Patents

Literature

33results about How to "Easy and flexible measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for measuring thickness of coatings through ultrasonic signal spectrum filter technology in nondestructive mode

ActiveCN103615996AAccurate measurementAccurate reading of propagating soundUsing subsonic/sonic/ultrasonic vibration meansUltrasonic thickness measurementSonification

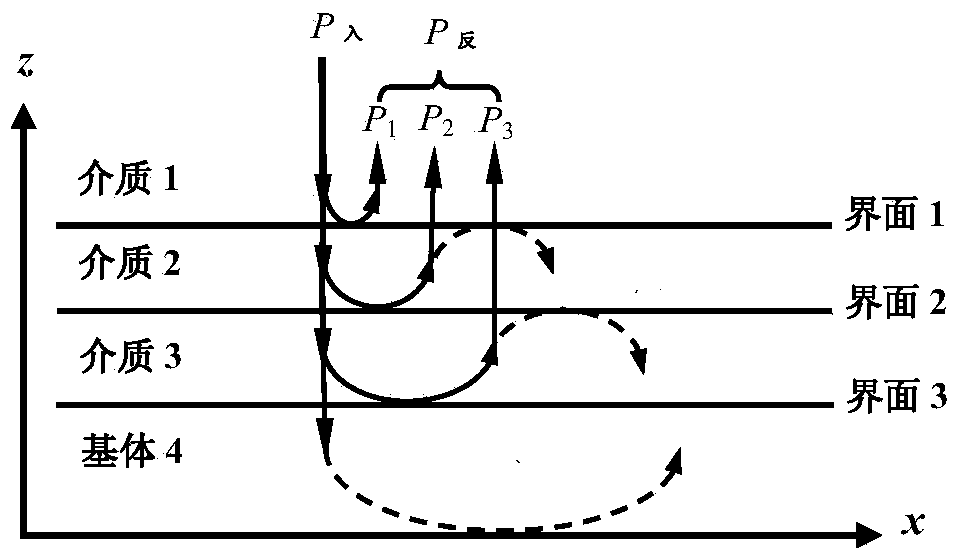

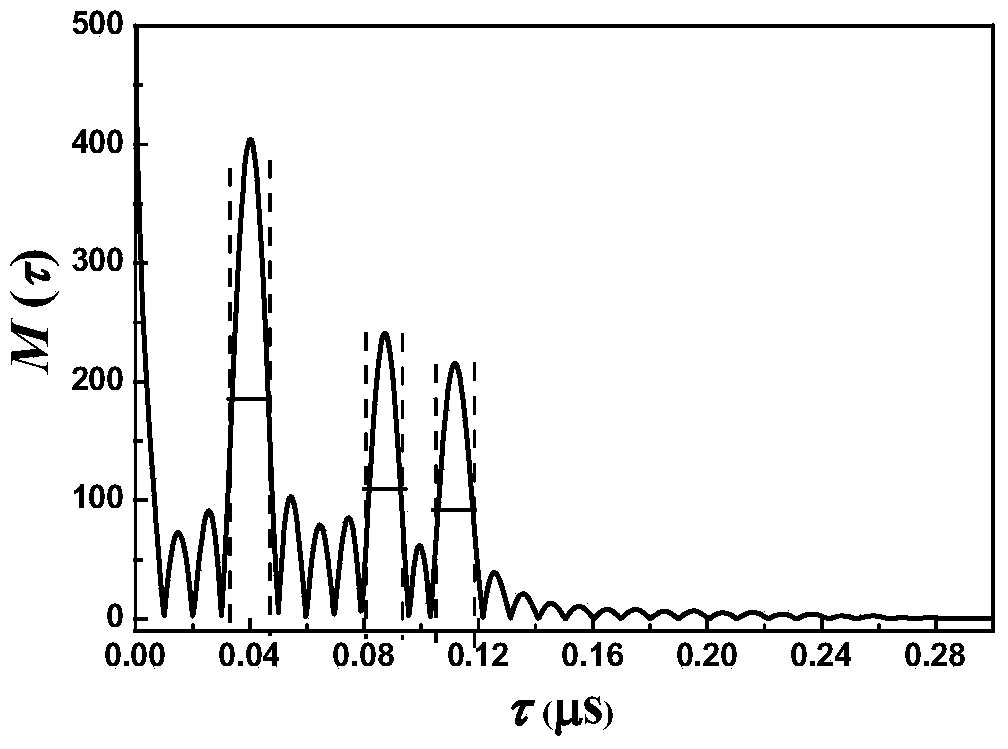

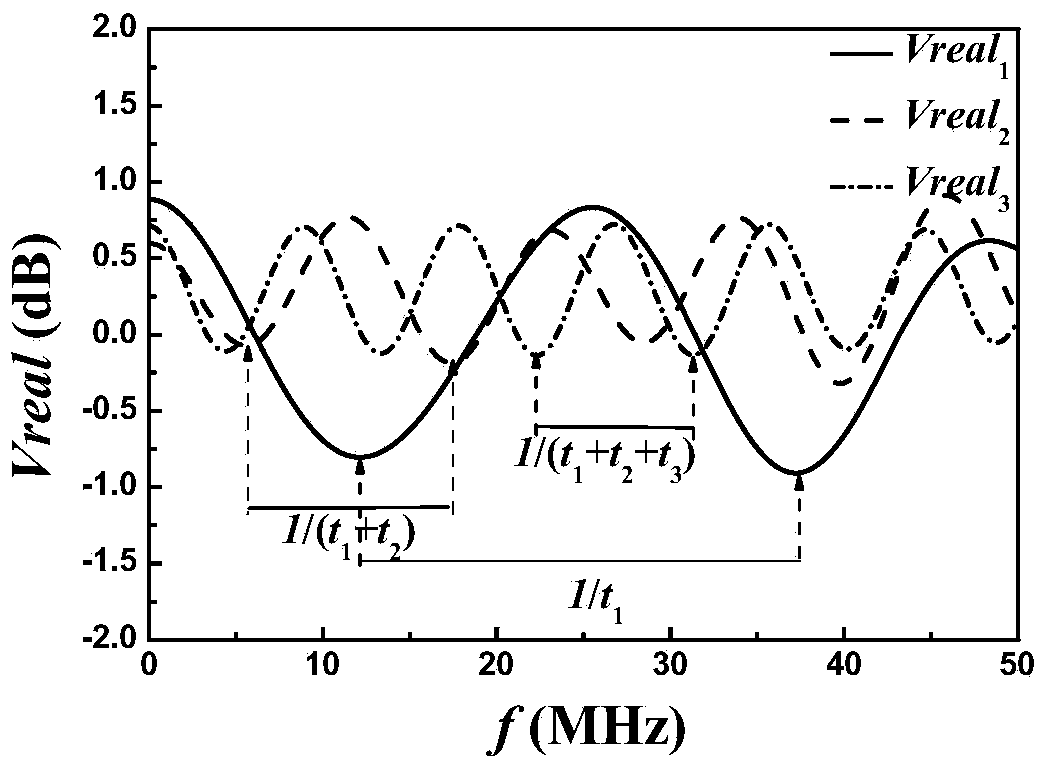

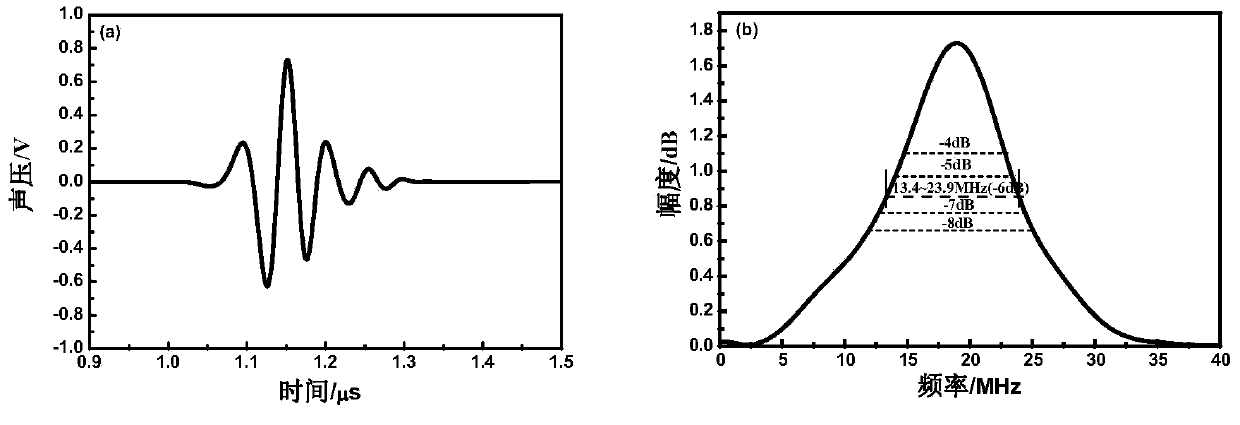

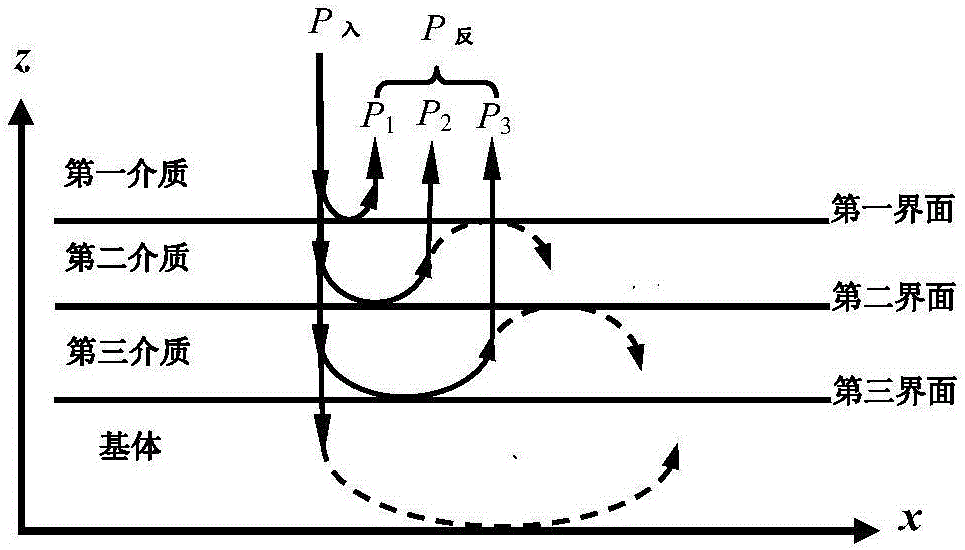

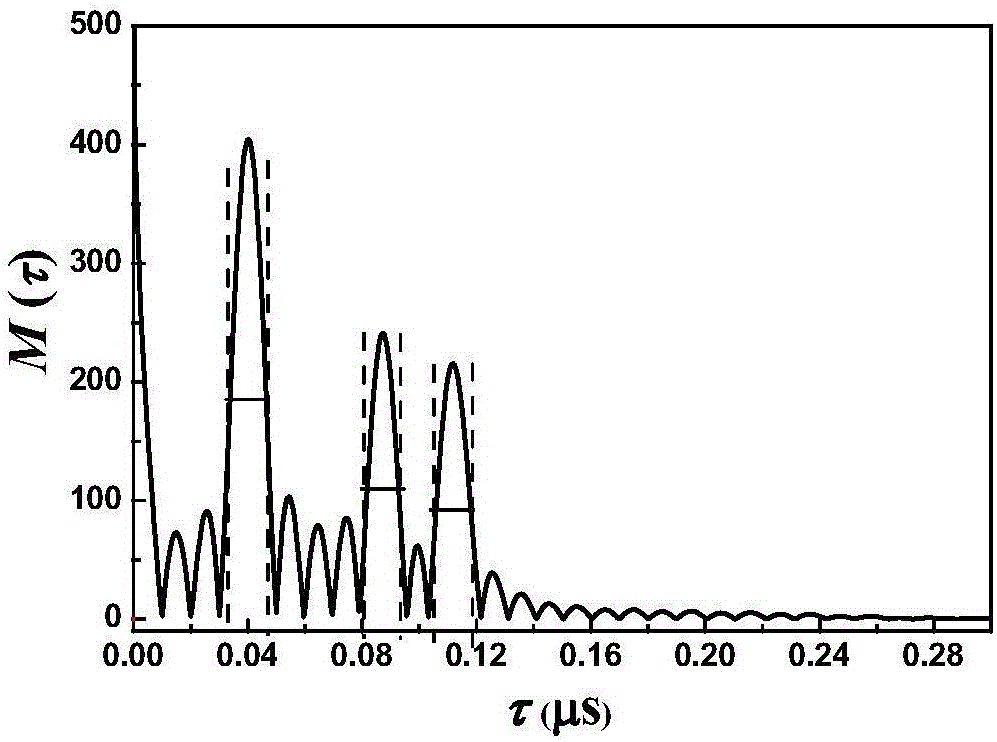

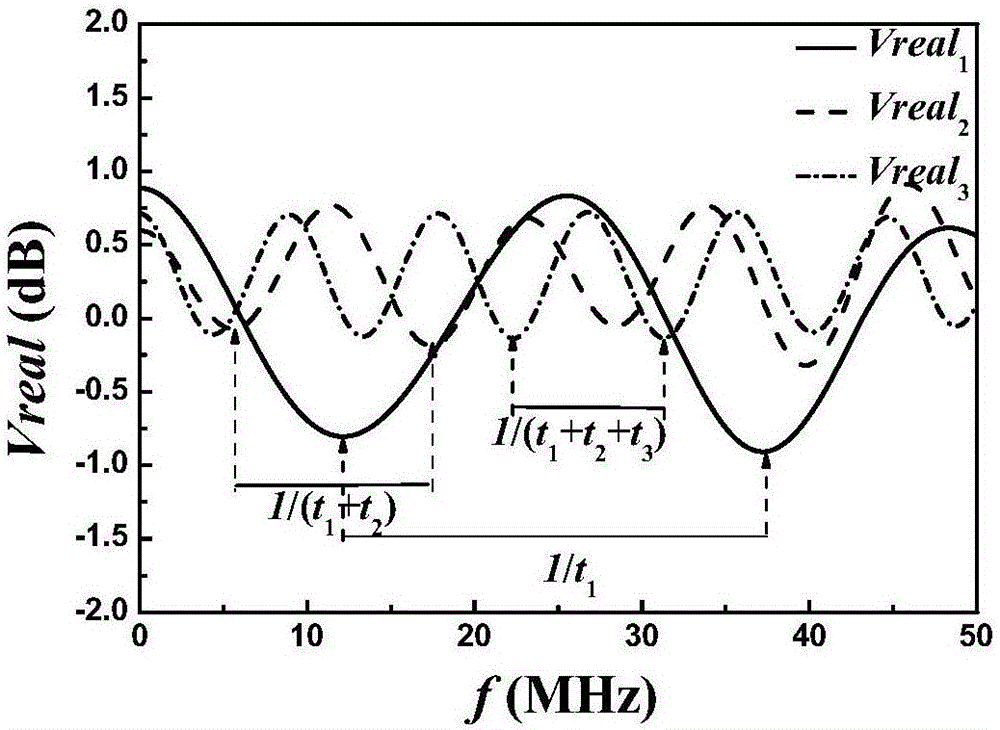

The invention provides a method for measuring thickness of coatings through the ultrasonic signal spectrum filter technology in a nondestructive mode, and belongs to the technical field of ultrasonic non-destructive testing. The method includes the steps that normalization processing is conducted on reflective sound pressure P[reflection] (x1) by ultrasonic incident sound pressure P[incidence] (x0), and then normalization sound pressure reflection coefficients R (x1-x0) of the coatings are acquired, and the R (x1-x0) is expanded to plural Fourier series through the spectrum analysis technology and divided into an independent real part function Real (f) and an independent imaginary part Imag (f); Fourier transformation is conducted on a real part function V[real] (f) in an effective frequency band acquired through windowing processing to acquire a power spectrum M (tau) of the real part function V real (f), FFT filtering bandwidths are selected according to the occurrence positions of maximum values of the power spectrum, the V[real] (f) is sequentially filtered to acquire a series of cosine functions, the periods of the cosine functions are read, propagation sound time ti of ultrasonic waves in the coatings is calculated, and then the thickness of the coatings is represented by the cooperation of longitudinal wave sound velocity of the coatings. The method is not affected by material attributes and the process environment, the problems that in a conventional ultrasonic method, aliasing occurs in time domains, and resonant frequency of the spectrum is difficult to recognize are solved, and the problem of ultrasonic thickness measurement of the multiple coatings is solved.

