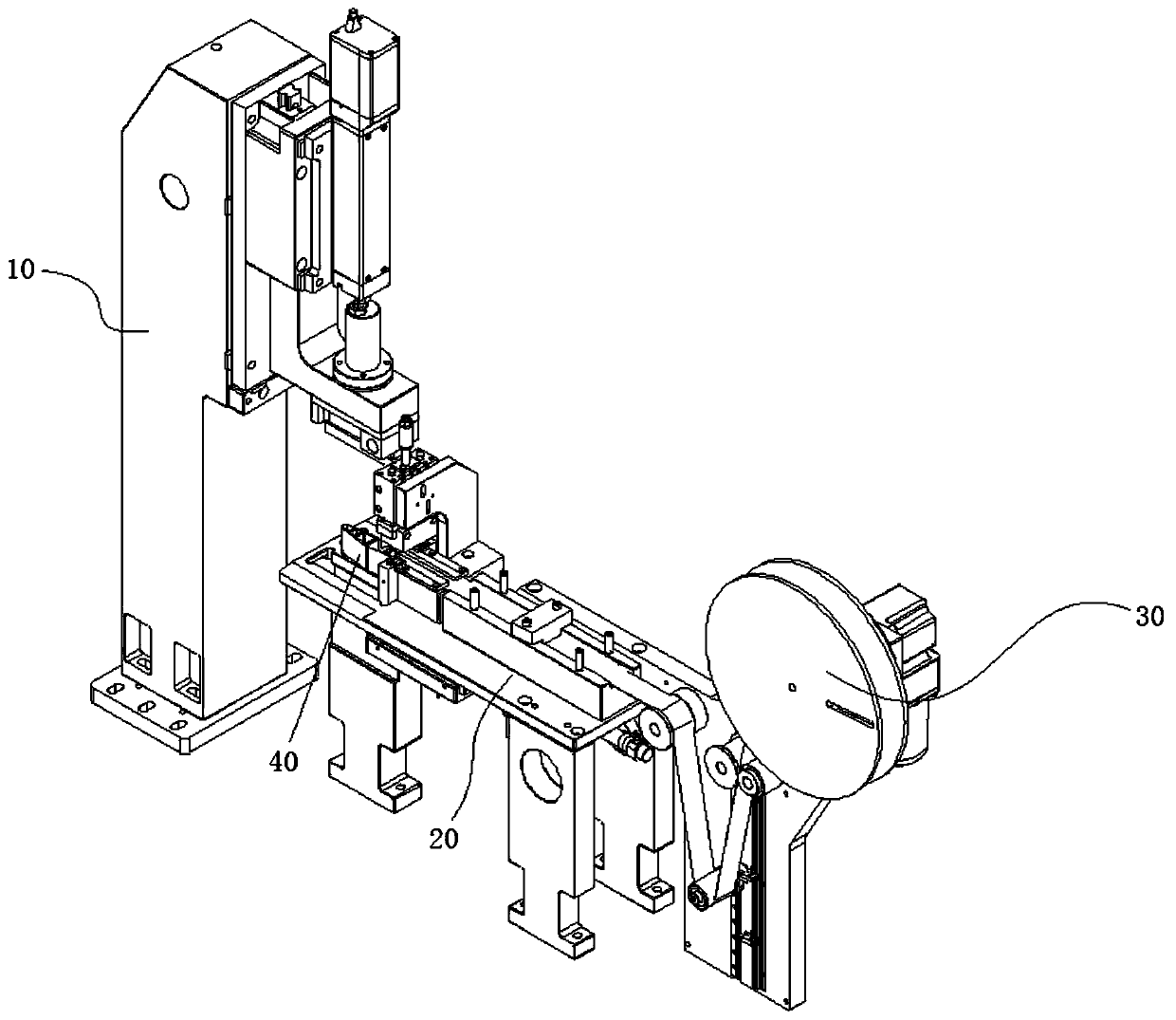

On-line heat sealing device

A technology of heat sealing device and mounting seat, which is applied in packaging, transportation packaging, transportation and packaging, etc., to achieve the effects of easy integration, low cost, and reduced sealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

