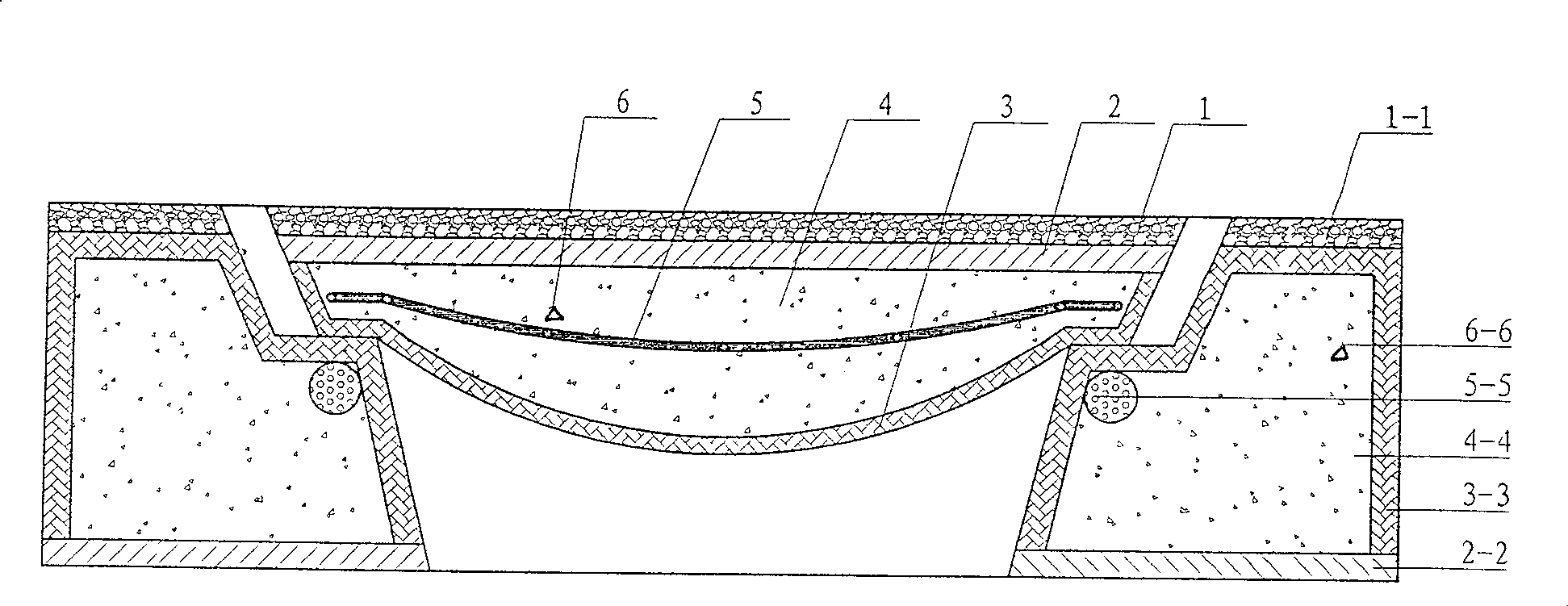

Manhole cover and method for producing same

A technology for inspecting wells and manhole covers, which is applied in the direction of chemical instruments and methods, layered products, artificial islands, etc., can solve the problems of heavy manhole covers, affecting performance, complex manufacturing process, etc., to enhance corrosion resistance and aging resistance, Improve the bearing capacity and service life, and the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Prepare various raw materials according to the process requirements and put them in the designated place for use. The composition of each part is as follows (percentage by weight):

[0045] Surface layer: functional resin 25%, quartz sand I 46%, corundum 10%, multicolored stone 8%, polypropylene fiber 5%, colorant 2%, anti-aging agent 2%, methyl ethyl ketone peroxide 1%, cobalt naphthenate 1%.