Owner:DALIAN UNIV OF TECH

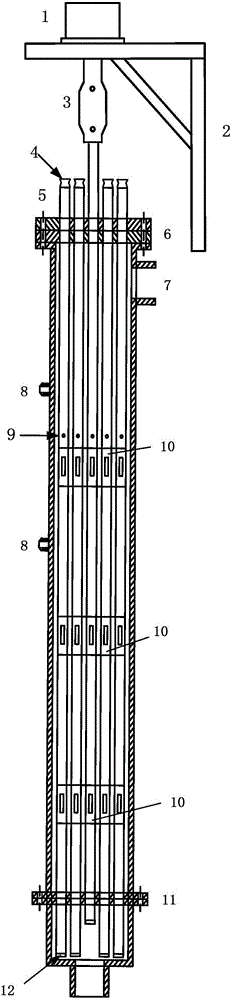

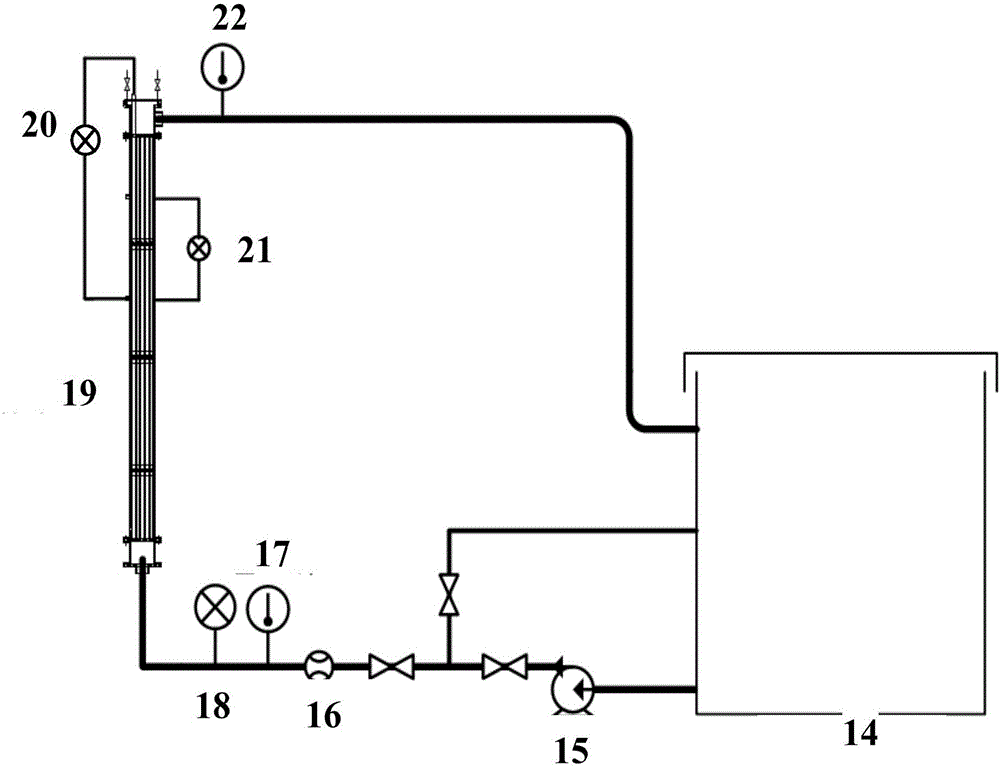

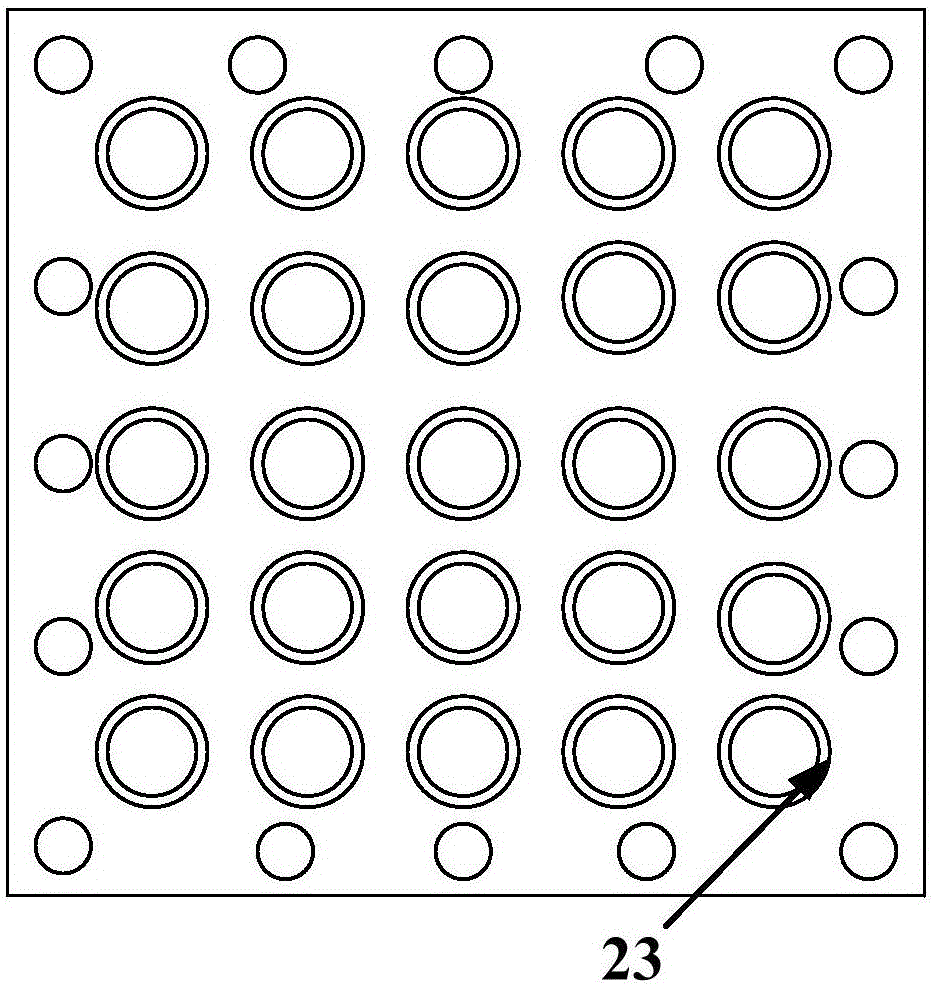

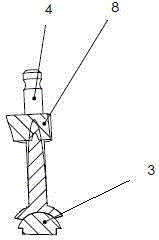

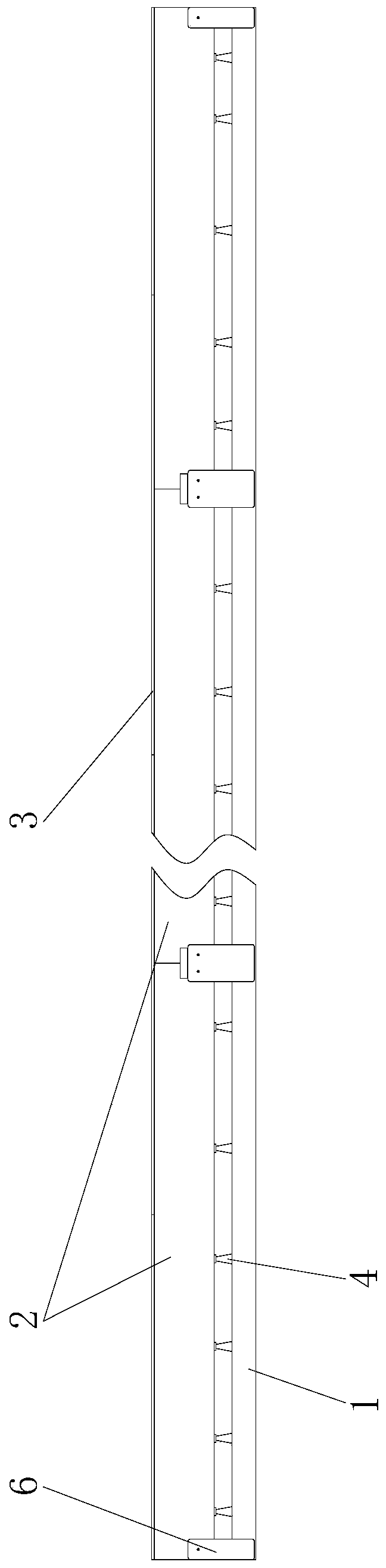

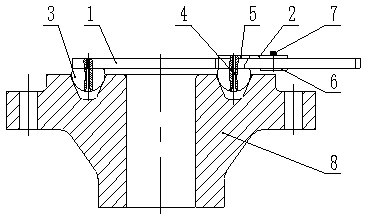

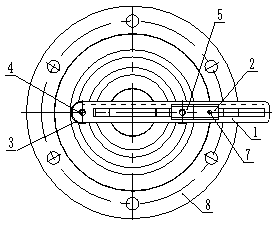

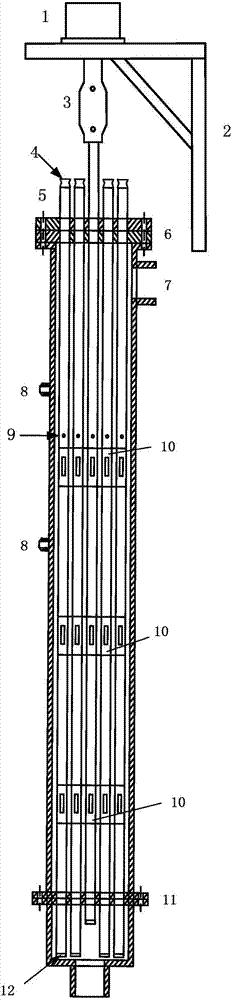

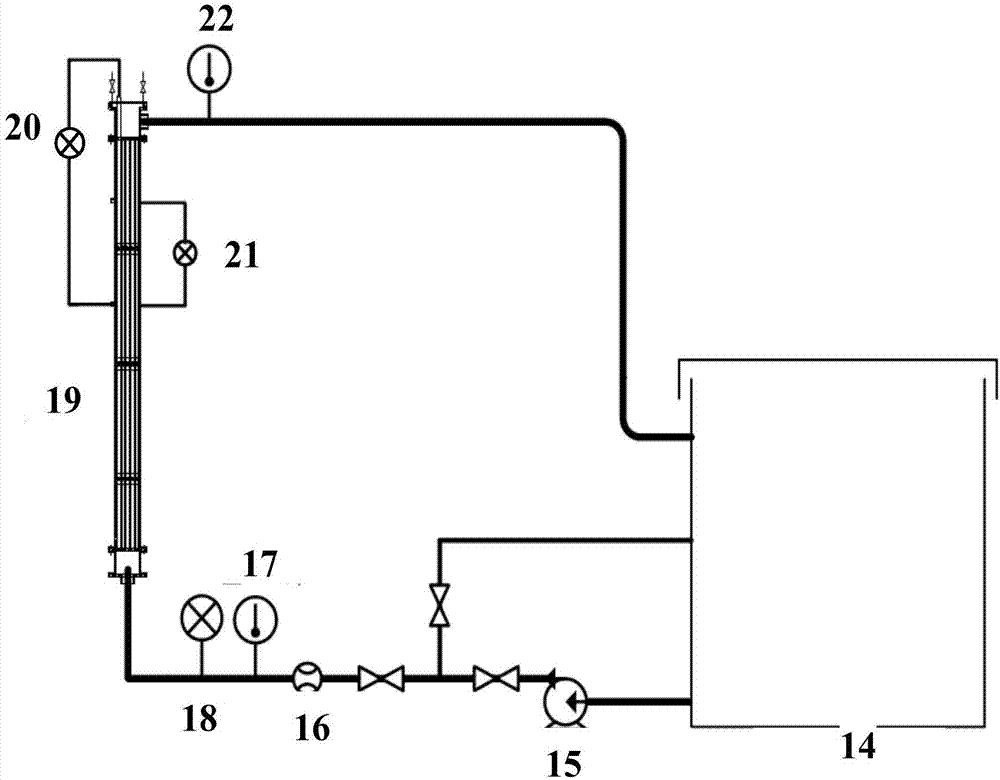

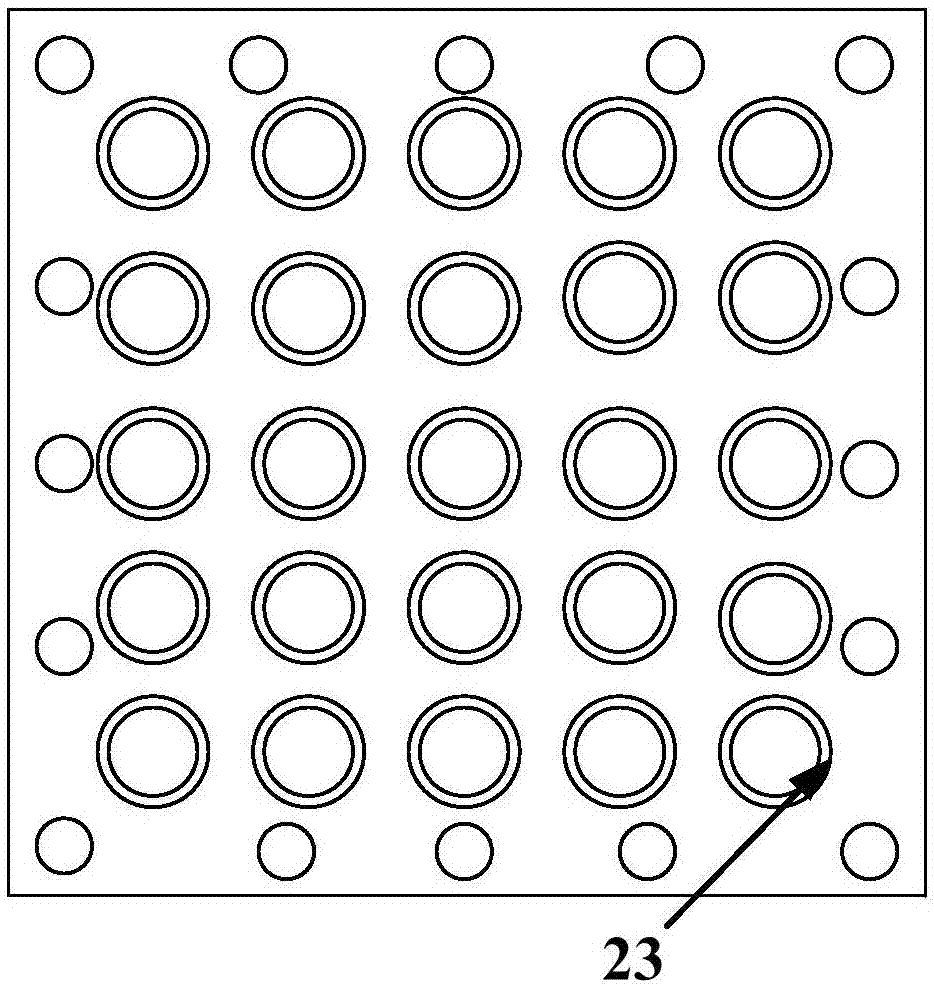

Rod bundle channel flow pressure measuring test device

ActiveCN106683722AEasy to moveSmooth rotationNuclear energy generationNuclear monitoringRotary stageCoupling

The invention provides a rod bundle channel flow pressure measuring test device, which comprises a water storage tank, a pressure measuring body, and a centrifugal pump, a regulating valve and a thermometer sequentially connected with the water storage tank through a pipeline, wherein the pressure measuring body comprises a rod bundle channel barrel, a rod bundle channel formed by rod bundles arranged in the rod bundle channel barrel; the upper ends of the rod bundles are connected with a high-accuracy rotating disk arranged on a rotating table support through a coupler; two body pressure ports formed up and down are formed in the rod bundle channel barrel; a pressure guiding port is formed in each rod bundle of the rod bundle channel; a sealing rubber plug is arranged at the lower end of each rod bundle; a fast adapter is arranged at the upper end of each rod bundle; pressure difference transmitters are respectively arranged between each pressure guiding port and each fast adapter as well as between the two body pressure ports. The rod bundle channel flow pressure measuring test device provided by the invention can simulate single-phase flow in a reactor rod bundle channel so as to research a resistance characteristic of the rod bundle channel, and is simple in structure, low in cost, accurate and convenient to acquire data, and wide in research working condition range.

Owner:HARBIN ENG UNIV

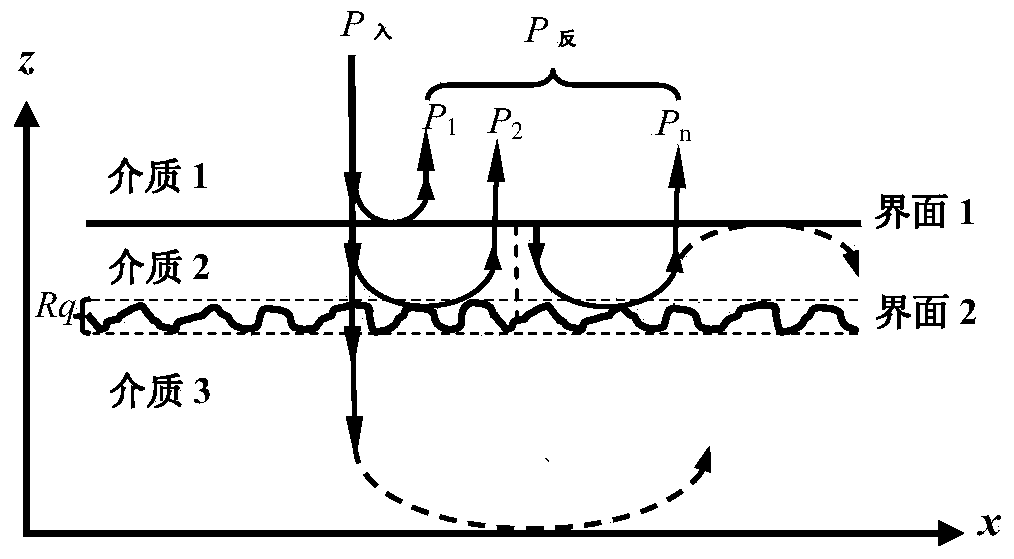

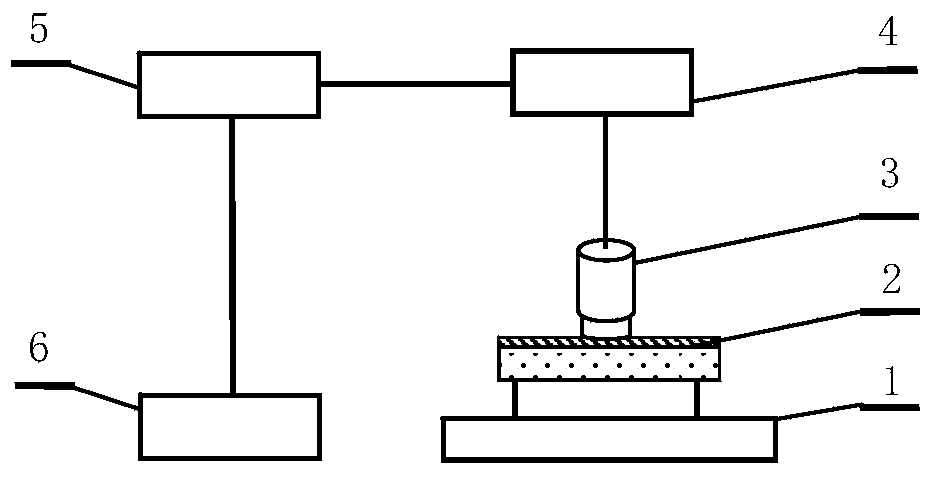

Method for measuring coating thickness and interfacial roughness simultaneously by ultrasonic

ActiveCN104197872AAccurate measurementEasy and flexible measurementUsing subsonic/sonic/ultrasonic vibration meansSound pressureNondestructive testing

The invention discloses a method for measuring coating thickness and interfacial roughness simultaneously by ultrasonic and belongs to the technical field of ultrasonic nondestructive test and evaluation for materials. The method adopts an ultrasonic pulse echo detection system which comprises a sample table, an interfacial roughened coating sample, a delay block probe, a flow detector, a digital oscilloscope and a computer. Aiming to solve the difficult problem about measuring thickness and roughness of the nondestructive characterization interfacial roughened coating, the method includes deriving a sound pressure reflection coefficient amplitude spectrum / r(f;rq,d) / of the interfacial roughened coating structure, performing correlation operation to theoretical and experimental sound pressure reflection coefficient amplitude spectrums of different frequency bandwidth to obtain thickness di and roughness Rqi of the coating corresponding to the maximum correlation coefficient eta<max>(Rq,d) of each bandwidth, averaging thickness and roughness measured within different frequency windows to obtain mean d and mean Rq which are respectively the coating thickness and the interfacial roughness needed to solve. The method fills a gap in the coating thickness and roughness nondestructive characterization methods.

Owner:DALIAN UNIV OF TECH

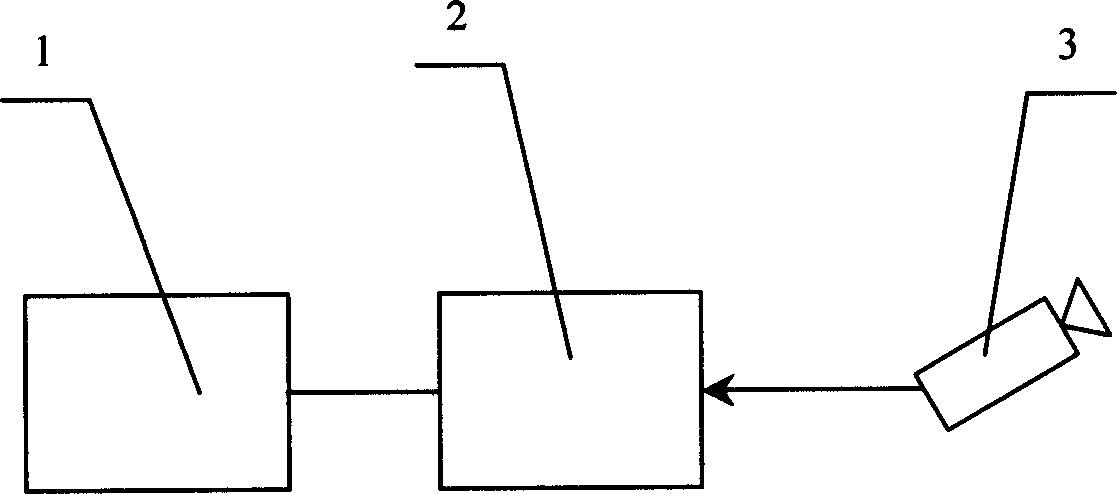

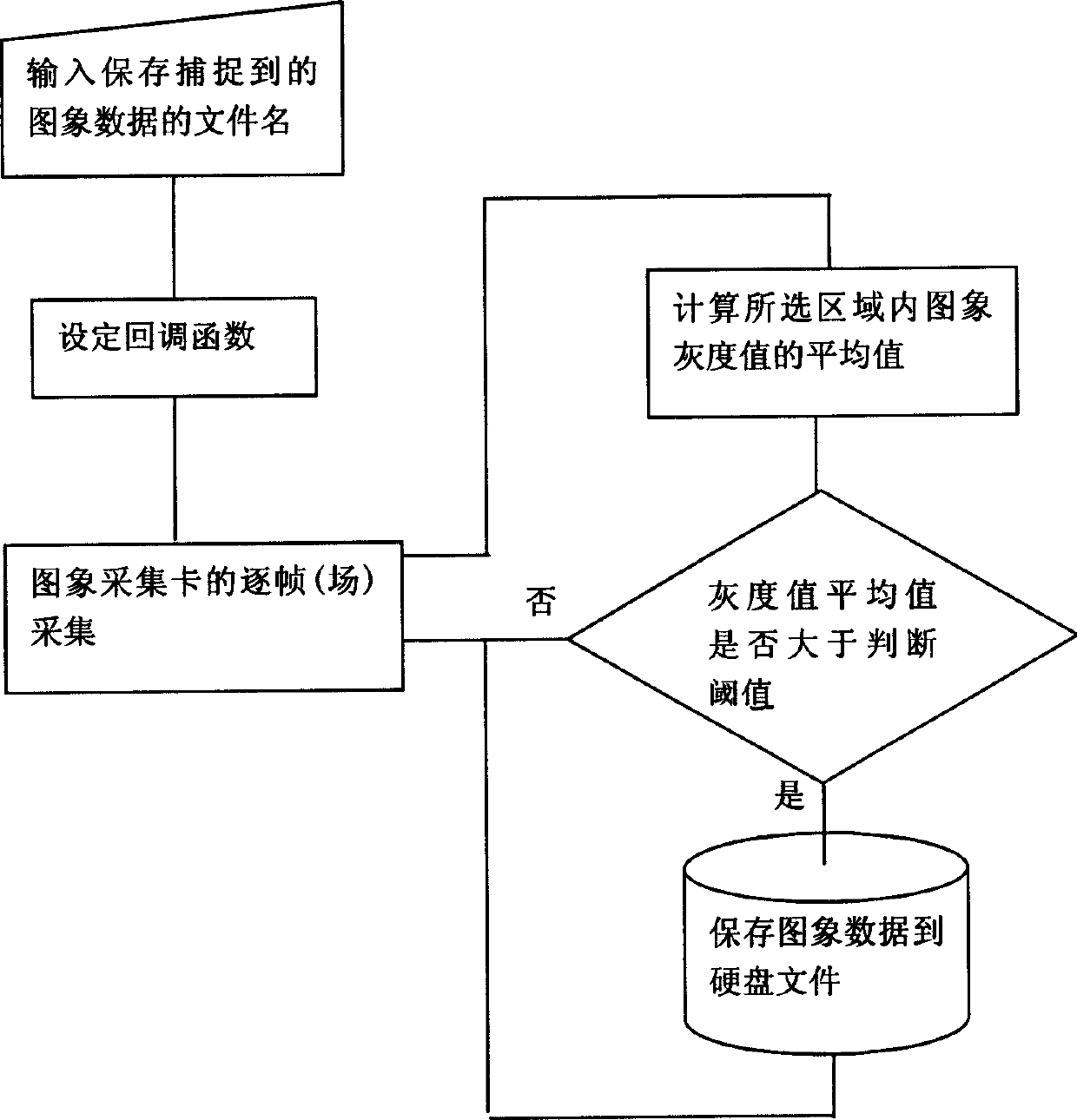

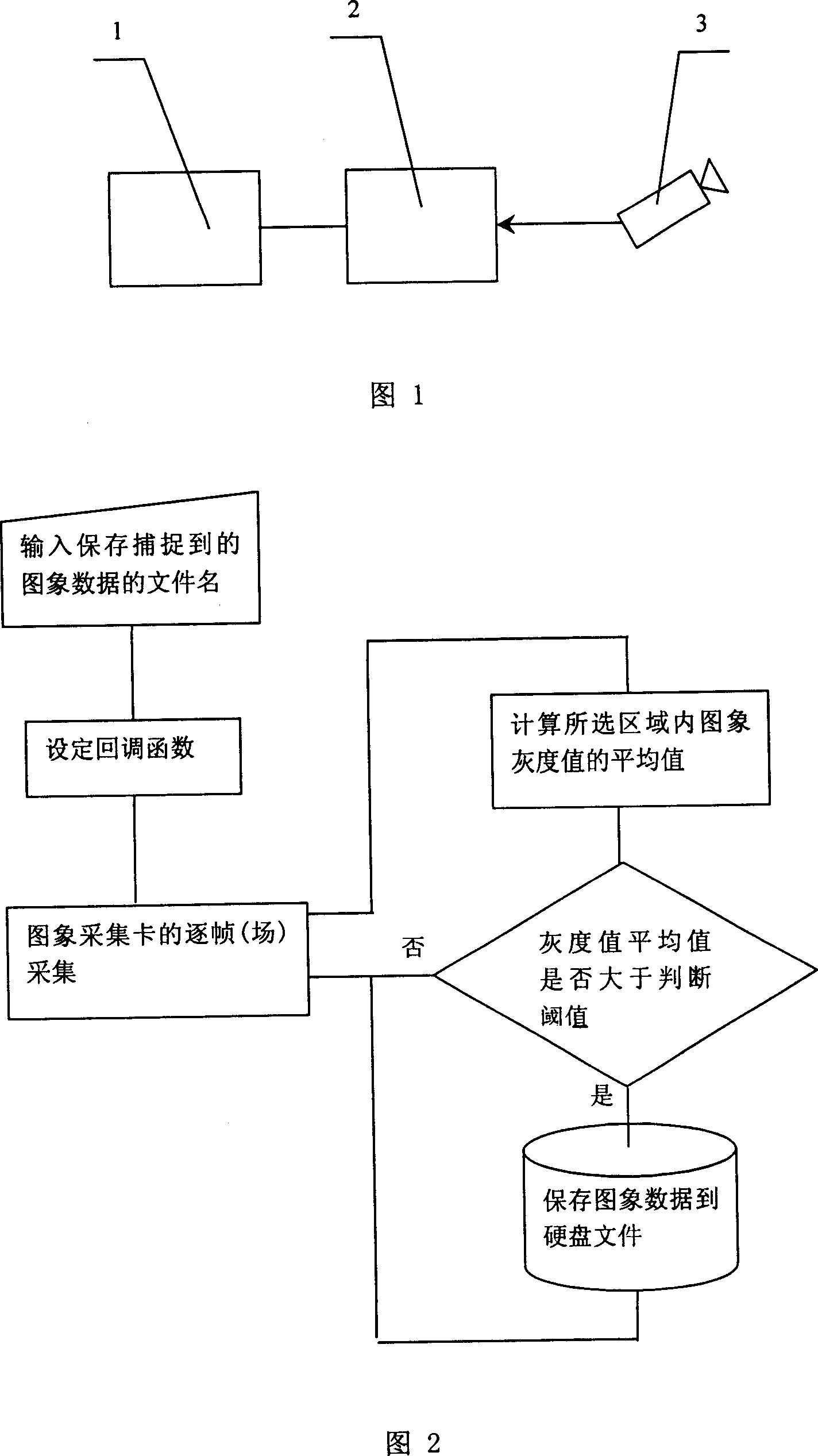

Pulsed laser spot software synchronization acquisition method

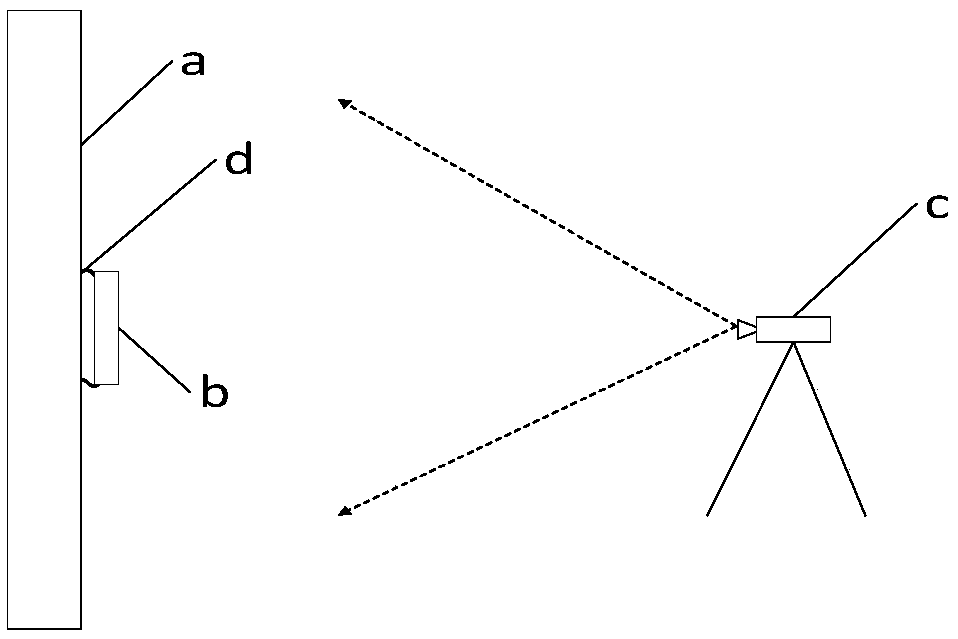

InactiveCN1700214AImprove stabilityNot easy to interferePhotometryImage data processing detailsComputer hardwareLaser light

The invention relates to a software synchronization acquisition method of impulse laser light spot, which adopts ridge CCD camera which can output standard video signal or infrared camera, image collection card and measuring system which is formed by main control computer with capture software program. It collects data by ridge CCD camera or infrared camera and controls image collection card which is connected with ridge CCD camera or infrared camera by video cable through capture software program which is connected with image collection card. It collects the light impulse laser spots and achieves totally software synchronization acquisition and analysis in executing function.

