Automatic break sealing machine for heat shrinking tube

An automatic cutting and sealing machine technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of unstable sealing quality, many sealing actions, and low sealing efficiency, so as to reduce sealing time and reduce sealing Action, the effect of reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

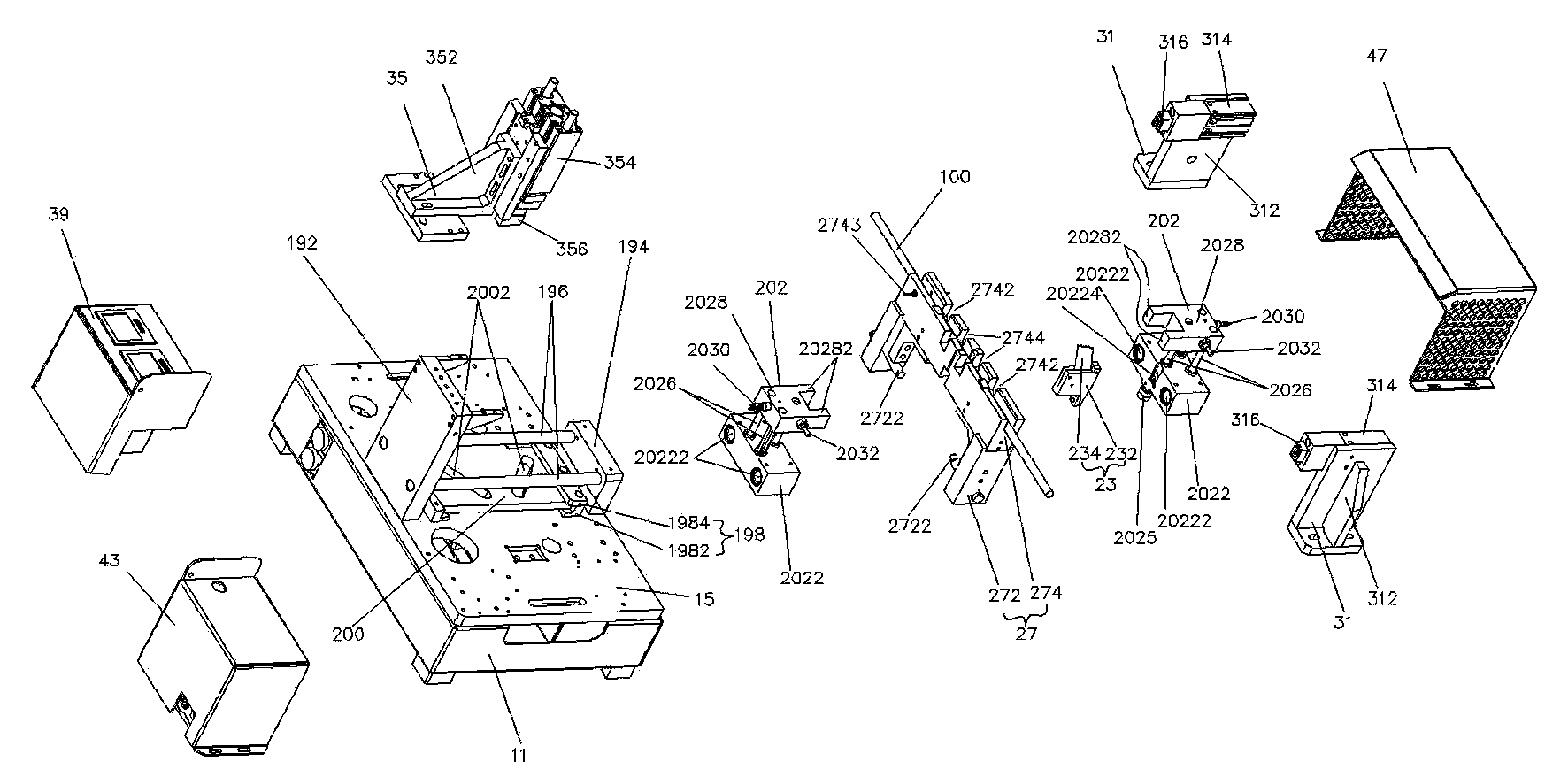

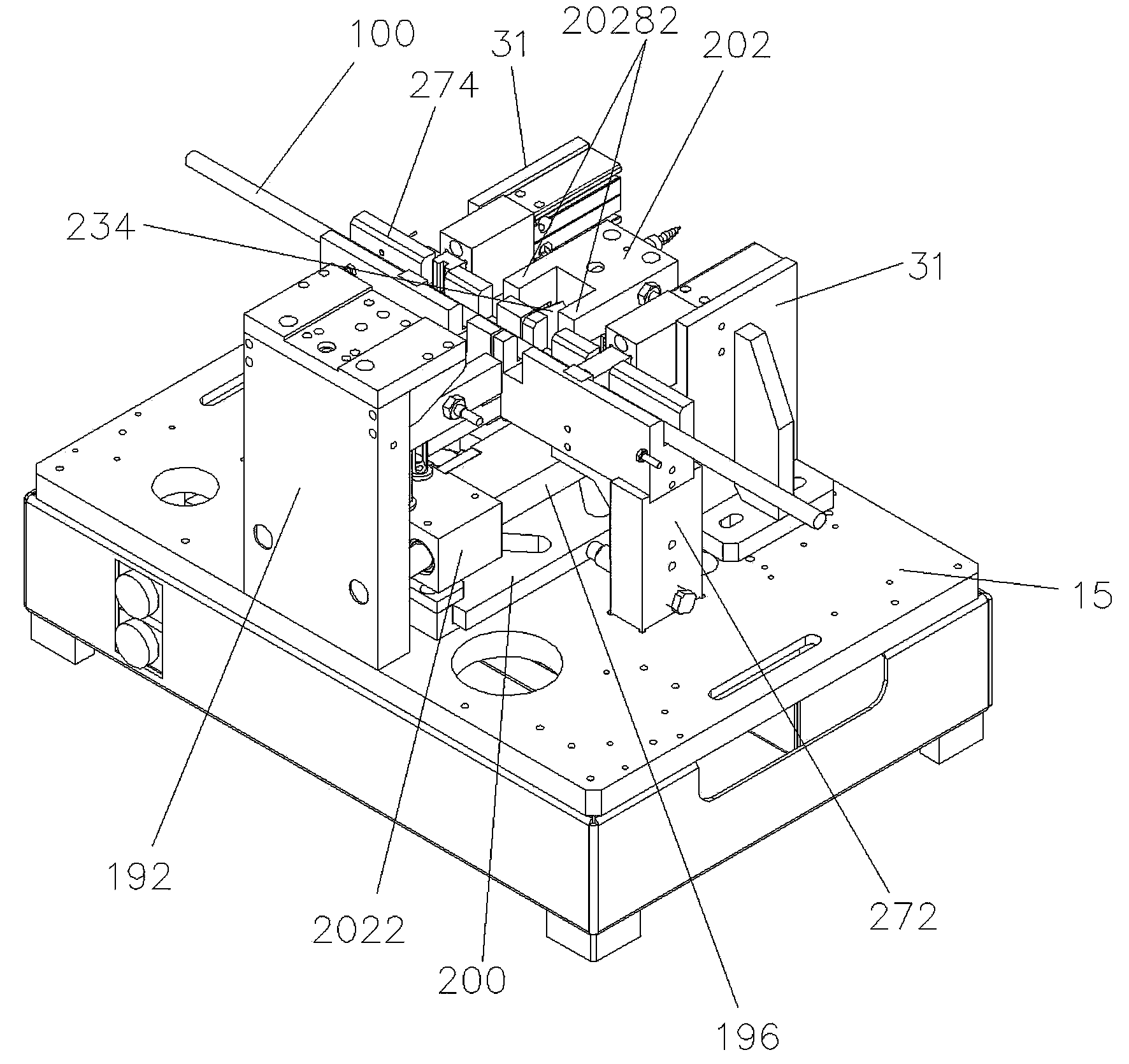

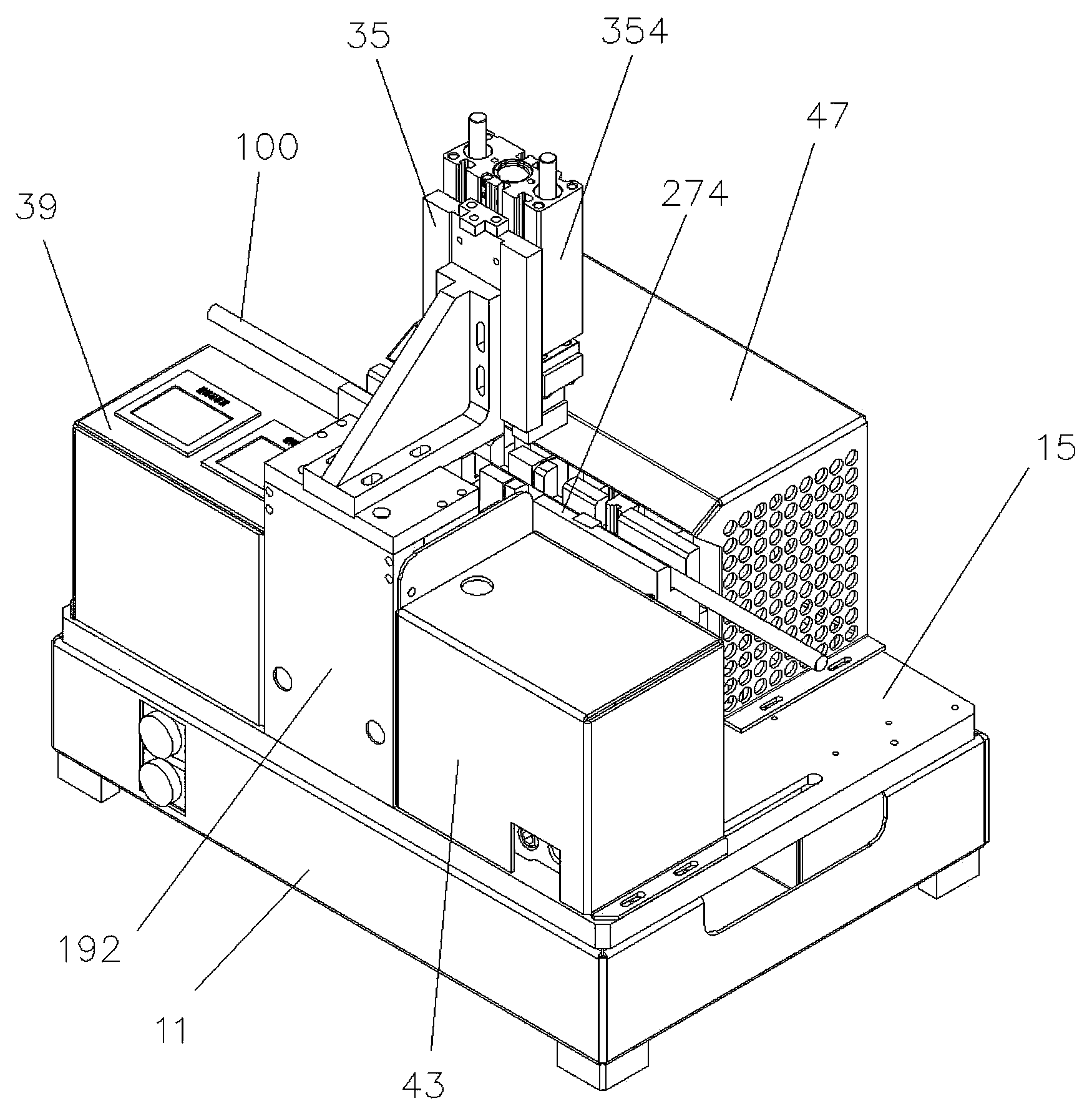

[0041] see Figure 1 to Figure 4 , a heat-shrinkable tube automatic cutting and sealing machine, including an electric control box 11, a mounting base 15, a heating mechanism (unlabeled), a cutting mechanism 23, a channel mechanism 27, two pressing and holding mechanisms 31, a Cooling compression mechanism 35, a temperature controller 39, a pneumatic control installation box 43, a safety shield 47.

[0042] A power switch (not labeled) is installed on the electric control box 11 .

[0043] The installation bottom plate 15 is fixedly installed on the top of the electric control box 11 .

[0044] The heating mechanism includes a front mounting block 192 , a rear mounting block 194 , two sliding rods 196 , two chute assemblies 198 , a stroke control sliding plate 200 , and two heating assemblies 202 .

[0045] The front mounting block 192 is fixedly mounted on the front edge of the mounting base 15 .

[0046] The rear mounting block 194 is fixedly mounted on the rear edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com