Compound resin hole cover and its manufacture method

A technology of composite resin and mixed resin, which is applied in the direction of manufacturing tools, artificial islands, underwater structures, etc., can solve the problems of poor toughness and rigidity, easy to be stolen, low strength, etc., and achieve good sealing performance, long service life, Good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

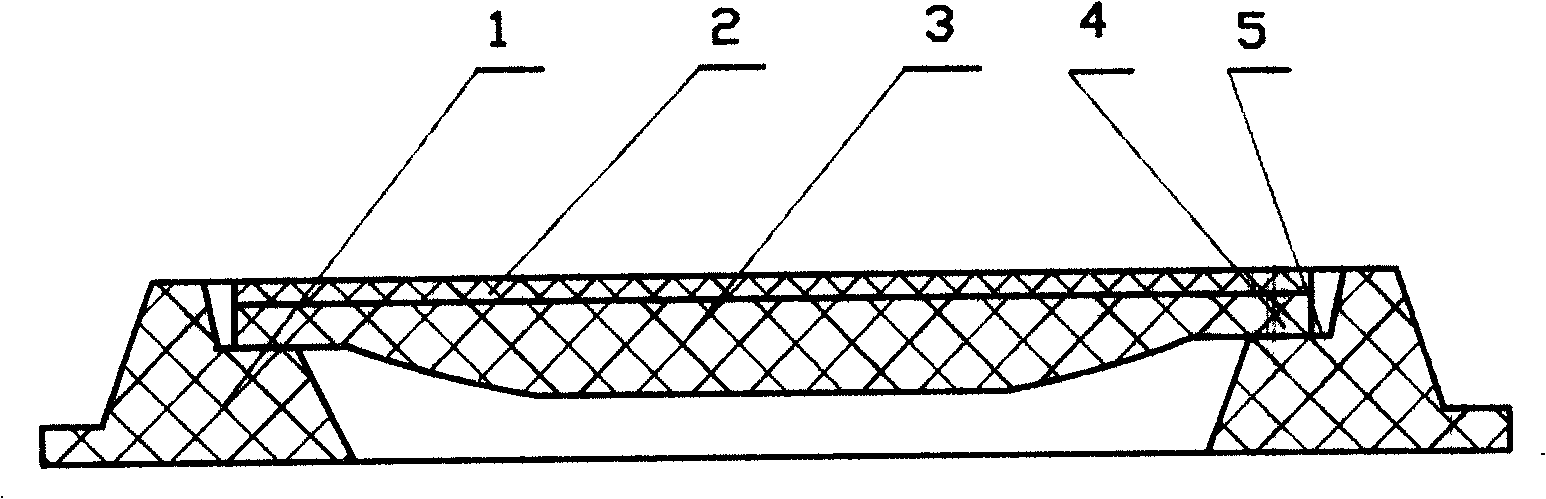

[0028] Example 1: A composite resin hole cover, containing an upper support 4 and a convex spherical boss 3 located in the middle and lower part of the upper support 4, the upper support 4 has a cover surface decoration layer 2, and the upper support 4 The outer periphery of is placed on the supporting surface 5 of the seat body 1. The materials used include unsaturated polyester resin, low-alkali glass fiber cloth, calcium carbonate, quartz sand, talc, methyl ethyl ketone peroxide curing agent and cobalt isozinic acid cobalt styrene solution accelerator, and also contain high-strength glass fiber tow Reinforced ribs made of mesh, including: resin 8 kg, glass fiber cloth and high-strength glass fiber tow made of reinforced rib 3.1 kg, calcium carbonate 3 kg, quartz sand 20.5 kg, talc powder 4.9 kg, methyl ethyl ketone peroxide The curing agent is 0.14 kg and the cobalt isozinate styrene solution accelerator is 0.07 kg.

[0029] The manufacturing method of the composite resin hole ...

Embodiment 2

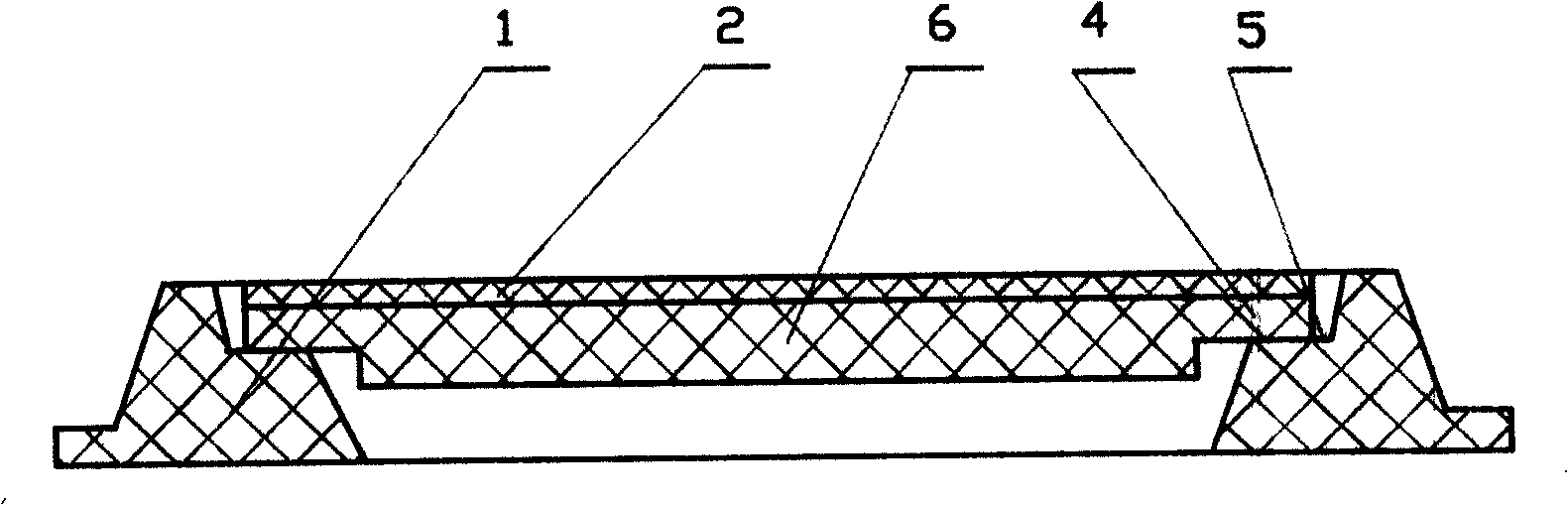

[0039] Embodiment two: a composite resin hole cover, containing an upper support body 4 and a convex cylindrical body 6 located in the middle and lower part of the upper support body 4, the upper support body 4 has a cover surface decoration layer 2, and the upper support body 4 The outer periphery is placed on the supporting surface 5 of the seat body 1. The materials used include unsaturated polyester resin, alkali-free glass fiber cloth, calcium carbonate, quartz sand, talc, methyl ethyl ketone peroxide curing agent and cobalt isozinate styrene solution accelerator, and also contain high-strength glass fiber tow Reinforced ribs made of a grid, including: 9 kg of resin, 6 kg of reinforcing ribs made of glass fiber cloth and high-strength glass fiber tow, 6.6 kg of calcium carbonate, 26.4 kg of quartz sand, 11.4 kg of talc, and methyl ethyl ketone peroxide Curing agent 0.24 kg and cobalt isozinate styrene solution accelerator 0.06 kg.

[0040] The manufacturing method of the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com