Owner:NAT UNIV OF DEFENSE TECH

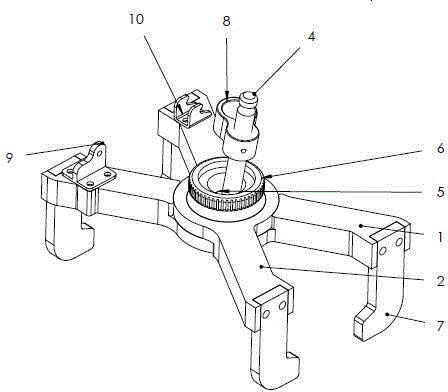

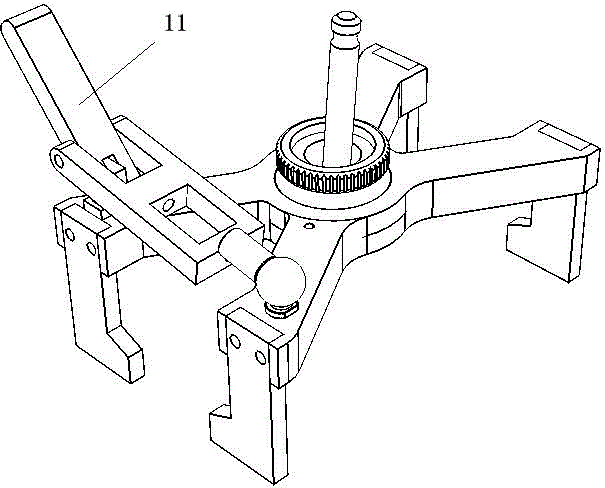

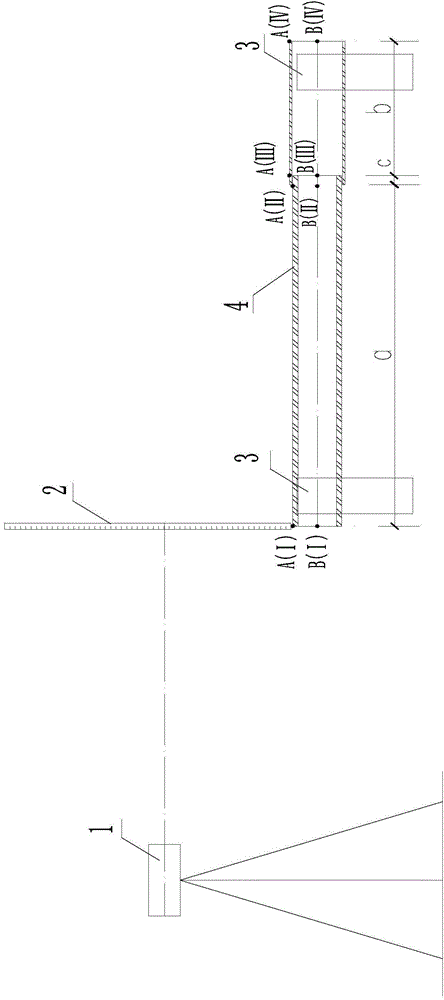

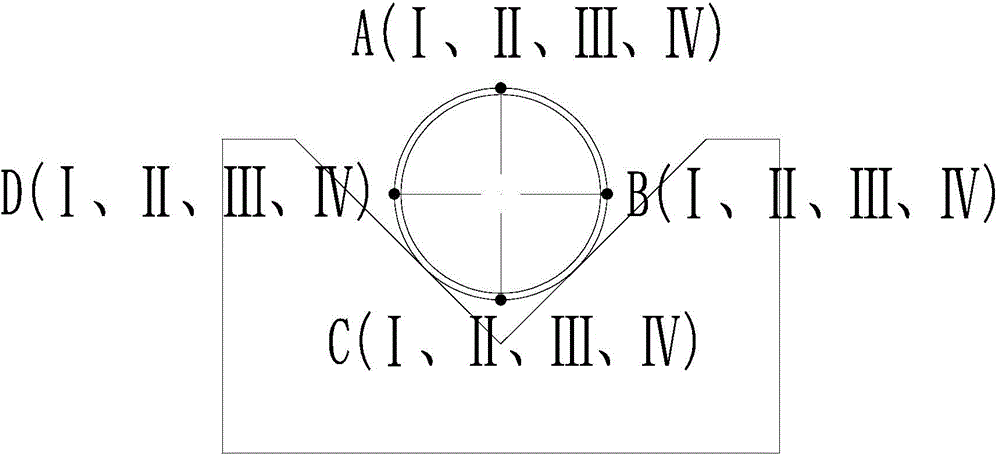

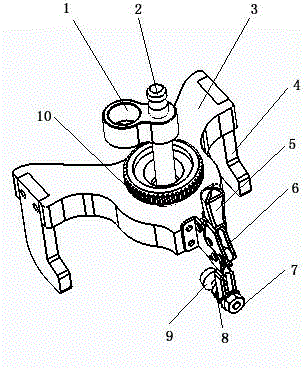

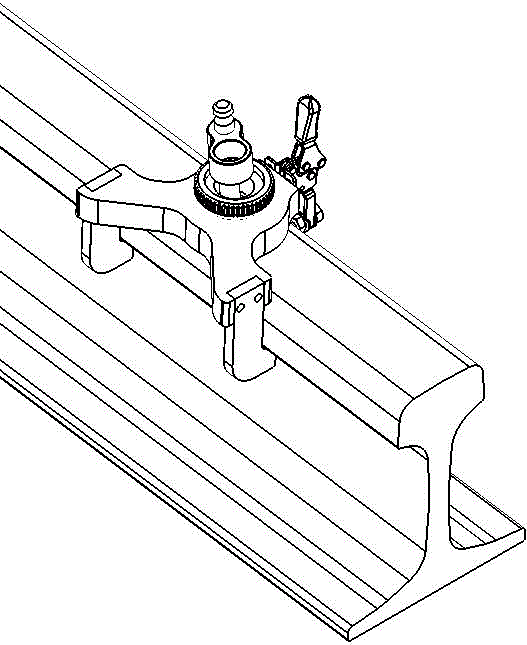

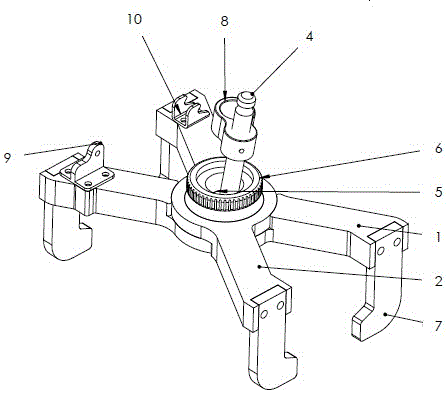

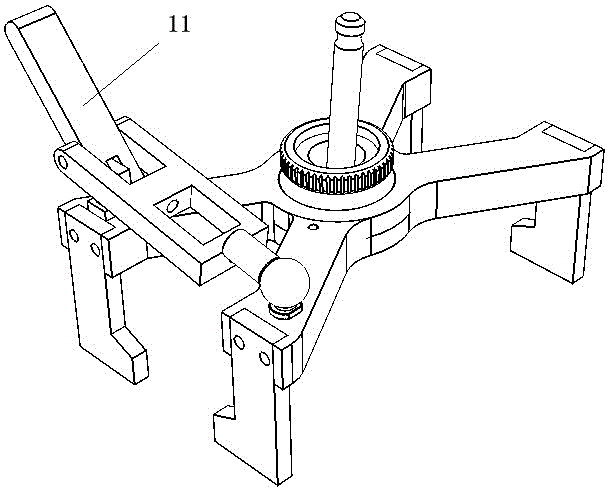

X-shaped fast positioning device for railway rail center position measurement

ActiveCN104674619ARapid positioningImprove collection efficiencyMeasuring apparatusThree-dimensional spaceStructural engineering

The invention relates to an X-shaped fast positioning device for railway rail center position measurement. For the steel rail three-dimensional space posture observation in the prior art, a rail geometrical state measuring instrument needs to be put in a steel rail measuring position for positioning, and the collecting efficiency is lower. The X-shaped fast positioning device comprises a lower layer X arm and an upper layer X arm provided with center open holes, wherein the two arms are respectively straight arms, the upper and lower center open holes are aligned, crossed and combined for forming an X shape; a locking screw nut is arranged in each center open hole, a prism rod is inserted in each locking screw nut, the bottom end of each prism rod is a concave spherical surface, a semi-cylinder is arranged under the concave spherical surface, and is positioned on the surface of the steel rail, the bottom surface of the semi-cylinder is a flat plane, and the top surface of the semi-cylinder is a spherical surface; the end part of the lower layer X arm and the end part of the upper layer X arm are respectively provided with downwards steel rail clamp hook heads which are positioned at the two sides of the steel rail; fixing buckles are arranged between the same ends of the lower layer X arm and the upper layer X arm positioned at the opposite sides of the steel rail. The X-shaped fast positioning device has the advantages that the fast positioning of the high-speed railway rail center position can be realized through a full station instrument, the collecting efficiency is improved, the measurement is simple, convenient and flexible, and the measuring precision is also greatly improved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

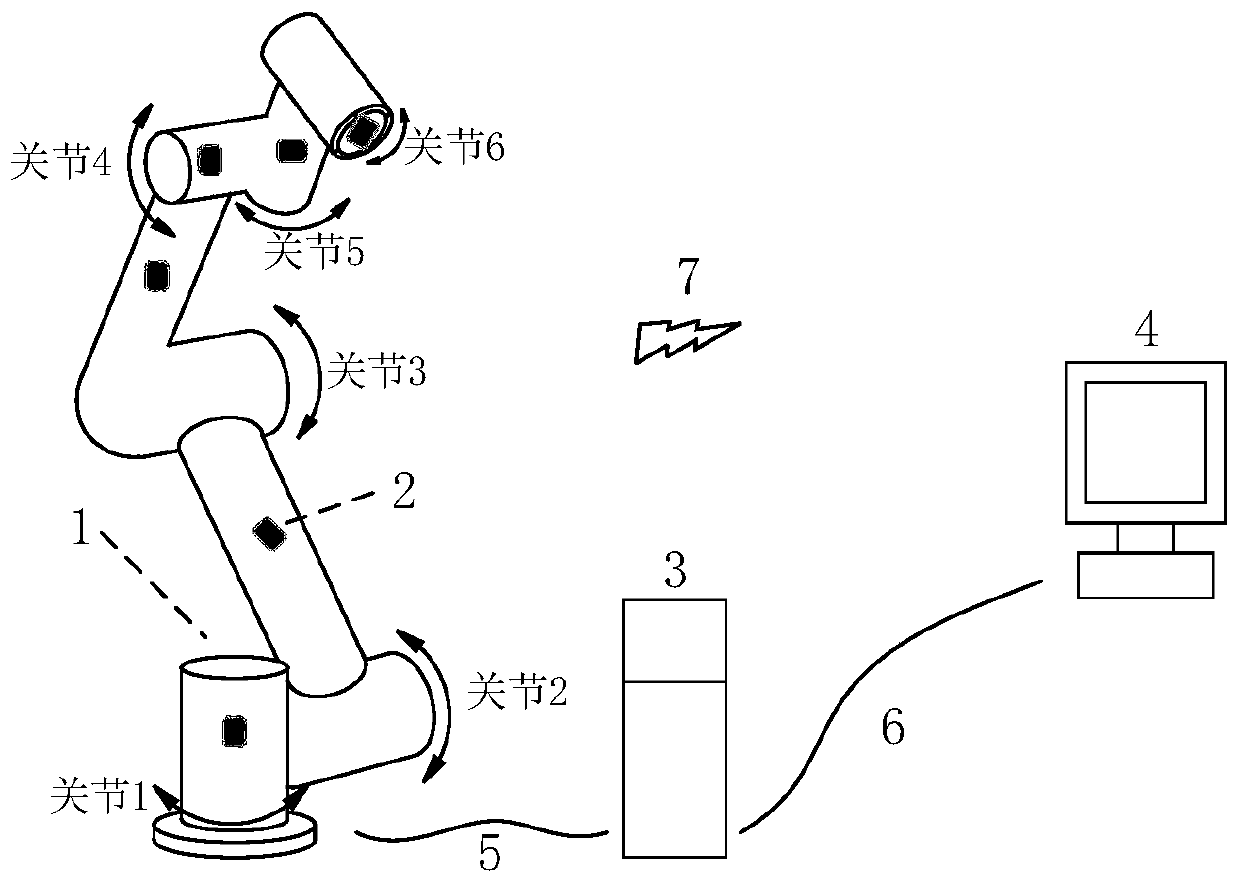

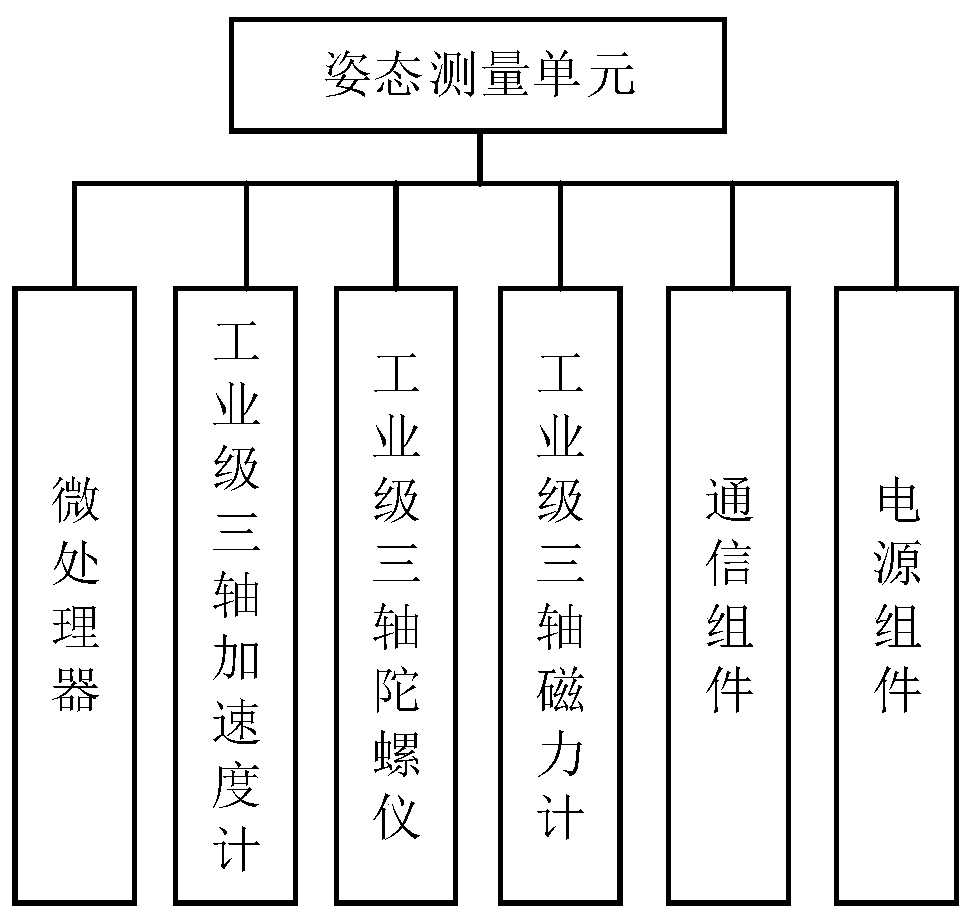

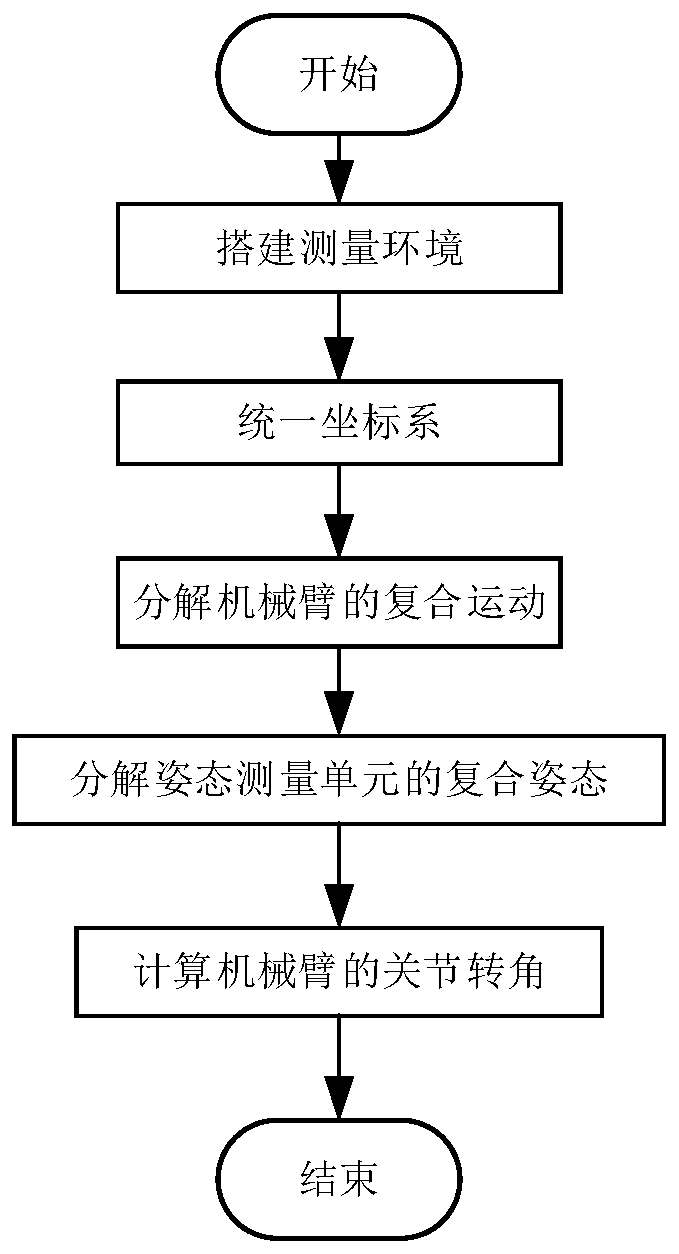

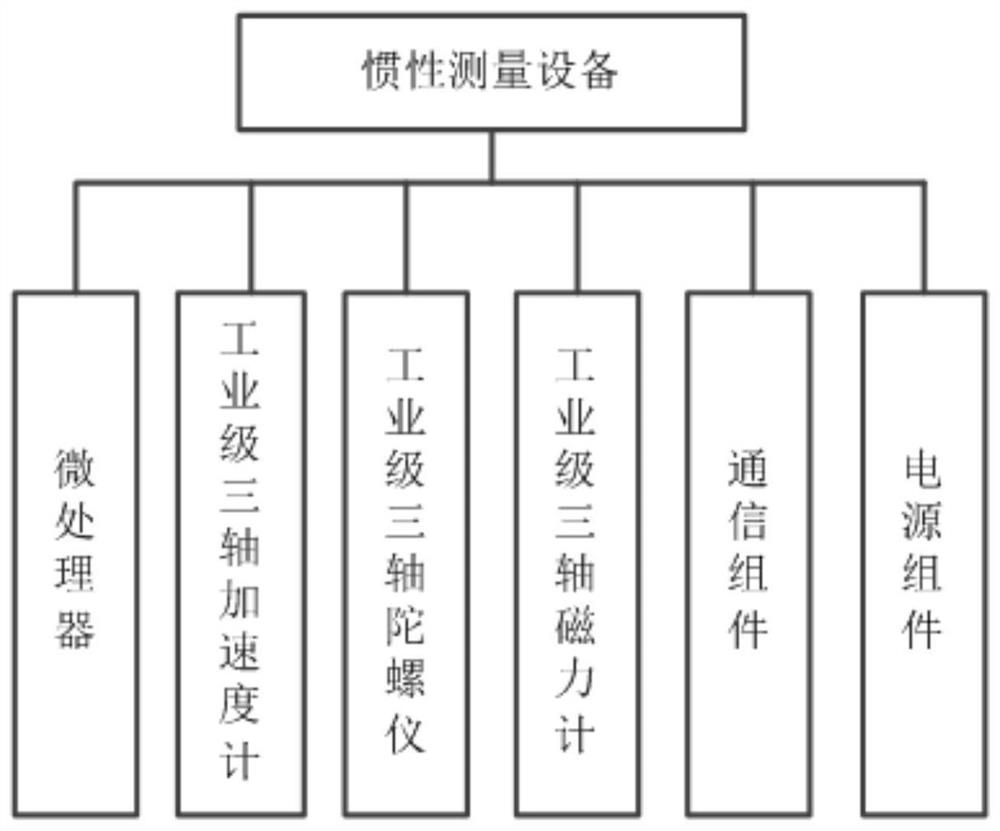

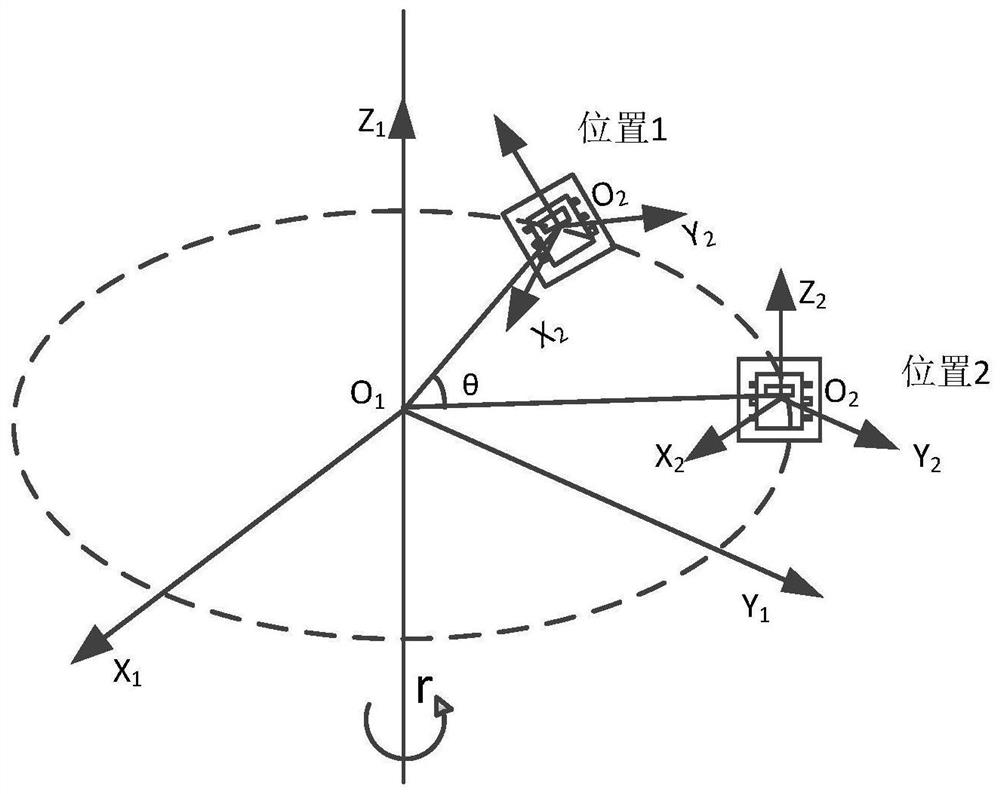

Joint rotating angle auxiliary measuring system and method of serial rotary joint mechanical arm

InactiveCN111152260AEasy and flexible measurementAccurate and efficient measurementJointsGyroscopeThree axis accelerometer

The invention provides a joint rotating angle auxiliary measuring system of a serial rotary joint mechanical arm. The joint rotating angle auxiliary measuring system comprises an attitude measuring unit and a computer. The attitude measuring unit comprises a microprocessor, a three-axis accelerometer, a three-axis gyroscope and a three-axis magnetometer, wherein the three-axis accelerometer, the three-axis gyroscope and the three-axis magnetometer are connected with the microprocessor through electric signals. The attitude measuring unit is further provided with a fixed end, and the attitude measuring unit is fixedly arranged at any position of any plane of each joint of the mechanical arm through the fixed end. The attitude measuring unit is in communication connection with the computer.The computer is used for calculating the joint rotating angles of the mechanical arm according to attitude information of the attitude measuring unit. Flexible, convenient, efficient and accurate joint rotating angle measuring is achieved without being affected by the environment. Measuring is not limited by the environment, joint rotating angle information of the serial mechanical arm in the movement process can be obtained through calculation, and the measuring process of the joint rotating angles of the mechanical arm is greatly simplified.

