Circular groove medium diameter detecting ruler and using method thereof

A technology of circular groove and measuring ruler, applied in the direction of mechanical diameter measurement, etc., can solve the problems of large measurement error and cumbersome method, and achieve the effect of improving measurement accuracy, flexible and convenient middle diameter, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

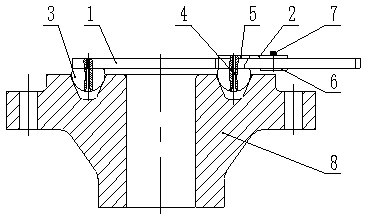

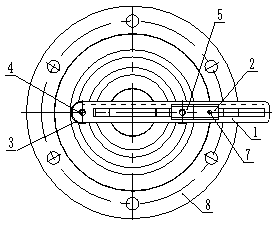

[0015] Taking the measurement of the middle diameter of the sealing groove of the connecting surface of the flange ring as an example, the present invention is specifically described in conjunction with the accompanying drawings.

[0016] Such as figure 1 figure 2 As shown, a circular groove middle diameter detection ruler has the following structure: a main ruler 1, a vernier ruler 2, two spherical measuring feet 3, two rotating shafts 4, a toggle slider 5, a sliding clamp 6, a tight Fixed screw 7; a long groove is opened in the middle of the main ruler 1, the boss at the lower end of the vernier ruler 2 and the toggle slider 5 is closely matched with the middle groove of the main ruler 1, and the boss at the lower end of the vernier ruler 2 and the toggle slider 5 penetrates into the main ruler 1 The middle groove; use a rotating shaft 4 to fix a spherical measuring foot 3 on one end of the main ruler 1, use another rotating shaft 4 to clamp another spherical measuring foo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com