Easily-recycled high-barrier low-temperature heat-sealing packaging composite film and production method thereof

A low-temperature heat-sealing and composite film technology, which is applied in the field of packaging, can solve the problem that the barrier property is difficult to achieve, and achieve the effects of shortening the packaging sealing time, good application effect, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

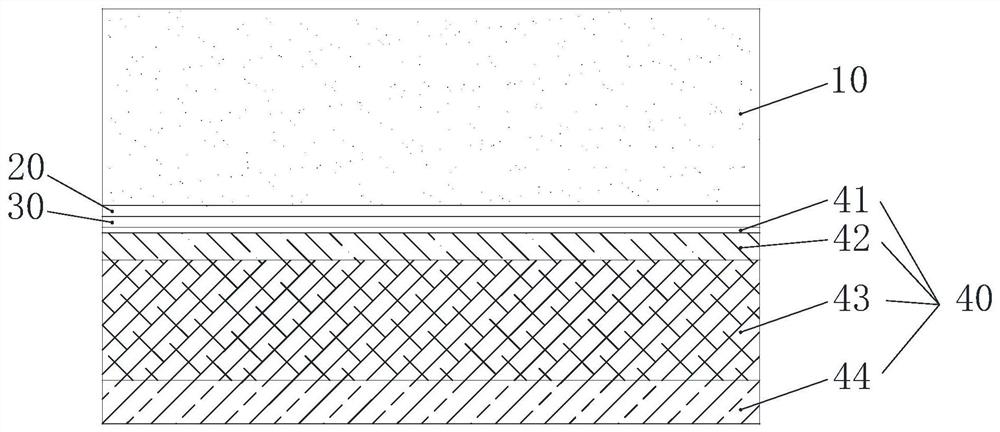

[0034] Such as figure 1 As shown, an easy-to-recycle high-barrier low-temperature heat-sealed packaging composite film is composed of a printed film 10 and an aluminized cast polypropylene film 40. The printed film 10 is a biaxially oriented polypropylene film BOPP or cast Polypropylene film CPP or polyethylene film PE. Aluminum-coated cast polypropylene film 40 (VMCPP) has a four-layer structure:

[0035] The first layer is an aluminum layer 41, and the printed film 10 is compounded on the surface of the aluminum layer 41;

[0036] The second layer is the composite layer 42, which is composed of 80%wt Borouge grade RD265 copolymerized PP resin of Borouge Petrochemical and 20%wt Japan Mitsui Chemicals grade MA9015 maleic anhydride grafted POE. Since the composite layer 42 adheres to the aluminum layer 41 , it needs to be easy to corona treatment and have high adhesion fastness to the aluminum layer 41 , and the lower the content of small molecules in the resin, the better. ...

Embodiment 2

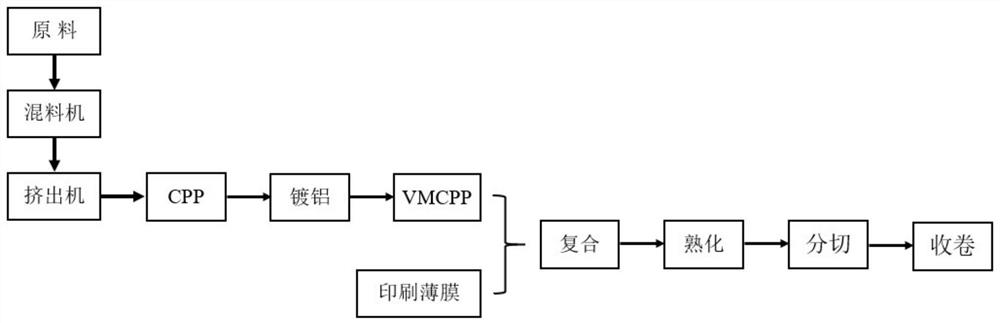

[0045] Such as figure 2 Shown, the production method of packaging composite film in embodiment 1, step is as follows:

[0046] S1. Prepare the raw materials of the aluminum-coated cast polypropylene film composite layer 42, the middle layer 43, and the heat-sealing layer 44 in proportion and mix them uniformly in a mixer, and then mix them according to the composite layer 42, the middle layer 43, and the heat-sealing layer. 44 arrangement sequence, utilizing extruder co-extrusion blown film, made cast polypropylene film CPP;

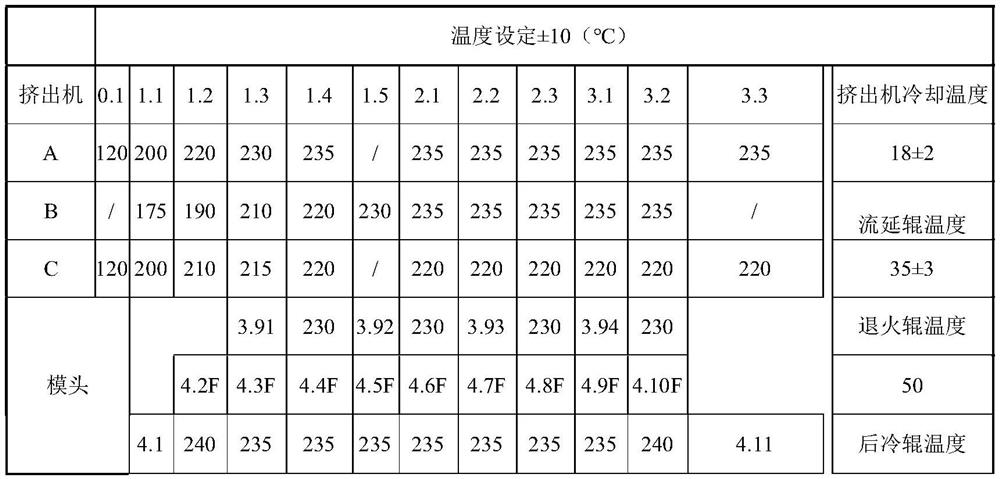

[0047] For the processing parameters in this part, please refer to Table 2:

[0048] Table 2 CPP processing parameters of cast polypropylene film

[0049]

[0050]

[0051] S2. Use low-temperature plasma to bombard the cast polypropylene film CPP, and then vapor-deposit aluminum on the surface of the composite layer 42 of the cast polypropylene film CPP to obtain an aluminum-coated cast polypropylene film 40 (VMCPP).

[0052] Before the cast po...

Embodiment 3

[0059] In the manner of Example 2, the 19 μm thick BOPP film and the 35 μm aluminized cast polypropylene film 40 were composited to test the performance of the composite film. Under the heat sealing pressure of 180KPa and the heat sealing time of 1s, the results are shown in the following table:

[0060] Table 4 Comparing the packaging composite film of the present invention with the prior art composite film heat-sealing performance

[0061]

[0062] Table 5 Packaging composite film of the present invention and prior art composite film performance comparison

[0063]

[0064] It can be seen from the above table that the packaging composite film prepared by the present invention has good heat sealing performance at 115°C, the heat sealing strength is 15-20N / 15mm, and the moisture permeability of the composite film is less than 0.5gm / m 2 24h, oxygen permeability is less than 1cc / m 2 ·24h, far superior to other packaging composite films, can well meet the requirements of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com