Owner:SHANDONG UNIV

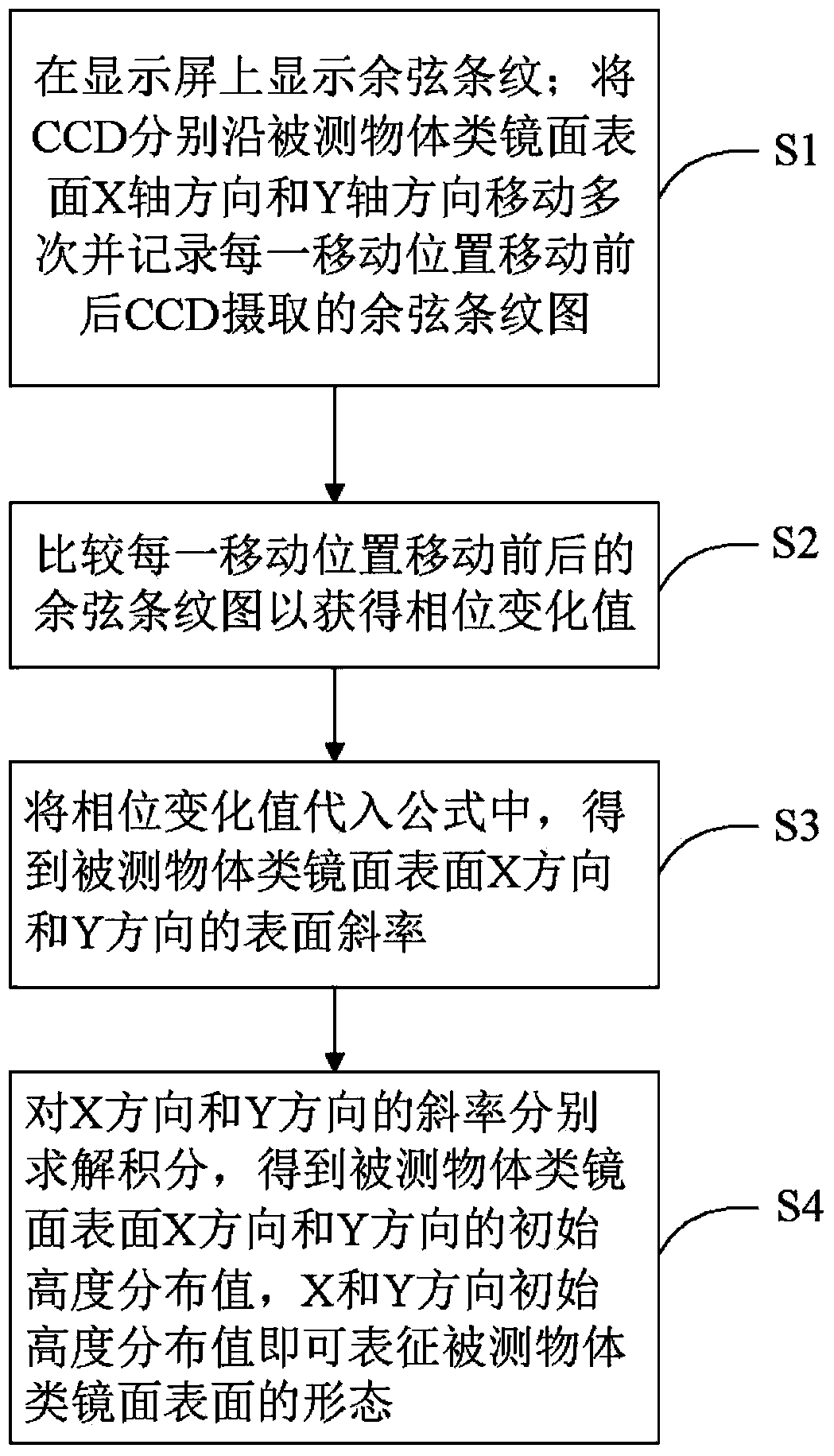

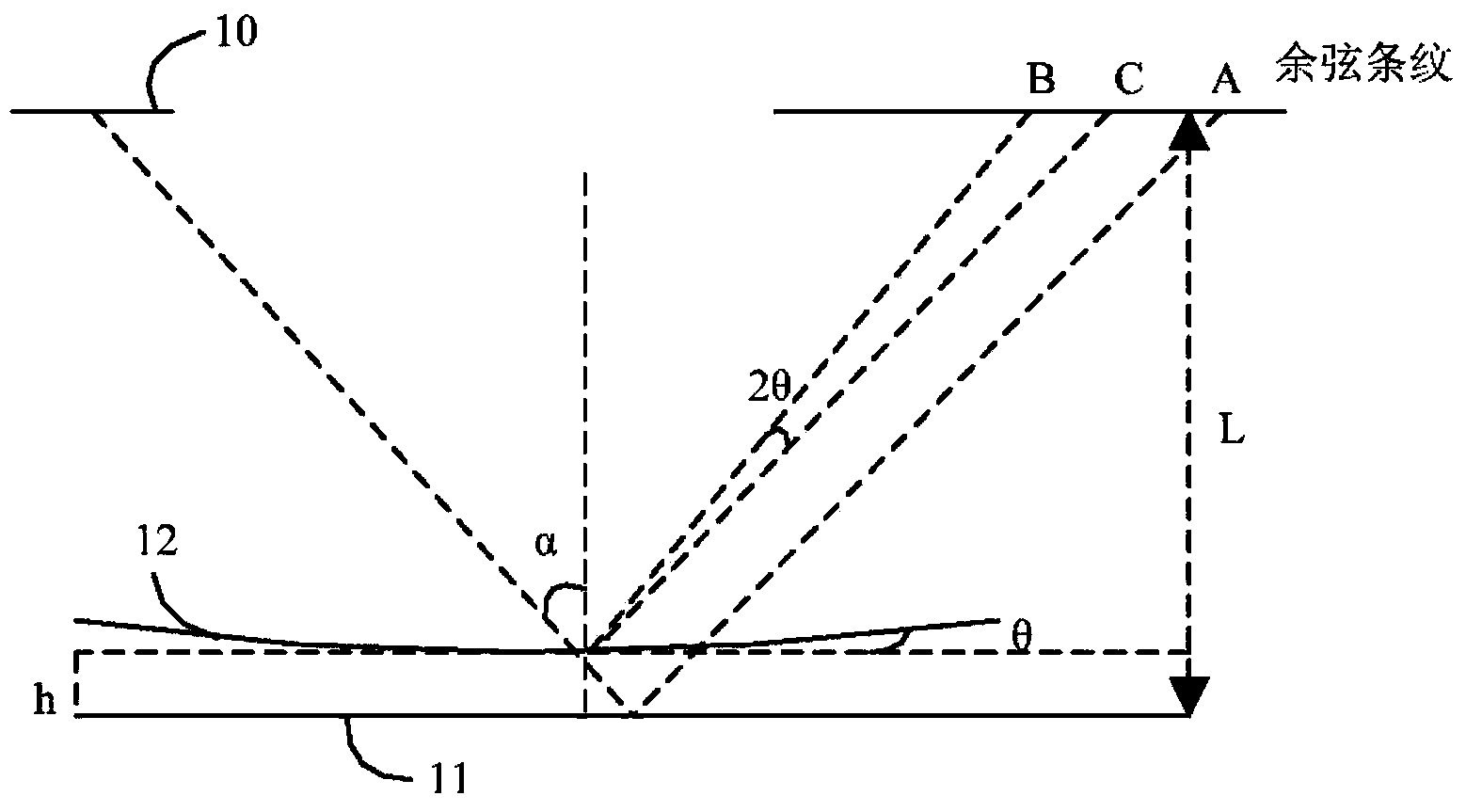

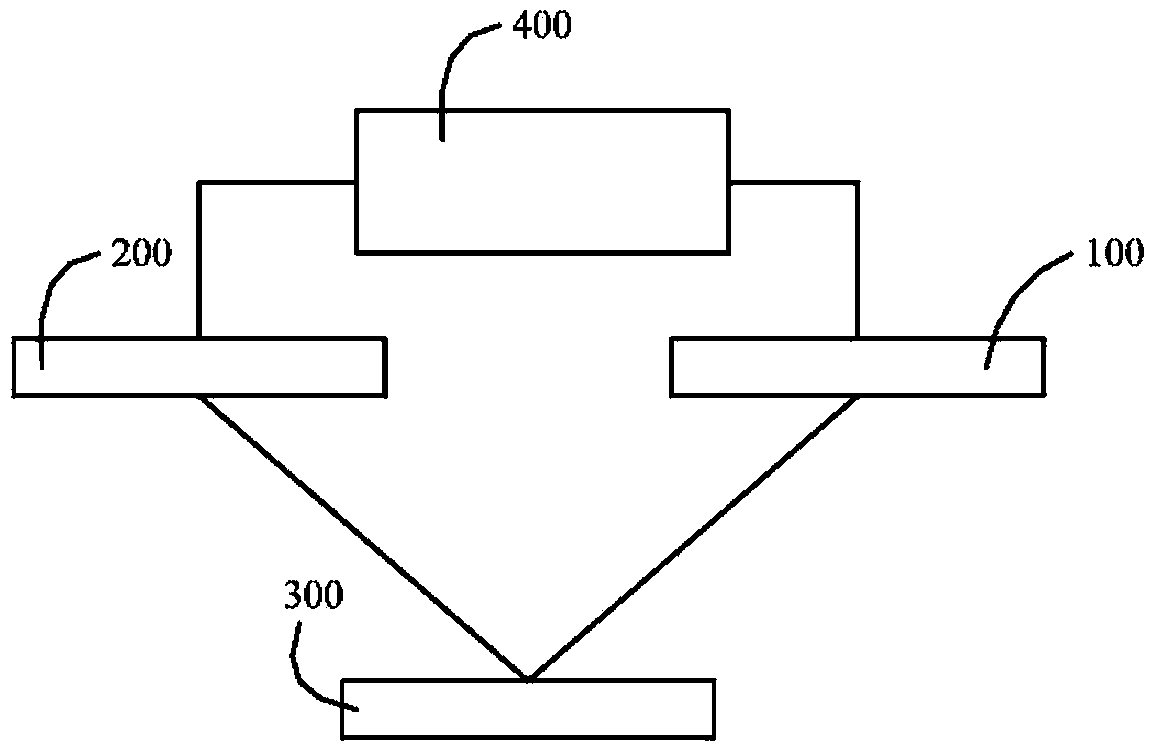

Mirror-like surface testing method

ActiveCN103727897AAccurately derive parameter valuesEasy and flexible measurementUsing optical meansCcd cameraPhase change

The invention discloses a mirror-like surface testing method and belongs to the technical field of measurement. The mirror-like surface testing method solves the problem of high testing costs of existing mirror-like surface testing methods and comprises displaying cosine stripes on a display screen, moving a CCD (charge coupled device) in the X-axis direction and the Y-axis direction of the surface of an object to be tested to obtain the cosine stripe images of every moving position before and after the movement, which are shot by the CCD, comparing the cosine stripe images of every moving position before and after the movement to obtain phase change value, obtaining the surface slopes of the X-direction and the Y-direction of the mirror-like surface of the object to be tested through the phase change value and obtaining the initial height distribution value of the X-direction and the Y-direction of the mirror-like surface of the object to be tested by integral-solving the slopes. The mirror-like surface testing method does not require an auxiliary reflector or an interferometer, requires only one CCD camera during testing and does not require calibration of the CCD camera, thereby effectively reducing the testing cost and simplifying the system structure. The invention also provides a mirror-like surface testing device.

Owner:SHINING 3D TECH CO LTD

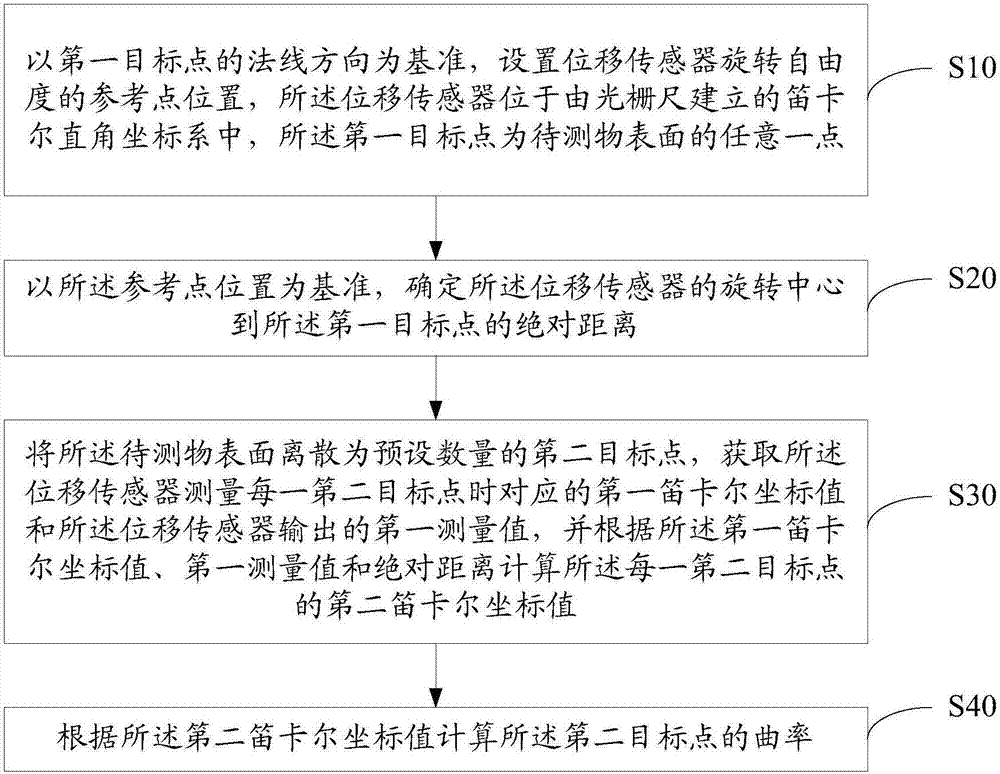

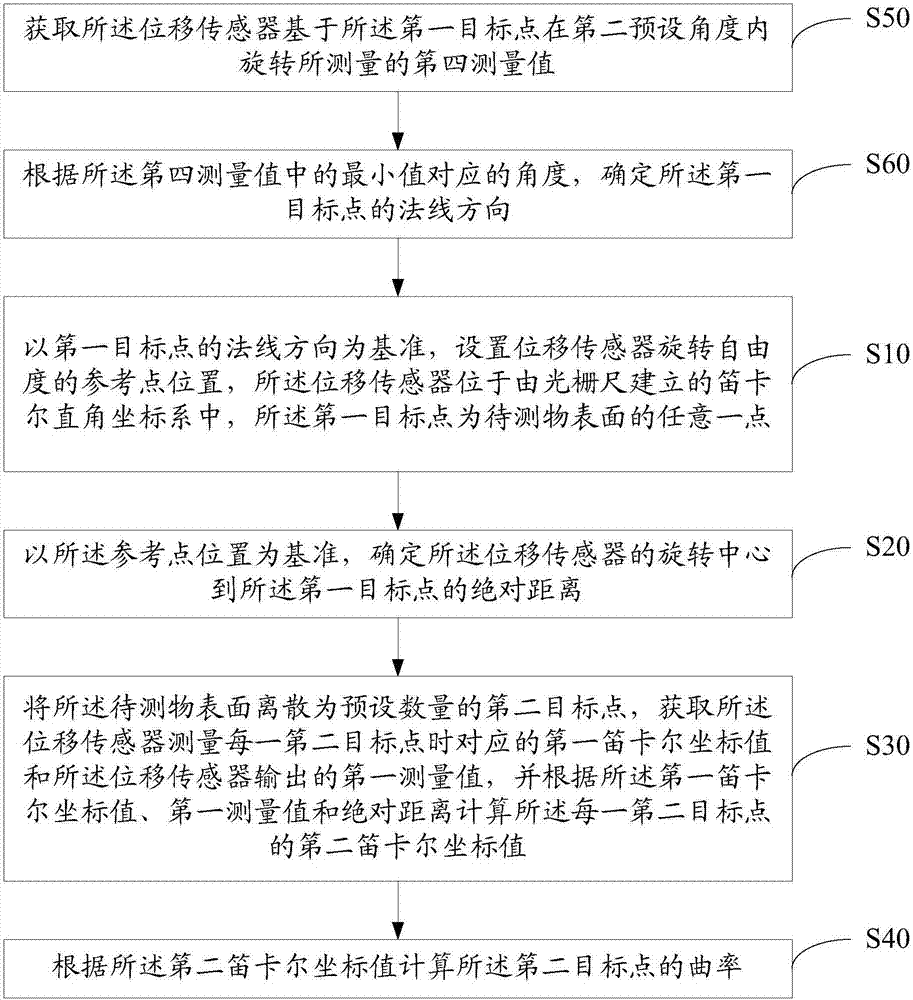

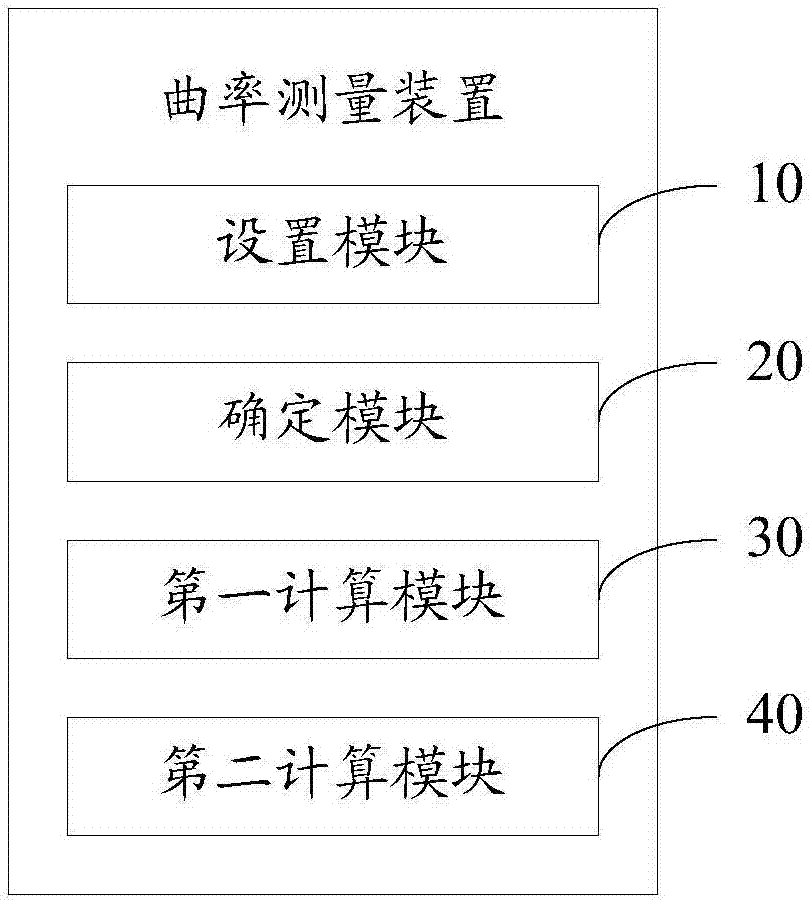

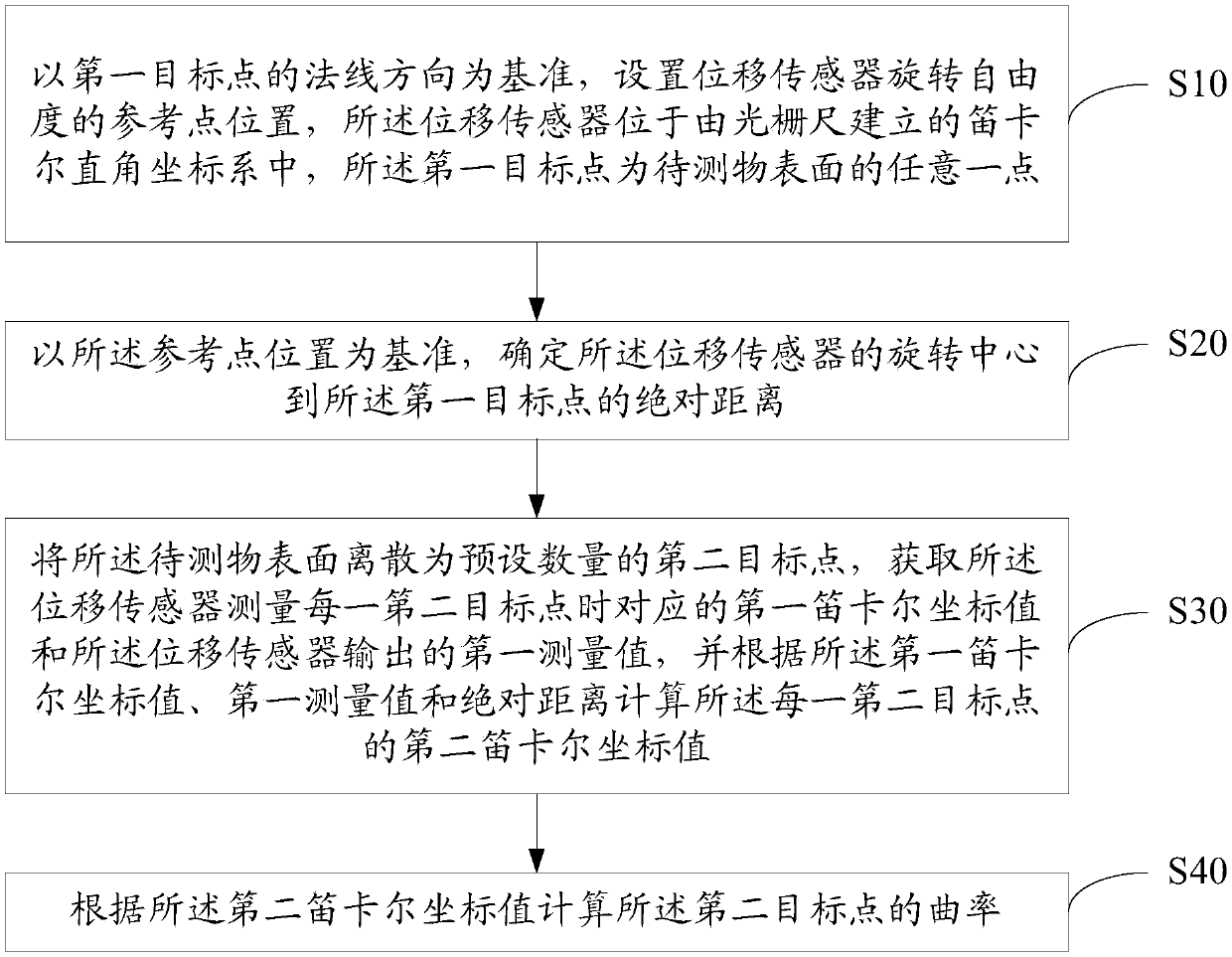

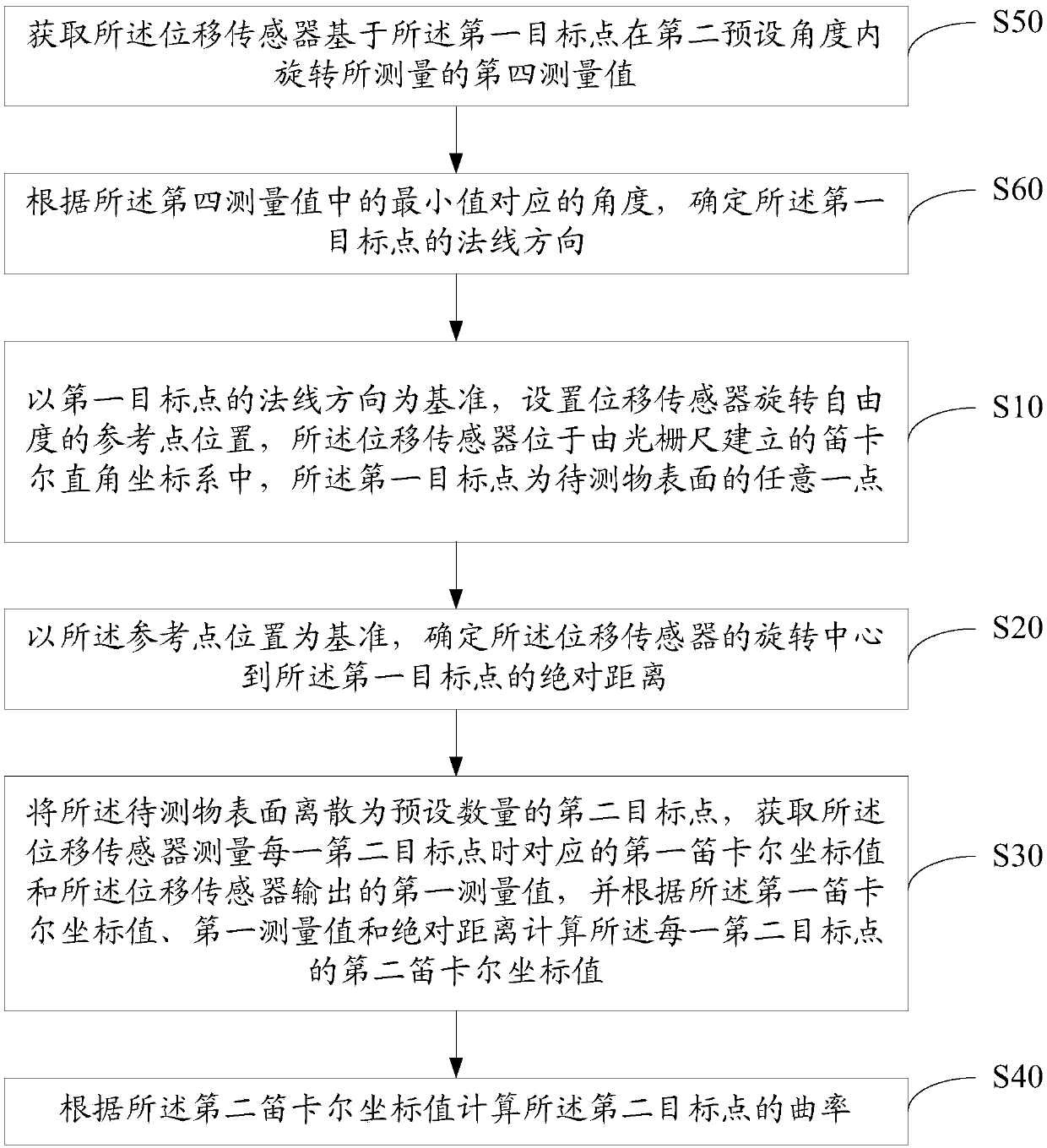

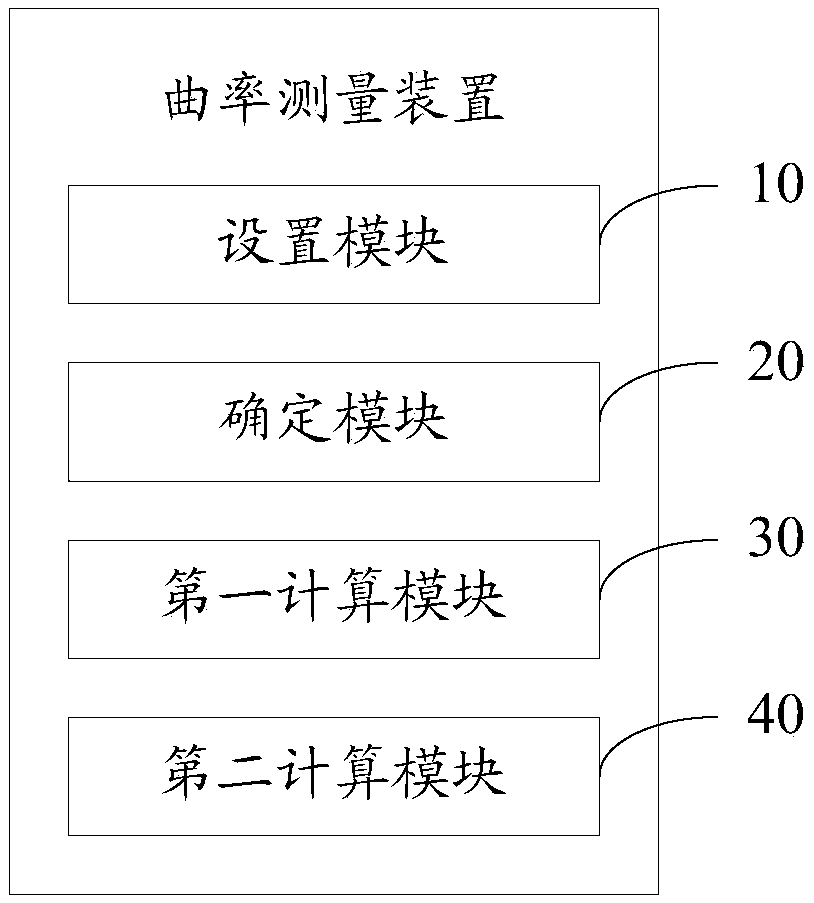

Curvature measuring method and apparatus

ActiveCN106908010AEasy and flexible measurementHigh precisionUsing optical meansRotational freedomClassical mechanics

The invention discloses a curvature measuring method and apparatus. The method comprises: a reference point position of a rotational freedom degree of a displacement sensor is set by using a normal direction of a first target point as a reference; the displacement sensor is controlled to rotate within a first preset angle based on the reference point position and measurement is carried out to obtain an absolute distance between the rotation center of the displacement sensor to the first target point; discrete processing is carried out on a to-be-measured object to obtain a preset number of second target points, a corresponding first Cartesian coordinate value when the displacement sensor measures each second target point and a first measurement value outputted by the displacement sensor, and a second Cartesian coordinate value of each second target point is calculated based on the first Cartesian coordinate value, the first measurement value and the absolute distance; and the curvature of each second target point is calculated based on the second Cartesian coordinate values. Because the Cartesian coordinate value of any point on the curved surface can be accurately calculated, the accuracy of curvature measurement is improved; and the measurement is more convenient and flexible.

