Manhole cover made of composite material with glass fibre reinforcing bar structure

A technology of composite materials and reinforcing ribs, applied in underwater structures, infrastructure engineering, hydraulic engineering, etc., can solve the problems of anti-aging, poor anti-fatigue effect, affecting service life, poor bearing capacity, etc., and achieve anti-aging effect Good, extended service life, strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

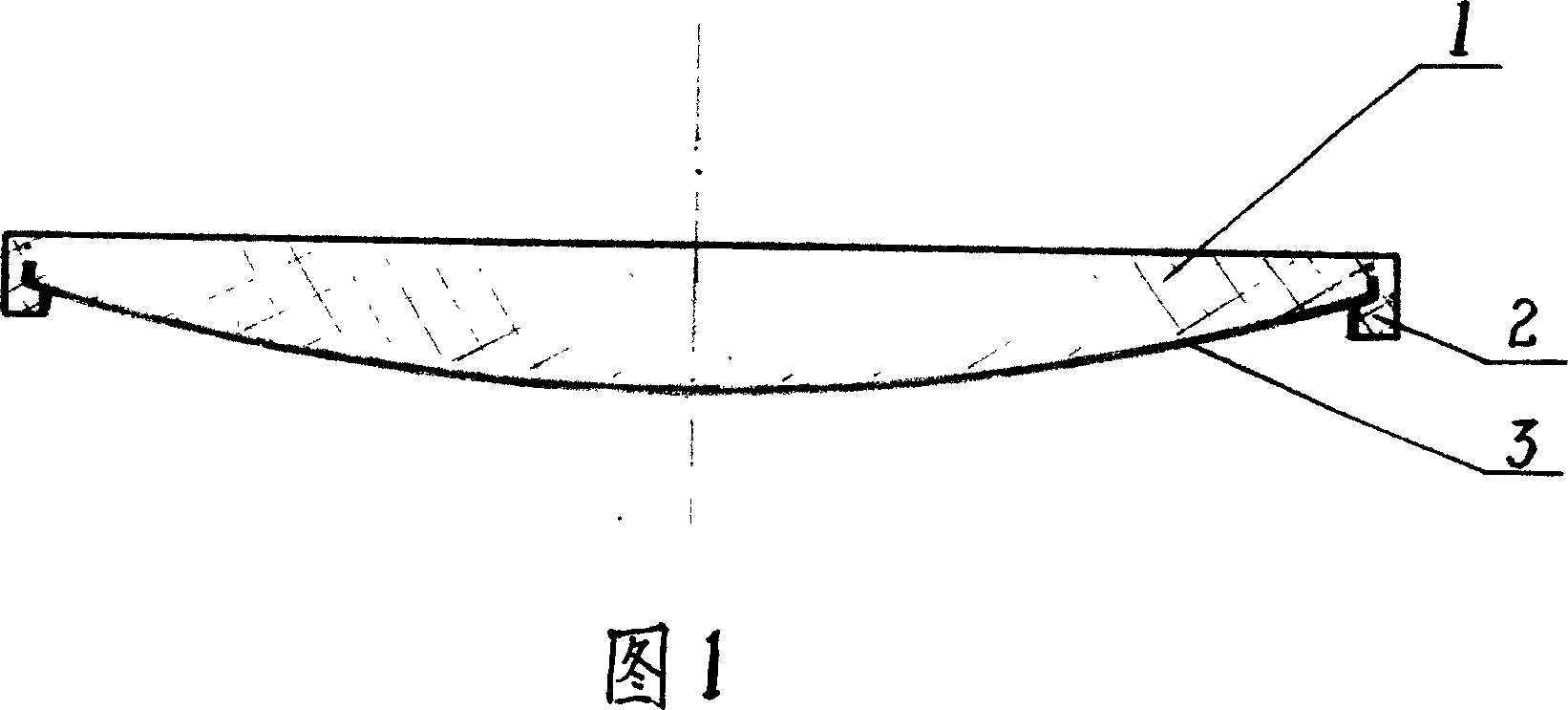

[0011] As shown in Figure 1, a composite material inspection well cover with a glass fiber reinforced rib structure is formed by a composite filler layer 1 and a glass fiber reinforced rib 3 through high-temperature molding. On surface 2, the periphery of glass fiber reinforced rib 3 is fastened and reinforced.

