Multicolor composite material well cover and production process thereof

A composite material, multi-color technology, applied in artificial islands, water conservancy projects, other household appliances, etc., can solve the problems of non-wearability of the upper surface for promotion and application, the quality does not meet the bearing requirements, and the personalized design cannot be achieved. Achieve the effect of improving artistic value and cultural taste, good decorative effect, and no recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

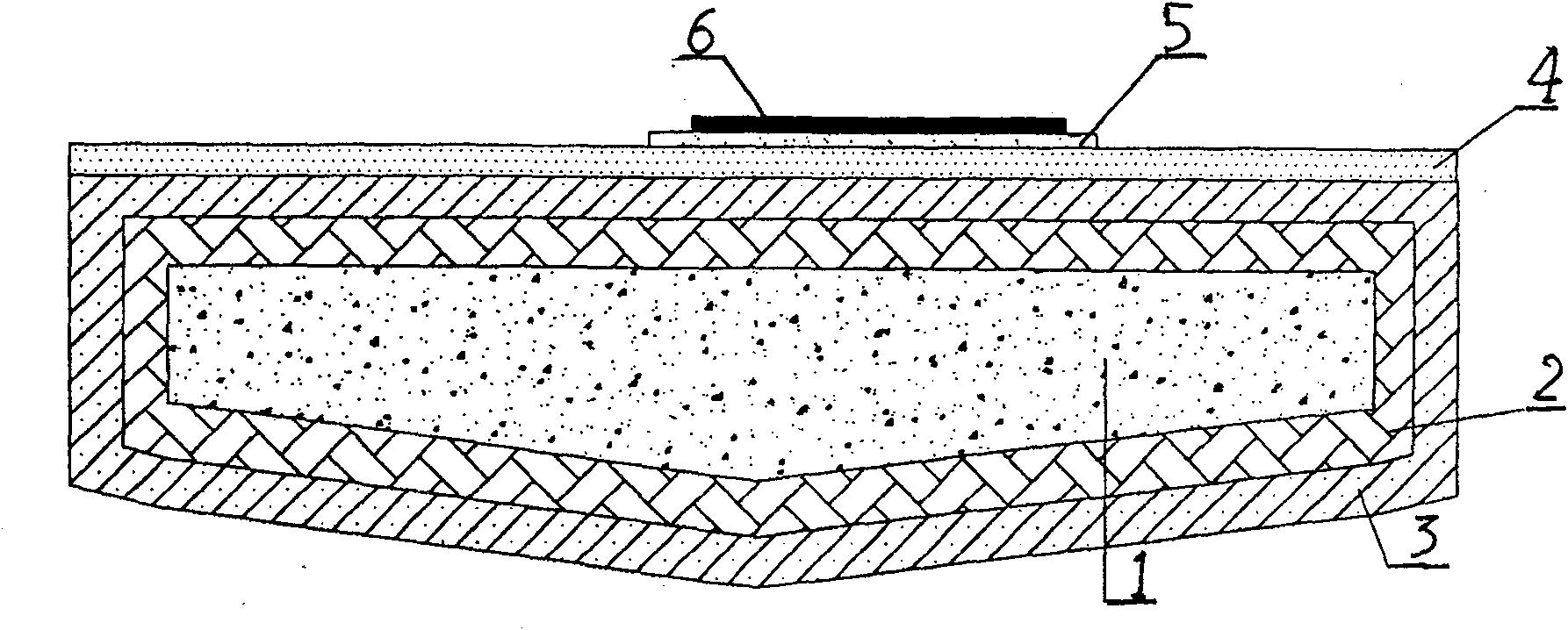

[0018] see figure 1 , The present embodiment consists of a core body 1, a network frame 2, a reinforcement layer 3, a color layer 4, a color isolation layer 5, and a color layer 6. The grid frame 2 is coated on the outer surface of the core body 1, the outer layer of the grid frame 2 covers the reinforcing layer 3, the color layer 4 is coated on the upper surface of the reinforcing layer 3, the upper surface of the color layer 4 is covered with a color layer 6, and the color isolation layer 5 It is arranged between the color layer 4 and the color layer 6 . The reinforcement layer 3 is 20mm thick, the color layer 4 is 10mm thick, and the color layer 6 is 4mm thick. Its production process is (a): the preparation of resin: add 1000 kilograms of marble resins into the raw material pool, and add 4 kilograms of cobalt isooctanoate accelerators, fully stir evenly, make the accelerators completely and evenly dispersed in the resin, and set aside; (b ) Preparation of color paste: in ...