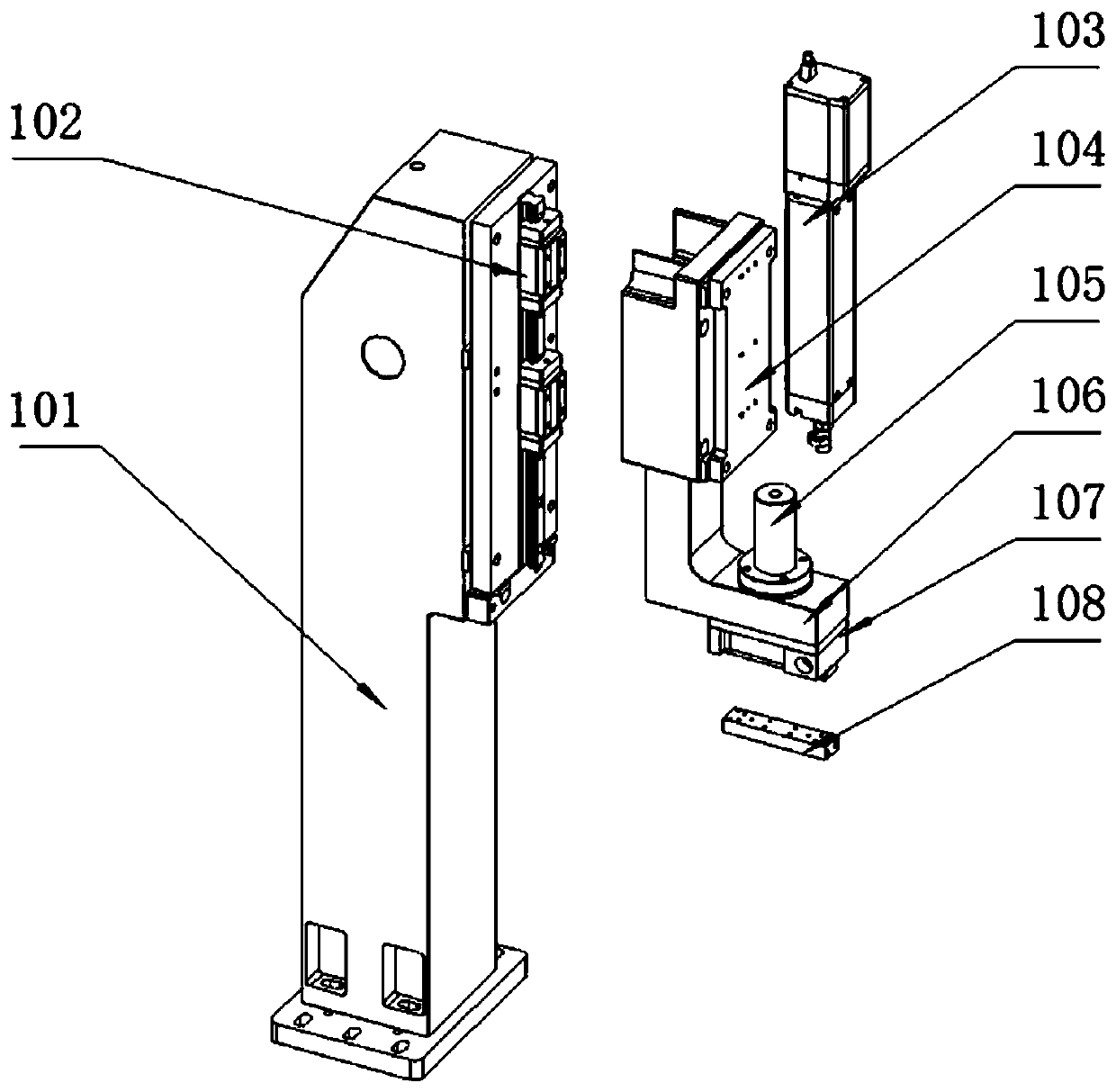

Method used

Image

Examples

Embodiment

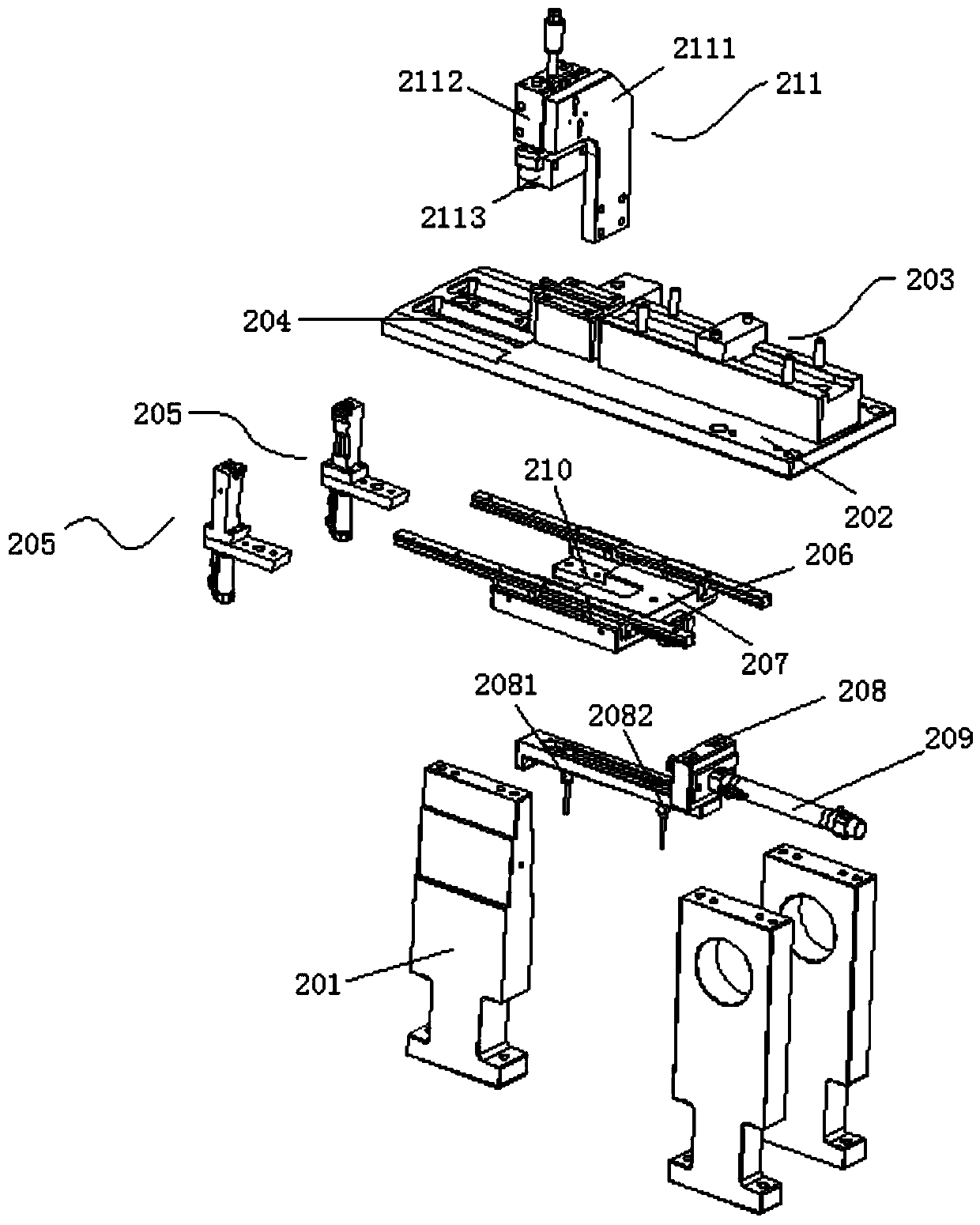

[0027] Such as Figure 6 As shown, the feeder 203 includes: a first feeder 2031, a second feeder 2032, a gap 2033 is provided at the front end of the first feeder 2031, a sandwich block 2053 is provided at the gap 2033, and the top of the first feeder 2031 A matching pressing plate 2034 is provided; three mounting pins 2035 are arranged on both sides of the top of the second material channel 2032 , and a pressing block 2036 is installed on the mounting pin 2035 in the middle of the top of the second material channel 2032 .

[0028] The clamping block 2053 cooperates with the lower stopper 2054 provided on the top of the clamping cylinder seat 2054, and is used to clamp the film at the gap at the front end of the first channel.

[0029] The film cutting mechanism 211 includes: a film cutting installation seat 2111, the film cutting installation seat 2111 is arranged on the fixed mounting plate 202, the film cutting installation seat 211 is provided with a film cutting cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com