Owner:SHENZHEN CITY POSONWONE TECH

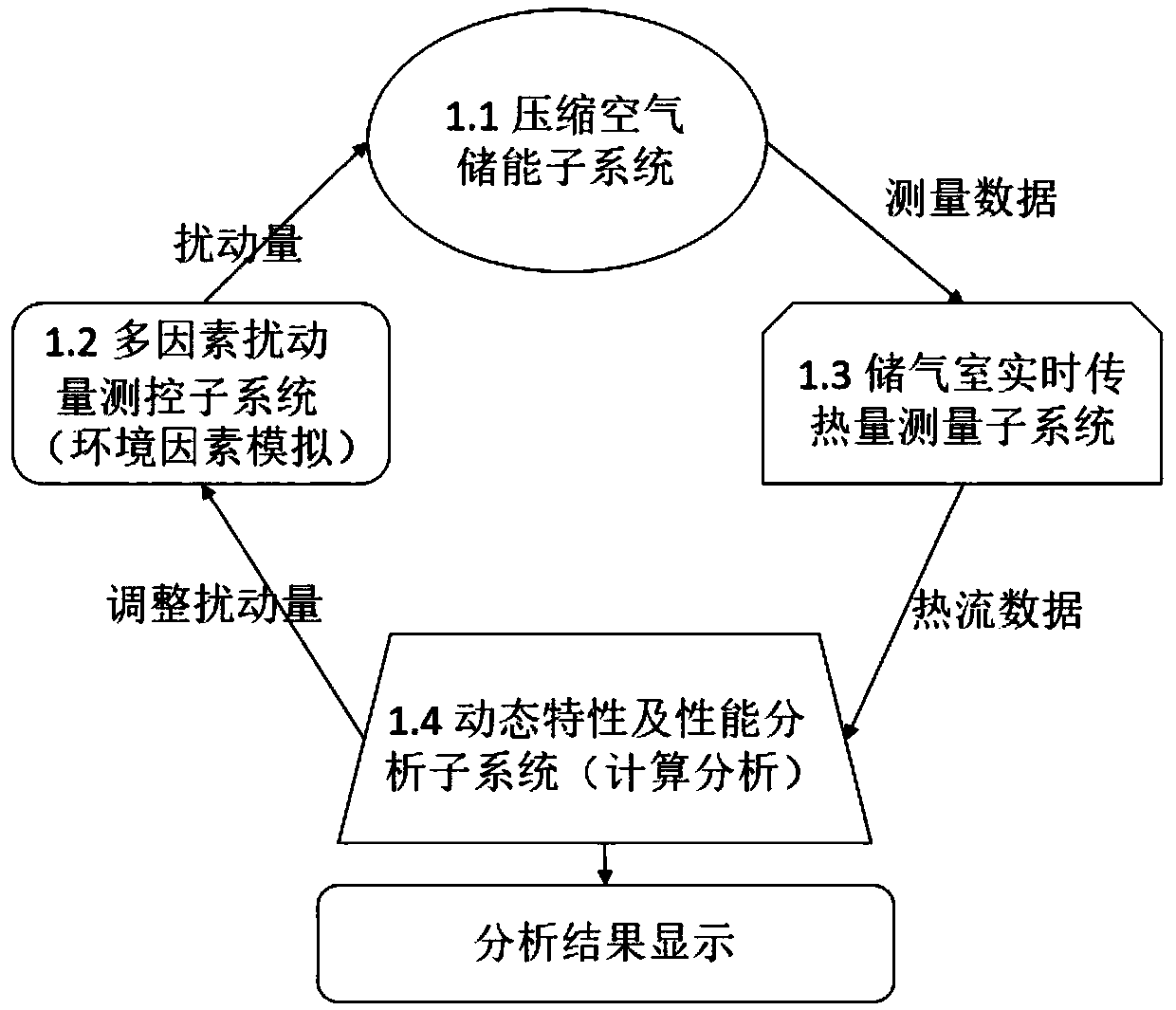

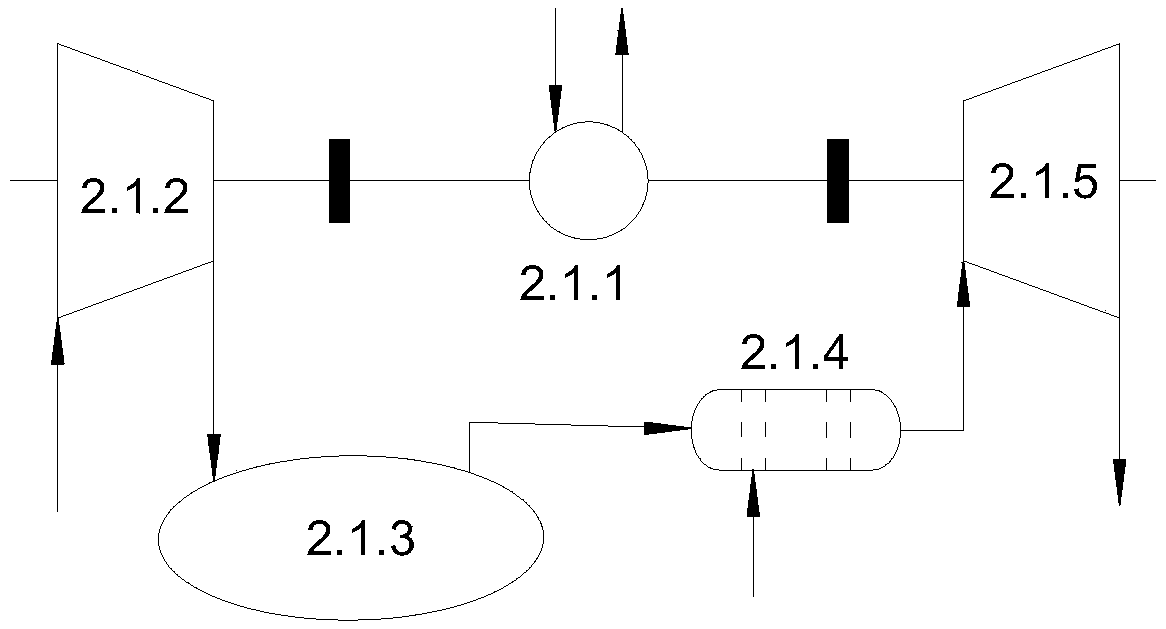

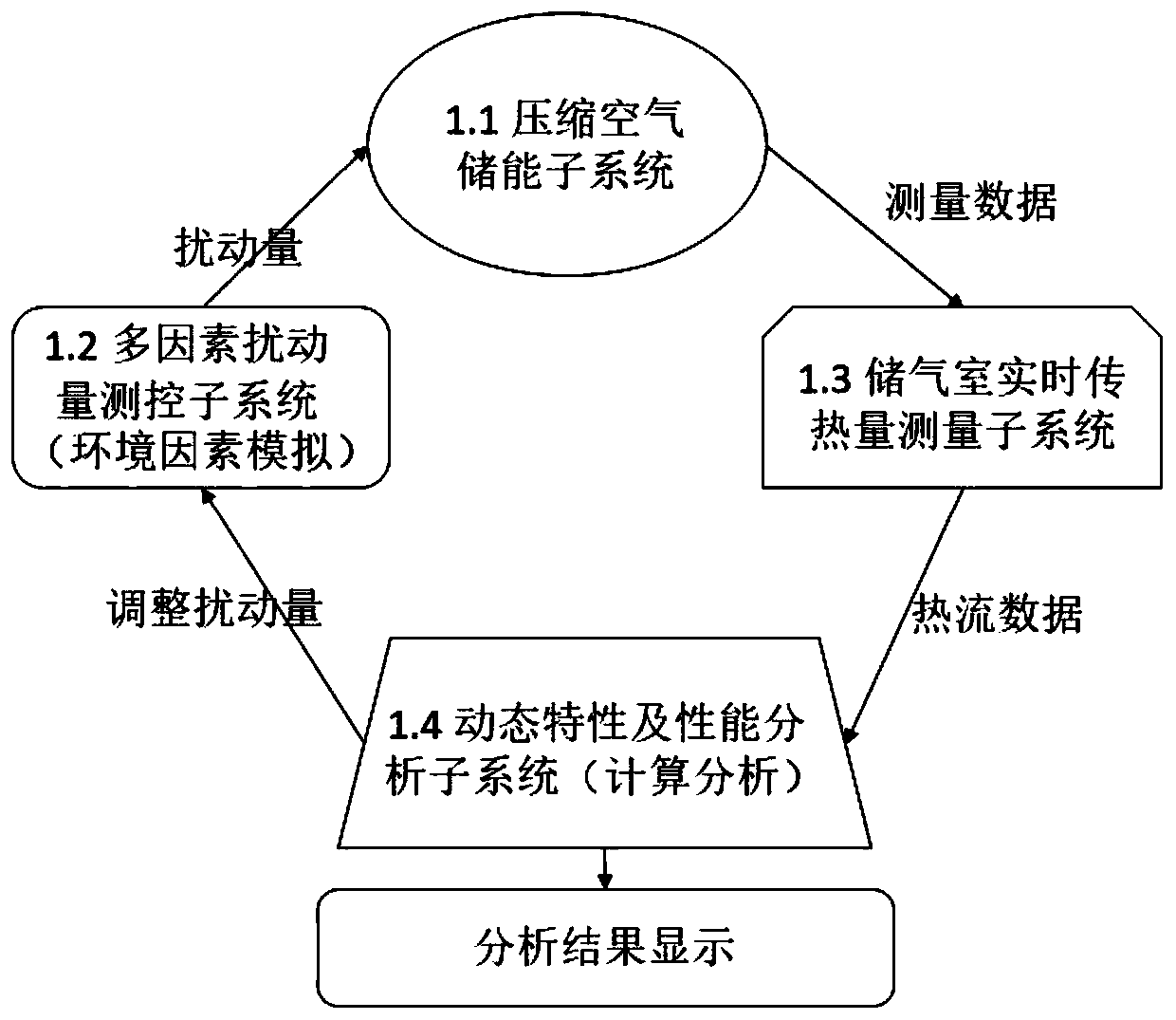

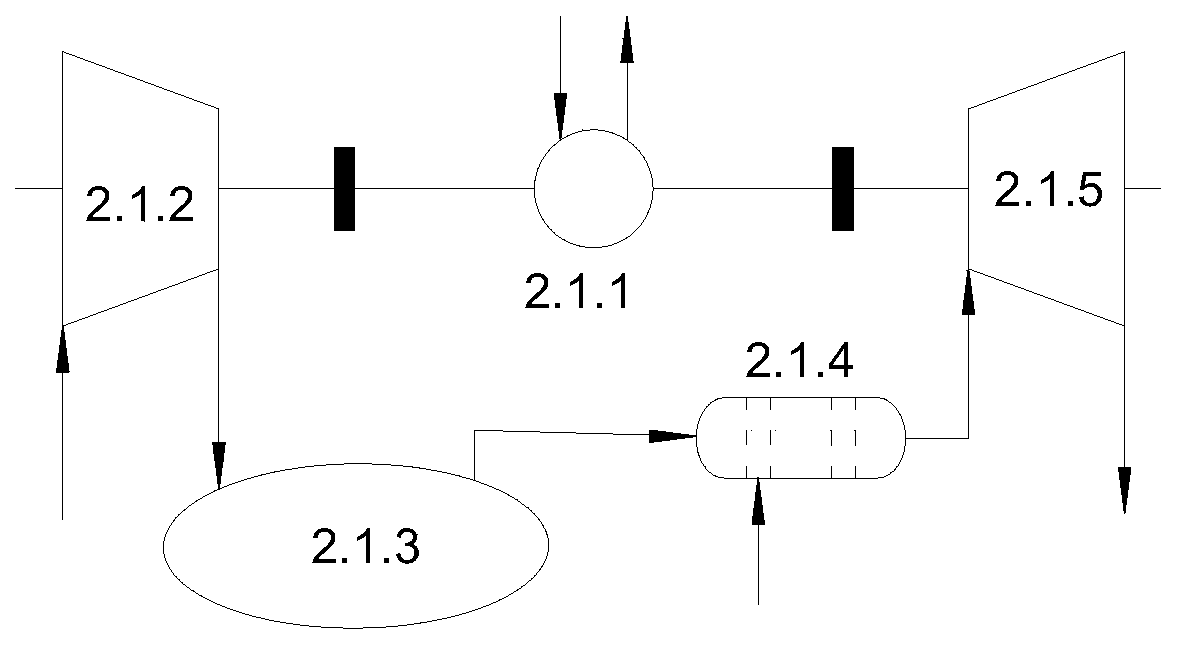

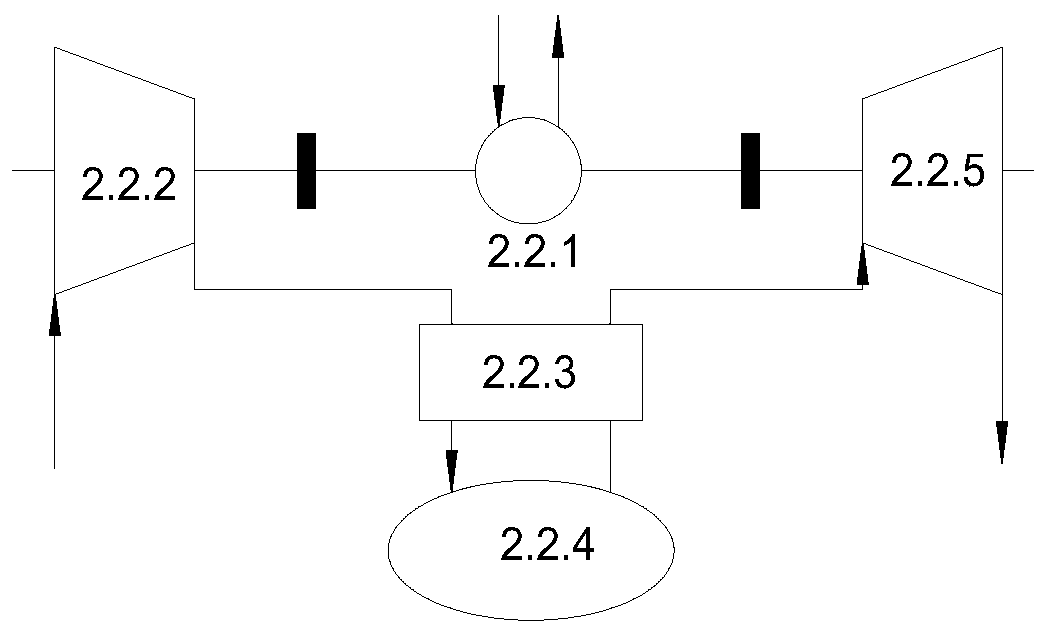

Measurement and performance analysis system for compressed air energy storage system

ActiveCN108680260AImprove economyAvoid destructionSensing radiation from gases/flamesThermal energy storageEngineering

The invention discloses a measurement and performance analysis system for a compressed air energy storage system. The measurement and performance analysis system is characterized by comprising a compressed air energy storage subsystem, a multi-factor disturbance quantity measurement and control subsystem, an air reservoir real-time heat transfer quantity measurement subsystem, and a dynamic characteristic and performance analysis subsystem. The measurement and performance analysis system can monitor and analyze the real-time heat transfer quantity of the air reservoir of the compressed air energy storage system under different inflation flow rates, deflation flow rates, maximum air storage pressures, external ambient temperatures, air reservoir surface wind speeds, air reservoir surface air humidity, and air reservoir surface smudginess, accurately grasps the dynamic operating characteristics of the compressed air energy storage system, and dynamically evaluates and analyzes the operation performance of the compressed air energy storage system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

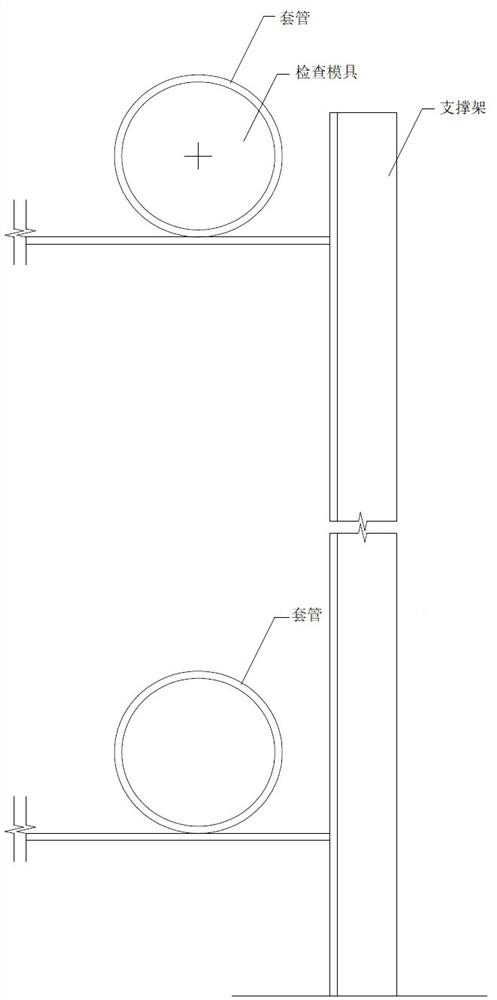

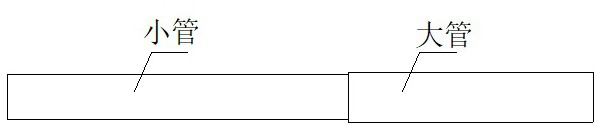

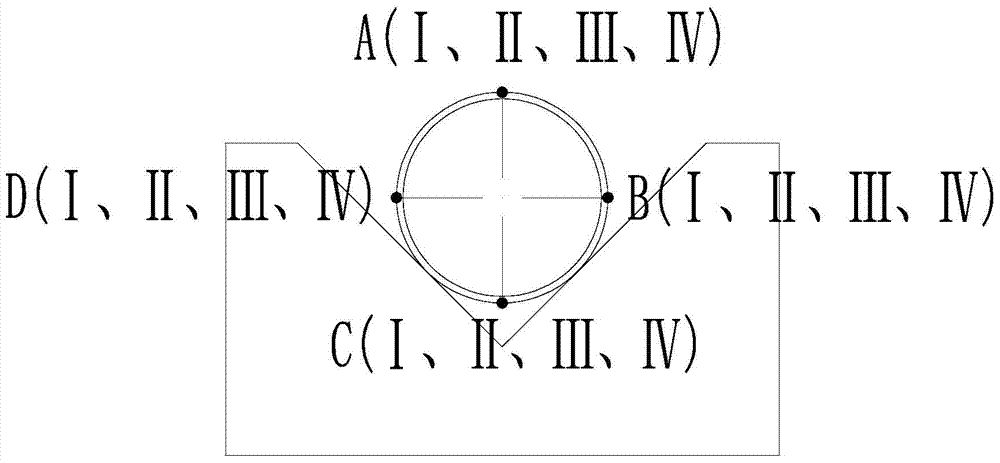

Method for detecting concentricity of combined pipes of different calibers

ActiveCN104534966AThe test result is accurateCheck quality is reliableMechanical measuring arrangementsNuclear powerQuality control

The invention relates to a method for detecting the concentricity of combined pipes of different calibers, belonging to the technical field of nuclear power station construction. The method comprises that the welded pipes of different calibers are horizontally placed on a fixing device, the pipes are fixed, a precise spirit level is used to measure the elevation of points in different directions of the pipes, theoretical elevation values of the different points are computed inversely via the distance between the points, and the central deviation of the pipes are obtained via calculation. The method can overcome the concentricity of the combined and welded pipes of different calibers is hard to detect, the method can be used to obtain accurate detection results, provides basis for practical position detection of the pipes, does not require a special lathe, is flexible in detection and convenient in measurement, and can satisfy requirements for quality control in onsite construction.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

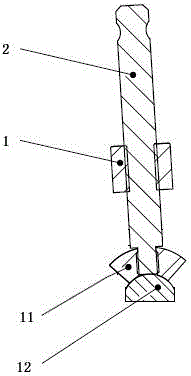

Y-type rapid positioning device for measuring center position of railway track

ActiveCN104634250ARapid positioningImprove collection efficiencyUsing optical meansThree-dimensional spaceTrackway

The invention relates to a Y-type rapid positioning device for measuring a center position of a railway track. At present, a track geometry state measuring instrument needs to be placed on a measurement position of a steel rail to carry out positioning in order to observe a three-dimensional space posture of the steel rail, and the collection efficiency is relatively low. The Y-type rapid positioning device disclosed by the invention comprises a Y-shaped baseplate with a hole in the middle; a locking nut is arranged in the hole in the middle of the Y-shaped baseplate; a prism bar is inserted into the locking nut; a half-cylinder is arranged at the bottom end of the prism bar and positioned on the surface of the steel rail; the top surface the prism bar is provided with a prism bar base of which the bottom surface is a concave spherical surface; the bottom end of the prism bar is inserted into a fixing groove formed in the top surface of the prism bar base; two symmetrical extruding ends are arranged on one side of the Y-type baseplate; the end part of each extruding end is provided with a downward steel rail clamp hook which is positioned on one side of the steel rail; the other end of each extruding end is connected with a fixing clamp which is positioned on the other side of the steel rail. The Y-type rapid positioning device disclosed by the invention can realize rapid positioning of the center position of the high speed railway track through a total station, so that the collecting efficiency is improved; the Y-type rapid positioning device is more portable, and simpler and more flexible to measure, and the measurement accuracy is greatly improved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

