Reflective composite material well cover and preparation method thereof

A technology of composite materials and reflective materials, which is applied in the field of modification of polymer composite materials, can solve the problems of easy damage, weak luminous intensity, and high production costs, so as to improve the dispersion effect, improve the uniformity, and avoid the deterioration of the workshop environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Proportion according to the following mass percentage composition: polypropylene 30.8% (brand PPH1315, Korean LG company), long glass fiber reinforced polypropylene masterbatch 35% (brand FHLFTG-50PP, Wuxi Longglass New Material Technology Co., Ltd.), talc Powder masterbatch 20% (commercially purchased conventional model), barium sulfate masterbatch 5% (commercially purchased conventional model), ethylene-octene copolymer 3% (brand 8200, DuPont, USA), high-refractive glass beads 5% ( Refractive index 2.2, Tianjin Ruida Xinhua Abrasives Co., Ltd.), 0.1% each of antioxidant 1010 and 168 (Swiss Ciba), 1% calcium stearate (commercially available). Except for high-refractive glass beads, the above-mentioned materials are accurately weighed and added to a high-speed mixer for 10 minutes, and then the above-mentioned materials that have been stirred evenly are added to a pressurized tumbling internal mixer, and the temperature in the internal mixing chamber is controlled at 170 ...

Embodiment 2

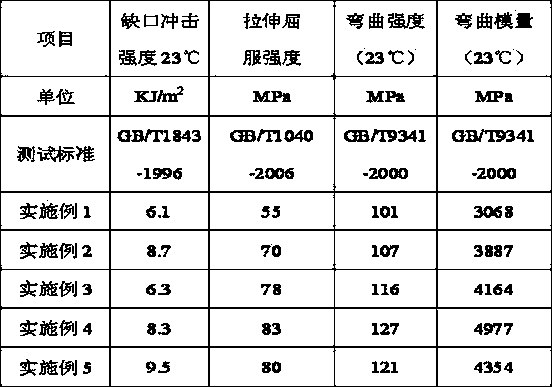

[0042] Proportion according to the following mass percentage composition: polypropylene 18.8% (brand PPH1315, Korean LG company), long glass fiber reinforced polypropylene masterbatch 45% (brand FHLFTG-50PP, Wuxi Longglass New Material Technology Co., Ltd.), talc Powder masterbatch 20% (commercially purchased conventional model), barium sulfate masterbatch 5% (commercially purchased conventional model), ethylene-octene copolymer 6% (brand 8200, DuPont, USA), high-refractive glass beads 4% ( Refractive index 2.2, Tianjin Ruida Xinhua Abrasives Co., Ltd.), 0.1% each of antioxidant 1010 and 168 (Swiss Ciba), 1% calcium stearate (commercially available). Its processing technology is with embodiment 1. (After cooling and crushing the melted blended material after banburying, standard test specimens were prepared by injection molding machine for physical and mechanical performance testing. The test results are shown in Table 1.)

Embodiment 3

[0044] Proportion according to the following mass percentage composition: polypropylene 17.8% (brand EPS30R, China Petrochemical Corporation Maoming Branch), long glass fiber reinforced polypropylene masterbatch 55% (brand B1050, Dongguan Suzhidao Polymer Material Co., Ltd. ), talcum powder masterbatch 15% (commercially available conventional model), ethylene-octene copolymer 8% (brand 8200, DuPont, USA), high-refractive glass beads 3% (refractive index 1.93, Tianjin Ruida Xinhua Abrasive Materials Co., Ltd.), 0.1% each of antioxidant 1010 and antioxidant 168 (Swiss Ciba), 1% calcium stearate (commercially available conventional model). Its processing technology is with embodiment 1. (After cooling and crushing the melted blended material after banburying, standard test specimens were prepared by injection molding machine for physical and mechanical performance testing. The test results are shown in Table 1.)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com