Embodiment 2

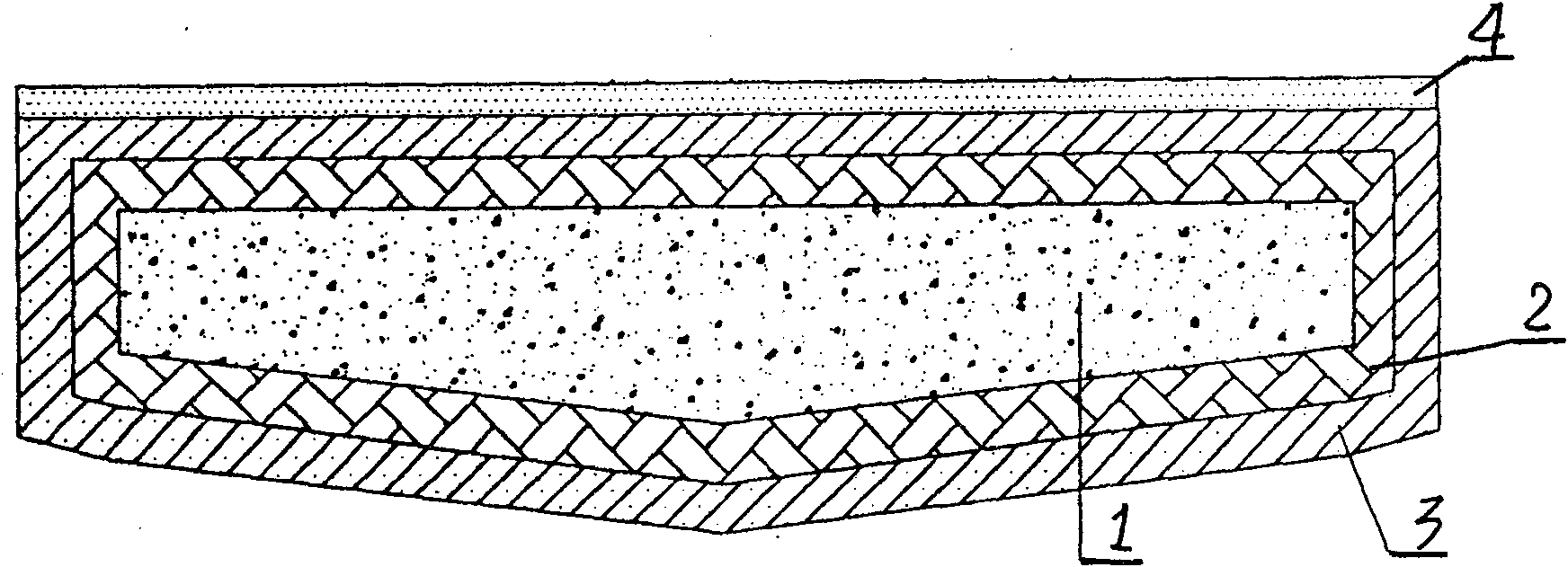

[0020] see figure 2 , this embodiment includes a core body 1, a network frame 2, a reinforcement layer 3, and a color layer 4. The network frame 2 is a reinforced steel network frame and a fiber prepreg network frame, and is coated on the exterior of the core body 1. On the network frame 2 The outer layer of the reinforcement layer covers the reinforcement layer 3, and the color layer 4 is coated on the upper surface of the reinforcement layer 3. The reinforcement layer 3 is 8mm thick, and the color layer 4 is 9mm thick. The 4 components of the color layer are proportioned by weight: for every 100 kilograms of resin A, add 0.8 kilogram of cyclohexanone peroxide curing agent, and then add 150 kilograms of agate powder and glass microsphere mixture to this mixture, wherein resin A The ratio is: 191 per 100 kg # Unsaturated polyester resin is mixed with 2 kilograms of cobalt naphthenate accelerator.

[0021] The production process is as follows: (a): preparation of resin A: f...