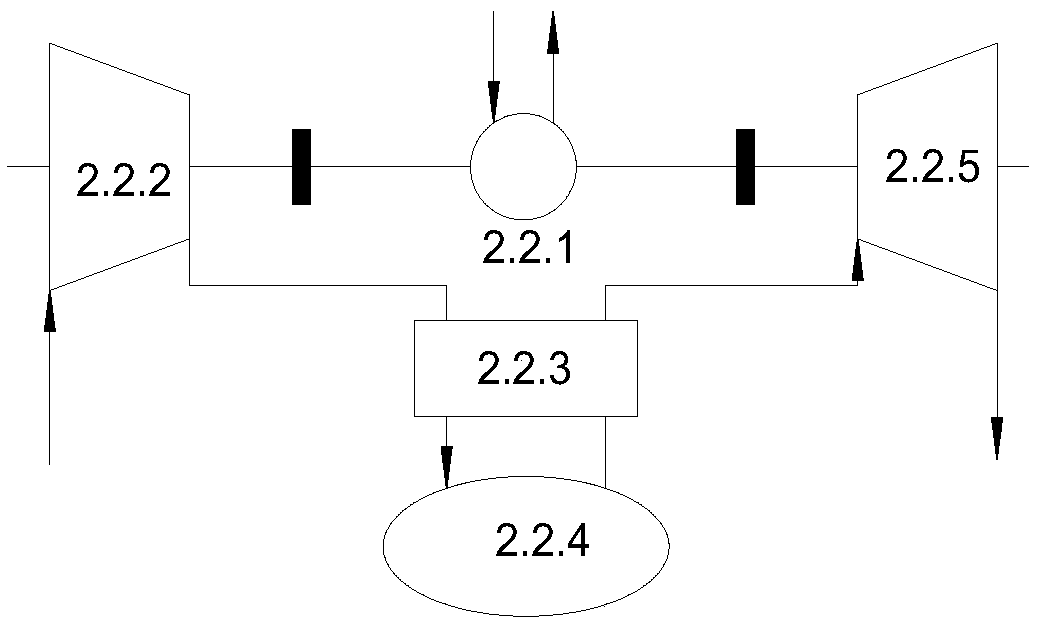

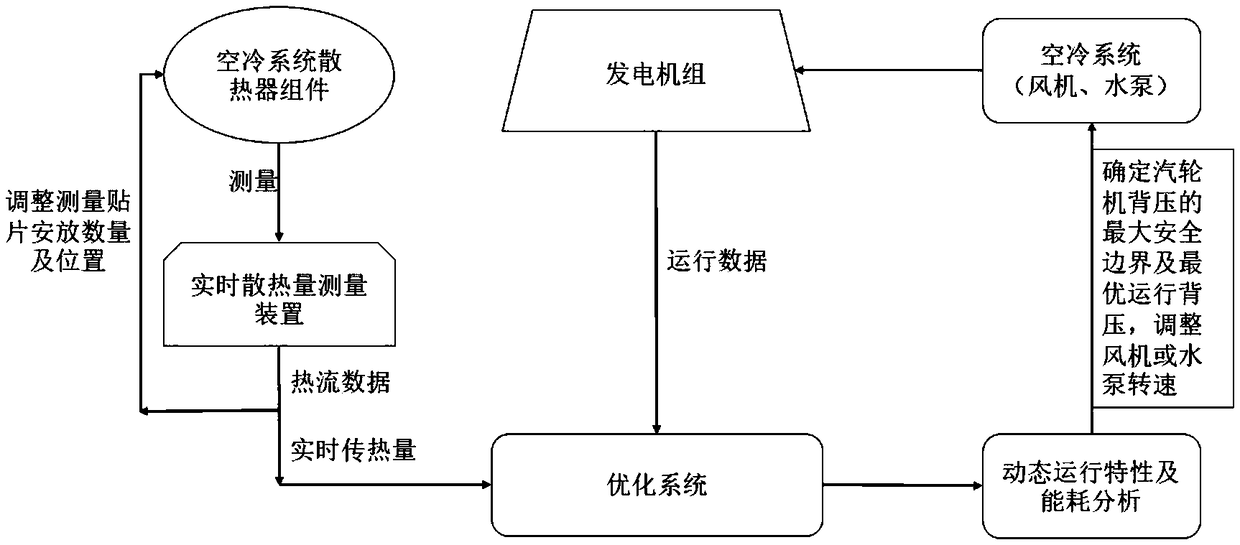

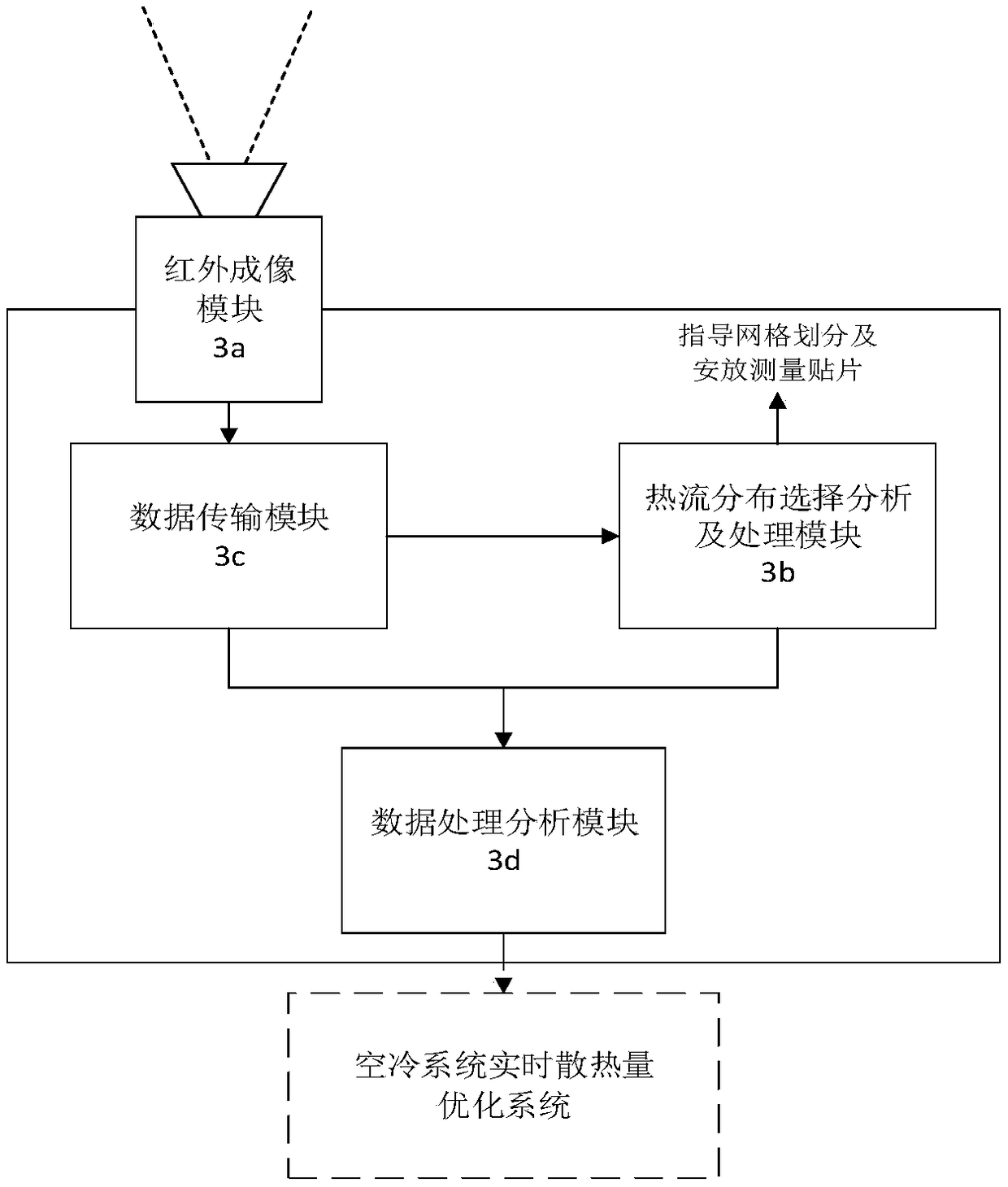

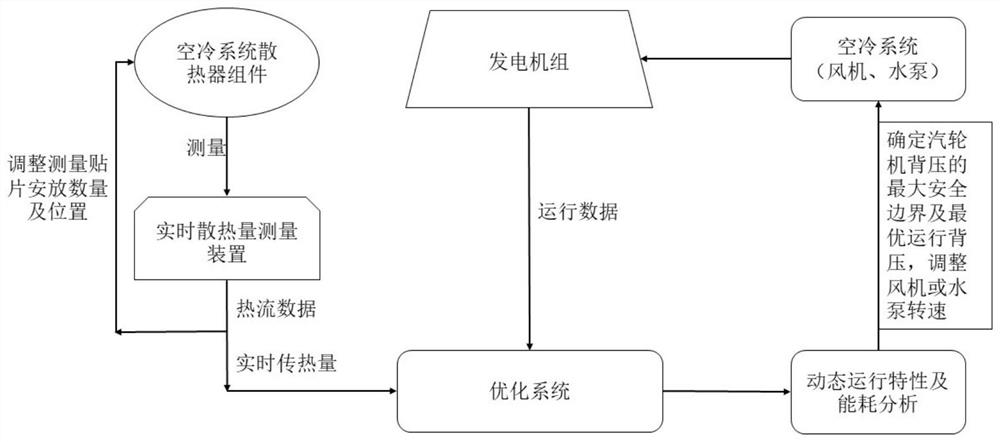

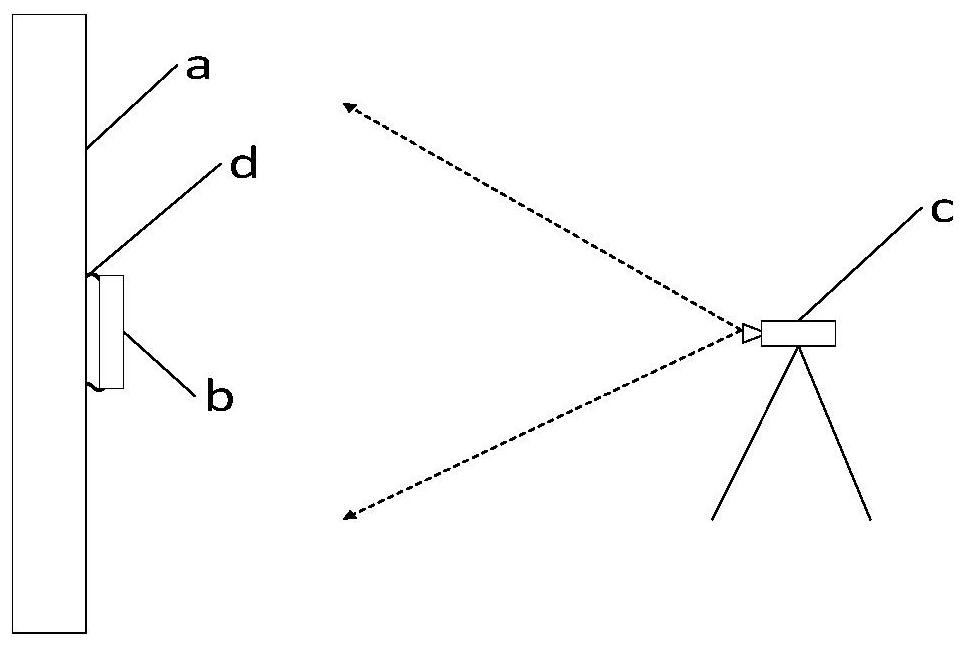

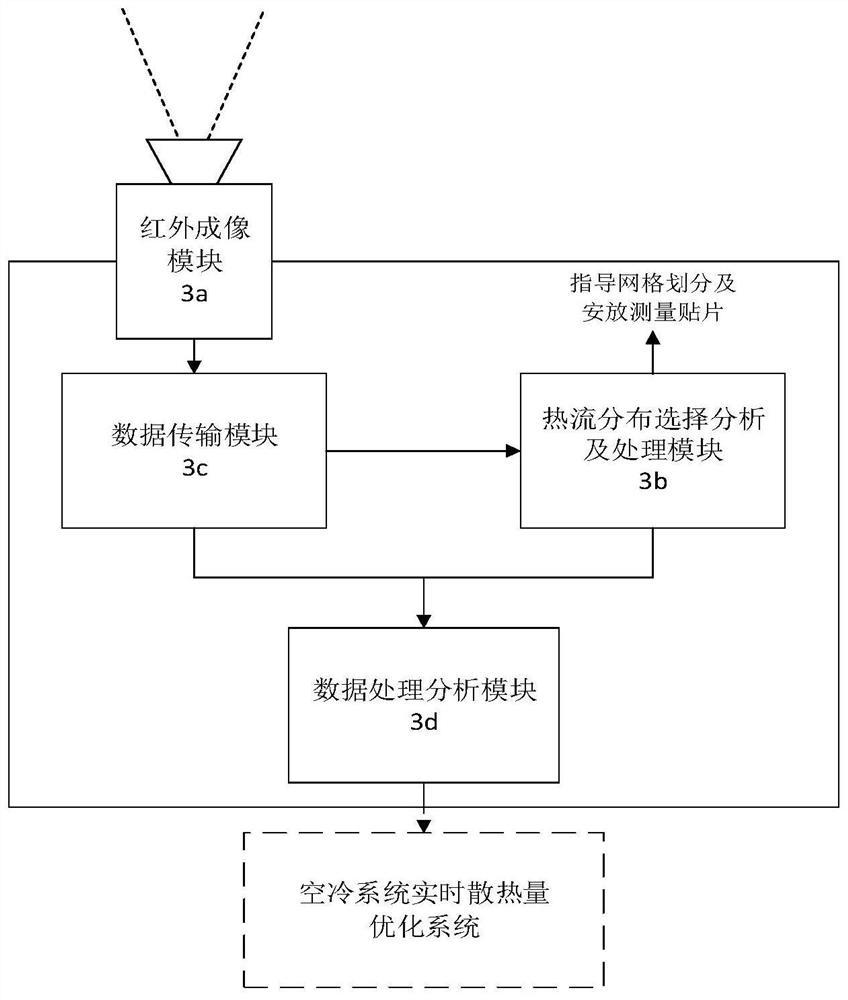

Air cooling system heat dissipation volume measurement based power plant optimization control system and method

The invention discloses an air cooling system heat dissipation volume measurement based power plant optimization control system and method. The system includes an air cooling radiator assembly, a radiator assembly real time heat transfer measurement sub system, a power generator dynamic operation feature analysis sub system, an air cooling system operation optimization sub system and a data transmission and data display sub system. According to the invention, based on a non-contact-type infrared measurement principle, damage to the surface of the air cooling system radiator assembly by a traditional contact-type temperature measurement device and interference on a temperature field on the surface of the radiator assembly are avoided. At the same time, compared with a traditional thermocouple temperature measurement method, the system does not need an exterla cable, so that the economical efficiency of the measurement platform is improved; high flexibility and convenience are achieved during the measurement process and larger air cooling system radiator assembly area can be measured, so that measurement efficiency is improved effectively.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

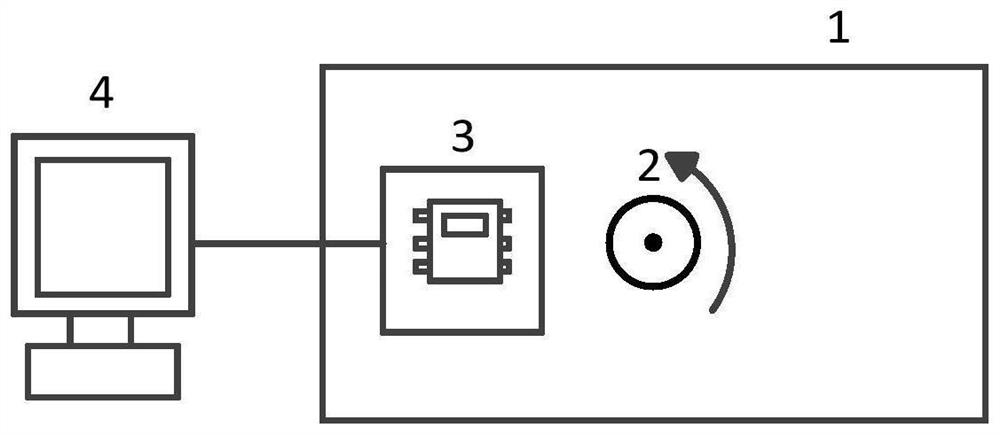

System and method for inertial measurement of rotating shaft angle of single-axis rotating carrier

ActiveCN111220114BEasy and flexible measurementAccurate and efficient measurementNavigation by speed/acceleration measurementsGyroscopeQuaternion

The invention provides a single-shaft rotating carrier rotating shaft rotating angle inertia measurement system and method, the system comprises inertia measurement equipment and a computer; the inertia measurement equipment comprises a microprocessor, and a three-axis accelerometer, a three-axis gyroscope and a three-axis magnetometer which are in electric signal connection with the microprocessor; the inertial measurement equipment is further provided with a fixed end, and the inertial measurement equipment is fixedly arranged at any position of any plane of the rotary carrier through the fixed end; the inertia measurement equipment is in communication connection with the computer; the computer is used for calculating the rotating shaft rotating angle of the rotating carrier according tothe attitude information of the inertial measurement equipment; by solving an incremental quaternion, the rotation shaft rotation angle information of the single-shaft rotation carrier can be outputin real time by combining the relation between the increment quaternion and the shaft angle pair, the method is easy to operate, complex measurement equipment does not need to be assumed, the measurement process is simplified, the equipment size is small, work completely depends on self equipment, concealment is good, work is not limited by the measurement environment, measurement is flexible, andreliability is high.

Owner:SHANDONG UNIV

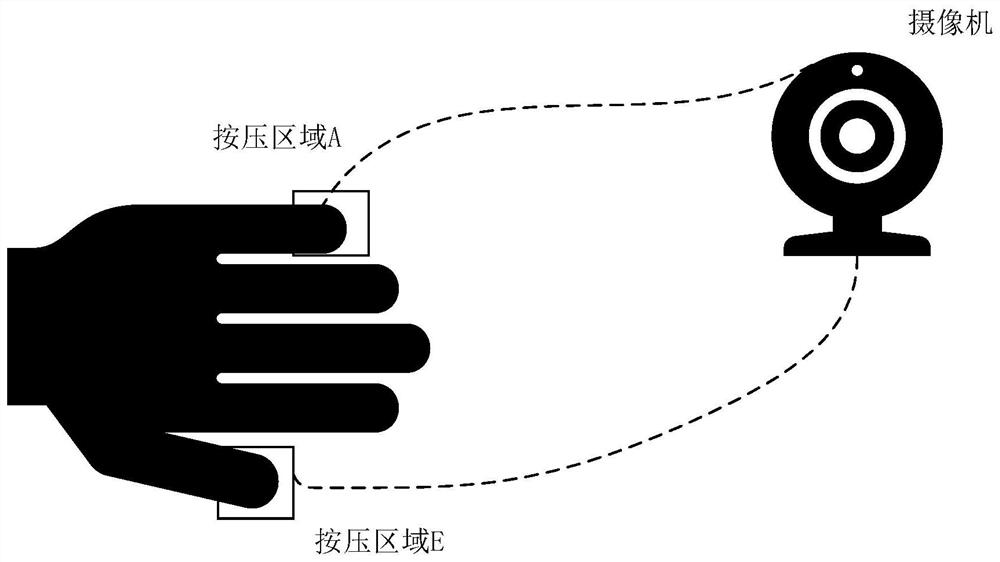

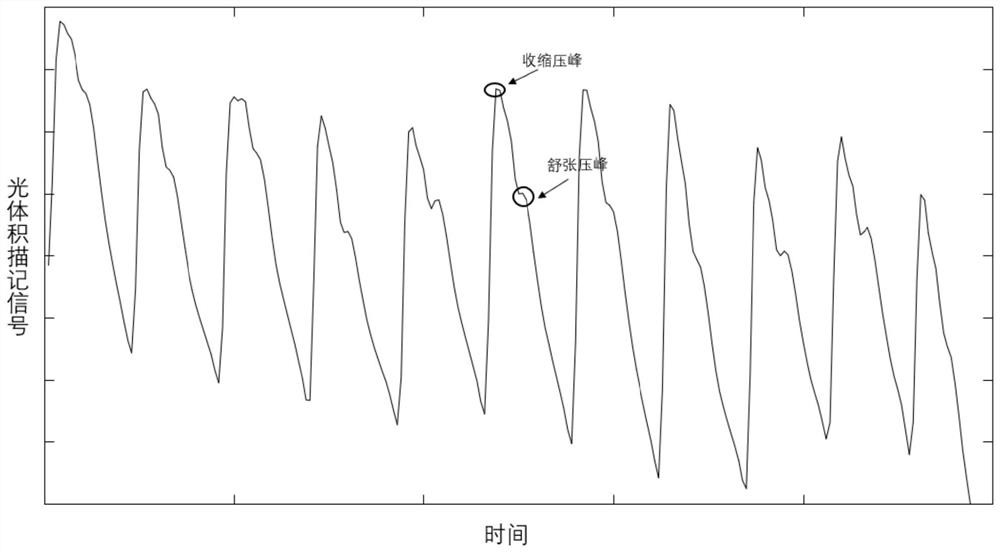

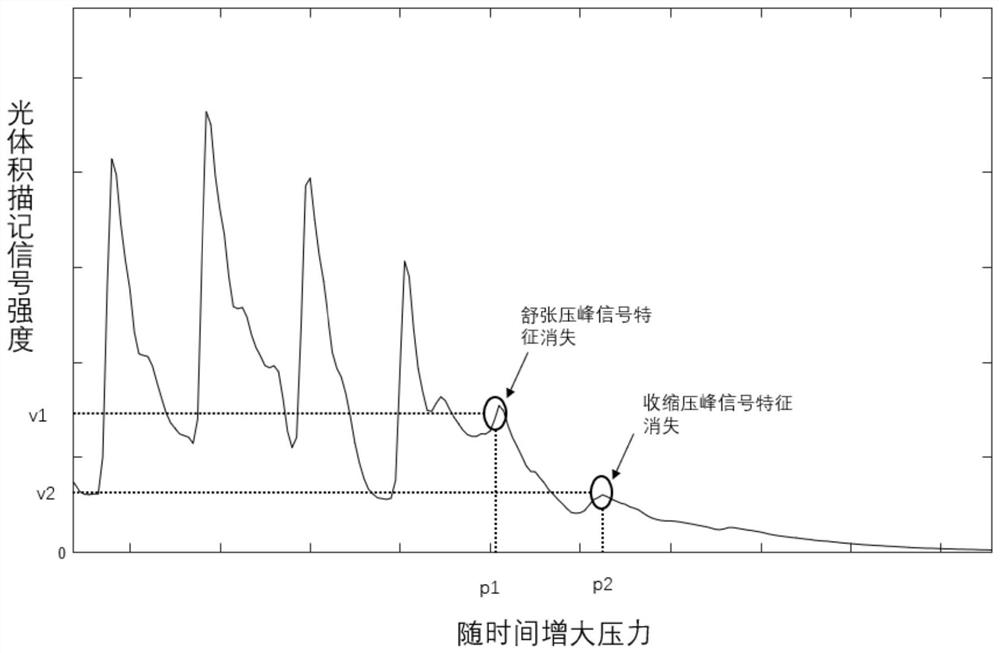

Pressing position positioning and pressure measuring method based on light volume change tracing imaging

PendingCN113670516AEasy and flexible measurementSimple methodEvaluation of blood vesselsAngiographyEngineeringPressure measurement

The invention discloses a pressing position positioning and pressure measuring method based on light volume change tracing imaging, and the method does not need a pressure sensor, only needs a camera, and can carry out the positioning of a pressing area and the measurement of a pressure value. Before measurement is started, only one-time simple calibration work is needed, light volume signal characteristics corresponding to diastolic pressure and systolic pressure disappear one by one along with gradual increase of pressing force, two groups of pressure values and corresponding light volume signal intensity values are recorded, and a relation curve of pressure and blood light volume change can be fitted. Through the relation curve, pressure values corresponding to different blood light volume signal intensities can be obtained. Different from a traditional technical route, the invention provides a non-contact measurement method for determining the pressing position and measuring the pressure through a camera. The method is simple, a pressure sensor does not need to be installed, and a plurality of pressing areas can be flexibly and conveniently measured on the surface of any object.

