An impact-resistant well grate and manhole cover

A technology of impact resistance and well grate, which is applied in the field of public transportation drainage facilities, can solve the problems of high impact performance, low impact resistance, and shortened service life of the well grate, so as to improve the overall mechanical performance and impact resistance , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

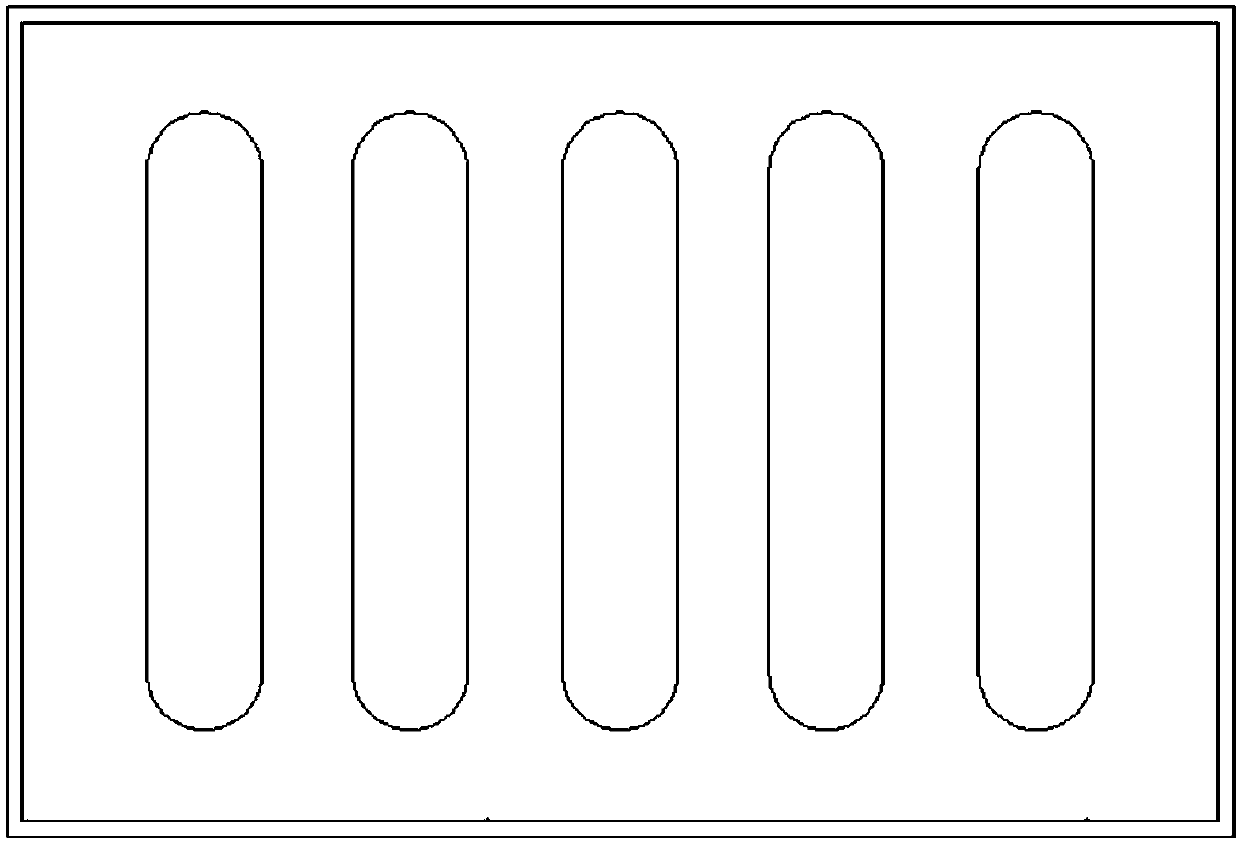

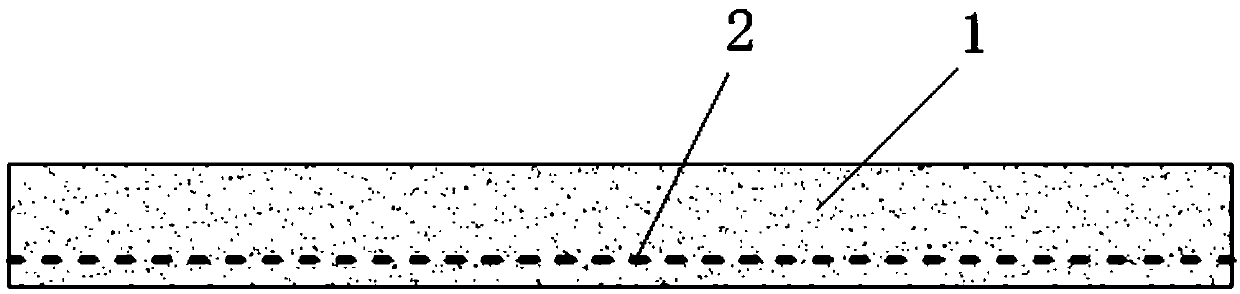

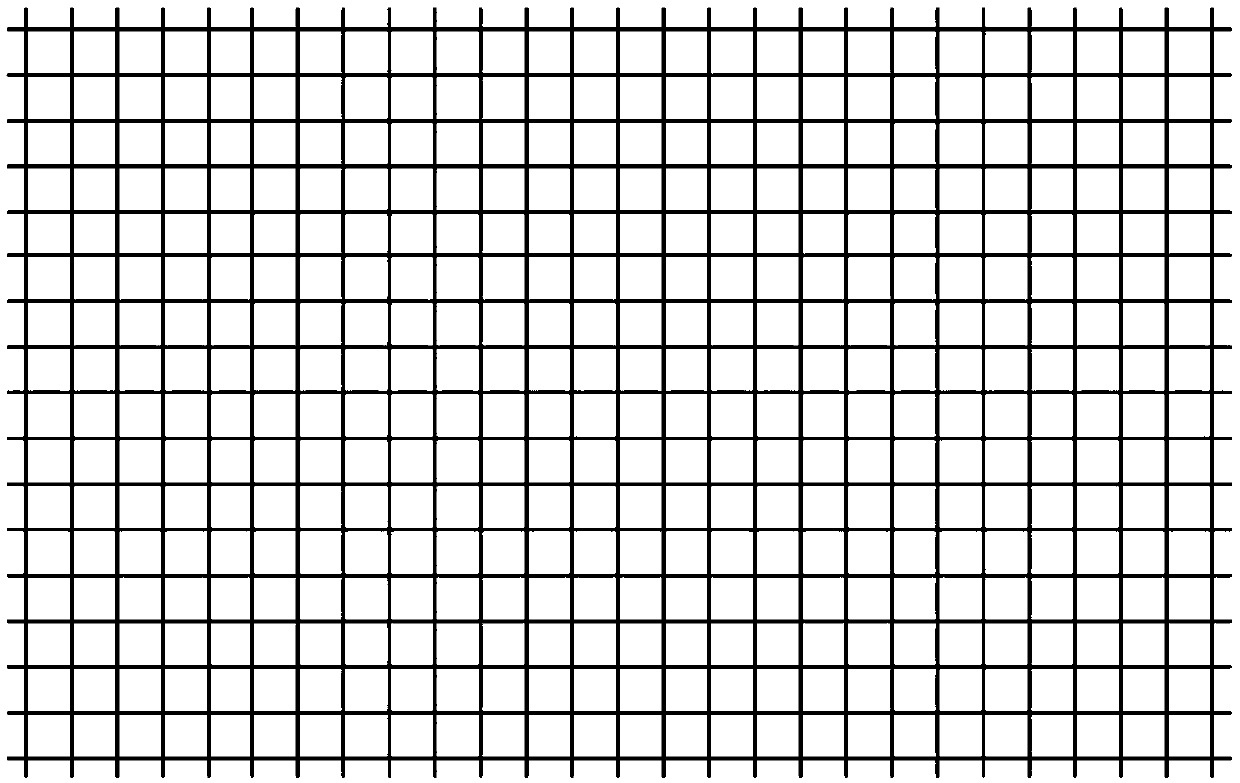

[0043] Such as figure 1 , figure 2 with image 3 As shown, an impact-resistant well grate includes a concrete body 1 and a carbon fiber mesh cloth 2 laid on the bottom of the concrete body 1. The material of the concrete body 1 is composed of the following components by weight: 1 part of cement, powder 1.2 parts of coal ash, 0.8 parts of sand, 0.001 parts of hydroxypropyl methylcellulose thickener, 0.0096 parts of polycarboxylate water reducer, 0.384 parts of water, the volume of polyvinyl alcohol fiber is 1 / 2 of the total volume of the concrete body 2%.

[0044] The specific coordination is as follows:

[0045] ECC material design mix ratio (accounting for cement proportion)

[0046]

[0047] The manufacturing method of the well grate mainly includes the following steps:

[0048](1) Pour cement, fly ash, thickener and quartz sand into the mixer for dry mixing;

[0049] (2) After the dry mixing is completed, add water and an admixture mixed solution to stir to obtain...

Embodiment 2

