Glass fiber reinforced plastic adhesive boundary sign bracket and production method thereof

A technology of reinforced plastic and glass fiber, which is used in road signs, buildings, roads, etc., can solve the problems of poor anti-aging performance, easy to break and damage, and short service life, and achieve strong anti-aging performance, long service life, and appearance. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A milky white glass fiber reinforced plastic attached delineator bracket, characterized in that:

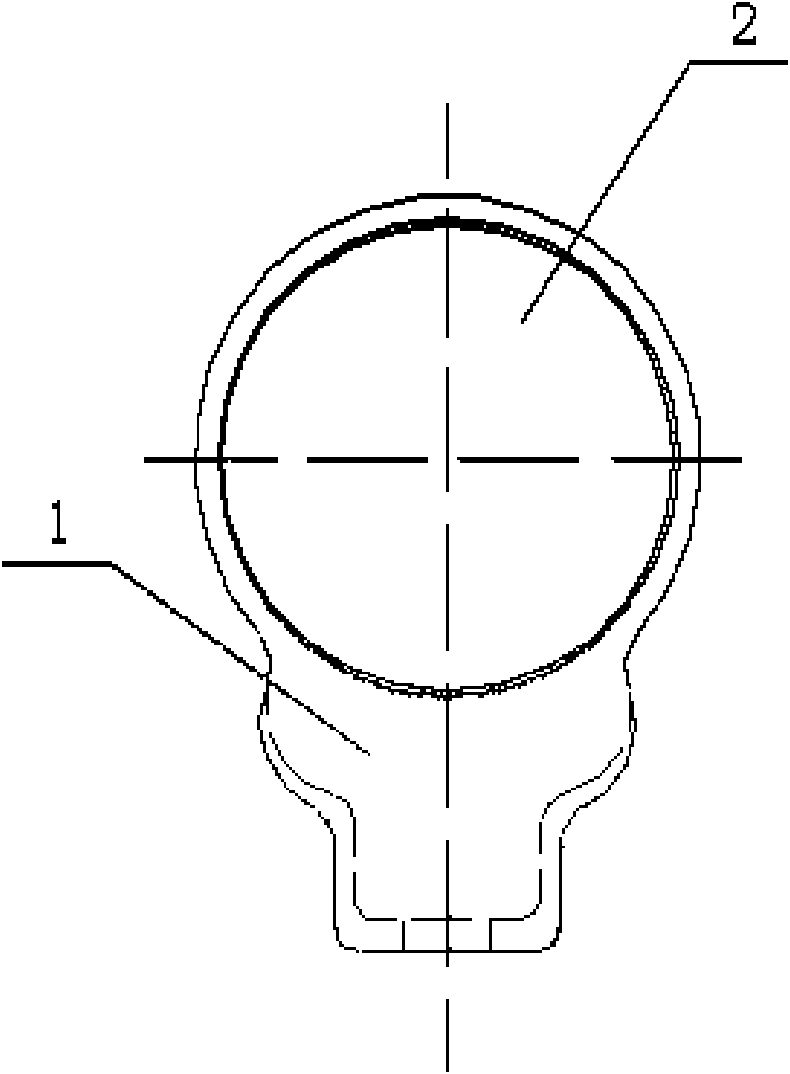

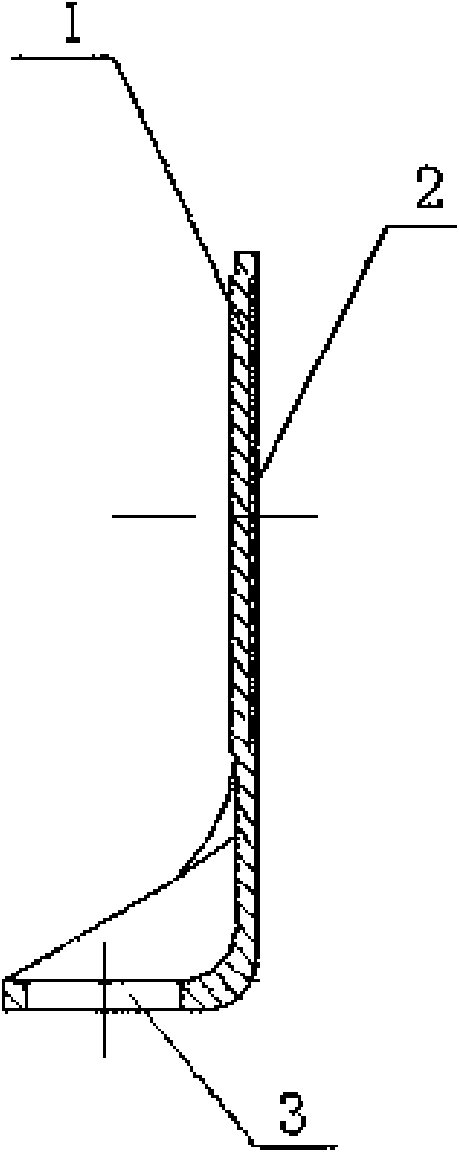

[0029] A. The delineator support 1 is an integral support molded by glass fiber reinforced plastic. The longitudinal section of the delineator support 1 is an L-shaped structure. The upper panel of the delineator support 1 is shaped like a table tennis racket, and the lower base is concave Shaped groove plate structure, the lower base of the support 1 is provided with a mounting hole 3 in the concave groove plate;

[0030] B. The height of the delineator support is 135-155mm, the thickness of the upper panel of the support 1 is 3.5-6mm, and the thickness of the lower base is 5-7.5mm.

[0031] Production method of the present invention is to be completed by following raw material and processing step:

[0032] The weight proportion of each raw material described is:

[0033] Unsaturated polyester resin 26%

[0034] Polymer solution of polystyrene and styrene 7%

[0035] ...

Embodiment 2

[0045] A light gray glass fiber reinforced plastic attached delineator bracket, the structure, shape and geometric dimensions are the same as those of the first embodiment.

[0046] The production method of the present invention adopts the compression molding process to manufacture, and is completed by the following raw materials and process steps:

[0047] The weight proportion of each raw material is:

[0048] Unsaturated polyester resin 30%

[0049] Polymer solution of polystyrene and styrene 6%

[0050] Chopped glass fiber strands 25%

[0051] Ground calcium carbonate 36.7%

[0052] Carbon black 0.1%

[0053] tert-butyl fat 1%

[0055] Described each processing step is:

[0056] (1) Preparation of polystyrene and styrene polymer solution; dilute polystyrene with styrene, that is, add a portion of polystyrene to a container containing twice its weight of styrene solution, and use a stirrer to Stir until the polystyrene is completely disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com