Owner:ZHEJIANG LAB

A method for non-destructive measurement of coating thickness by ultrasonic signal spectrum filtering technology

ActiveCN103615996BAccurate measurementAccurate reading of propagating soundUsing subsonic/sonic/ultrasonic vibration meansUltrasonic thickness measurementSonification

Owner:DALIAN UNIV OF TECH

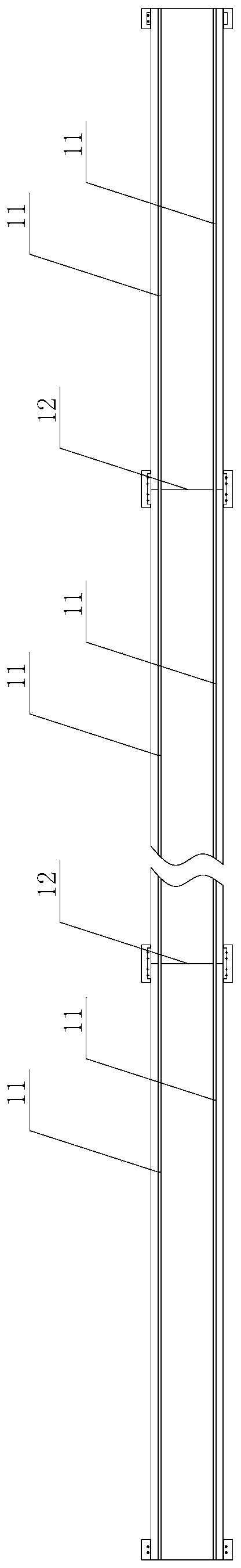

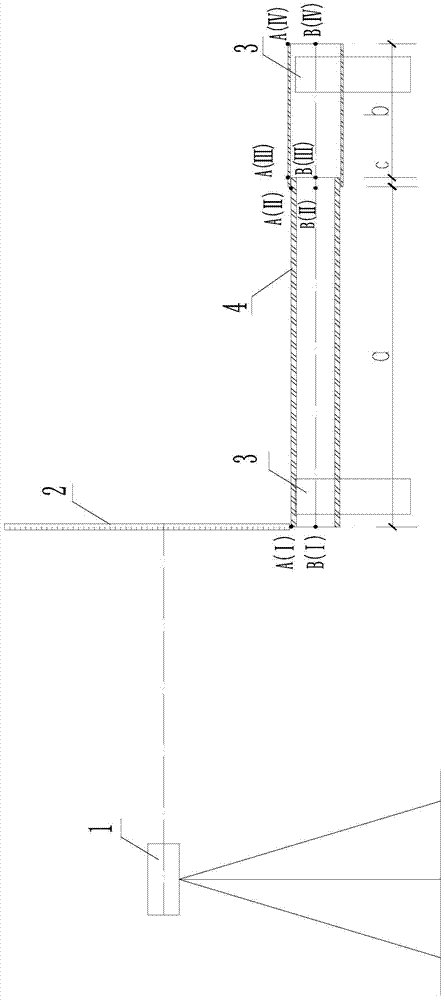

a long-length baseline

ActiveCN108051236BImprove structural stabilityImprove straightnessStructural/machines measurementSatellite radio beaconingEngineeringMechanical engineering

The invention discloses a long-length base line. The long-length base line comprises a foundation, guide rail platforms and linear guide rails, wherein the plurality of guide rail platforms are spliced along q straight line and are mounted on the foundation through hoisting supports arranged at the bottoms of the guide rail platforms; left and right side walls of the guide rail platforms in a splicing direction are provided with protruding positioning blocks; positioning plates are arranged at the left and right sides on the foundation in the splicing direction of the guide rail platforms; positioning grooves for inserting the positioning blocks are formed in the positioning plates; positioning screw holes are formed in two side walls along the splicing direction of the guide rail platforms, a top side wall in a vertical direction and a transverse wall surface vertical to the splicing direction of the guide rail platforms of each positioning groove; the plurality of linear guide railsare spliced and paved on the top surfaces of the guide rail platforms along the splicing direction of the guide rail platforms. According to the long-length base line disclosed by the invention, a guide rail system is used for replacing a traditional observation pier, so that the measurement efficiency is effectively improved, and automatic measurement in a whole process can be realized; the laborintensity of a measurement process is reduced, and a standard value is measured through an interferometer; the detection and calibration precision is effectively improved.

Owner:中国测试技术研究院机械研究所

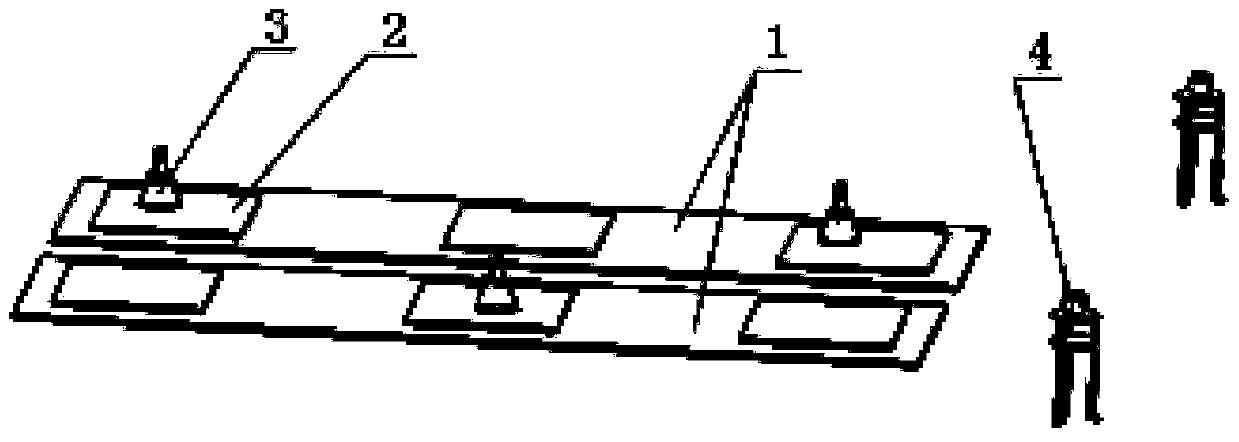

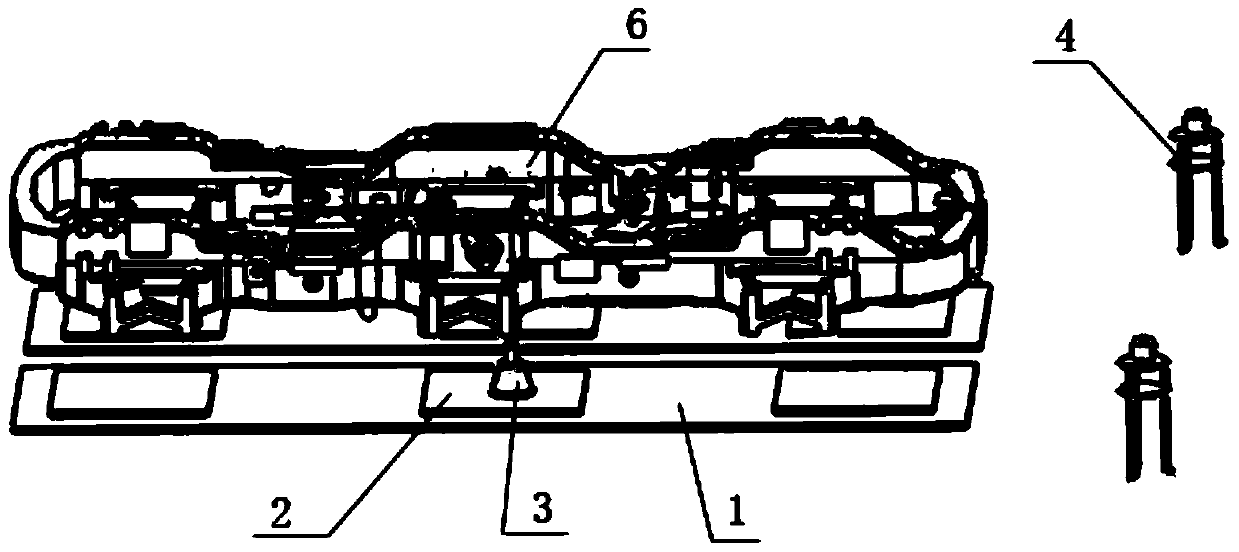

A method and device for measuring the flatness of a rail transit locomotive bogie without a platform

The invention relates to a method and device for measuring the straightness of a rail transit locomotive bogie platform without a platform. A rubber mat is laid on the field; a supporting plate is placed on the rubber mat; a thimble is placed on the supporting plate; a laser marking instrument is arranged outside the rubber mat. Adjust the adjustable bracket of the laser marking instrument to make it horizontal and on a plane; hoist the bogie and place it on the thimble; adjust the casting parting surface of the bogie, and the parting surface and the horizontal light emitted by the laser marking instrument coincide until. Its structure includes a rubber pad, supporting plate, thimble, and laser marking instrument. A supporting plate is set on the rubber mat for the finished font, an thimble is arranged on the supporting plate, and a laser marking instrument is installed next to the rubber pad. The advantages are: the rubber pad can reduce the damage to the ground, the supporting plate forms a local stable structure, and then supports the bogie through the thimble to form a temporary measuring platform, which can measure the flatness flexibly and conveniently, and the operation is simple, reducing the number of operators Quantity; tooling is simple, easy to adjust, intuitive.

Owner:LIAONING FU-AN HEAVY INDUSTRY CO LTD

Power plant optimization control system and method based on heat dissipation measurement of air cooling system

The invention discloses a power plant optimization control system and method based on the heat dissipation measurement of an air cooling system. The system includes: an air cooling radiator assembly, a real-time heat transfer measurement subsystem of the radiator assembly, a dynamic operating characteristic analysis subsystem of a generator set, Air cooling system operation optimization subsystem and data transmission and data display subsystem. Based on the principle of non-contact infrared measurement, the invention avoids the damage of the traditional contact temperature measuring device to the surface of the radiator assembly of the air cooling system and the interference to the temperature field of the surface of the radiator assembly. At the same time, compared with the traditional thermocouple temperature measurement method, the measurement The system does not need external cables, which improves the economy of the measurement platform; it is more flexible and convenient during the measurement process, and can measure a larger area of the radiator component of the air cooling system, effectively improving the efficiency of the measurement.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A method for checking the parallelism of pipeline installation

ActiveCN110534215BTroubleshoot parallelism checksThe test result is accurateNuclear energy generationNuclear monitoringRebarPipe

Owner:CHINA NUCLEAR IND HUAXING CONSTR

Pulsed laser spot software synchronization acquisition method

InactiveCN100367281CImprove stabilityNot easy to interferePhotometryImage data processing detailsComputer hardwareHardware structure

The invention relates to a software synchronization acquisition method of impulse laser light spot, which adopts ridge CCD camera which can output standard video signal or infrared camera, image collection card and measuring system which is formed by main control computer with capture software program. It collects data by ridge CCD camera or infrared camera and controls image collection card which is connected with ridge CCD camera or infrared camera by video cable through capture software program which is connected with image collection card. It collects the light impulse laser spots and achieves totally software synchronization acquisition and analysis in executing function.

Owner:NAT UNIV OF DEFENSE TECH

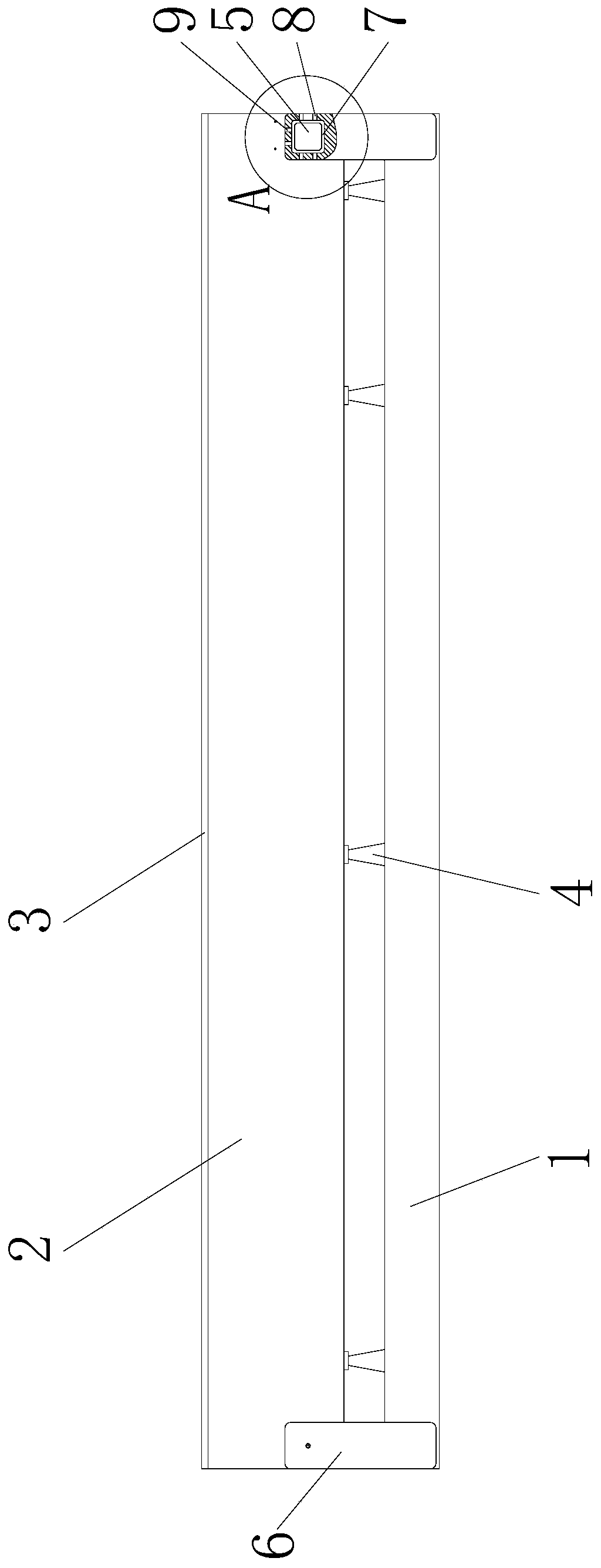

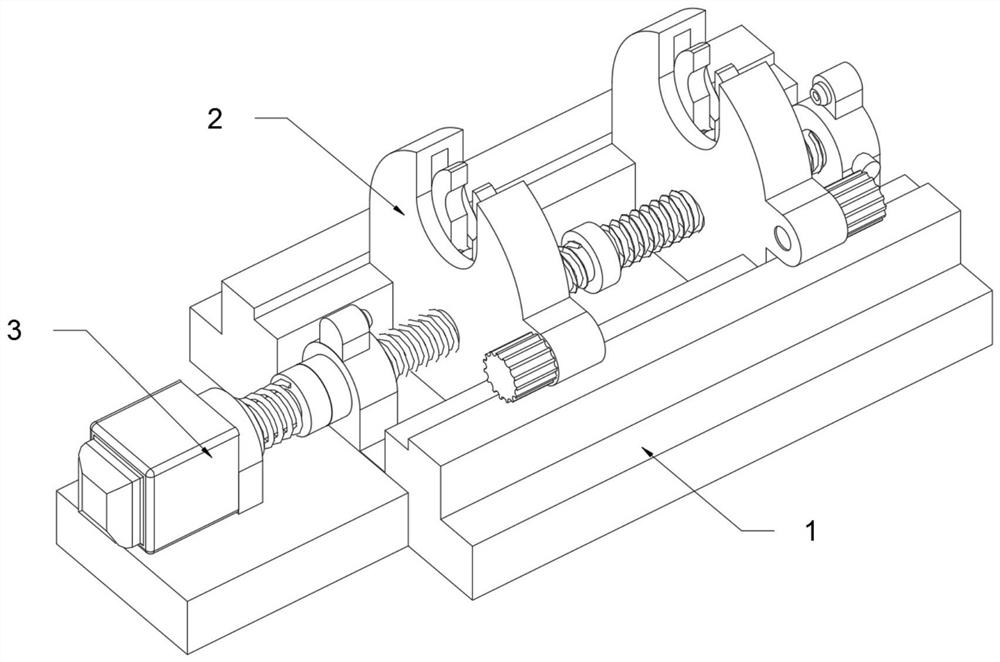

Circular groove medium diameter detecting ruler and using method thereof

PendingCN110017756AReduce labor intensityEasy and flexible measurementMechanical diameter measurementsEngineeringDiameter measurement

The invention relates to a circular groove medium diameter detecting ruler and a using method thereof, which belong to the field of pressure container and pressure pipe sealing and overcome the defects of inconvenient measurement and large errors in the prior art. The structure comprises a main ruler 1, a vernier ruler 2, two spherical measuring feet 3, two rotating shafts 4, a toggle slider 5, asliding clamp 6 and the like, wherein the vernier ruler 2 and the boss at the lower end of the toggle slider 5 pass through the middle groove of the main ruler 1; one rotating shaft 4 fixes one spherical measuring foot 3 on one end of the main ruler 1, the other rotating shaft 4 clamps the other spherical measuring foot 3 and the toggle slider 5 in the long groove of the main ruler and can slide in the long groove of the main ruler 1. The two spherical measuring feet 3 are placed in circular grooves in use, the main ruler 1 is rotated along the circular groove, and when the vernier ruler 2 moves to the maximum distance, the center distance between the two spherical measuring feet 3 is the circular groove medium diameter. The ruler and the method are applicable to medium diameter measurement for pressure container and pressure pipe-used flange ring connection surface sealing grooves and also all circular grooves.

Owner:LANZHOU LS HEAVY EQUIP

X-type rapid positioning device for measuring the center position of railway track

ActiveCN104674619BRapid positioningImprove collection efficiencyMeasuring apparatusMeasuring instrumentThree-dimensional space

The invention relates to an X-shaped fast positioning device for railway rail center position measurement. For the steel rail three-dimensional space posture observation in the prior art, a rail geometrical state measuring instrument needs to be put in a steel rail measuring position for positioning, and the collecting efficiency is lower. The X-shaped fast positioning device comprises a lower layer X arm and an upper layer X arm provided with center open holes, wherein the two arms are respectively straight arms, the upper and lower center open holes are aligned, crossed and combined for forming an X shape; a locking screw nut is arranged in each center open hole, a prism rod is inserted in each locking screw nut, the bottom end of each prism rod is a concave spherical surface, a semi-cylinder is arranged under the concave spherical surface, and is positioned on the surface of the steel rail, the bottom surface of the semi-cylinder is a flat plane, and the top surface of the semi-cylinder is a spherical surface; the end part of the lower layer X arm and the end part of the upper layer X arm are respectively provided with downwards steel rail clamp hook heads which are positioned at the two sides of the steel rail; fixing buckles are arranged between the same ends of the lower layer X arm and the upper layer X arm positioned at the opposite sides of the steel rail. The X-shaped fast positioning device has the advantages that the fast positioning of the high-speed railway rail center position can be realized through a full station instrument, the collecting efficiency is improved, the measurement is simple, convenient and flexible, and the measuring precision is also greatly improved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

A measurement and performance analysis system for compressed air energy storage system

ActiveCN108680260BImprove economyAvoid destructionSensing radiation from gases/flamesAtmospheric sciencesAir humidity

The invention discloses a measurement and performance analysis system for a compressed air energy storage system. The measurement and performance analysis system is characterized by comprising a compressed air energy storage subsystem, a multi-factor disturbance quantity measurement and control subsystem, an air reservoir real-time heat transfer quantity measurement subsystem, and a dynamic characteristic and performance analysis subsystem. The measurement and performance analysis system can monitor and analyze the real-time heat transfer quantity of the air reservoir of the compressed air energy storage system under different inflation flow rates, deflation flow rates, maximum air storage pressures, external ambient temperatures, air reservoir surface wind speeds, air reservoir surface air humidity, and air reservoir surface smudginess, accurately grasps the dynamic operating characteristics of the compressed air energy storage system, and dynamically evaluates and analyzes the operation performance of the compressed air energy storage system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A method for detecting the concentricity of combined pipes with different diameters

ActiveCN104534966BThe test result is accurateCheck quality is reliableMechanical measuring arrangementsQuality controlReducer

The invention relates to a method for detecting the concentricity of welded and connected pipes with combined pipes of different diameters, belonging to the technical field of nuclear power plant construction. The method includes placing welded pipes of different diameters horizontally on a fixture, keeping the pipes fixed, measuring the point elevations in all directions of the pipes with a precision level, and calculating the elevation of each point according to the distance between the points. value, and then calculate the deviation of the pipe center. The present invention solves the difficult problem of checking the concentricity of a pipe after welding of a combination pipe with different diameters. basis, and does not require a special lathe, flexible detection, convenient measurement, help to meet the quality control needs of on-site construction.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

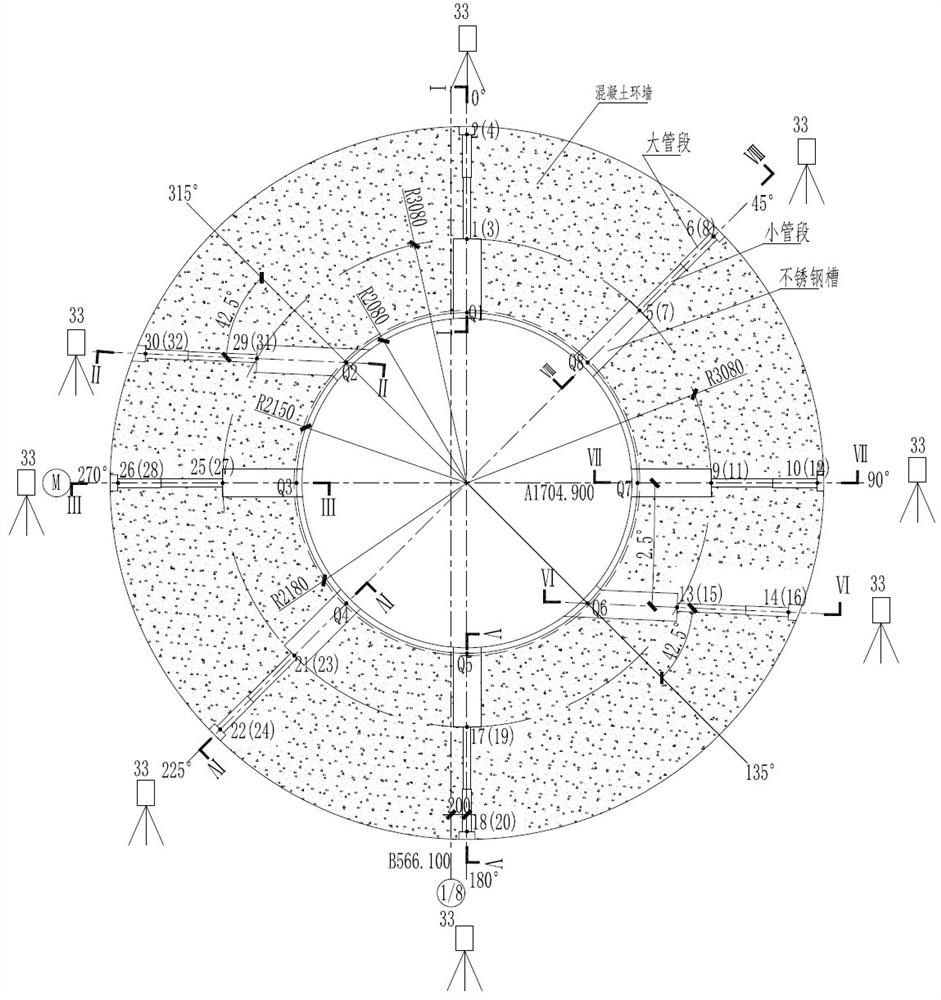

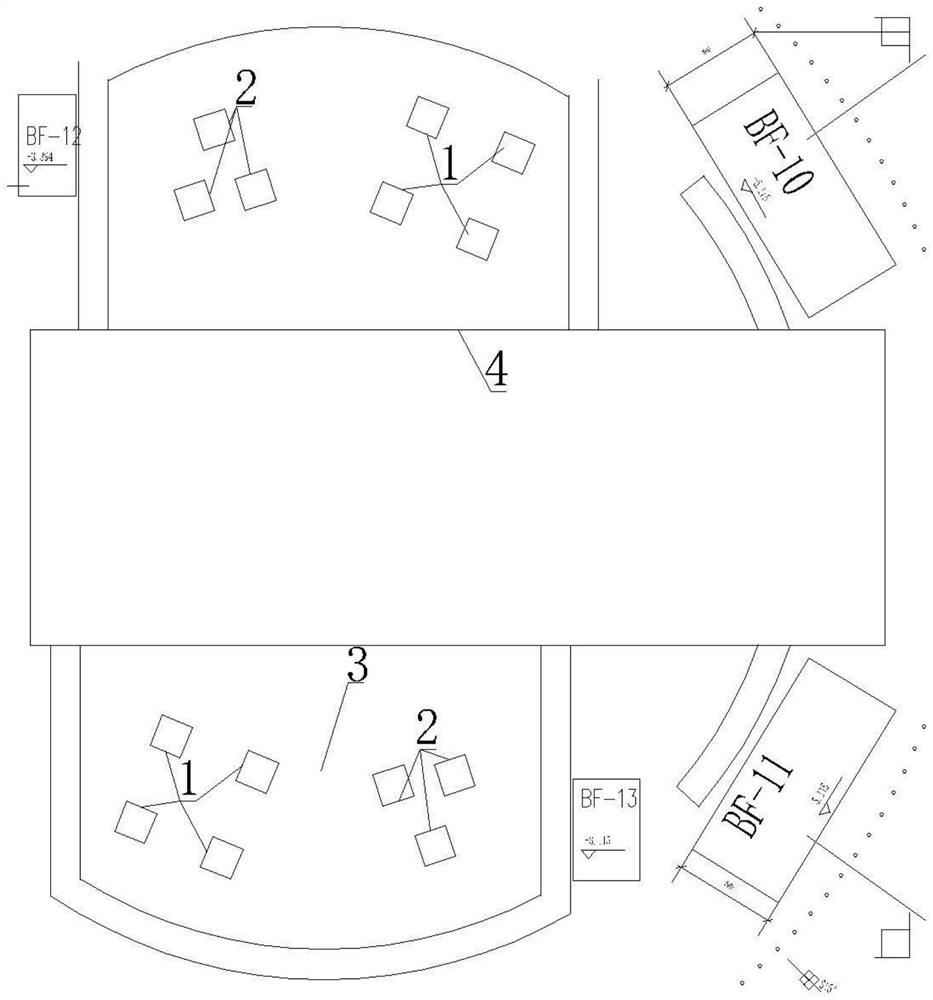

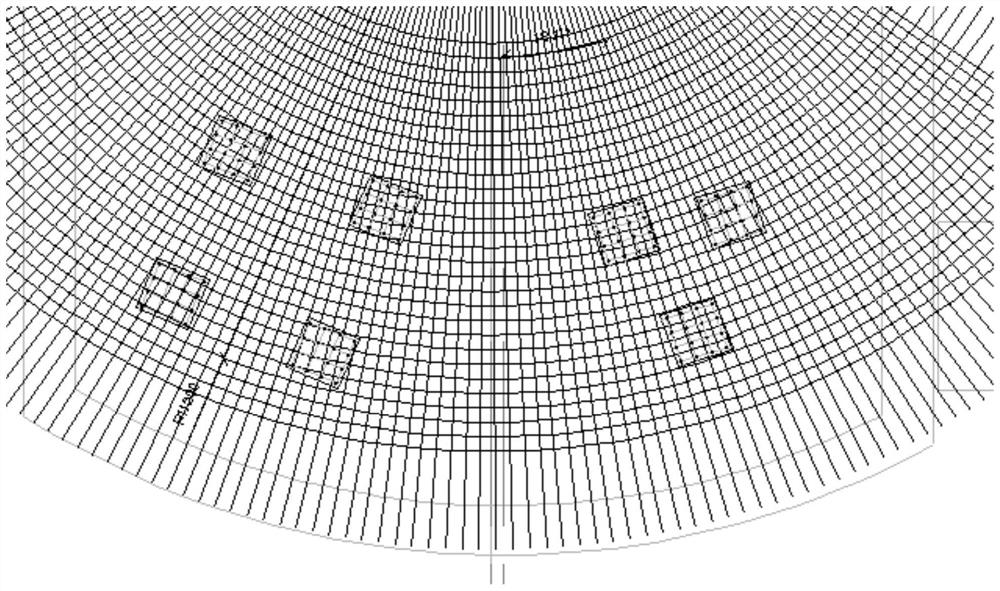

Mounting and positioning method for main pump evaporator embedded part

PendingCN114645550ASolve the difficulty of installation adjustment inspectionThe test result is accurateFoundation testingDesign optimisation/simulationSocial benefitsEconomic benefits

