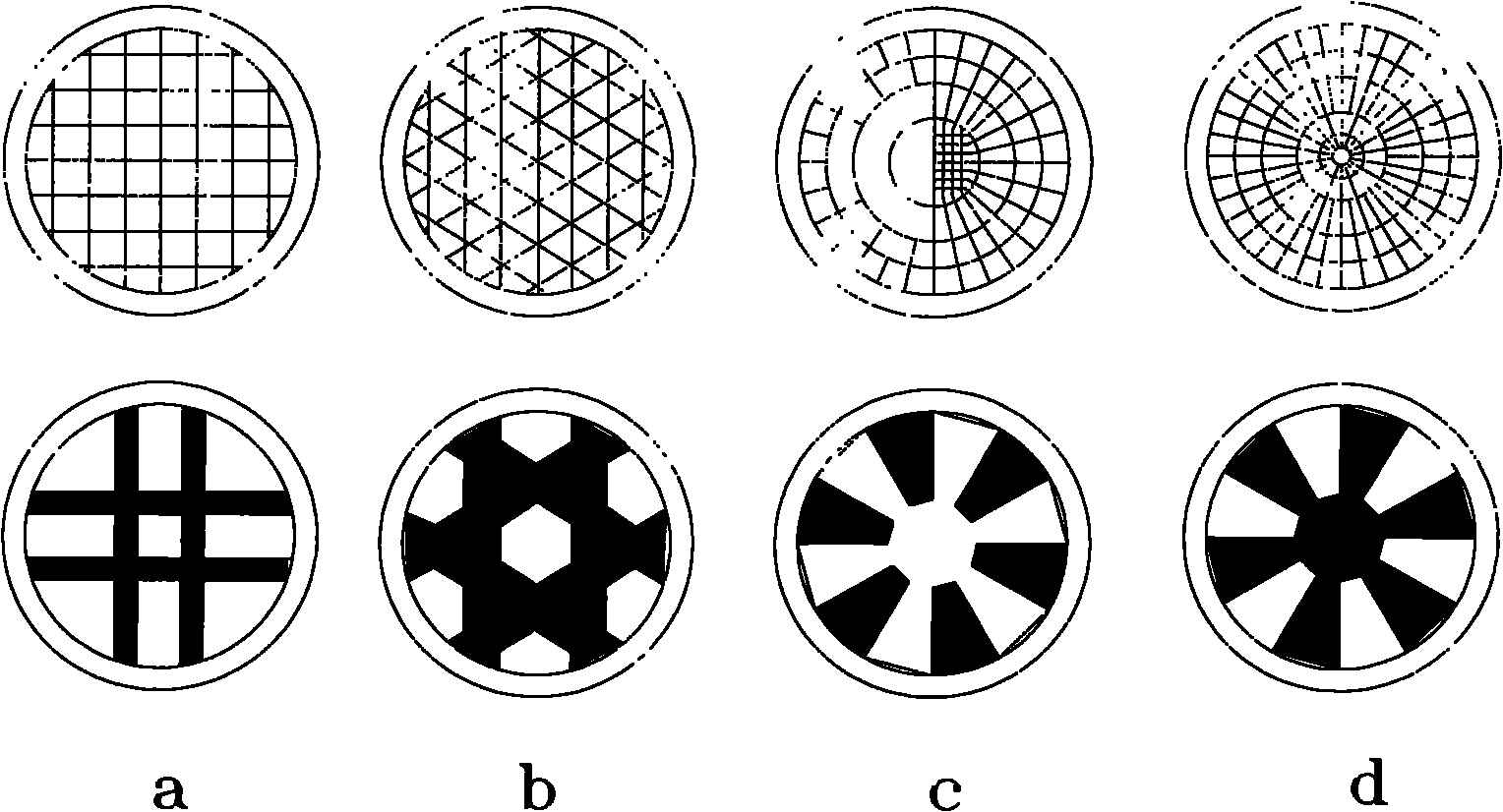

InactiveCN101265710AMeet strength requirementsNo recycling valueArtificial islandsCeramic extrusion diesGrid patternRebar

A compound resin manhole cover comprises an upper support body and an outer-convex-shaped and arc-shaped curved solid positioned in the middle-lower part of the upper support body. The manhole cover contains: resin 12-26%, glass cloth and strengthening rib made of high strength glass fiber tow 4-15%, calcium carbonate 3-12%, quartz sand 40-60%, talcum powder 6-20%, solidifying agent 0.1-0.5% and accelerant 0.05-0.4%. The processing method includes: cleaning up upper and lower moulds, waxing with the stripping wax; respectively filling with the resin, the quartz sand, the calcium carbonate, the talcum powder, the solidifying agent and the accelerant; putting on a grid-patterned strengthening rib made of the high strength glass fiber tow; assembling, pressuring, solidifying; demoulding and edging. The manhole cover has the advantages of high loading capacity, high strength, high toughness, long service life, excellent sealing performance, insulation, abrasion resistance, good corrosion resistance and rust resistance. Since the manhole cover contains no steel bar, the cover has no recycling value, thereby fully solving the stealing problem.

Owner:黄亮

Magnesite material product

InactiveCN1850712AFlexural strength exceedsReduce manufacturing costSolid waste managementBrown iron oxideCorrosion

The invention is a magnesite product, using magnesium oxide 30-40%, magnesium chloride solution 30-40%, iron oxide powder pigment 0.5-1%, yellow sand 17-25%, sawdust or rice hull powder 5-10%, crushed glass fiber 0.2-1%; firstly placing magnesium oxide, yellow sand and iron oxide powder into a blender and blending for 1-10 minutes, then placing magnesium chloride solution into the blender and blending for 1-10 minutes, and finally placing sawdust or rice hull powder, and crushed glass fiber into the blender and blending for 3-15 minutes, so as to make magnesite pulp; placing above two layers of fillings into a mould, pouring the magnesite pulp into the mould, vibrating uniformly, naturally solidifying at 25 deg.C-30 deg.C, so as to make the magnesite product. And it has advantages of: 1. good anti-theft effect; 2. no pollution and low manufacturing cost; 3. stronger shock resistance, strong bearing ability and good antiaging property; 4. good corrosion resistance.

Owner:徐建军

Cast stone manhole cover and its preparation method

InactiveCN1651349AGood flexural strength and fracture toughnessReduce the possibilityArtificial islandsSolid waste managementSmeltingFracture toughness

Owner:吕云南

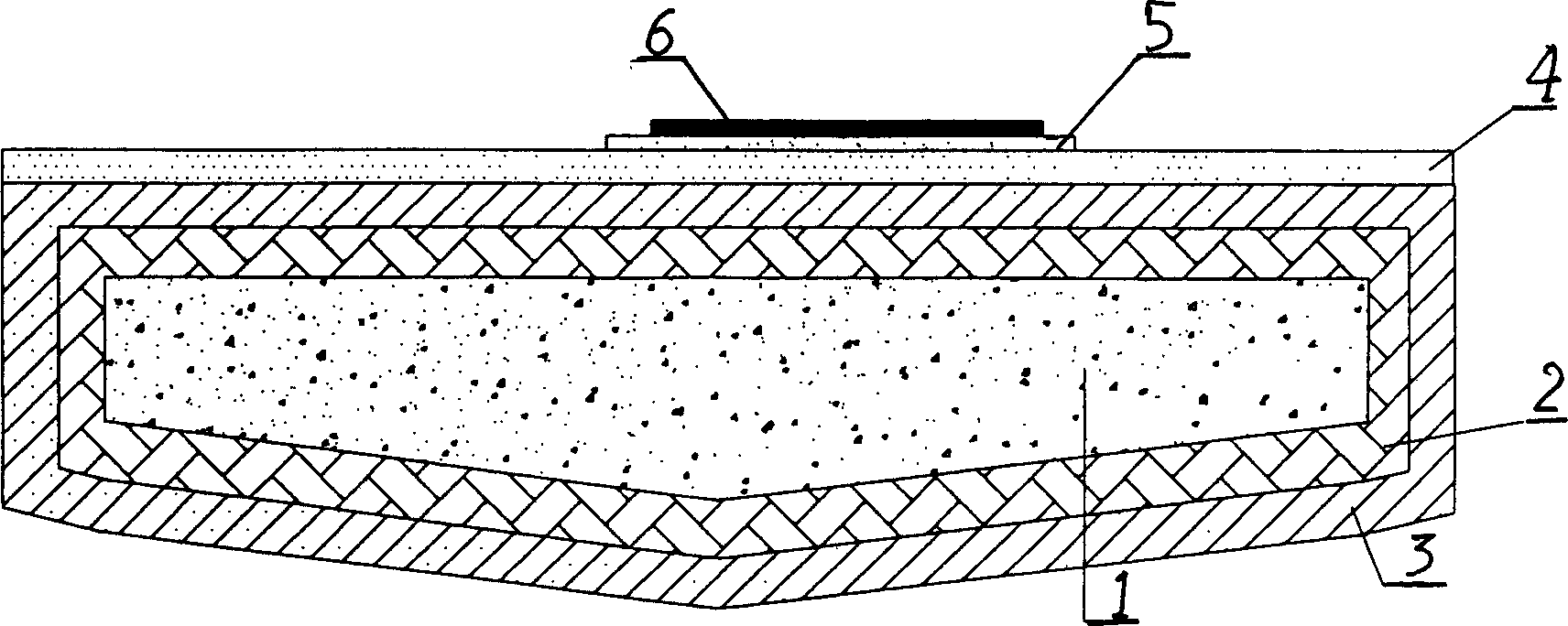

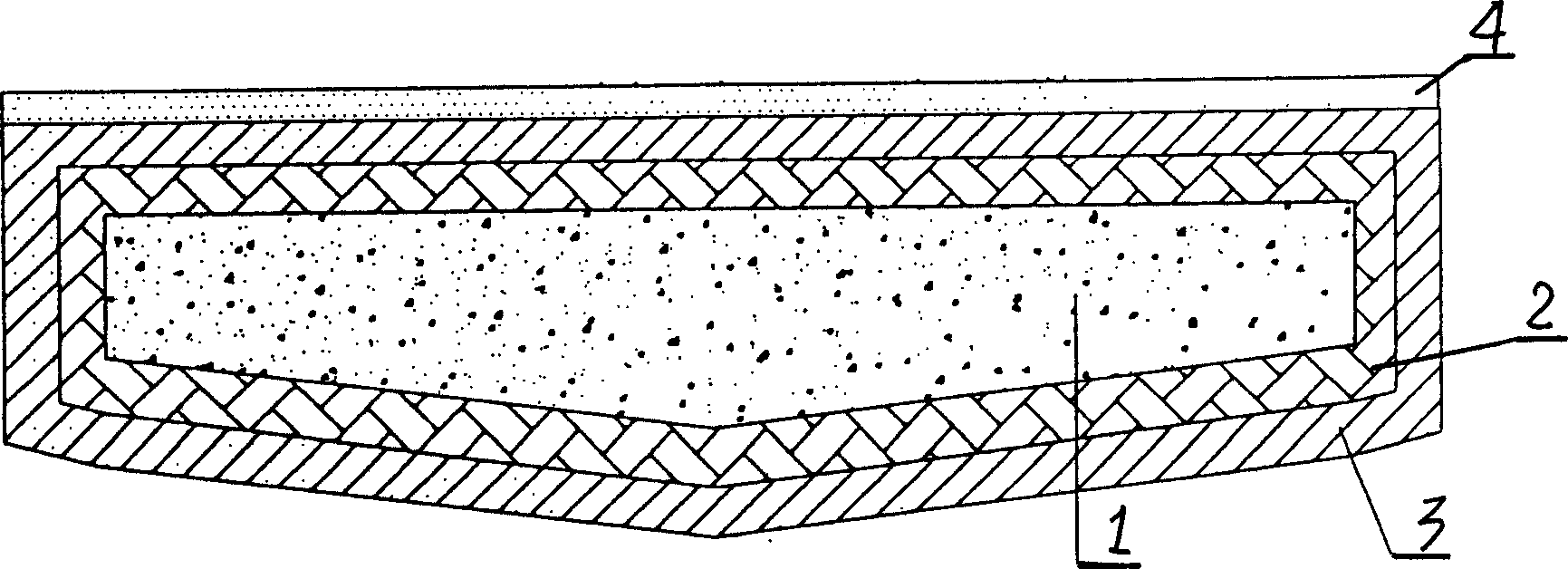

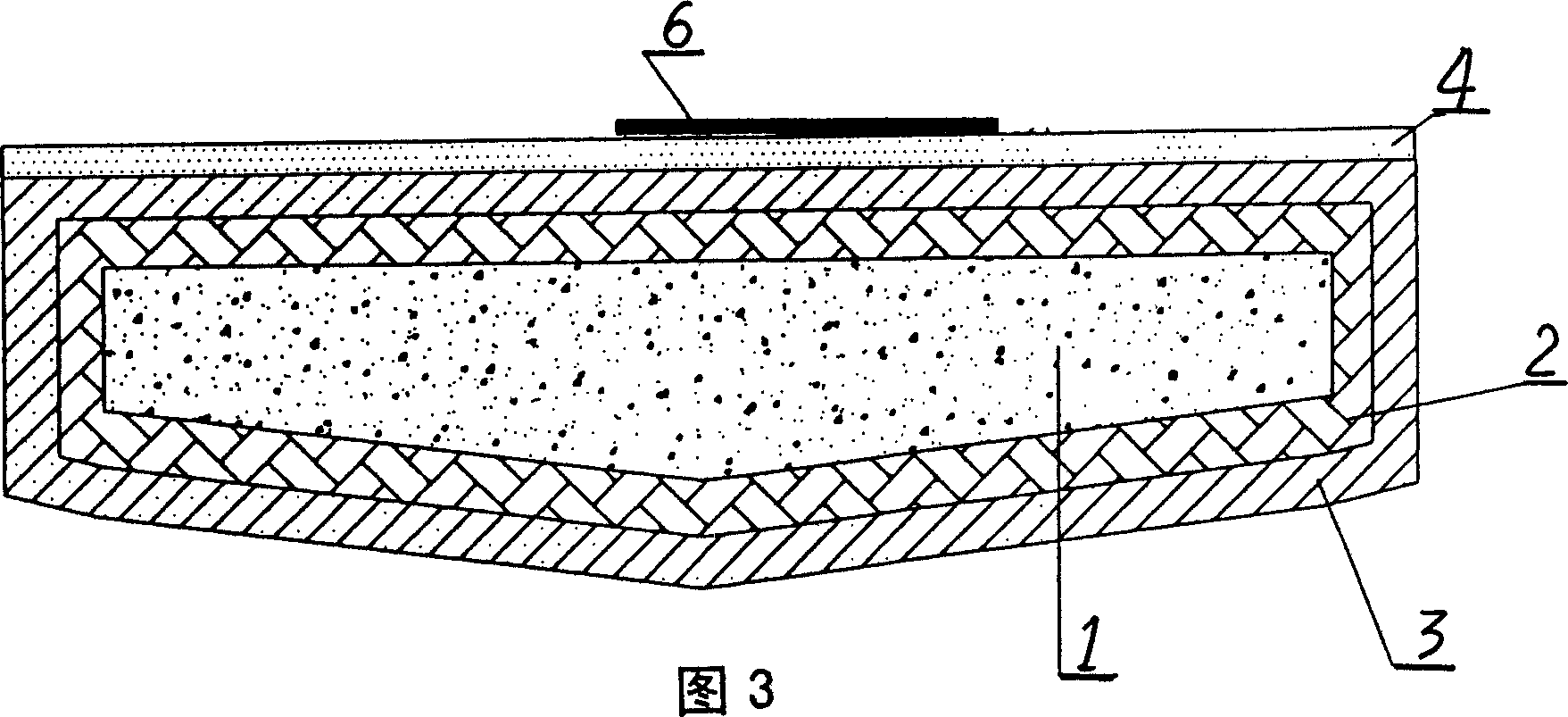

Multicolor composite material well cover and production process thereof

InactiveCN1594760ASolve the stolenHigh artistic valueArtificial islandsUnderwater structuresUltimate tensile strengthAccelerant

