Luminescent material special for street manhole cover and preparation method thereof

A technology of special materials and luminescent materials, which is applied in the field of modification of polymer composite materials, can solve the problems of poor impact toughness of well covers, poor product toughness, and low production efficiency, so as to improve the dispersion effect, reduce luminance, and avoid workshop The effect of environmental degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

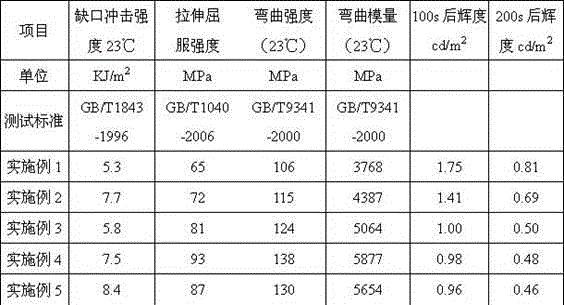

Embodiment 1

[0032]Proportion according to the following mass percentage composition: polypropylene 25.8% (brand PPH1315, South Korea LG company), long glass fiber reinforced polypropylene masterbatch 30% (brand B1050, Dongguan Suzhidao Polymer Material Co., Ltd.), talc powder masterbatch Granules 10% (commercially available type), barium sulfate masterbatch 10% (commercially available type), ethylene-octene copolymer 3% (brand 8200, DuPont, USA), aluminate-based light-storing self-luminous material 20% % (Chongqing Upstream Luminescent Materials Co., Ltd.), 0.1% each of antioxidant 1010 and antioxidant 168 (Swiss Ciba), 1% calcium stearate (commercially available conventional model). Accurately weigh the above-mentioned materials and add them to a high-speed mixer and stir for 10 minutes, then put the above-mentioned materials evenly stirred into a pressurized tumbling internal mixer, control the temperature in the internal mixing chamber to 170-180°C, and the rotor speed to 40r / min, the...

Embodiment 2

[0034] Proportion according to the following mass percentage composition: polypropylene 17.8% (brand PPH1315, South Korea LG company), long glass fiber reinforced polypropylene masterbatch 40% (brand B1050, Dongguan Suzhidao Polymer Material Co., Ltd.), talc powder masterbatch Granules 5% (commercially available type), barium sulfate masterbatch 15% (commercially available type), ethylene-octene copolymer 5% (brand 8200, DuPont, USA), aluminate-based light-storing self-luminous material 16 % (Chongqing Upstream Luminescent Materials Co., Ltd.), 0.1% each of antioxidant 1010 and antioxidant 168 (Swiss Ciba), 1% calcium stearate (commercially available conventional model). Accurately weigh the above-mentioned materials and add them to a high-speed mixer and stir for 10 minutes, then put the above-mentioned materials evenly stirred into a pressurized tumbling internal mixer, control the temperature in the internal mixing chamber to 170-180°C, and the rotor speed to 40r / min, the ...

Embodiment 3

[0036] Proportion according to the following mass percentage composition: polypropylene 13.8% (brand EPS30R, China Petrochemical Corporation Maoming Branch), long glass fiber reinforced polypropylene masterbatch 50% (brand B1050, Dongguan Suzhidao Polymer Material Co., Ltd. ), barium sulfate masterbatch 15% (conventional model purchased in the market), ethylene-octene copolymer 8% (brand 8200, DuPont Company of the United States), aluminate-based light-storing self-luminous material 12% (Chongqing Upstream Luminescent Material Co., Ltd. ), 0.1% each of antioxidant 1010 and antioxidant 168 (Swiss Ciba), 1% calcium stearate (commercially available conventional model). Accurately weigh the above-mentioned materials and add them to a high-speed mixer and stir for 10 minutes, then put the above-mentioned materials evenly stirred into a pressurized tumbling internal mixer, control the temperature in the internal mixing chamber to 170-180°C, and the rotor speed to 40r / min, the banbu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com