Method for manufacturing manhole cover or water grate cover

A technology for inspecting wells and water grates, which is applied in the field of manufacturing inspection well covers or water grate covers with autoclaved technology, and the field of unfixed cover plates with drain holes, which can solve the problems of easy cracking, anti-theft, and easy breakage. and other issues, to achieve the effect of light weight, obvious economic and social benefits, and high carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

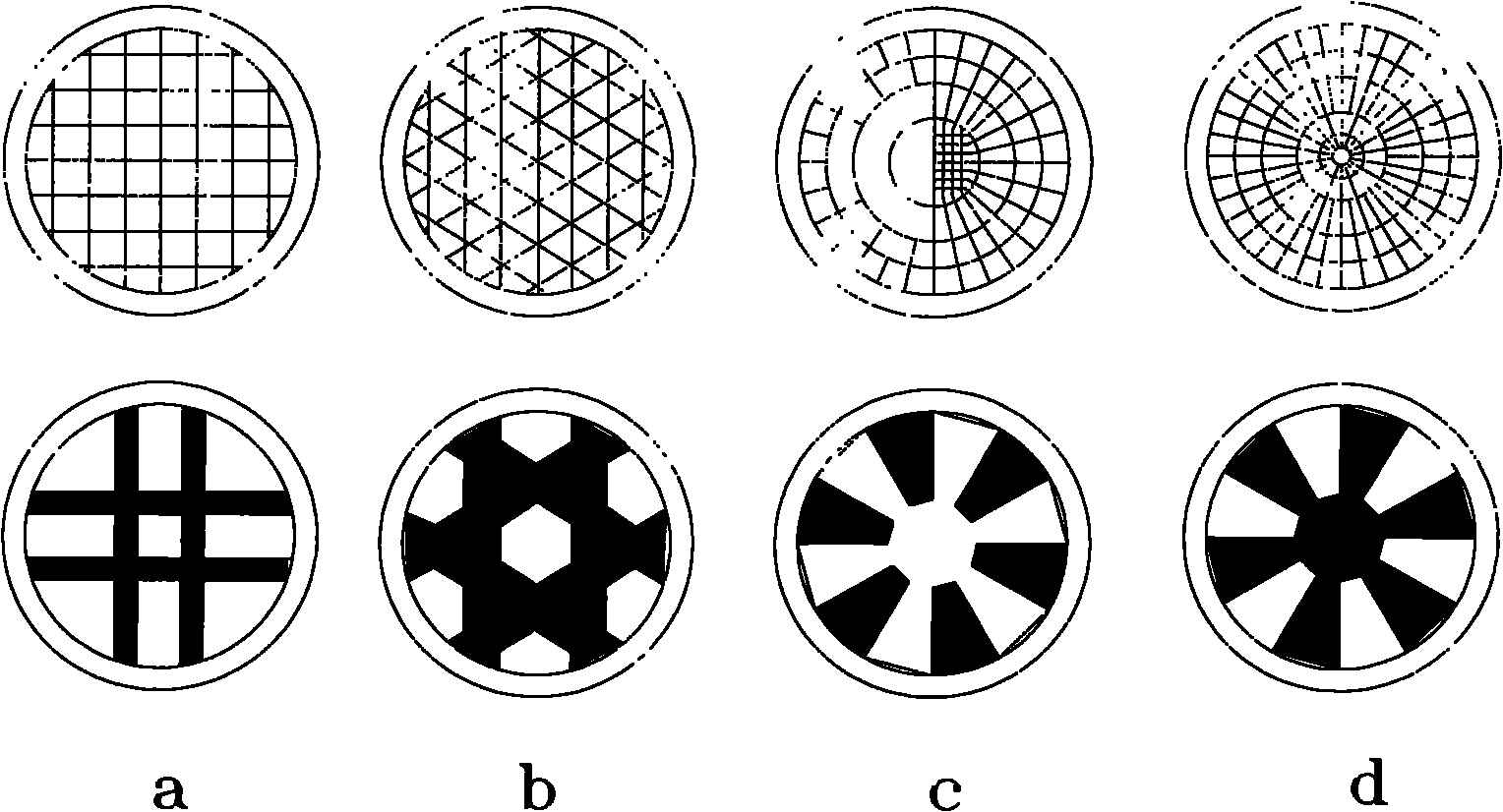

Image

Examples

Embodiment 1

[0026] Step 1, make the steel skeleton and arrange it in the manhole cover mold;

[0027] Step 2, mix evenly according to the ratio of P.I cement 238.0kg, sand 595.0kg, stone 1071.0kg, FDN3.0kg, ground quartz sand powder 71.4kg, water 80.0kg, lime 23.8kg, and prepare a concrete mixture;

[0028] Step 3, injecting the concrete mixture into the mould;

[0029] Step 4, curing at room temperature (25°C) for 3 days;

[0030] Step 5, autoclave at constant temperature for 6 hours in an autoclave with a saturated vapor pressure of 1.2MPa, and leave the autoclave;

[0031] Step 6, impregnating methyl methacrylate on the concrete substrate of the manhole cover.

Embodiment 2

[0033] Step 1, make the steel skeleton and arrange it in the manhole cover mold;

[0034] Step 2, according to the ratio of P.I cement 240.0kg, sand 624.0kg, stone 1152.0kg, polycarboxylate water reducer 3.1kg, ground quartz sand 72.0kg, wollastonite 24.0kg, water 73.5kg, mix evenly, and prepare concrete mix;

[0035] Step 3, injecting the concrete mixture into the mould;

[0036] Step 4, curing under steam curing (80°C) for 6 hours;

[0037] Step 5, autoclave at a constant temperature for 6 hours in an autoclave with a saturated vapor pressure of 1.2 MPa, and exit the autoclave.

[0038] Step 6, impregnating methyl methacrylate on the concrete substrate of the autoclaved manhole cover.

Embodiment 3

[0040] Step 1, making the reinforcement skeleton and placing it in the water grate cover mould;

[0041] Step 2, according to the ratio of P.I cement 240.0kg, sand 624.0kg, stone 1152.0kg, polycarboxylate water reducer 3.1kg, ground quartz sand 72.0kg, wollastonite 24.0kg, water 73.5kg, mix evenly, and prepare concrete mix;

[0042] Step 3, injecting the mixed concrete mixture into the mould;

[0043] Step 4, curing under steam curing (75°C) for 6 hours;

[0044] Step 5, autoclave at a constant temperature for 4 hours in an autoclave with a saturated vapor pressure of 1.0 MPa, and exit the autoclave.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com