The invention discloses a multicolor composite material well cover and production process thereof, comprising: core body, network frame, enhancing layer, color layer. The outer layer of the network frame coats the outer surface of the core body and the enhancing layer on the outer surface of the network frame. The color layer coats on the upper surface of the enhancing layer. The proportion of the color layer components by weight is that: adding 0.1-1 portion by weight of solidifying agent in 100 portion by weight of resin A, then adding 50-300 portion by weight of colorful stone powder and / or agate powder and / or glass micro bead into the mixture, in which the proportion of the resin A is that: adding 0.4-2.5 portion by weight of accelerant in 100 portion by weight of unsaturated polyester resin. The inventive multicolor composite material well could adopt a plurality of colors for a personalized design.

Owner:刘英华

Composite material

The invention designs a composite material which is prepared by adding unsaturated resin, polystyrene, styrene and calcium hydroxide to a kneading machine and stirring for 10 to 13 minutes, adding limestone continuously and stirring for 20 to 23 minutes, and then adding glass fiber and stirring for 3 to 5 minutes. The obtained composite material has good percussion resistance and corrosion resistance, light weight, good seal performance and long service life, and the material has no value in recycling and fundamentally solves safety concerns caused by stealing.

Owner:恒基建设集团有限公司

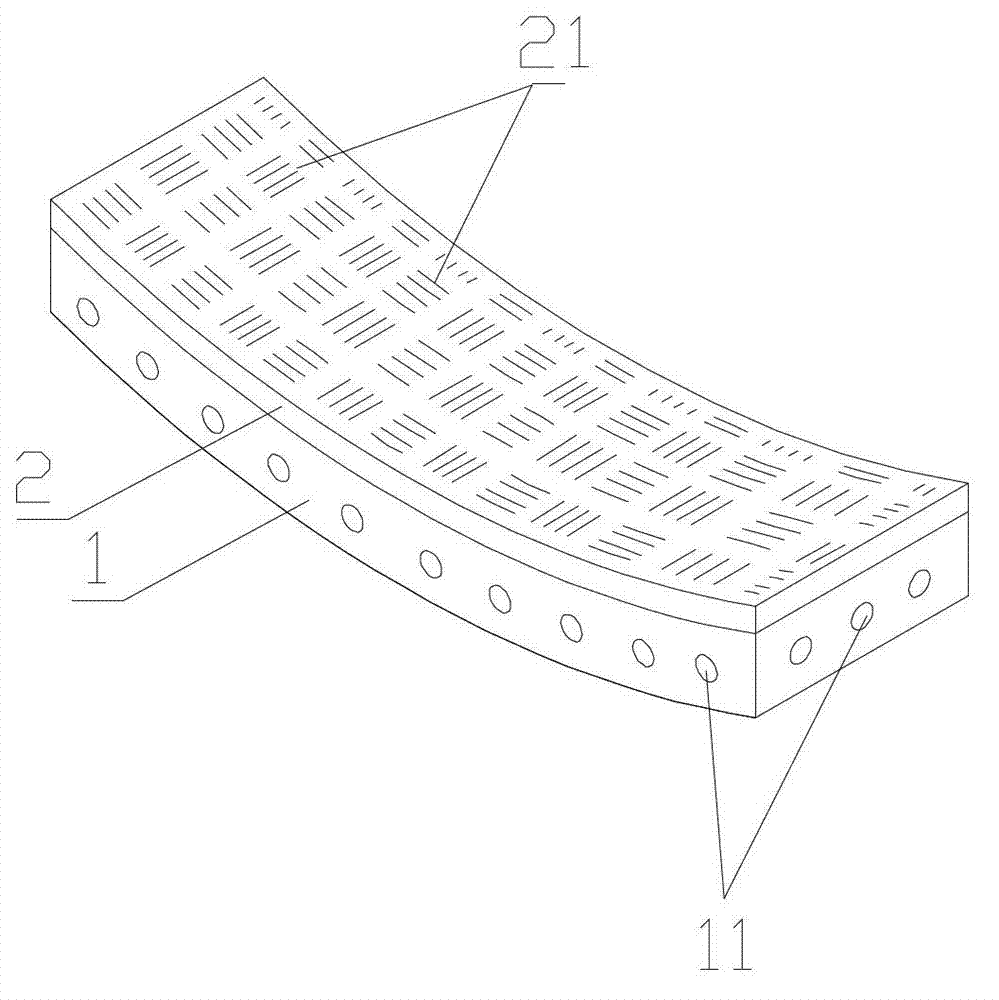

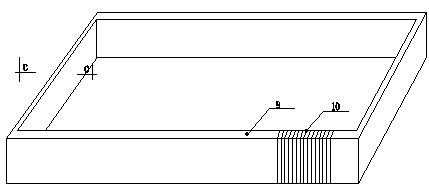

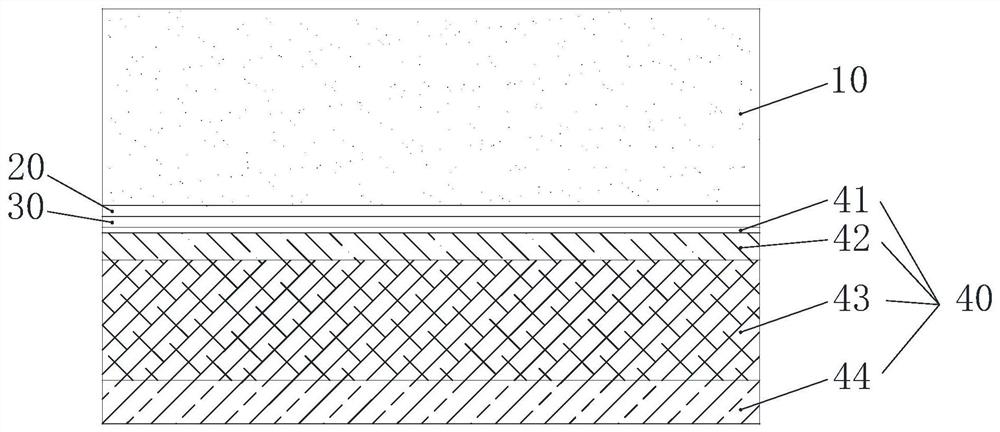

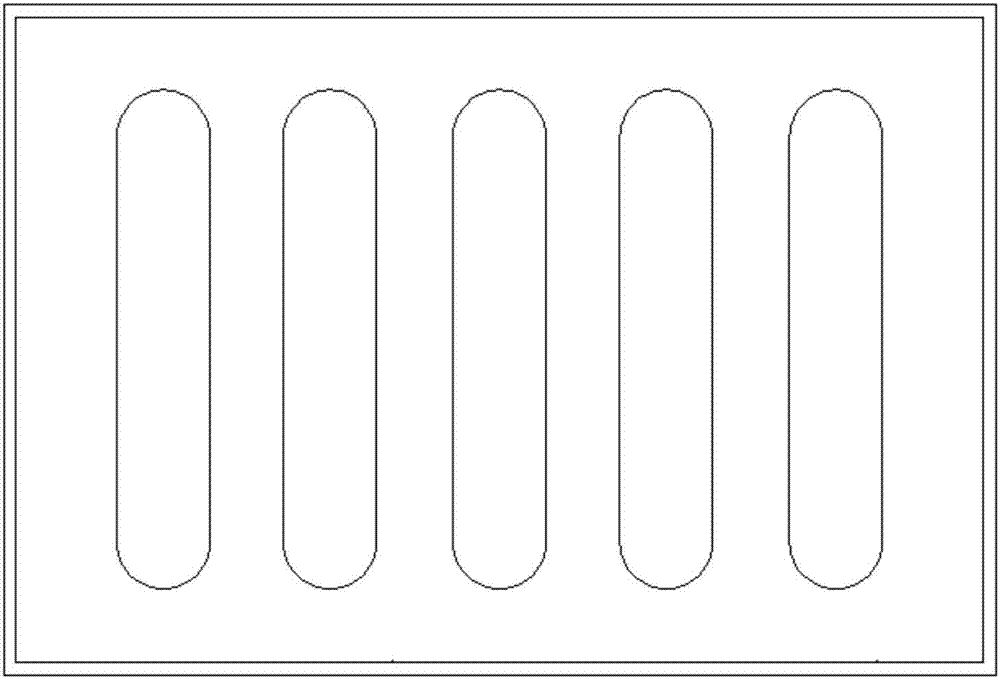

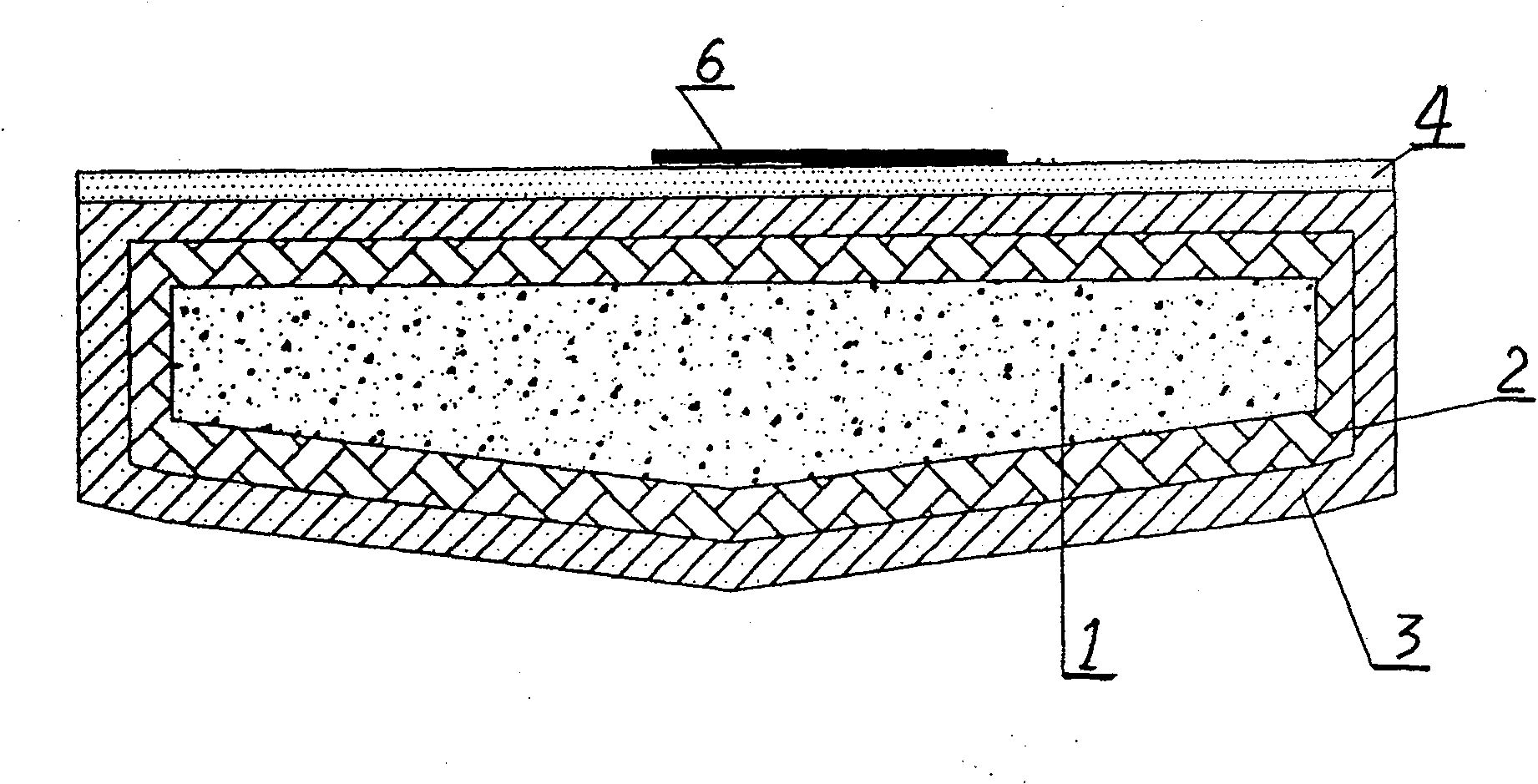

Cable working well cover plate

InactiveCN102926405AIncreased load-bearing capacityLow costArtificial islandsSynthetic resin layered productsEngineeringRebar

The invention discloses a cable working well cover plate, which comprises a bearing layer and an anti-slip layer which is fixedly connected to the surface of the bearing layer, wherein the bearing layer and the anti-slip layer are in an anti-arch bridge shape; the bearing layer is shaped and formed by coating a steel reinforcement framework by employing bulk molding compounds; the anti-slip layer is shaped and formed by the bulk molding compounds; and transverse and vertical anti-slip stripes in a staggered mode are formed on the surface of the anti-slip layer. The cable working well cover plate has the characteristics of low recycling value, high bearing capacity, high durability, moderate weight and anti-slip effectiveness, and a vehicle does not generate noise while driving through the cover plate.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Glass fiber reinforced plastic adhesive boundary sign bracket and production method thereof

The invention relates to a glass fiber reinforced plastic adhesive boundary sign bracket and a production method thereof. The bracket is of a moulding integral structure, a panel on the upper part ofthe bracket is in the shape of a table tennis racket, a base on the lower part of the bracket is in the shape of a concave groove plate, and the longitudinal cross section of the bracket is in an L shape. The invention comprises the following raw materials and steps: taking unsaturated polyester resin, polystyrene and styrene polymer solution, chopped glass fiber, packing, carbon black, curing agent, zinc stearate and the like as raw materials; firstly, preparing polystyrene and styrene into a polymer solution for standby; then, uniformly mixing the seven raw materials; and finally, filling the raw materials in a metal mould to cure and form the raw materials through pressurization and heating, and then depanning and tripping the formed materials. A reflection film is stuck on the bracketto form an adhesive boundary sign. The bracket has the advantages of smooth surface, high strength, favorable performance of corrosion resistance and aging resistance, low cost and long service life,and avoids pilferage because of no recycling value. The invention greatly reduces cost in purchase and maintenance.