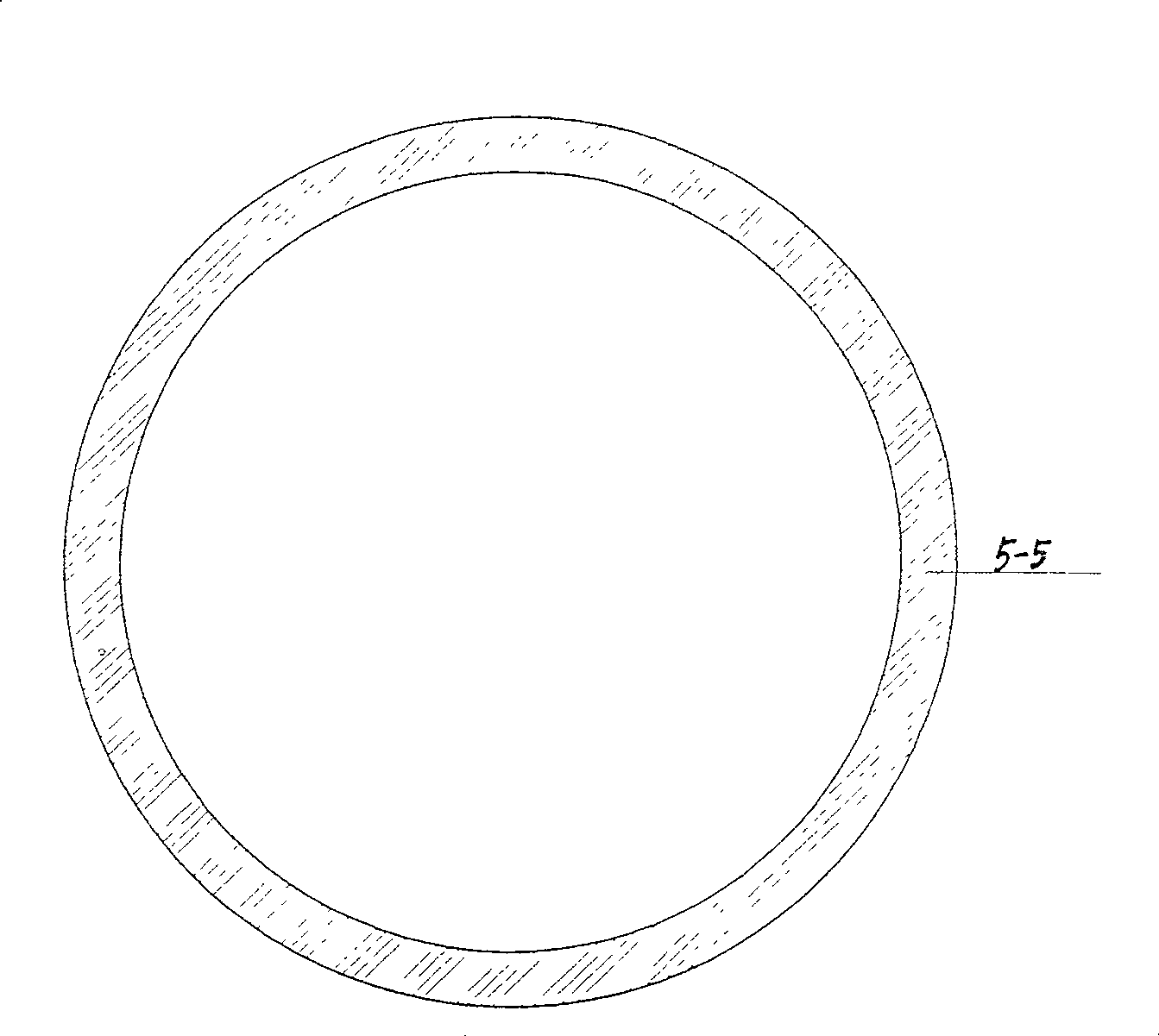

[0046] Reinforcing layer and outer layer: 60% functional resin, 38% glass fiber cloth, 1% methyl ethyl ketone peroxide, 1% cobalt naphthenate.

