All hole depth different-diameter hole protecting and hole sealing system and method for deep-buried soft coal seam

A soft coal seam and hole sealing technology, which is applied in earthwork drilling, safety devices, sealing/isolation, etc., can solve the problems of gas leakage in gas drainage boreholes and low gas drainage efficiency, and improve the gas drainage rate , Improving the efficiency of drilling gas drainage and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

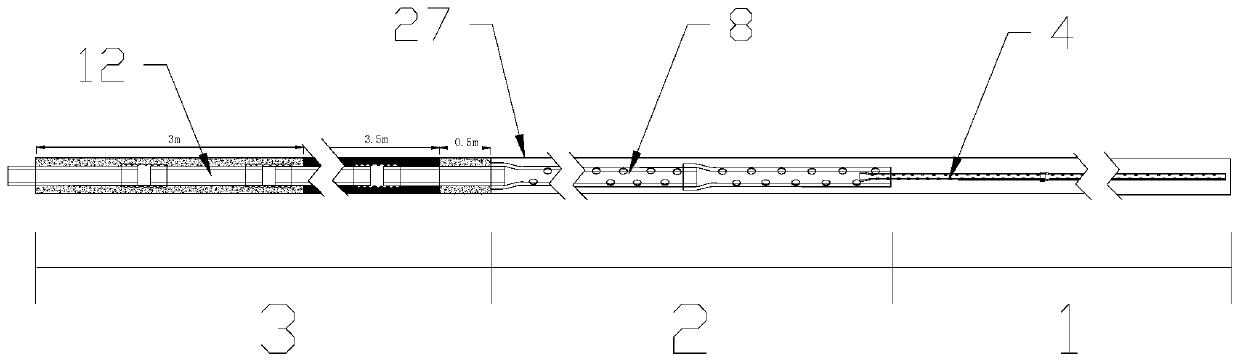

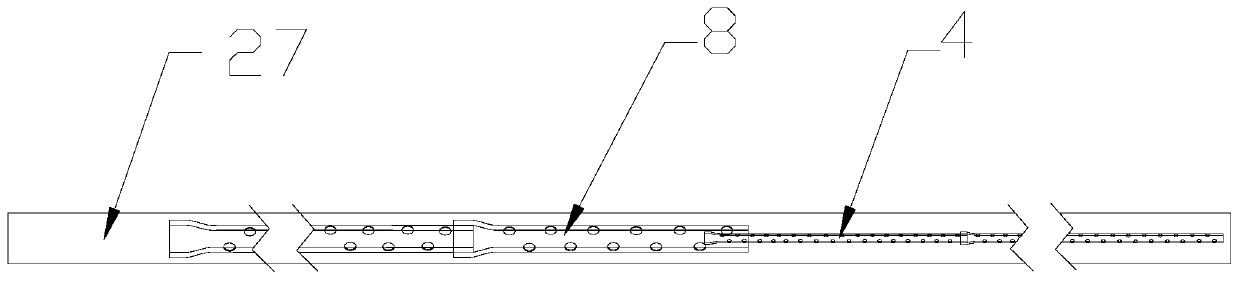

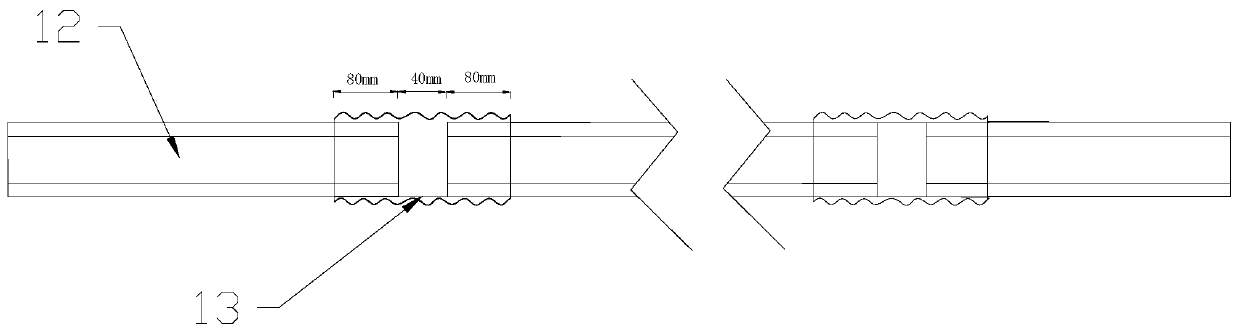

[0043] Such as Figure 1-2 As shown, a deep-buried soft coal seam full-hole deep different-diameter hole protection and sealing system includes small flower tubes 4 hole protection sections 1 and large flower tubes 8 hole protection sections 2 arranged in sequence from the bottom of the borehole 27 to the hole opening With the sealing section 3, the floret tube 4 hole protection section 1 is provided with a plurality of floret tubes 4 connected end to end along the borehole 27 axial direction, as Figure 7 and 8 As shown, the floret tube 4 includes a floret tube body 5 and a floret tube socket 6 arranged at one end of the floret tube body 5, the floret tube body 5 and the floret tube socket 6 are integrally structured, and the adjacent floret tubes 4 pass through the floret tube socket 6 are connected, and the floret tube socket 6 is positioned at the end of the floret tube body 5 towards the borehole 27 aperture. The material of the floret tube 4 is PVC double-resistance tu...

Embodiment 2

[0047] Such as Figure 1-13 Shown, a kind of deeply buried soft coal seam full-hole deep different-diameter protective hole sealing method comprises the following steps:

[0048] (1) After the construction of the borehole 27 for gas drainage is completed, the first large flower pipe 8 is sent into the borehole 27, and the second large flower pipe 8 is inserted into the large flower pipe holder of the first large flower pipe 8. In the mouth 10, push the second large flower tube 8 into the drill hole 27, so that the first large flower tube 8 is pushed into the deep part of the drill hole 27, and in this process, a plurality of large flower tubes 8 are pushed into the drill hole in sequence. In the hole 27, when the resistance increases significantly during the jacking process of inserting the Nth large flower tube 8, push the N and large flower tubes 8 deep into the borehole 27, so that the socket end of the Nth large flower tube 8 Part apart from the orifice of borehole 27 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com