Owner:醴陵市万通新型材料有限公司

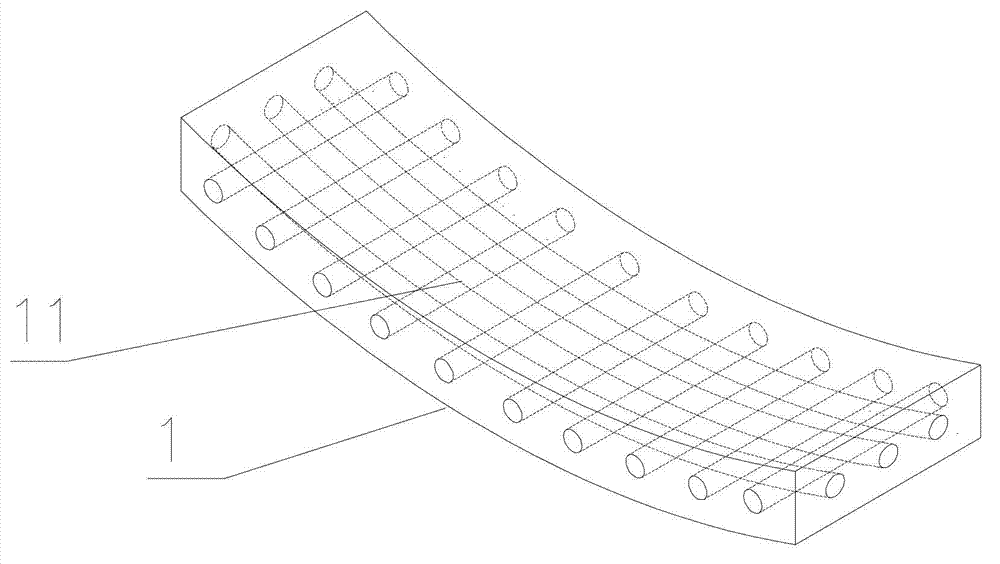

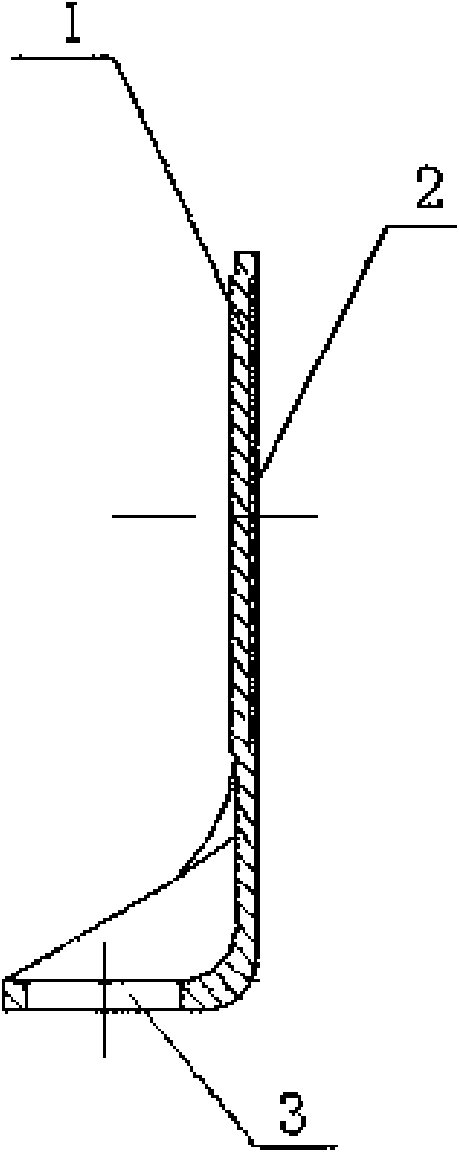

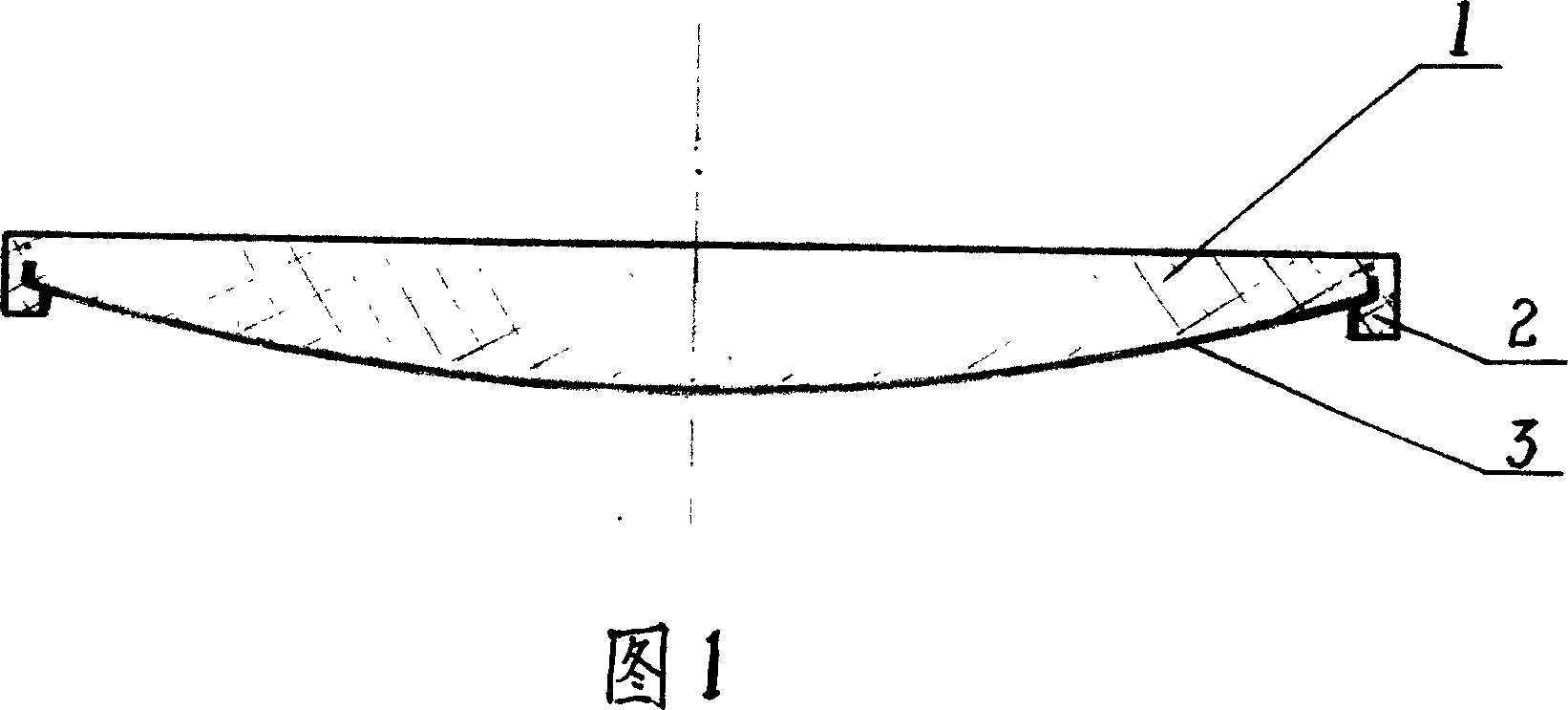

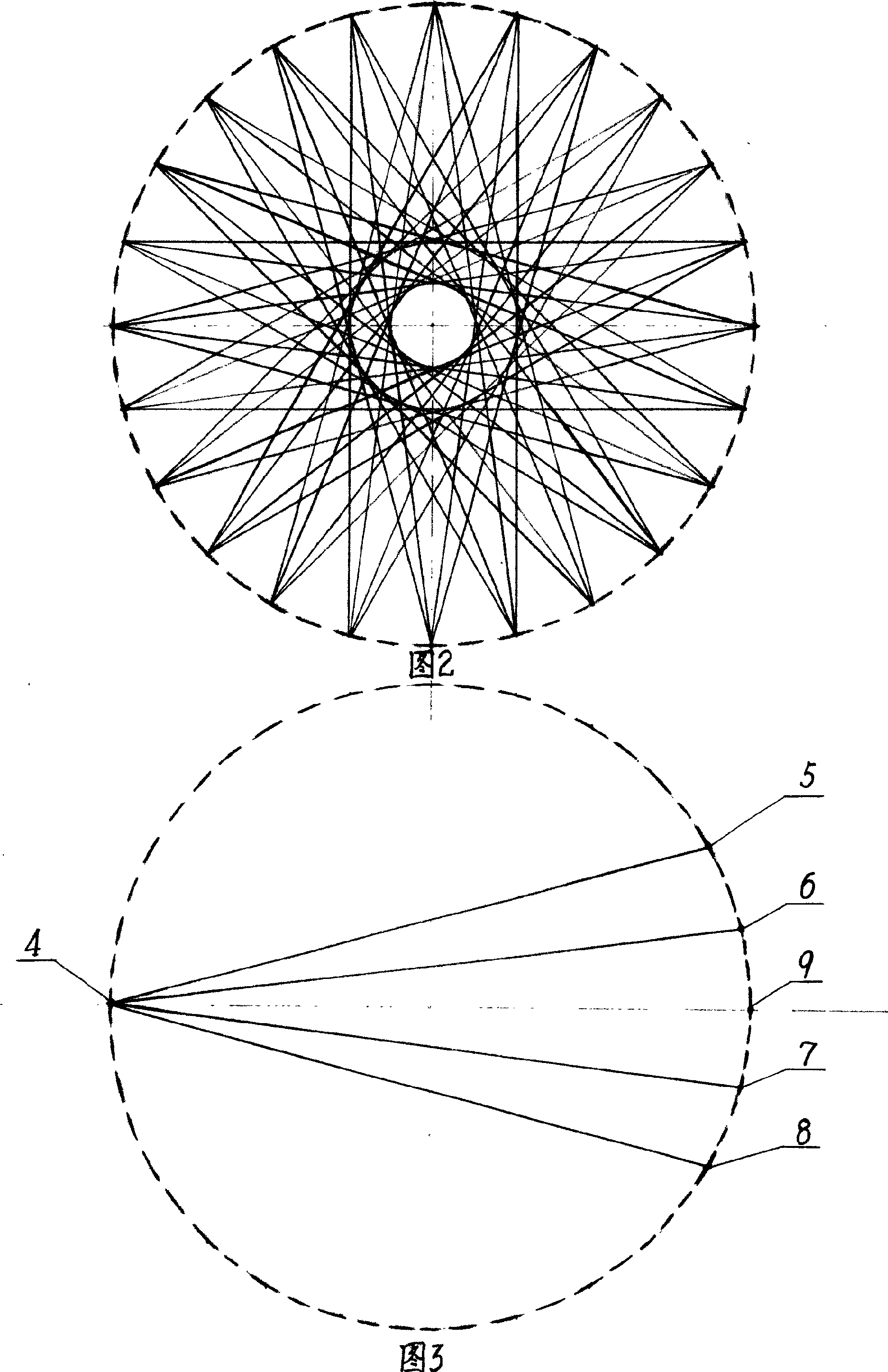

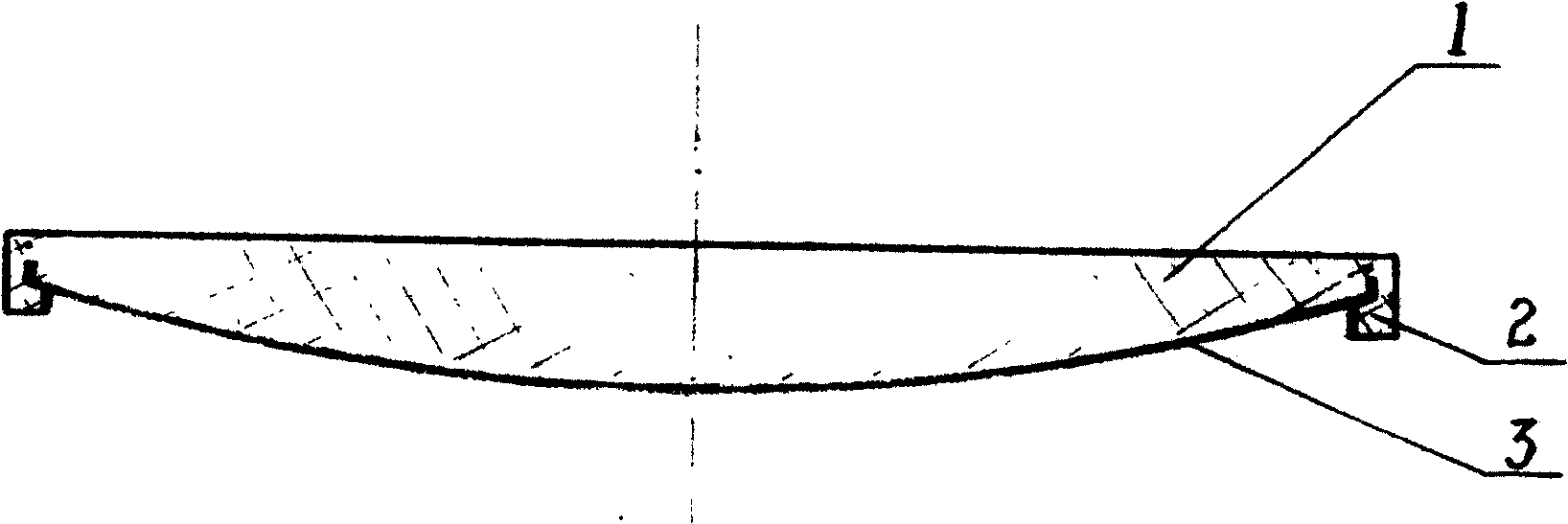

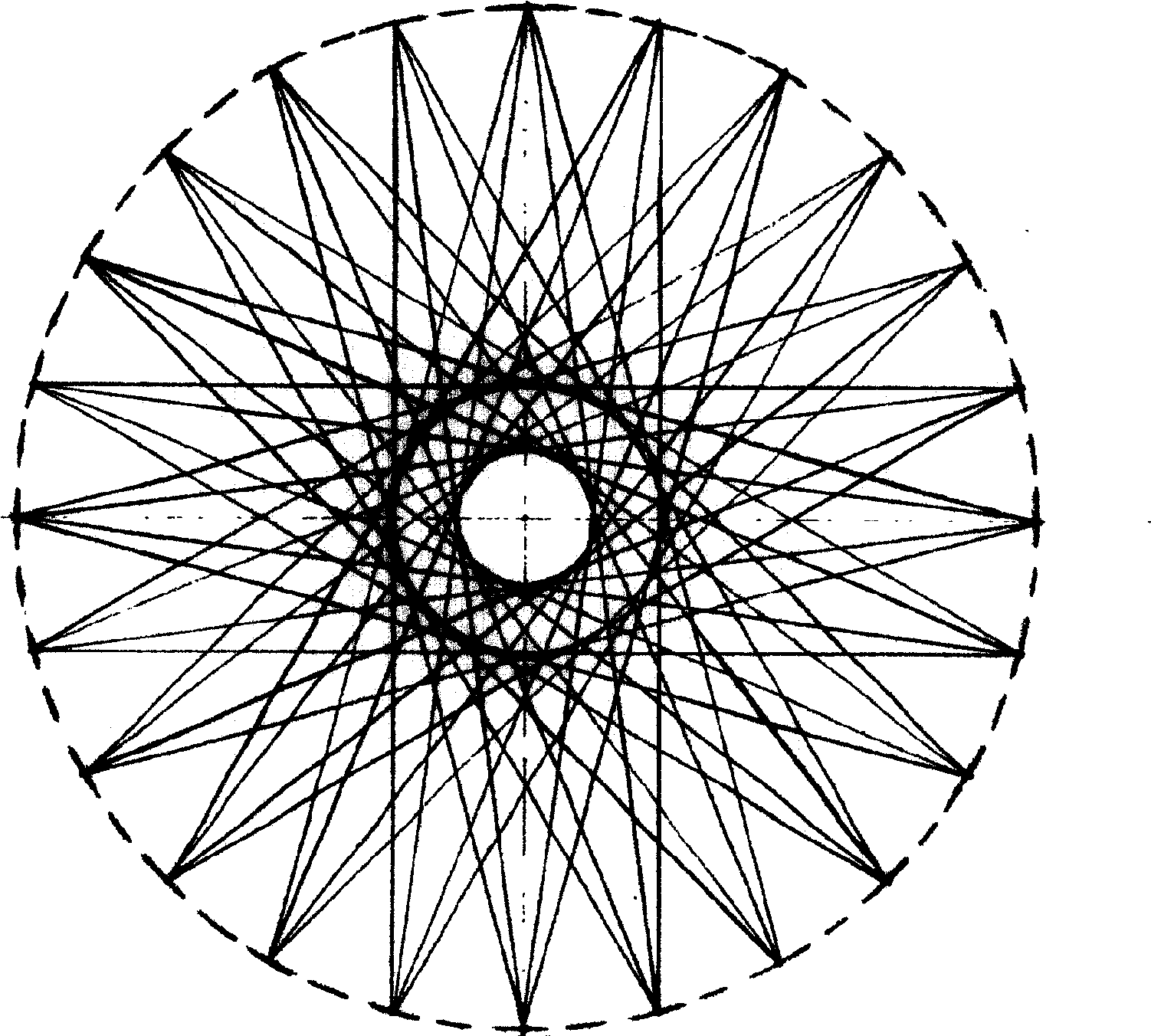

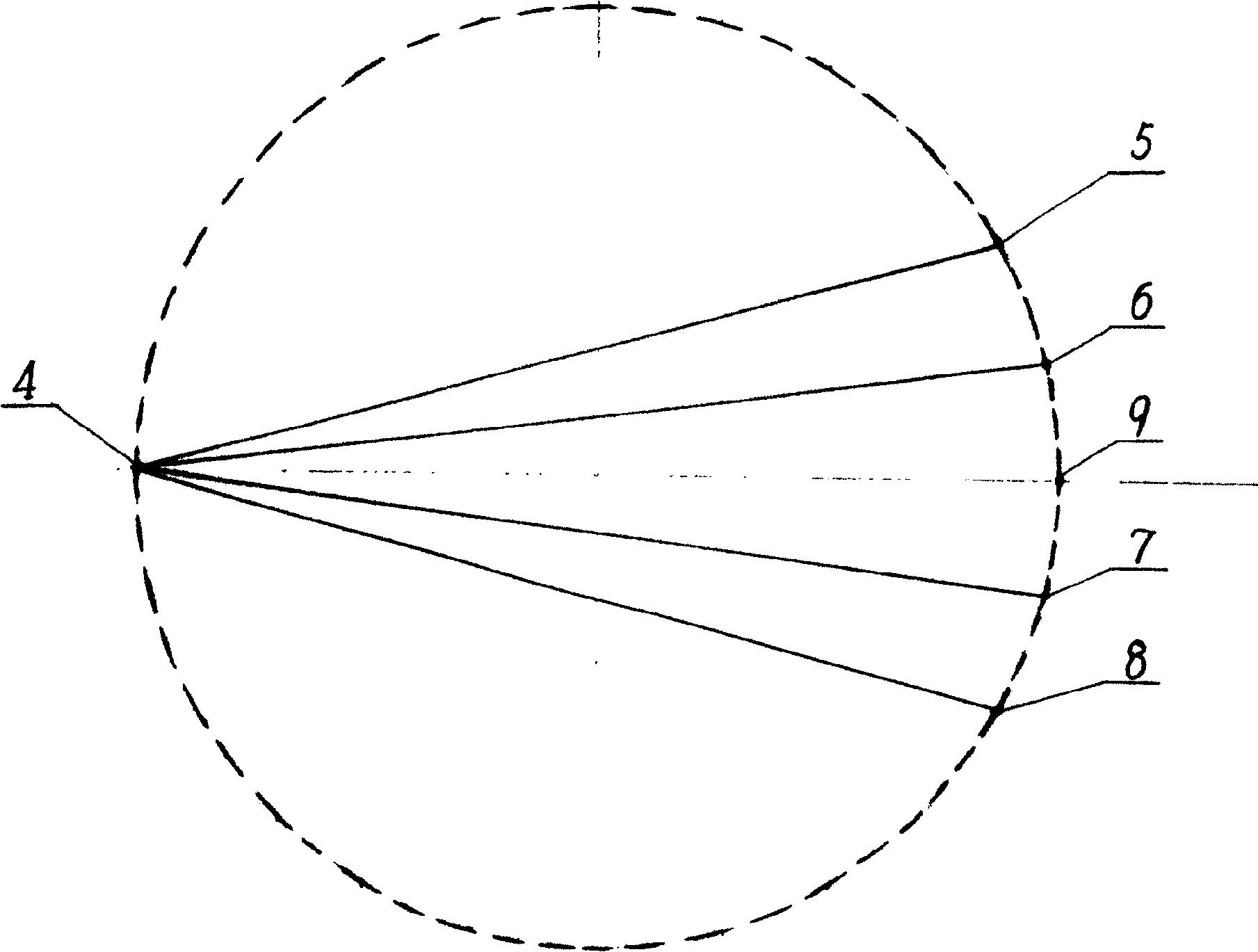

Manhole cover made of composite material with glass fibre reinforcing bar structure

ActiveCN100999901AAddressing Stolen Social IssuesImprove carrying capacityArtificial islandsUnderwater structuresGlass fiberEngineering

The present invention relates to one kind of manhole cover of glass fiber reinforced composite material. The manhole cover includes one composite material layer and one arched reinforcing glass fiber rib layer with 16-32 ends in the circumference, with each of the ends being intersecting point of four ribs. The manhole cover has reasonably distributed reinforcing glass fiber ribs in optimized stress state, great bearing capacity, low cost and long service life.

Owner:JIANGSU CHANGAN COVERS

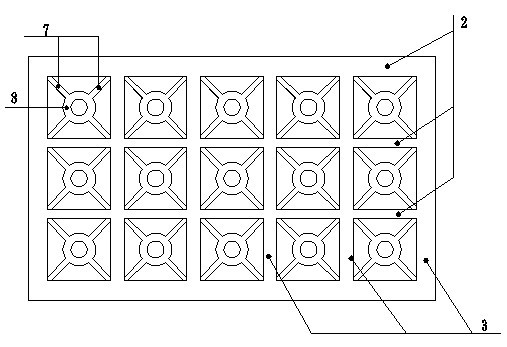

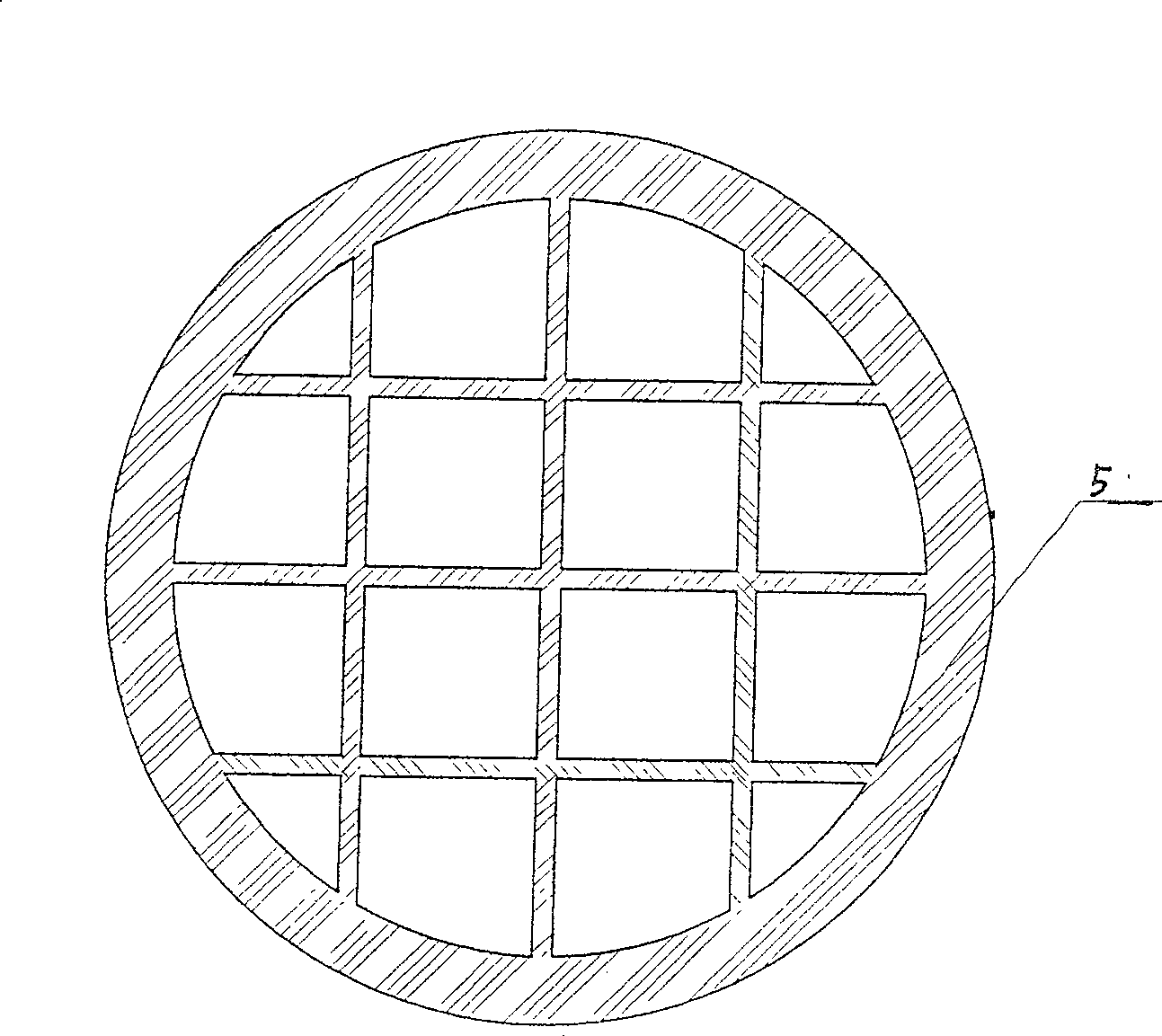

Water grate

InactiveCN102080412AImprove carrying capacityUnique structureSewerage structuresClimate change adaptationWater flowStringer

The invention relates to a water grate, which comprises a grate body, wherein the grate body consists of 4 to 20 square grids formed by crossly encircling 3 to 5 longitudinal beams and 3 to 6 cross beams; a group of patterns is engraved in each square grid; and the longitudinal beams, the cross beams and the patterns are molded integrally. The water grate is suitable for sealing entrances of underground box culverts, pipelines and blind ditches into which sewage and rainwater flow, allows water to pass through, intercepts impurities, bears loads of pedestrians and vehicles and can be opened. Compared with the conventional water grate, the water grate has a unique structural form and has high bearing capability; and the water grate has an exquisite structure and a larger water flow cross section compared with the conventional water grate which has an ordinary structure and is made of a cement-based material or a resin-based material. Moreover, the grate body is made of a cement-based composite material, so that the grate body does not have any recycling value and is theft-proof.