Embodiment 3

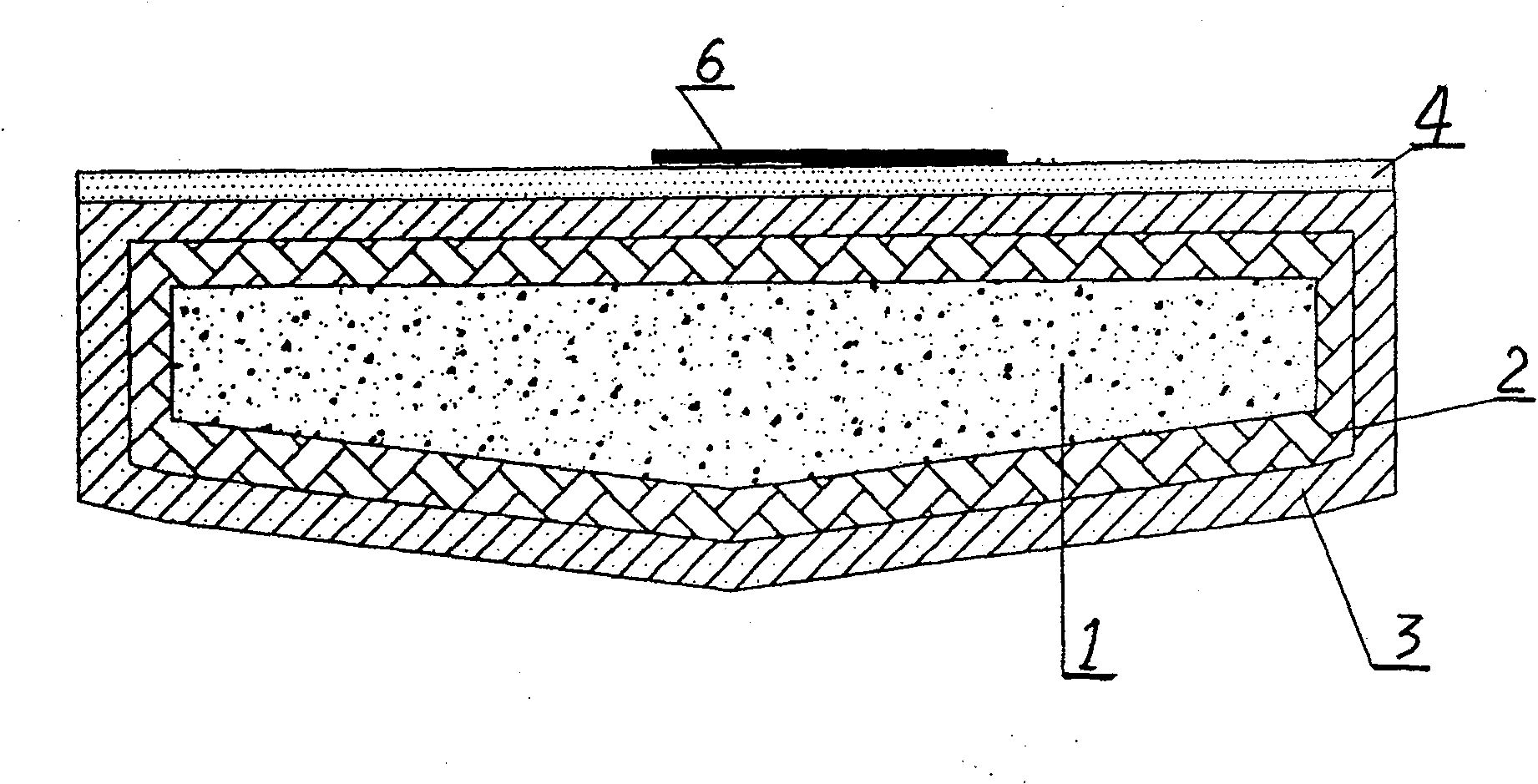

[0023] see image 3 , this embodiment includes a core body 1, a network frame 2, a reinforcement layer 3, a color layer 4 and a color layer 6. The grid frame 2 is a reinforced grid frame and a fiber prepreg grid frame, and is coated on the outside of the core body 1, and the outer layer of the grid frame 2 is covered with a reinforcement layer 3, and the color layer 4 is coated on the upper surface of the reinforcement layer 3 , the upper surface of the color layer 4 is covered with the color layer 6 . The reinforcement layer 3 is 10mm thick, the color layer 4 is 15mm thick, and the color layer 6 is 1mm thick. The proportioning of the color layer components is as follows: every 100 kilograms of resin A, add 0.5 kilogram of methyl ethyl ketone peroxide curing agent, then add 280 kilograms of colored stone powder and agate powder mixture in this mixture, wherein the proportioning of resin A is : 191 per 100 kg # The resin is mixed with 0.9 kg of cobalt isooctanoate accelerato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com