The invention discloses a main pump evaporator embedded part installing and positioning method which comprises the steps of base plate reinforcing steel bar position indoor adjustment, reinforcing steel bar position adjustment conflicting with embedded part anchoring reinforcing steel bars, main pump evaporator embedded part anchoring reinforcing steel bar position lofting, base plate reinforcing steel bar position lofting, reinforcing steel bar binding acceptance inspection and main pump evaporator embedded part supporting elevation adjustment. The main pump evaporator embedded part is preliminarily in place, the position of the embedded part is preliminarily adjusted, the elevation of the embedded part is accurately adjusted, and the position of the embedded part is accurately adjusted. By the adoption of the installation method, the one-time installation precision and efficiency of the high-precision embedded part are improved, labor consumption caused by improper installation and reworking due to steel bar position obstacles and the like is reduced, the embedded part can be rapidly and accurately installed in place, the construction efficiency is improved, and large economic benefits and social benefits are created.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

Method and device for measuring curvature

ActiveCN106908010BEasy and flexible measurementHigh precisionUsing optical meansRotational freedomClassical mechanics

The invention discloses a curvature measuring method and apparatus. The method comprises: a reference point position of a rotational freedom degree of a displacement sensor is set by using a normal direction of a first target point as a reference; the displacement sensor is controlled to rotate within a first preset angle based on the reference point position and measurement is carried out to obtain an absolute distance between the rotation center of the displacement sensor to the first target point; discrete processing is carried out on a to-be-measured object to obtain a preset number of second target points, a corresponding first Cartesian coordinate value when the displacement sensor measures each second target point and a first measurement value outputted by the displacement sensor, and a second Cartesian coordinate value of each second target point is calculated based on the first Cartesian coordinate value, the first measurement value and the absolute distance; and the curvature of each second target point is calculated based on the second Cartesian coordinate values. Because the Cartesian coordinate value of any point on the curved surface can be accurately calculated, the accuracy of curvature measurement is improved; and the measurement is more convenient and flexible.

Owner:SHENZHEN CITY POSONWONE TECH

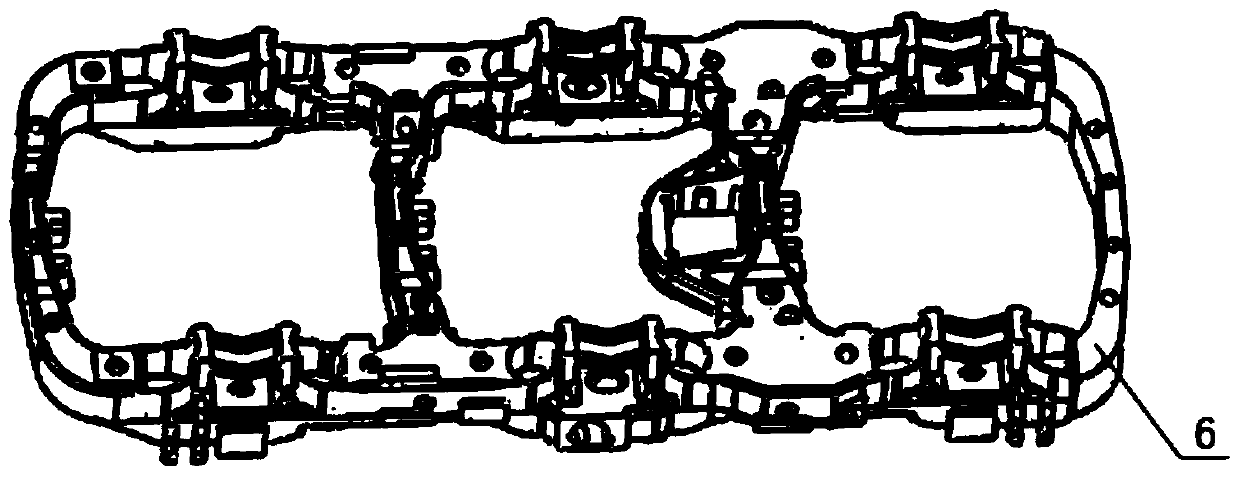

Rod bundle channel flow pressure measurement experimental device

ActiveCN106683722BEasy to moveSmooth rotationNuclear energy generationNuclear monitoringRotary stageWater storage tank

The invention provides a rod bundle channel flow pressure measuring test device, which comprises a water storage tank, a pressure measuring body, and a centrifugal pump, a regulating valve and a thermometer sequentially connected with the water storage tank through a pipeline, wherein the pressure measuring body comprises a rod bundle channel barrel, a rod bundle channel formed by rod bundles arranged in the rod bundle channel barrel; the upper ends of the rod bundles are connected with a high-accuracy rotating disk arranged on a rotating table support through a coupler; two body pressure ports formed up and down are formed in the rod bundle channel barrel; a pressure guiding port is formed in each rod bundle of the rod bundle channel; a sealing rubber plug is arranged at the lower end of each rod bundle; a fast adapter is arranged at the upper end of each rod bundle; pressure difference transmitters are respectively arranged between each pressure guiding port and each fast adapter as well as between the two body pressure ports. The rod bundle channel flow pressure measuring test device provided by the invention can simulate single-phase flow in a reactor rod bundle channel so as to research a resistance characteristic of the rod bundle channel, and is simple in structure, low in cost, accurate and convenient to acquire data, and wide in research working condition range.

Owner:HARBIN ENG UNIV

Device for measuring axial clearance of bearing with shaft based on automobile water pump

PendingCN114264265AImprove measurement efficiencyIncrease flexibilityMachine bearings testingMeasurement deviceStructural engineering

The invention provides a device for measuring the axial clearance of a bearing with a shaft based on an automobile water pump, and relates to the technical field of measuring devices.The device comprises a measuring clamp assembly, a clamping disc is inserted into the top of a measuring base, and the measuring clamp assembly can clamp and fix bearings with different specifications and lengths so as to complete the subsequent measurement of the axial clearance; meanwhile, the driving control assembly of the device can accurately measure the axial clearance of the shaft connecting bearings with different specifications and lengths through the measuring clamp assembly, so that a fixing tool and a measuring tool do not need to be replaced, the measuring efficiency is greatly improved, and the problem that when an existing measuring device is used, the measuring precision is high is solved. The problems that in the prior art, a tool can only fix the shaft connecting bearing to measure the axial clearance, adaptability is poor, corresponding fixing and measuring tools need to be replaced when shaft connecting bearings of different specifications and lengths need to be measured, and the steps are tedious are solved.

Owner:唐晓风

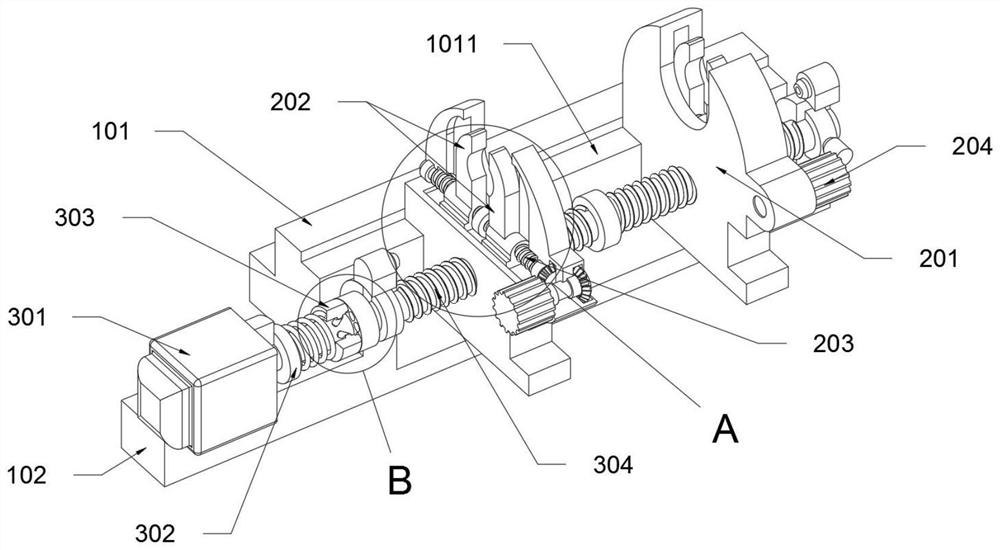

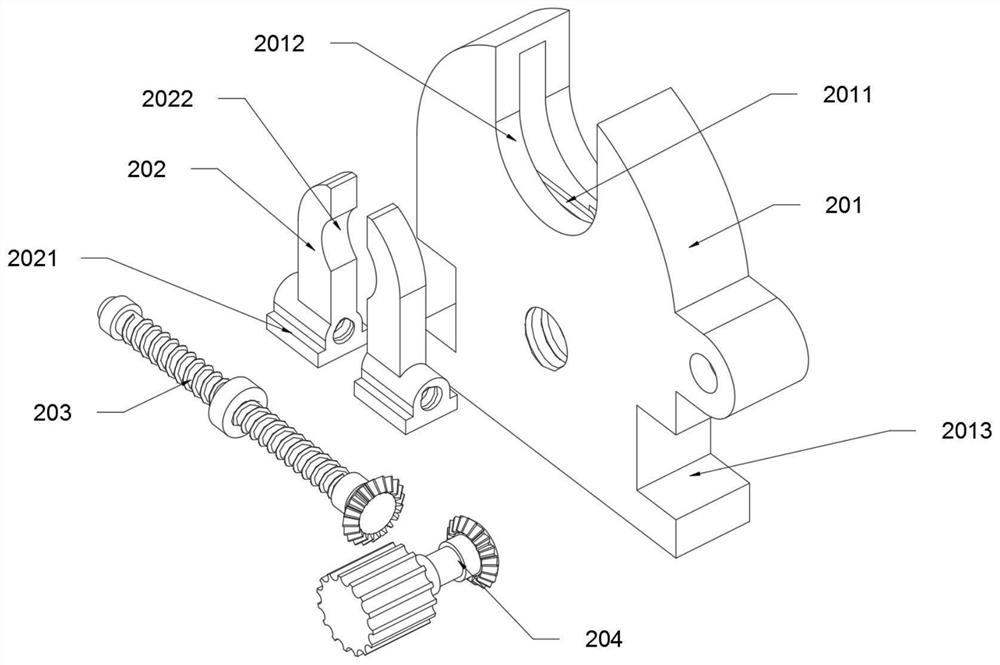

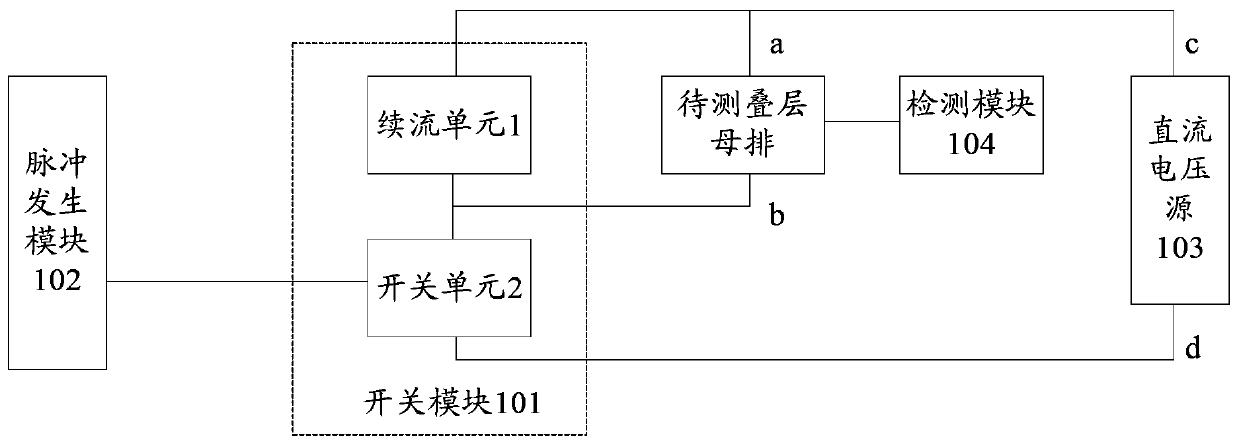

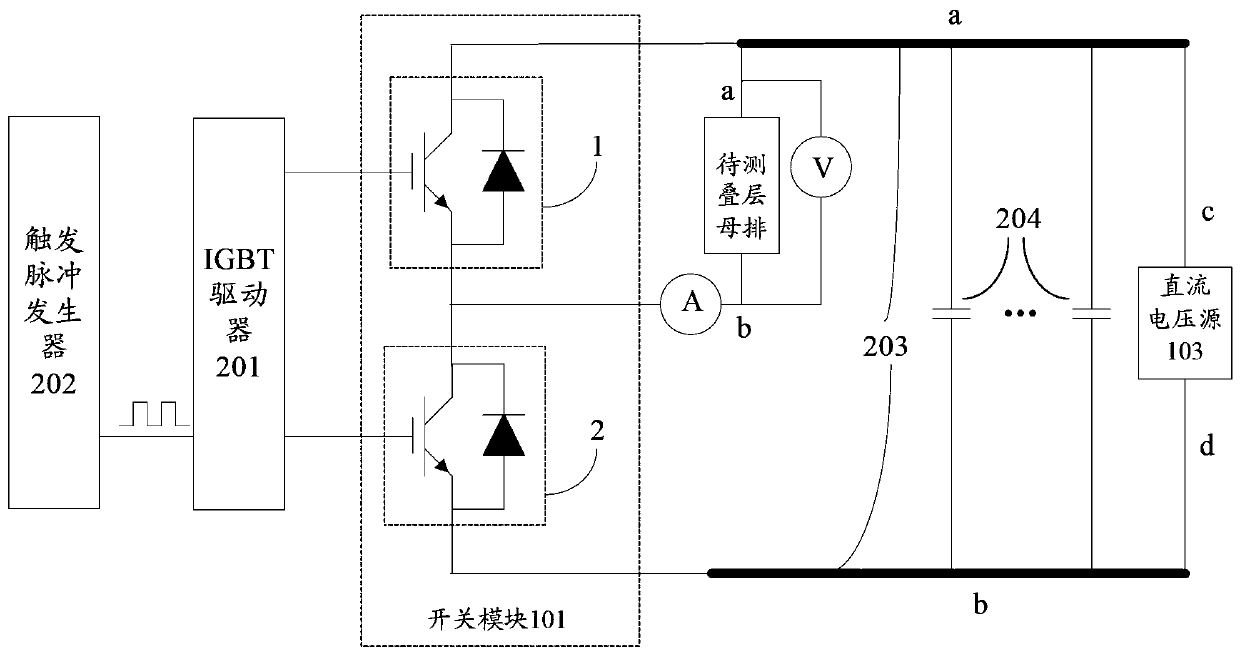

Stray inductance detection device for laminated busbar

ActiveCN103630754BEasy and flexible measurementAccurate measurementResistance/reactance/impedenceBusbarStray inductance

The present invention proposes a stray inductance detection device for laminated busbars, including: a switch module, the switch module includes a freewheeling unit and a switch unit; a pulse generation module, used to generate a driving pulse signal to enable the switch unit to conduct pass; a DC voltage source, the first output end of the DC voltage source is connected to the freewheeling unit, and the second output end of the DC voltage source is connected to the switch unit; After the first path and the second path of the busbar are connected in parallel with the freewheeling unit, the detection module is used to detect the voltage and current changes generated by the laminated busbar to be tested when the switch unit is turned on rate, and calculate the stray inductance of the laminated busbar to be tested according to the voltage and current rate of change. The device can improve detection accuracy and reduce detection cost.

Owner:BYD CO LTD

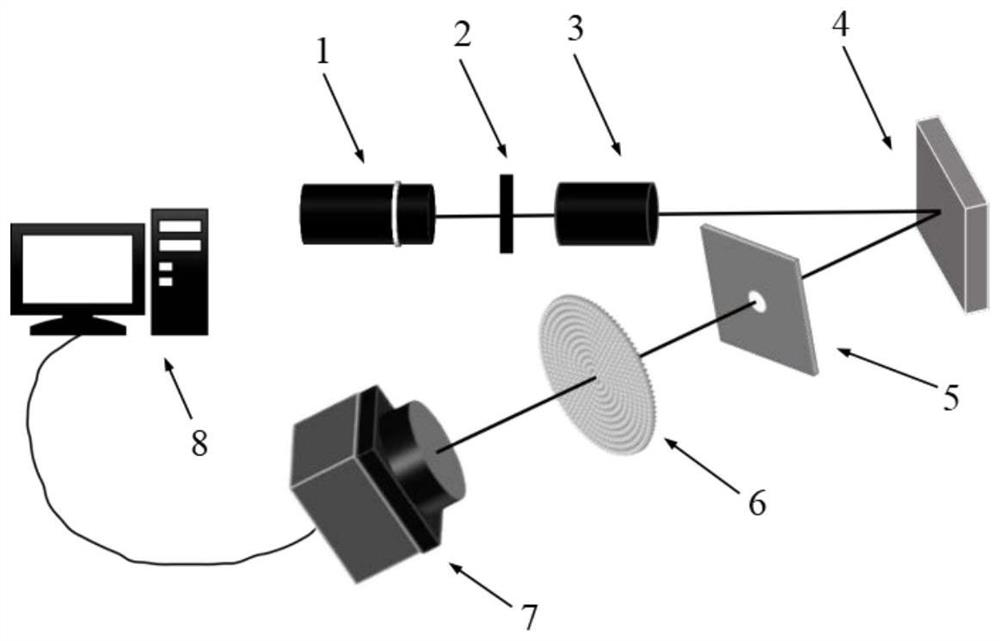

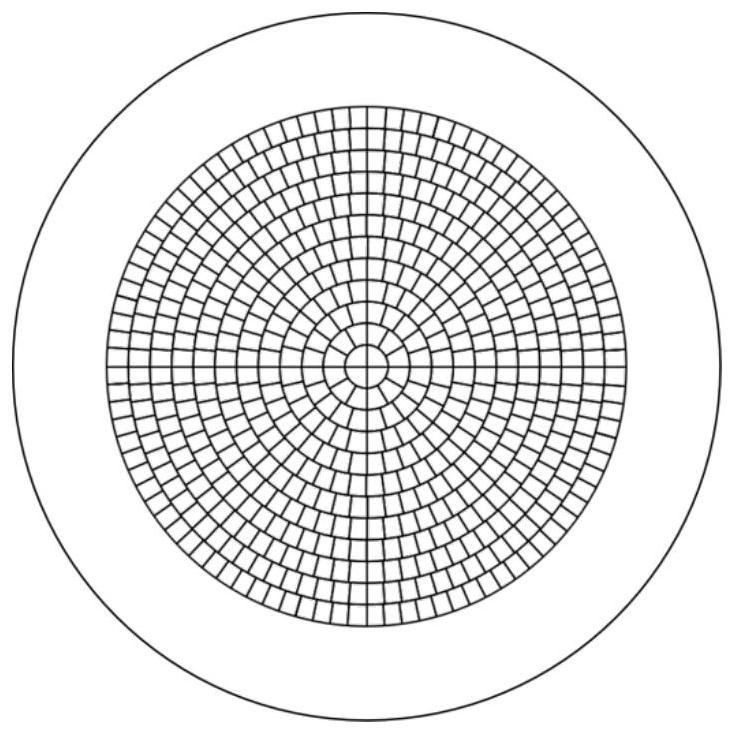

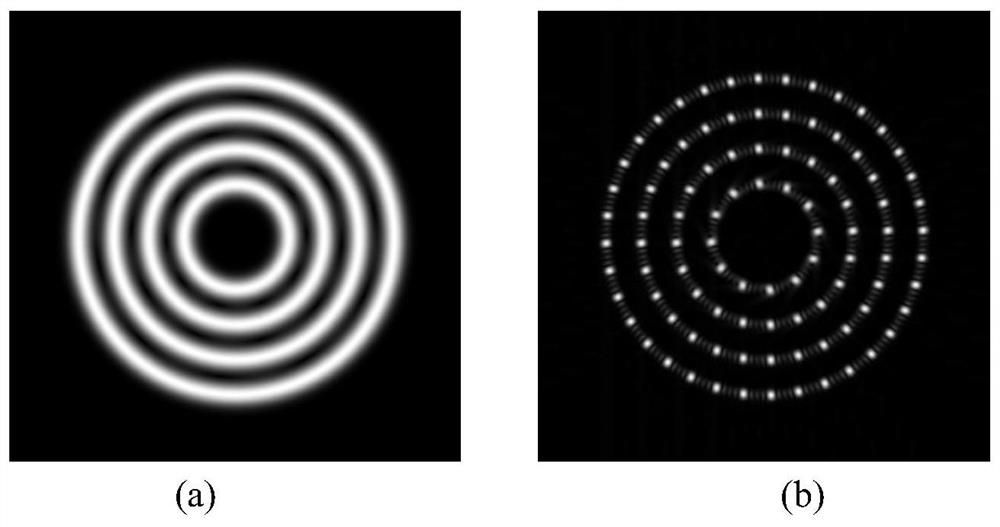

A method and apparatus for measuring multimode perfect vortex beams

ActiveCN111473872BEasy to splitRealize measurementOptical measurementsPhotometry using electric radiation detectorsLight spotLight beam

The invention discloses a method and a device for measuring a multi-mode perfect vortex beam. The invention utilizes a fan-shaped microlens array arranged in an annular shape to segment the information of each ring of a multi-mode perfect vortex beam, and solves the size and sign of each mode through closed curve integration. After the multi-mode perfect vortex beam is incident on the fan-shaped microlens array, a circularly distributed light spot array is obtained on the focal plane, and then the circular scanning starts from the center of the light spot array. The phase slope is finally brought into the closed curve integration to get the result. The method is easier to classify and process data, and can measure a wider range of modes; the method is simple in structure, convenient and fast in measurement, and has great application prospects in the fields of free-space optical communication, optical fiber communication, and optical tweezers technology.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com