Owner:吕云南

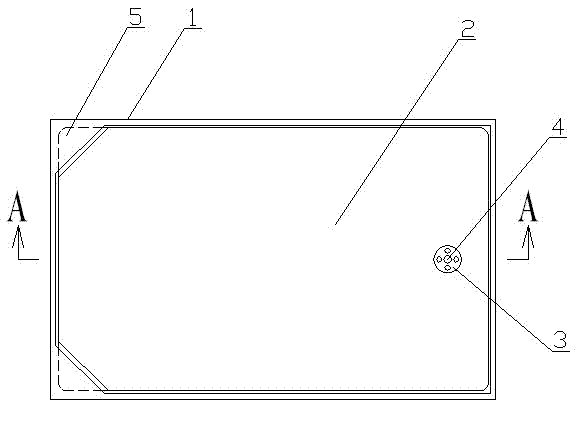

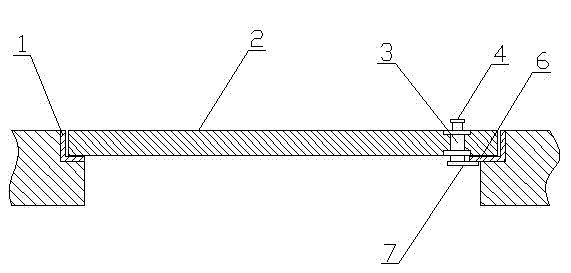

Anti-theft well cover with wooden core coated with compound material

InactiveCN102808424AImprove corrosion resistanceAnti-corrosion hasArtificial islandsUnderwater structuresSolid woodAging resistance

The invention discloses an anti-theft well cover with a wooden core coated with a compound material. The anti-theft well cover comprises a well cover body and a frame, wherein the well cover body comprises a wooden core and a compound material layer covering the outer surface of the wooden core, wherein a built-in locking device capable of locking the well cover body onto the frame is arranged on the well cover body. A crossly-laminated solid wood plate is adopted as the wooden core, and the compound material with a certain thickness covers the outer surface of the wooden core, so that the anti-theft well cover is endowed with good corrosion resistance, aging resistance and slip resistance; and the anti-theft well cover comprises the frame with an insert hole and a built-in locking hole as well as a well cover with a built-in lock part and a special lock remover, so that compared with the conventional cement product and cast iron material, the anti-theft well cover has the advantages of high strength, light weight, corrosion resistance, long service life and the like, and the problem that the well cover is lost is also radically solved.

Owner:江门市德山复合材料科技有限公司

Picture-character mosaic type underground pipeline mark plate and manufacturing method and application thereof

A mark plate of picture-character embedded type for indicating under ground pipeline is prepared as applying polymer to form base plate and picture-character material making picture-character material be at color-difference to base plate clearly and embedding picture-character material in base plate to form mark plate, sticking mark plate on ground near to underground pipeline to indicate alignment of underground pipeline.

Owner:朱鸿利

Ceramic inspection well cover and its preparing method

InactiveCN1743293ANo recycling valueImprove flexural strengthArtificial islandsUnderwater structuresCeramicRaw material

This invention relates to a ceramic manhole cover made from ceramic material. The raw material to produce this ceramic and their percentages are: 2-100% Al2O3, 0-95% MgO, 0-74% SiO2, 0-15% SiC, 0-20% ZrO2, 0-15% Si3N4, 0-15% B4C, 0-15% SiO2, 0-15% B2O3, 0-15% TiO2, 0-10% Li2O, 0-2% CaO, 0-2% TiO2 and 0-6.2% ZnO. The sum amount of Al2O3, MgO and SiO2 is not less than 65%. The preparation method is as follow: first, produce preforms with the raw material; under 40-100MPa pressure, these preforms are pressure formed, surface strengthened and plasticized. Advantages: good in anti-bending strength, good fracture toughness. As the cover has no recovering value, the possibility of being stolen is reduced.

Owner:吕云南

Unsaturated polyester resin fence and production method thereof

InactiveCN101565932AHigh strengthNo pollution in the processExtensible doors/windowsRoadway safety arrangementsUltraviolet lightsPolystyrene

An unsaturated polyester resin fence comprises the following raw materials at the mixture ratio of: 20-40 percent of unsaturated polyester resin, 2-6 percent of polystyrene, 2-6 percent styrene, 5-30 percent of chopped glass silk, 25-40 percent of ground calcium carbonate, 1-1.5 percent of pigment, 2-4 percent of curing thickener, 3-4 percent of flame retardant and 3-4 percent of ultraviolet light resistant agent. The polystyrene is diluted by the styrene, all components are stirred uniformly pro rata, pressed by a die and heated, and the temperature and pressure are maintained for curing and forming, then the flash is removed after demoulding and the edges and corners are polished to form the members of the fence; the bottom is provided with rolling wheels, and jointing and splicing are conducted to assemble a set of retractable moving fence which has high strength, no toxicity or pollution, corrosion resistance, beautiful appearance, low production cost, convenient assembly and is applicable at the openings of the central isolation belts of highways.

