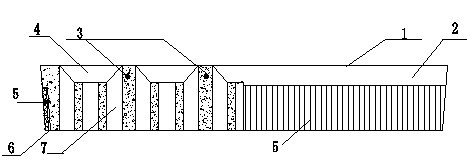

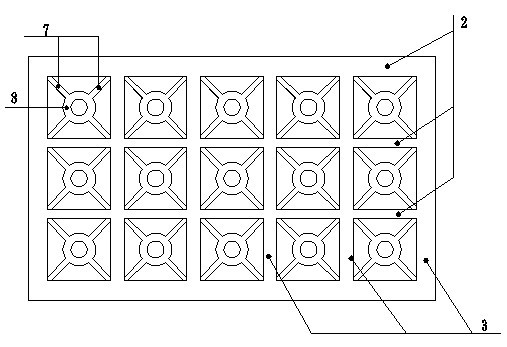

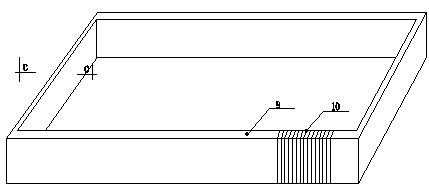

Water grate

A water grate and water grate technology, which is applied in water supply devices, waterway systems, drainage structures, etc., can solve the problems of fast attenuation of bearing capacity, small water cross section, poor wear resistance, etc., and achieve improved bearing capacity and exquisite structure , the effect of the unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the cement-based composite water grate of the present invention mainly includes the following steps: preparing materials, molding the grate, preparing fiber bars, and installing fiber bars.

[0036] 1. Preparation

[0037] 1. Sieve the sand and keep the medium-coarse sand;

[0038] 2. Wash the sand and dry it;

[0039] 3. The fiber filaments prepared from grates are made into 5-25 mm long chopped fibers;

[0040] 4. Take out an appropriate amount of resin in the large container and stir evenly. For the resin with high viscosity, heat it in a water bath to about 40°C, add the diluent, and stir evenly for later use;

[0041] 5. If a stainless steel sheet is used as the surface cladding material, it must first be made into a 3-5 mm wide steel strip.

[0042] 2. Cover molding

[0043] The raw material composition of the cement-based composite water grate body of the present invention is as in Table 1.

[0044] (1) Make the installation mold. ...

Embodiment 1

[0073] Embodiment 1: cement-based composite water grate, its grate body is made of 23.63wt% fluoroaluminate cement; 7.15wt% water; 4.3wt% wollastonite fiber; 58.22wt% sand; 6.7wt% polyurethane Made of resin.

[0074] The specific manufacturing method is: divide the mold for preparing the grate body into several parts such as surface mold, core mold, side mold, bottom mold, and vibration source, etc., and make them separately. Put the side form on the support and connect it with the support spring, the vibration source is installed on the side form, and the rotation axis of the vibration source is parallel to the plane of the bottom form; the core form is fixed on the bottom plate of the side form; The bottom plate of the side form; the surface form passes through the mandrel and is placed on the upper part of the side form, and the surface form can be opened.

[0075] Use a two-speed high-shear mixer (high speed 900-1200 rpm; low speed 45-60 rpm), first mix cement, water, and...

Embodiment 2

[0084] Embodiment 2: cement-based composite water grate, the grate body is made of 34.06wt% colored cement; 9.54wt% water; 2.1wt% diabase fiber; 48.3wt% sand; 6wt% styrene resin. Its preparation method refers to embodiment one.

[0085] The bearing capacity of the obtained grate body is not less than 240KN, the self-weight is not more than 38KG, and the water-passing section is not less than 40% of the wellhead section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com