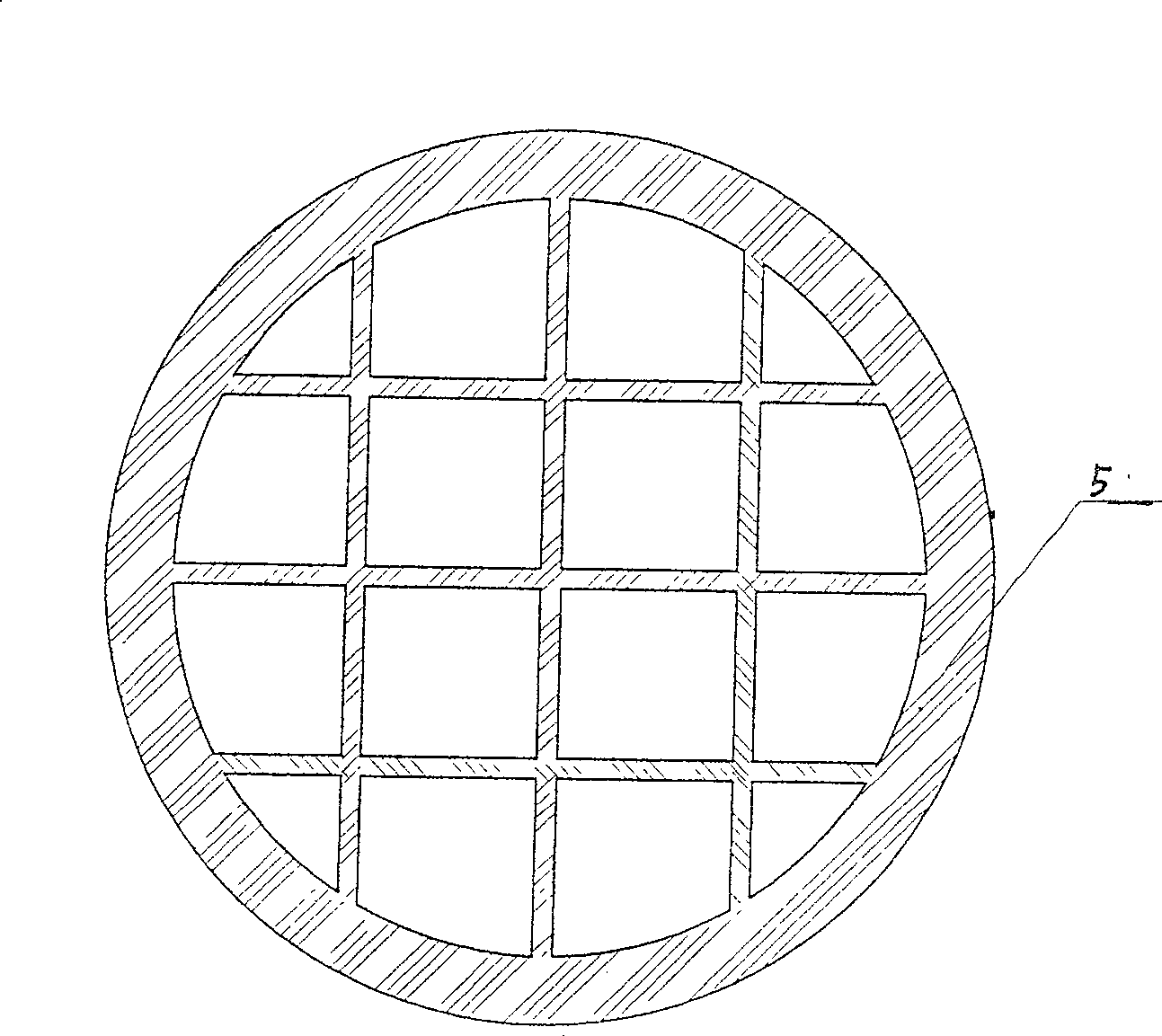

[0047] Rib: 36% functional resin, 55% glass fiber bundle, 8% carbon fiber bundle, 0.5% methyl ethyl ketone peroxide, 0.5% cobalt naphthenate.

[0048] Filler: 10% functional resin, 88% quartz sand II, 1% methyl ethyl ketone peroxide, 1% cobalt naphthenate.

[0049]The production is carried out according to the production process steps of well covers and well bases. The production cycle is controlled at 20 minutes. After the gel is so...

Embodiment 2

[0051] Prepare various raw materials according to the process requirements and put them in the designated place for use. The composition of each part is as follows (percentage by weight):

[0052] Surface layer: 30% functional resin, 36% quartz sand I, 20% corundum, 8% polypropylene fiber, 3% colorant, 1.5% anti-aging agent, 0.5% methyl ethyl ketone peroxide, 1.0% cobalt naphthenate.

[0053] Reinforcing layer and outer layer: functional resin 64%, glass fiber cloth 35%, methyl ethyl ketone peroxide 0.5%, cobalt naphthenate 0.5%.

[0054] Rib: 40% functional resin, 49% glass fiber bundle, 10% carbon fiber bundle, 0.5% methyl ethyl ketone peroxide, 0.5% cobalt naphthenate.

[0055] Filler: 20% functional resin, 35% quartz sand II, 30% waste glass fiber reinforced plastic slag, 13% river sand, 1% methyl ethyl ketone peroxide, 1% cobalt naphthenate.

[0056] The production is carried out according to the production process steps of well covers and well bases, and the production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com