Owner:醴陵市万通新型材料有限公司 +1

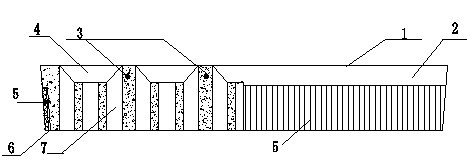

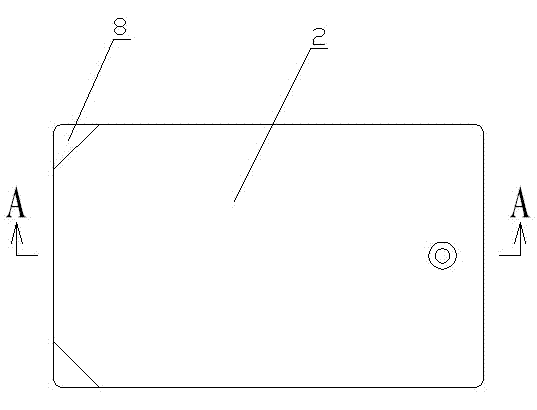

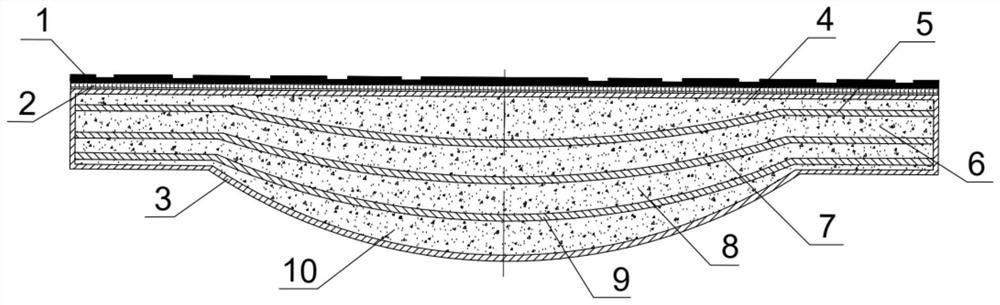

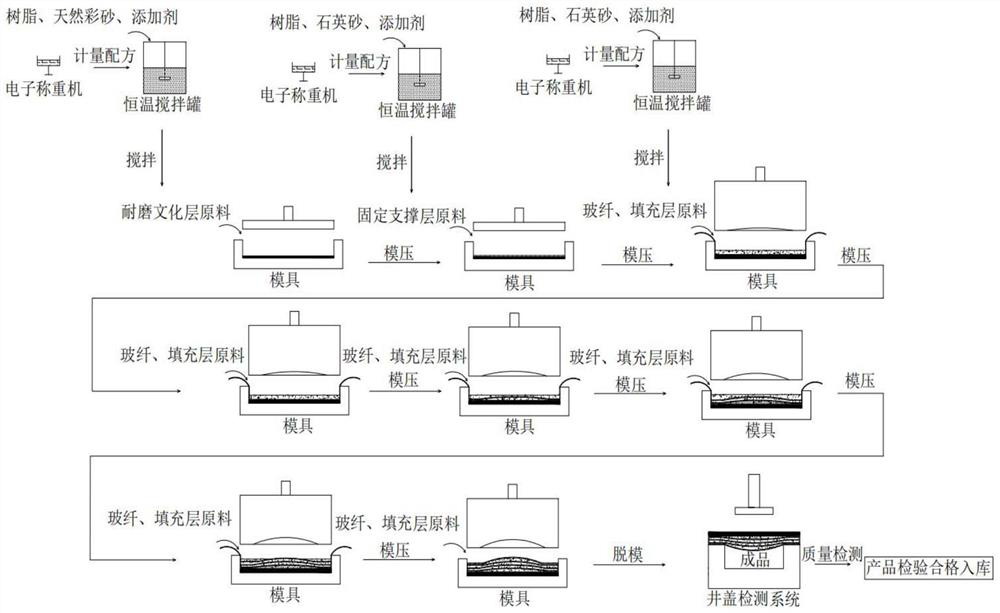

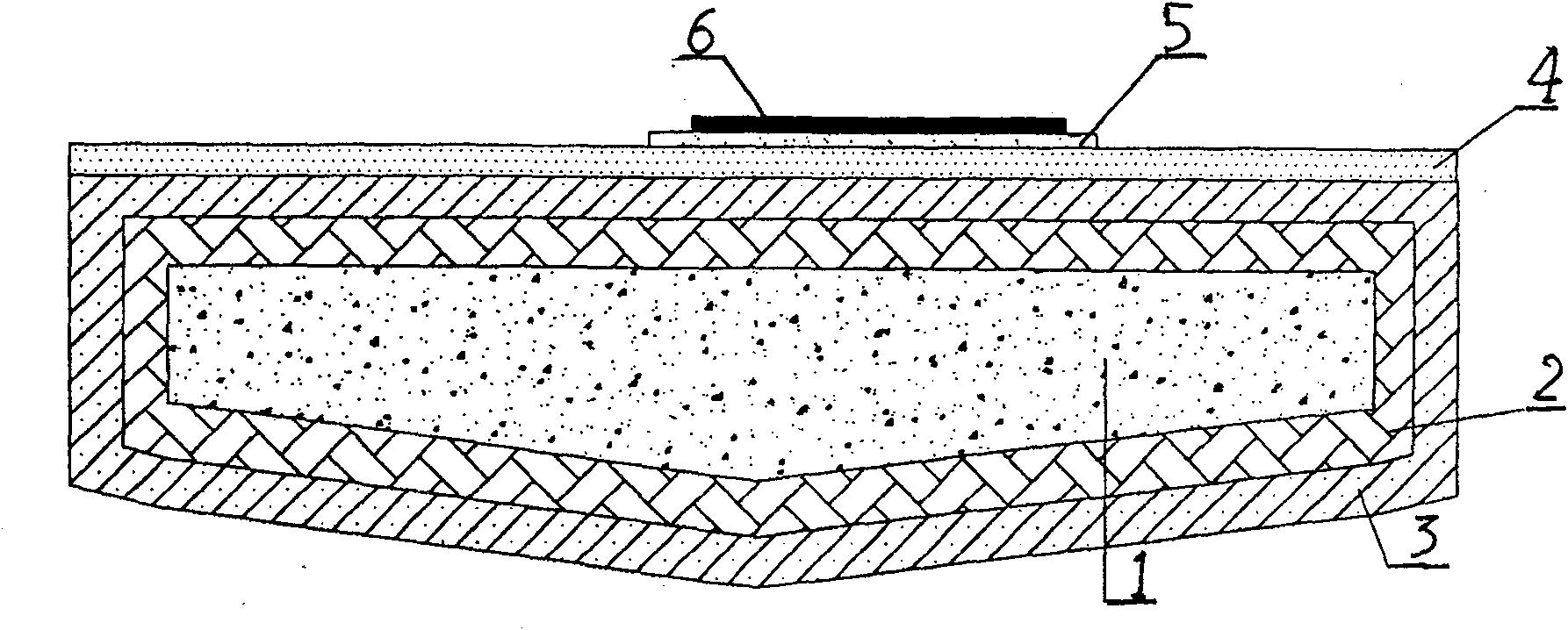

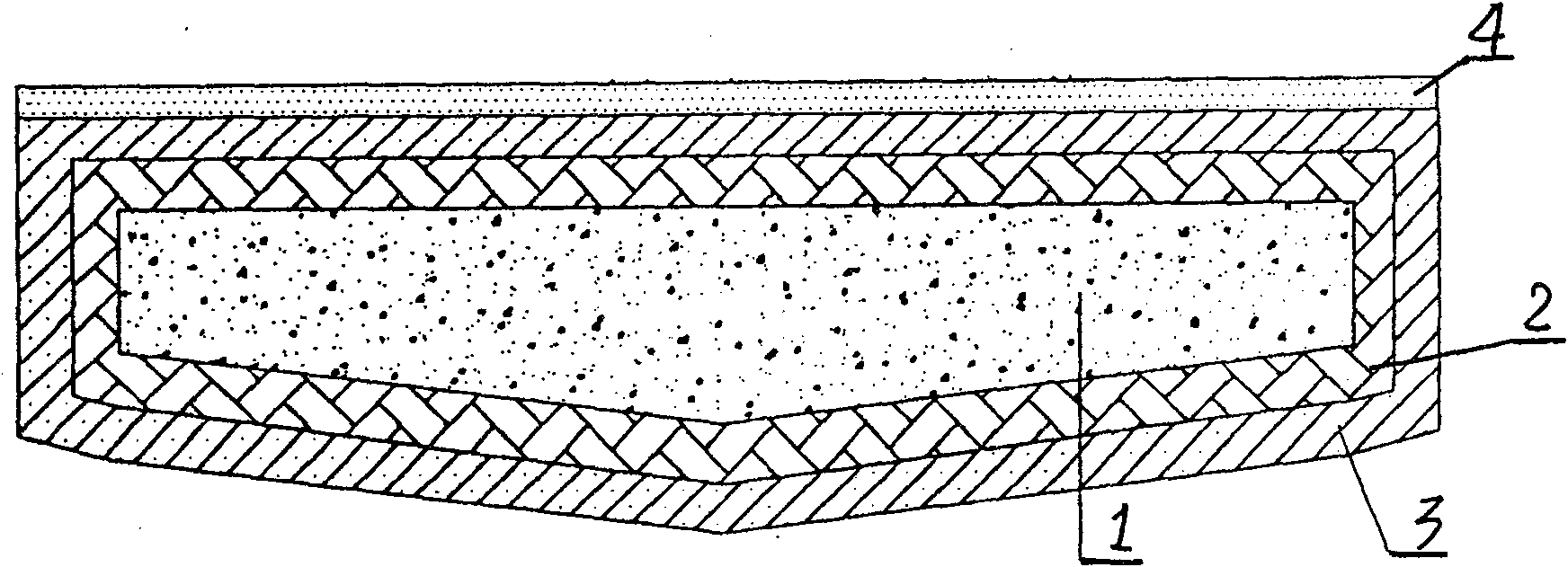

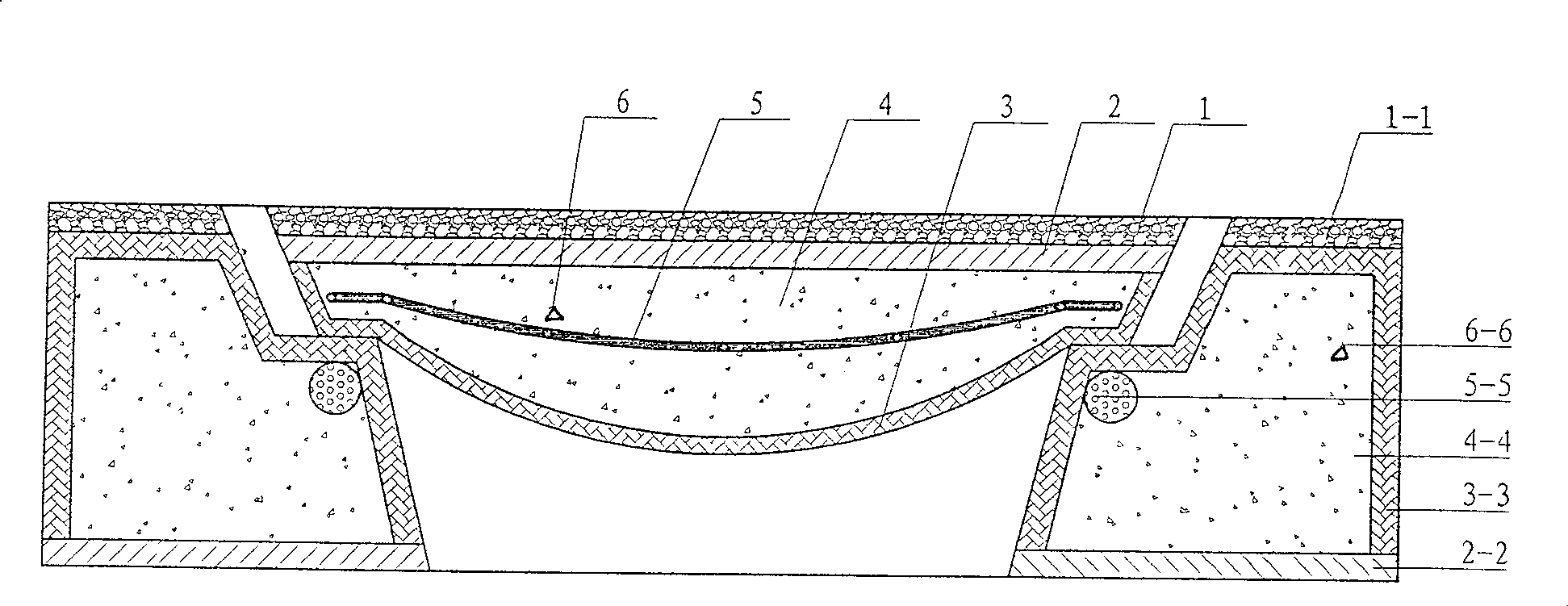

Multi-layer molded high-load-bearing municipal road well lid and manufacturing method thereof

ActiveCN113737859AImprove toughnessImprove fatigue resistanceArtificial islandsClimate change adaptationConstruction engineeringStructural engineering

The invention relates to a multi-layer molded high-load-bearing municipal road well lid and a manufacturing method thereof, and belongs to the technical field of municipal engineering roads. The well lid comprises a wear-resistant layer, a fixed supporting layer, a protective layer, a first filling layer, a first reinforcing layer, a second filling layer, a second reinforcing layer, a third filling layer, a third reinforcing layer and a fourth filling layer, wherein the upper surface of the protective layer is covered with the fixed supporting layer, the wear-resistant layer is installed on the fixed supporting layer, the first reinforcing layer, the second reinforcing layer and the third reinforcing layer are sequentially arranged in the protective layer from top to bottom, the space between the top face in the protective layer and the first reinforcing layer is filled with the first filling layer, the second filling layer is filled between the first reinforcing layer and the second reinforcing layer, the third filling layer is filled between the second reinforcing layer and the third reinforcing layer, and the fourth filling layer is filled between the third reinforcing layer and the inner bottom surface of the protective layer. By the adoption of the multi-layer reverse tensioning force enhanced curved surface type structure, stress in the well lid is more uniform, and the strength is better.

Owner:KUNMING UNIV OF SCI & TECH +1

Nylon alloy component for anti-theft road manhole cover and manufacturing technology

InactiveCN102898071AGuaranteed to be strong against theftNo recycling valueGlass fiberManufacturing technology

The present invention relates to a nylon alloy component for anti-theft road manhole cover and a manufacturing technology. The nylon alloy component includes nylon 6, MC nylon, glass fiber, sand or gravel, and the weight ratio of the components is 1:0.1:0.2:2.6-3. The manufacturing technology includes: preliminarily stirring the above substances with a weight ratio of 1:0.1:0.2:2.6-3, placing the preliminary stirred material at the temperature of 250-260 DEG C in a dedicated synthesis machine to fully mix into a state of soft plasticine, then placing the soft plasticine material in a mold provided with a steel rib shift force frame, pressurizing to 120-200 tons, keeping the pressure for 5-10 minutes to demold, putting the product into a tempering pool after demolding to cook by boiling water in order to eliminate the internal stress. The manhole cover obtained by the invention can not be recycled, thereby achieving the purpose of anti-theft.

Owner:刘士祥

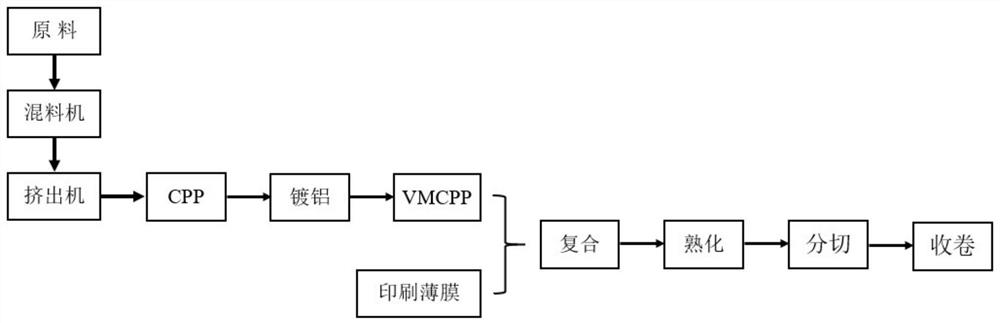

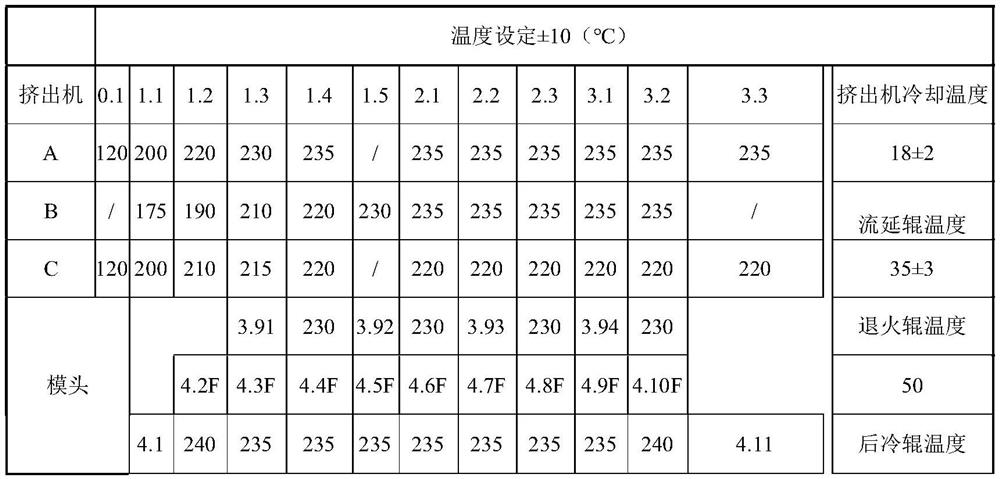

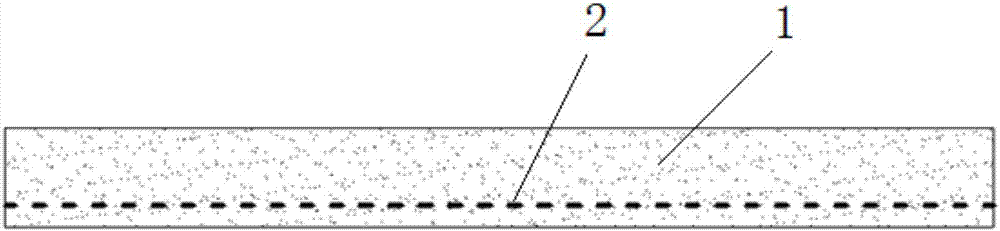

Easily-recycled high-barrier low-temperature heat-sealing packaging composite film and production method thereof

PendingCN113815280ANo recycling valueLow heat seal strengthPackage recyclingFlexible coversPolymer sciencePolyolefin

The invention relates to the field of packaging, in particular to an easily-recycled high-barrier low-temperature heat-sealing packaging composite film and a production method thereof. The composite film is formed by compounding a printing film and an aluminum-plated casting polypropylene film VMCPP, the aluminum-plated casting polypropylene film VMCPP is of a four-layer structure, the first layer is an aluminum layer, and the printing film is compounded on the surface of the aluminum layer; the second layer is a composite layer and is composed of copolymerized PP resin and maleic anhydride grafted POE; the third layer is a middle layer and is made of homo-polypropylene resin; and the fourth layer is a heat sealing layer and is composed of a metallocene-based polypropylene random copolymer, a butenyl polymer and an anti-blocking agent. The composite film is a single polyolefin material composite film, is easy to melt and recycle, has high recovery value, has the advantages of high barrier property, low-temperature heat sealing and high heat sealing strength, and can well meet the requirements of high barrier and high-speed packaging.

Owner:HUANGSHAN NOVEL

Glass reinforced plastic-pressed marble-imitated blind track brick

InactiveCN107288009AHigh strengthImprove compactnessEdge grinding machinesSingle unit pavingsBrickHigh pressure

The invention discloses a glass reinforced plastic-pressed marble-imitated blind track brick. The brick is prepared by mixing and hot-pressing SMC sheets, quartz sand, broken pebbles, carborundum and marble-imitated glass fiber cloth, wherein in parts by weight, 3-10 parts of SMC sheets and a total of 0.5-1.5 parts of quartz sand, broken pebbles and carborundum are used, the weight ratio of the quartz sand to the broken pebbles to the carborundum is 1:(1-1.5):(0.2-0.5), and the dosage of the marble-imitated glass fiber cloth is supposed to be able to cover the upper surface of the marble-imitated blind track brick. The glass reinforced plastic-pressed marble-imitated blind track brick is prepared by mixing the SMC sheets, the quartz sand, the carborundum and the broken pebbles through high-temperature high-pressure mold shaping, is great in degree of density, high in strength and good in wear-resisting property, and is combined with the corrosion-resistant and anti-aging advantages of glass reinforced plastic.

Owner:东营市天诚建材有限公司

Picture-character mosaic type underground pipeline mark plate and manufacturing method and application thereof

InactiveCN100435179CColorfulNot easy to wearStampsAdvertisingStructural engineeringMechanical engineering

A mark plate of picture-character embedded type for indicating under ground pipeline is prepared as applying polymer to form base plate and picture-character material making picture-character material be at color-difference to base plate clearly and embedding picture-character material in base plate to form mark plate, sticking mark plate on ground near to underground pipeline to indicate alignment of underground pipeline.

Owner:朱鸿利

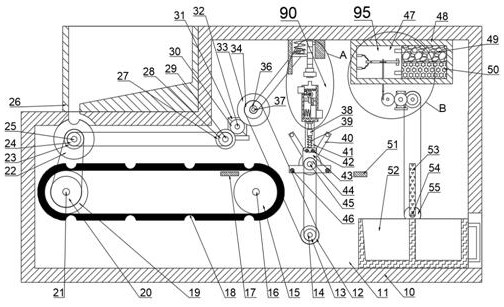

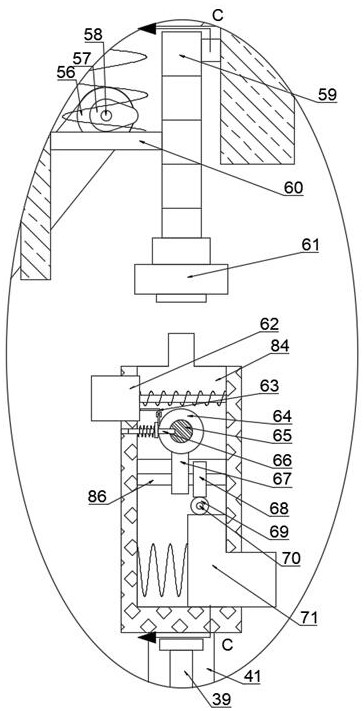

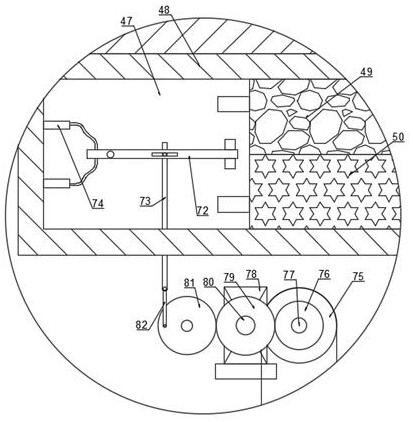

18650 lithium battery detection and classification device

InactiveCN112570316ASimple structureSimple and fast operationSortingInternal resistanceStructural engineering

The invention discloses a 18650 lithium battery detection and classification device. The device comprises a box body, a classification cavity is formed in the box body, a classification mechanism is arranged in the classification cavity, a detection box is fixedly arranged at the upper end of the classification cavity, a detection cavity is formed in the detection box, a detection mechanism is arranged in the detection cavity, two second limiting columns symmetric left and right are fixedly arranged at the front end of the classification cavity, and two first limiting columns symmetric left and right are fixedly arranged at the front end of the classification cavity. The 18650 lithium battery detection and classification device is simple in structure, easy and convenient to operate, high in integration degree, capable of automatically clamping, detecting and sorting 18650 types of lithium batteries, capable of separating good lithium batteries from bad lithium batteries, and can measure the internal resistance and the voltage of the lithium batteries to be recycled, and when the internal resistance of a certain lithium battery exceeds 12-100 milliohms or the voltage is lower than 2.75 V, the lithium battery is automatically judged to be a fault battery, does not have a recycling value and is classified into a waste material grid.

