Cable working well cover plate

A cable well, cover plate technology, applied in artificial islands, water conservancy projects, infrastructure engineering and other directions, can solve the problems of cover plate structure cracking, corrosion, heavy weight, etc., to improve load-bearing capacity, long service life, cost Moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

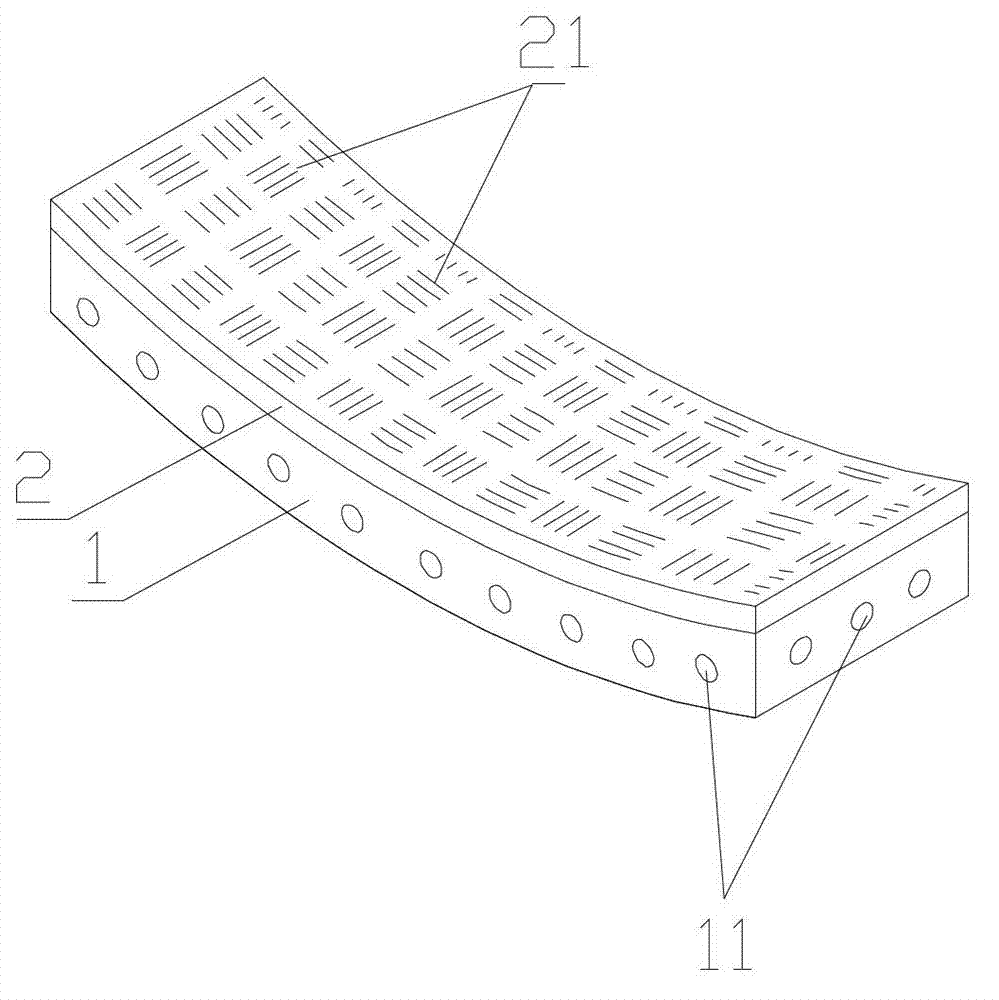

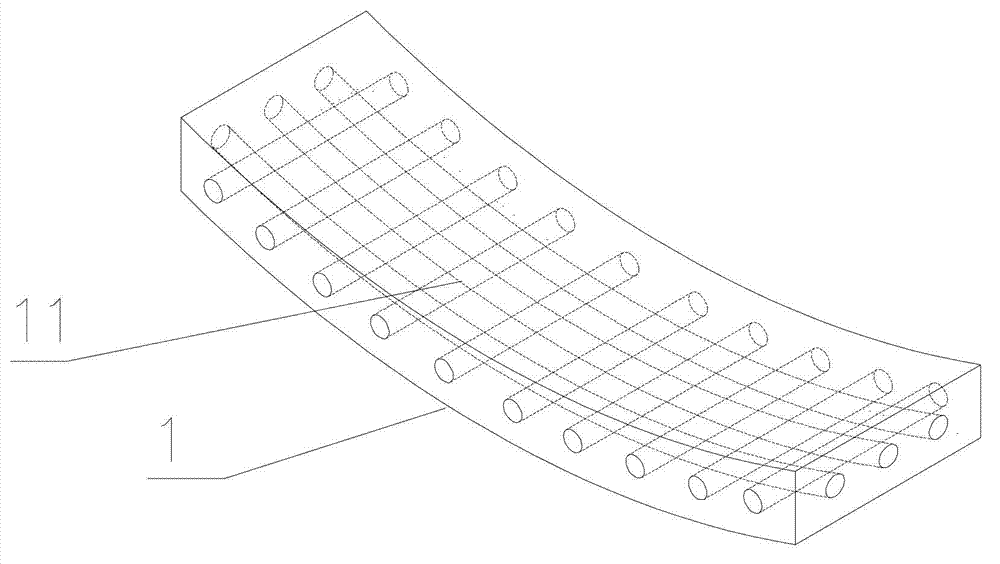

[0020] see figure 1 and figure 2 , the cableman's manhole cover of the present invention includes a load-bearing layer 1 and a non-slip layer 2 fixed (such as bonded) on the surface of the load-bearing layer 1, wherein:

[0021] The load-bearing layer 1 and the anti-slip layer 2 are all in the shape of a reverse arch bridge, so as to have better load-bearing capacity, and the specific size of the reverse arch bridge shape depends on the actual situation; The arch bridge is arc-shaped (such as figure 1 shown), the central angle of the arc is 40 degrees, and the radius of the circle where it is located is 220mm;

[0022] The anti-slip layer 2 is molded by a mass molding compound, and the surface of the anti-slip layer 2 is evenly arranged with anti-slip stripes 21 in the form of horizontal and vertical staggered forms. Compared with other types, such as figure 1 The anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com