Rod bundle channel flow pressure measurement experimental device

A rod beam channel and experimental device technology, which is used in nuclear reactor monitoring, reactor, nuclear power generation and other directions, can solve the problems of difficulty in measuring pressure distribution without disturbance, and achieve the effects of simple structure, accurate measurement and small angle error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

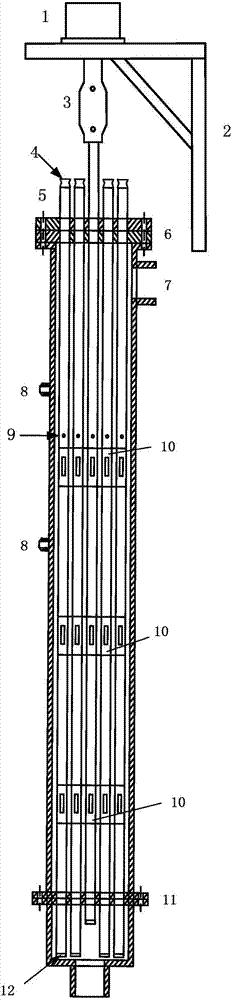

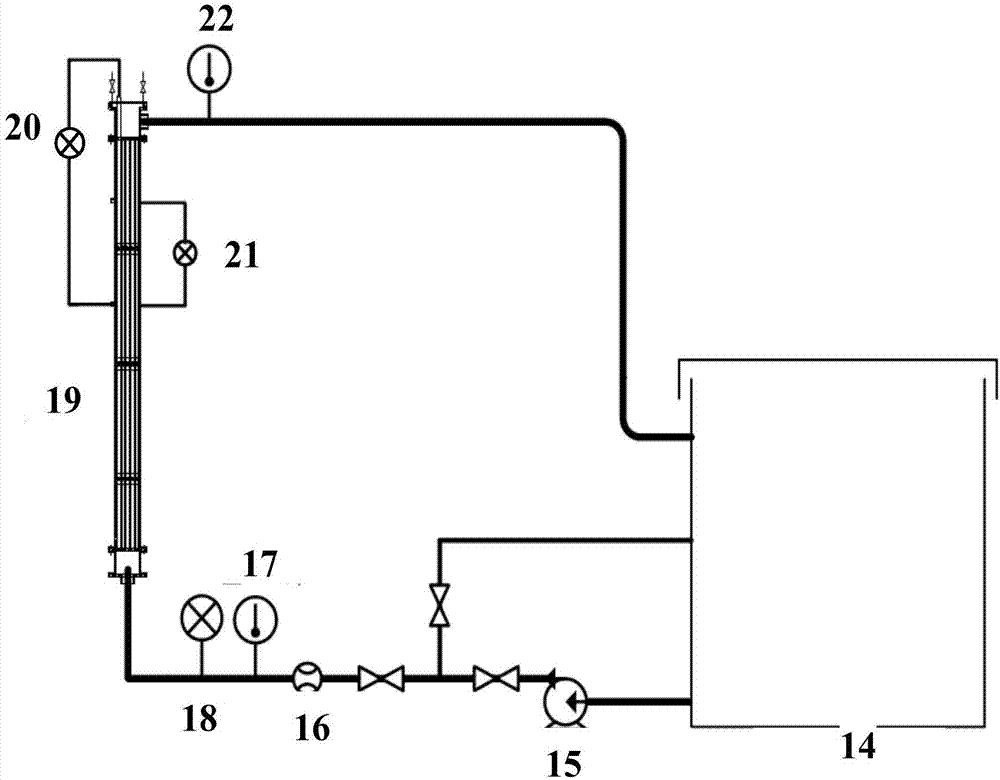

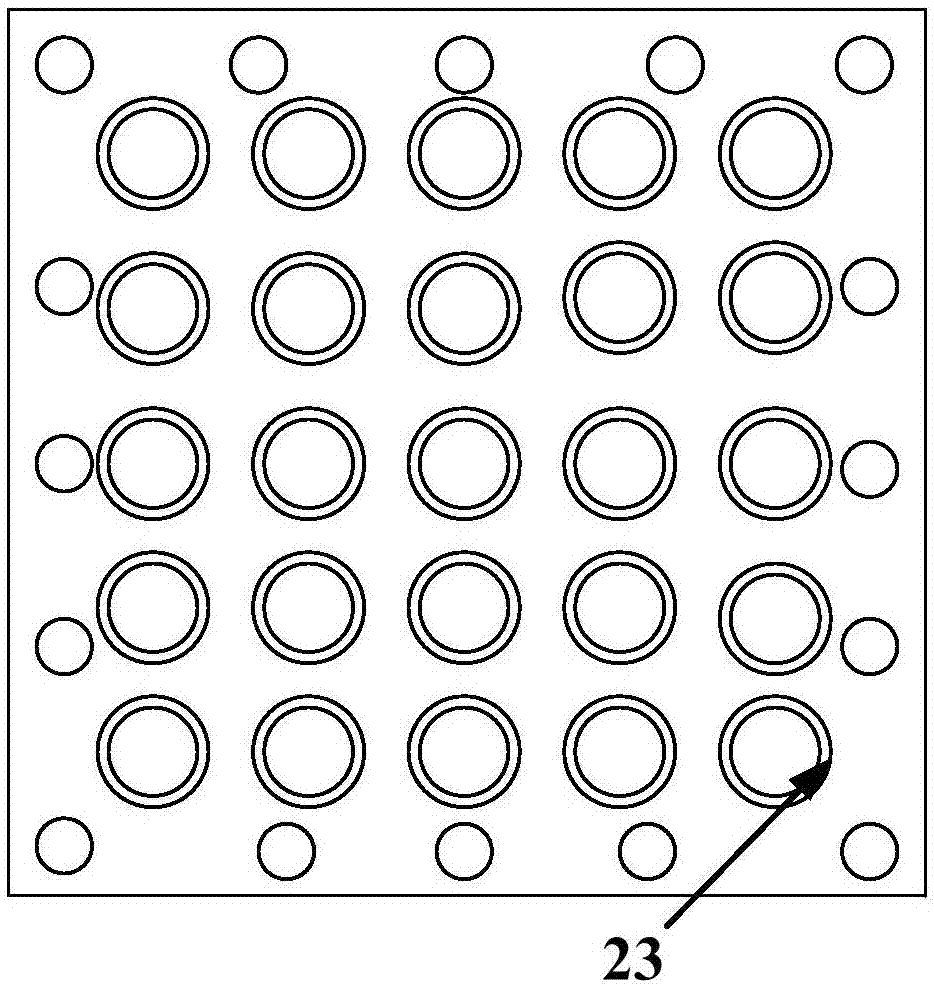

[0015] combine figure 1 The measuring body is used to measure the pressure distribution of the rod bundle channel, and realizes the measurement of the pressure drop along the rod bundle and the anisotropic pressure distribution caused by the positioning grid. The setting of the pressure measuring body mainly includes high-precision rotating disk 1, rotating table bracket 2, coupling 3, quick adapter 4, rod bundle (experimental rod bundle) 5, sealing flange group 6, outlet 7, pressure introduction hole of the body 8. The rod bundle pressure hole 9, the positioning grid 10, the positioning flange 11, the sealing rubber plug 12, the water inlet 13, the rod bundle channel composed of stainless steel rod bundles acts as a structural part in the channel in the measurement body, and at the same time It also acts as a part of the pressure pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com