Owner:深圳市微笑软件技术有限公司

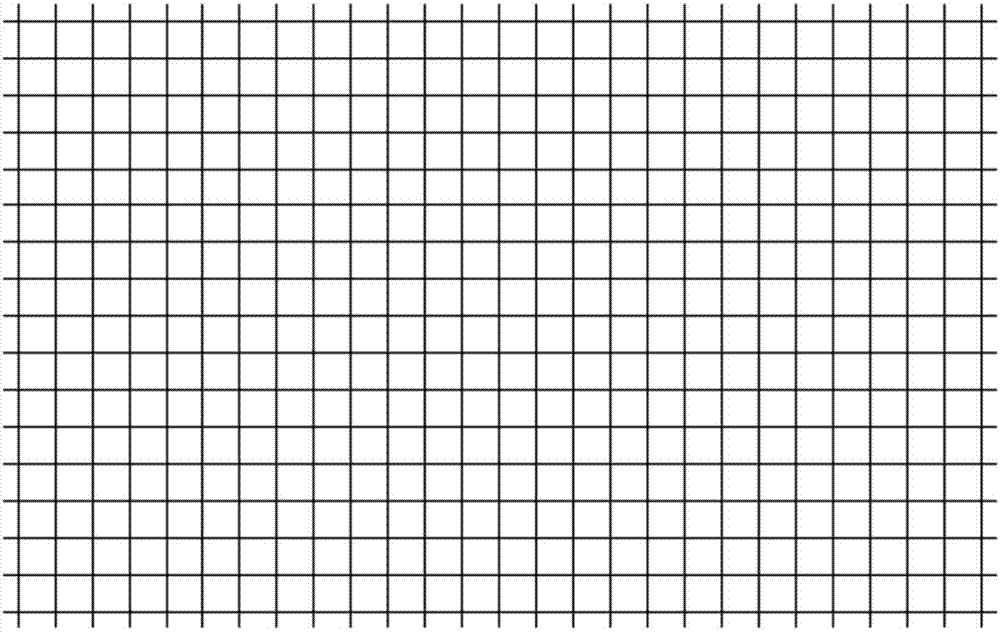

Impact-resistant water grate, and impact-resistant manhole cover

InactiveCN106946506AImprove integrityImprove mechanical performanceDischarging arrangementSewerage structuresFiberCarrying capacity

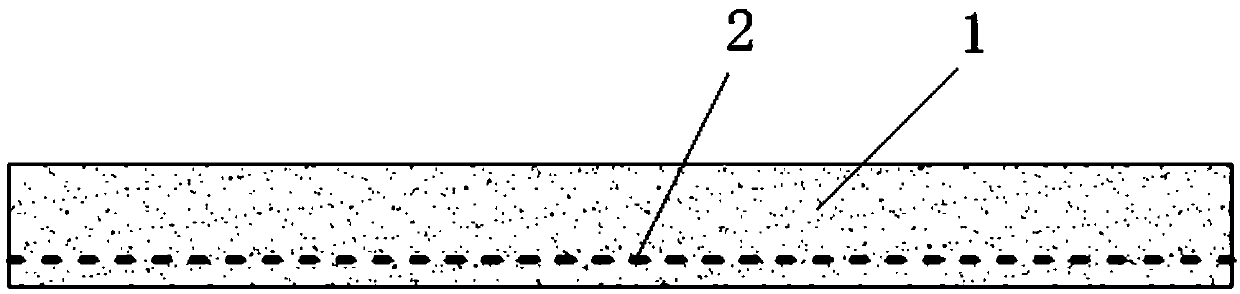

The invention discloses an impact-resistant water grate, and an impact-resistant manhole cover. The impact-resistant water grate and the impact-resistant manhole cover comprise a concrete main body, and carbon fiber gridding cloth used for covering the bottom of the concrete main body; the concrete main body is composed of, by weight, 1 to 1.2 parts of cement, 1.2 to 1.4 parts of fly ash, 0.6 to 0.8 part of sand, 0.001 to 0.002 part of a thickening agent, 0.009 to 0.01 part of a water reducing agent, 0.3 to 0.4 part of water, and polyvinyl alcohol fiber; the volume amount of polyvinyl alcohol fiber accounts for 1 to 2% of the total volume of the concrete main body. The impact-resistant water grate is prepared from the PVA fiber concrete material, so that the carrying capacity of the impact-resistant water grate is improved, and impact resistance is improved effectively because of the excellent strain hardening performance and impact resistance of the PVA fiber concrete material; and in addition, the PVA fiber concrete material possesses extremely high durability, so that the service life of the impact-resistant water grate is prolonged.

Owner:SHANDONG UNIV

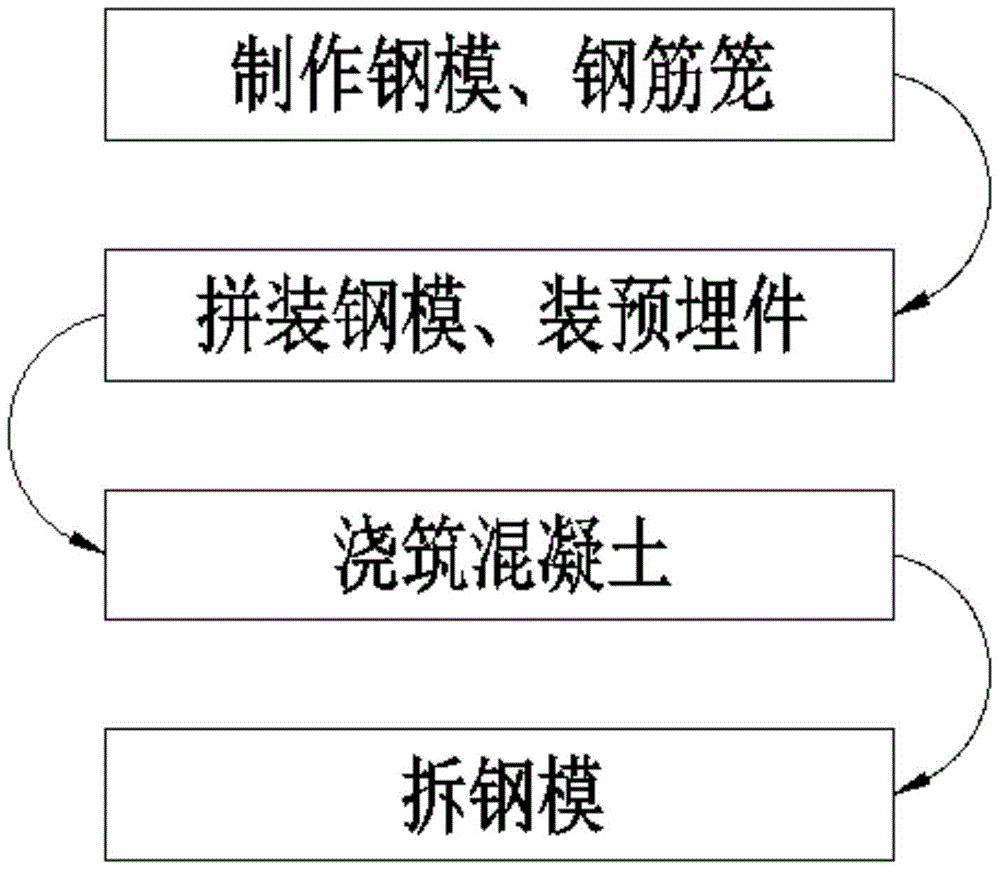

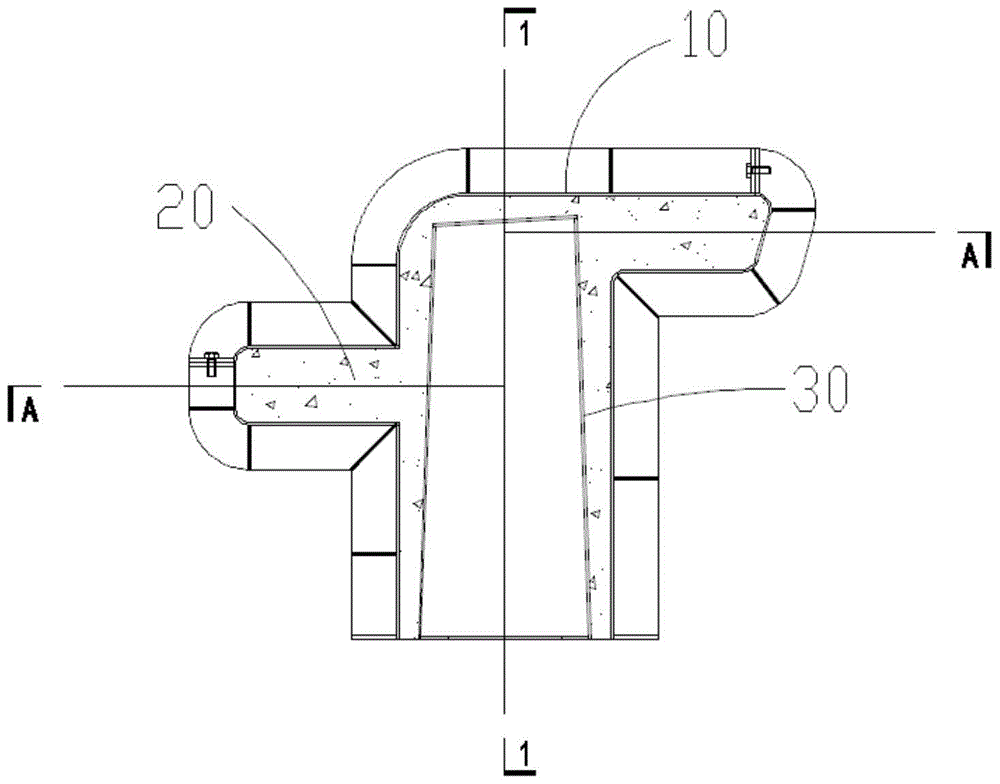

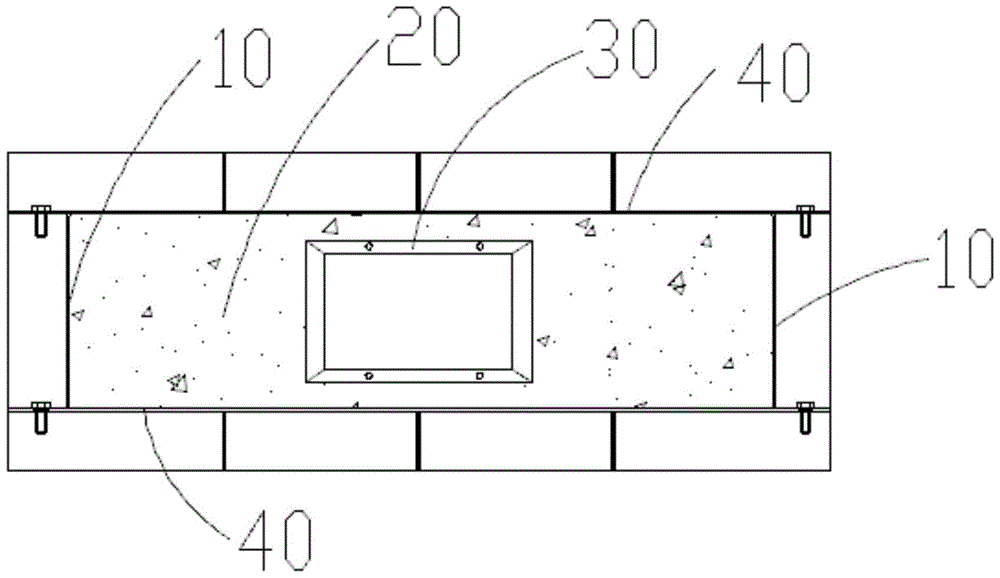

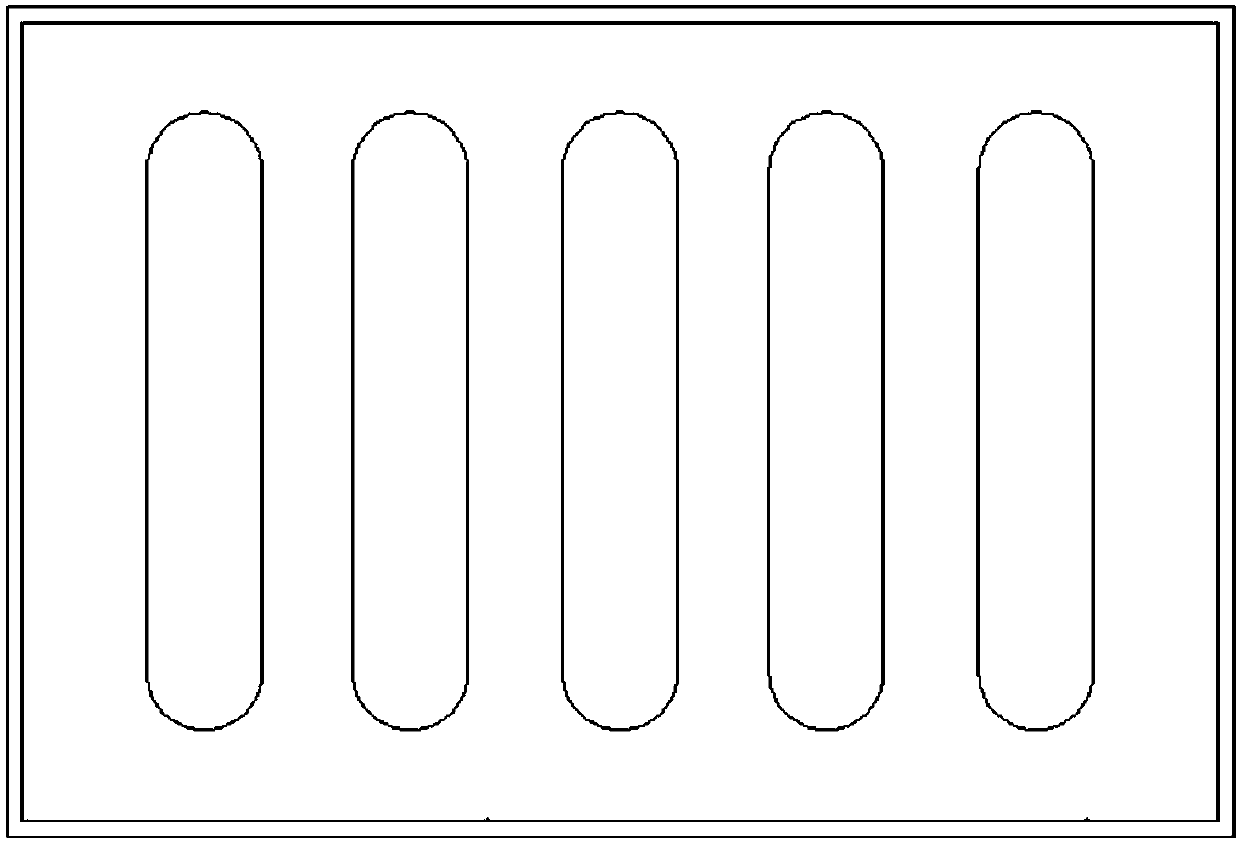

Manufacturing method of prefabricated concrete drinking water table and concrete drinking water table