[0058] The difference from Example 1 is that the material of the concrete body 1 is composed of the following components in parts by weight: 1.2 parts of cement, 1.3 parts of fly ash, 0.6 parts of sand, and 0.0015 parts of hydroxypropyl methylcellulose thickener , 0.009 parts of polycarboxylate water reducer, 0.384 parts of water, and the volumetric dosage of polyvinyl alcohol fibers is 2% of the total volume of the concrete body.

[0059] Due to the obvious strain hardening performance of the prepared well grate, its uniaxial tensile strain can reach 5% to 5.5% stably, and it has strong impact resistance. Cracks will only begin to appear after 420 times of falling weight impact, reaching The state of being slightly cracked but not scattered.

Embodiment 3

[0061] The difference from Example 1 is that the material of the concrete body 1 is composed of the following components in parts by weight: 1.1 parts of cement, 1.4 parts of fly ash, 0.7 parts of sand, and 0.002 parts of hydroxypropyl methylcellulose thickener , 0.01 part of polycarboxylate water-reducer, 0.4 part of water, and the volume dosage of polyvinyl alcohol fiber is 2% of the total volume of the concrete body.

[0062] Due to the obvious strain hardening performance of the prepared well grate, its uniaxial tensile strain can reach 5% to 5.5% stably, and it has strong impact resistance. Cracks will only begin to appear after 410 times of falling hammer impact, reaching The state of being slightly cracked but not scattered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com