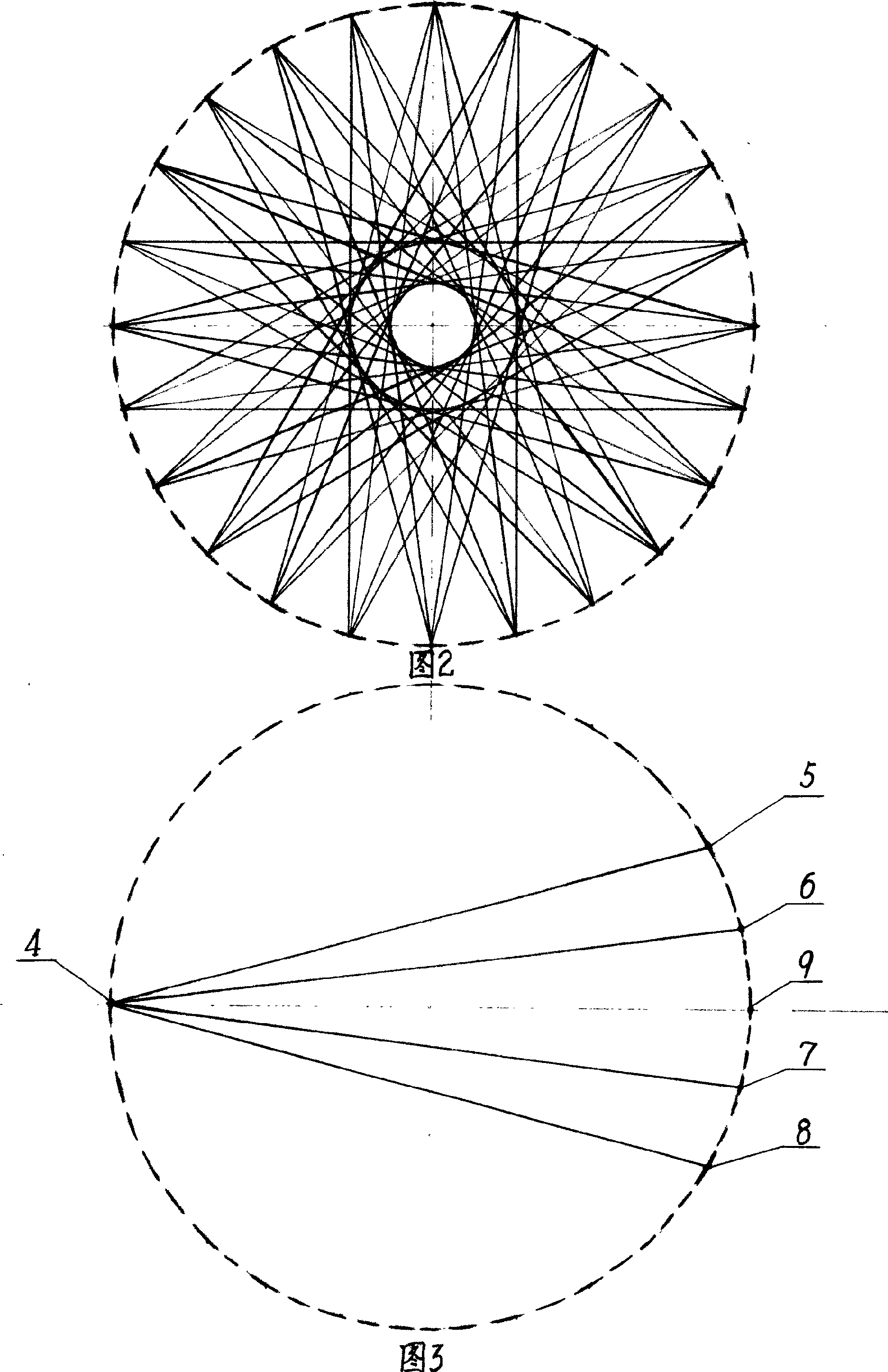

[0012] The glass fiber reinforced ribs 3 shown in Figures 2 and 3 are embedded in the back of the composite filler layer 1 in an arc shape, and 24 reinforcing rib endpoints are evenly distributed on the arc-shaped geometric circumference, and each endpoint is the intersection point 4 of four ribs. Two of the other endpoints are distributed on adjacent endpoints 6 and 7 on both sides of the symmetrical point 9 of the junction, and the other two endpoints are distributed on the second endpoints 5 and 8 on both sides of the symmetrical po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com