ActiveCN104191520BIncreased durabilityNo recycling valueCeramic shaping apparatusBeverage vesselsWater tableRebar

The invention discloses a method for making a prefabricated concrete drinking water table, which includes the following steps: after making a steel mold and a steel cage respectively according to the shape and size of the drinking water table; Assemble the steel form and check the size; S2: place the reinforcement cage in the steel form and hang and install the inner steel form at the set position; S3: pour concrete into the assembled steel form with the reinforcement cage placed, and Vibration, compaction and smoothing; S4: Remove the steel mold after the concrete reaches the predetermined strength; S5: After taking out the concrete platform, perform surface treatment on the surface of the concrete platform and spray a layer of waterproof and anti-fouling water-based acrylic waterproof agent; the present invention also provides a prefabricated concrete direct drinking water station made by the above method, the concrete body of reinforced concrete has good durability and anti-theft performance, and the adult drinking water table, children's drinking water table and hand washing area are arranged in partitions, so that the whole applicability is better.

Owner:珠海采筑电子商务有限公司

An impact-resistant well grate and manhole cover

InactiveCN106946506BImprove integrityImprove mechanical performanceDischarging arrangementSewerage structuresFiberCarrying capacity

The invention discloses an impact-resistant water grate, and an impact-resistant manhole cover. The impact-resistant water grate and the impact-resistant manhole cover comprise a concrete main body, and carbon fiber gridding cloth used for covering the bottom of the concrete main body; the concrete main body is composed of, by weight, 1 to 1.2 parts of cement, 1.2 to 1.4 parts of fly ash, 0.6 to 0.8 part of sand, 0.001 to 0.002 part of a thickening agent, 0.009 to 0.01 part of a water reducing agent, 0.3 to 0.4 part of water, and polyvinyl alcohol fiber; the volume amount of polyvinyl alcohol fiber accounts for 1 to 2% of the total volume of the concrete main body. The impact-resistant water grate is prepared from the PVA fiber concrete material, so that the carrying capacity of the impact-resistant water grate is improved, and impact resistance is improved effectively because of the excellent strain hardening performance and impact resistance of the PVA fiber concrete material; and in addition, the PVA fiber concrete material possesses extremely high durability, so that the service life of the impact-resistant water grate is prolonged.

Owner:SHANDONG UNIV

Composite material

The invention designs a composite material which is prepared by adding unsaturated resin, polystyrene, styrene and calcium hydroxide to a kneading machine and stirring for 10 to 13 minutes, adding limestone continuously and stirring for 20 to 23 minutes, and then adding glass fiber and stirring for 3 to 5 minutes. The obtained composite material has good percussion resistance and corrosion resistance, light weight, good seal performance and long service life, and the material has no value in recycling and fundamentally solves safety concerns caused by stealing.

Owner:恒基建设集团有限公司

Multicolor composite material well cover and production process thereof

InactiveCN100575619CSolve the stolenHigh artistic valueArtificial islandsUnderwater structuresUltimate tensile strengthAccelerant

The invention discloses a multicolor composite material well cover and production process thereof, comprising: core body, network frame, enhancing layer, color layer. The outer layer of the network frame coats the outer surface of the core body and the enhancing layer on the outer surface of the network frame. The color layer coats on the upper surface of the enhancing layer. The proportion of the color layer components by weight is that: adding 0.1-1 portion by weight of solidifying agent in 100 portion by weight of resin A, then adding 50-300 portion by weight of colorful stone powder and / or agate powder and / or glass micro bead into the mixture, in which the proportion of the resin A is that: adding 0.4-2.5 portion by weight of accelerant in 100 portion by weight of unsaturated polyester resin. The inventive multicolor composite material well could adopt a plurality of colors for a personalized design.

Owner:刘英华

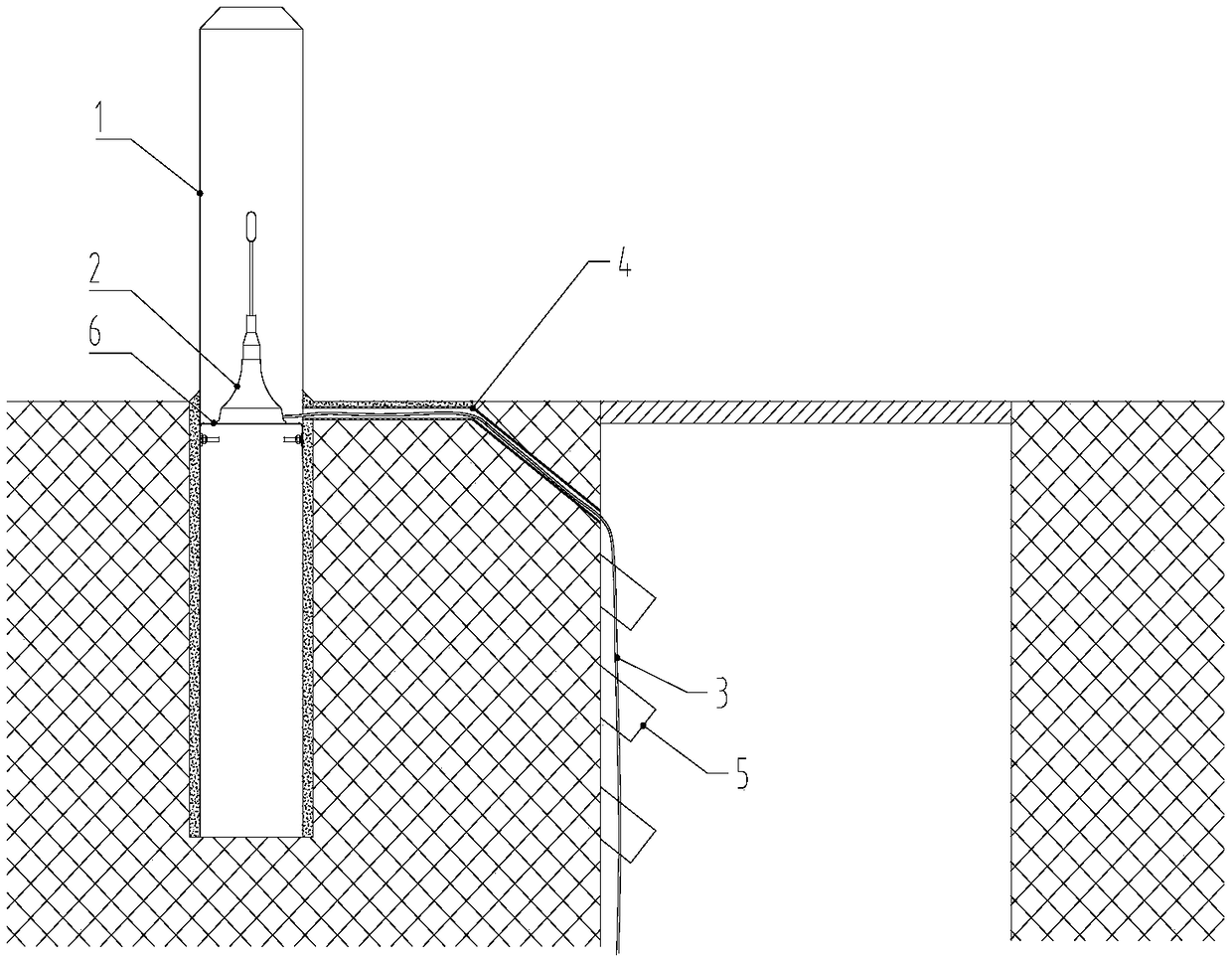

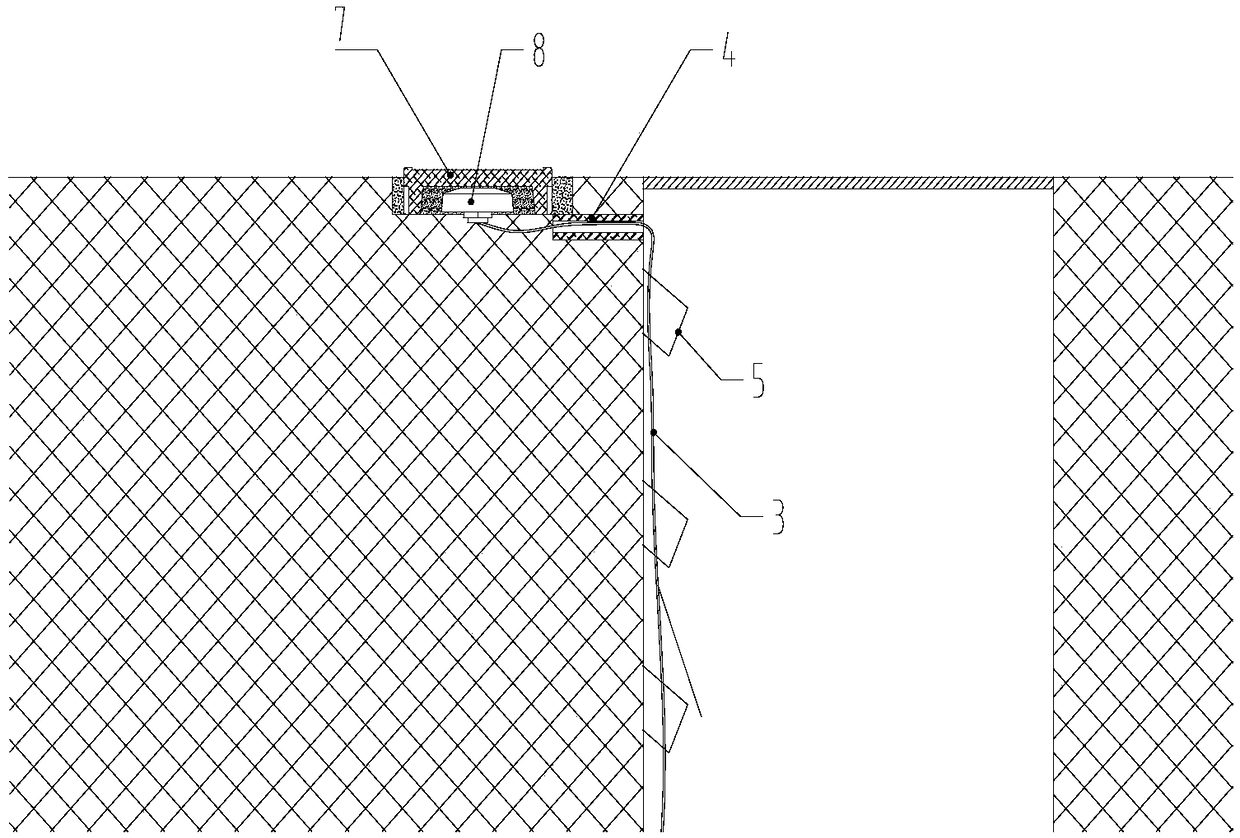

Hidden antenna structure for underground communication

PendingCN108649329AAvoid exposureAvoid damageAntenna supports/mountingsRadiating elements structural formsWireless transmissionEngineering

The invention discloses a hidden antenna structure for underground communication. The hidden antenna structure comprises a cable identifier,a ground surface antenna and an antenna extension line,and the cable identifier is installed on the ground surface close to a cable tunnel or a wellhead of a joint well; the ground surface antenna is arranged in the cable identifier,one end of the antenna extension line is connected with the ground surface antenna,and the other end of the antenna extension line is connected with an underground device. According to the hidden antenna structure for underground communication,wireless signals can be normally received through the ground surface antenna on the ground,so that wireless communication between a tunnel and equipment in the joint well is achieved,and the situation that signals of wireless transmission in the tunnel and the joint well are not good and accordingly data transmission cannot be achieved is eliminated. Meanwhile,the cable identifiercan protect and shield the ground surface antenna,the ground surface antenna can be prevented from being damaged,and normal and stable operation of the earth surface antenna is guaranteed.

Owner:CHANGLAN CABLE ACCESSORIES

Manhole cover made of composite material with glass fibre reinforcing bar structure

ActiveCN100458025CAddressing Stolen Social IssuesImprove carrying capacityArtificial islandsUnderwater structuresGlass fiberStressed state

The present invention relates to one kind of manhole cover of glass fiber reinforced composite material. The manhole cover includes one composite material layer and one arched reinforcing glass fiber rib layer with 16-32 ends in the circumference, with each of the ends being intersecting point of four ribs. The manhole cover has reasonably distributed reinforcing glass fiber ribs in optimized stress state, great bearing capacity, low cost and long service life.

Owner:JIANGSU CHANGAN COVERS

Manhole cover and method for producing same

InactiveCN100494586CIncreasing the thicknessImprove corrosion resistanceArtificial islandsSolid waste managementEngineeringStructural engineering

The present invention discloses a production method of manhole cover. It includes manhole cover and manhole seat. Said manhole cover and manhole seat are formed from surface layer, reinforcing layer, external surface layer and filling layer respectively, in which the filling layer is composed of reinforcing bar and filling material.

Owner:CHANGSHA YUANPENG CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com