Joint rotating angle auxiliary measuring system and method of serial rotary joint mechanical arm

A joint angle and auxiliary measurement technology, applied in the direction of manipulators, manufacturing tools, joints, etc., to achieve the effect of simplifying the equipment installation process, simplifying the joint angle measurement process, and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

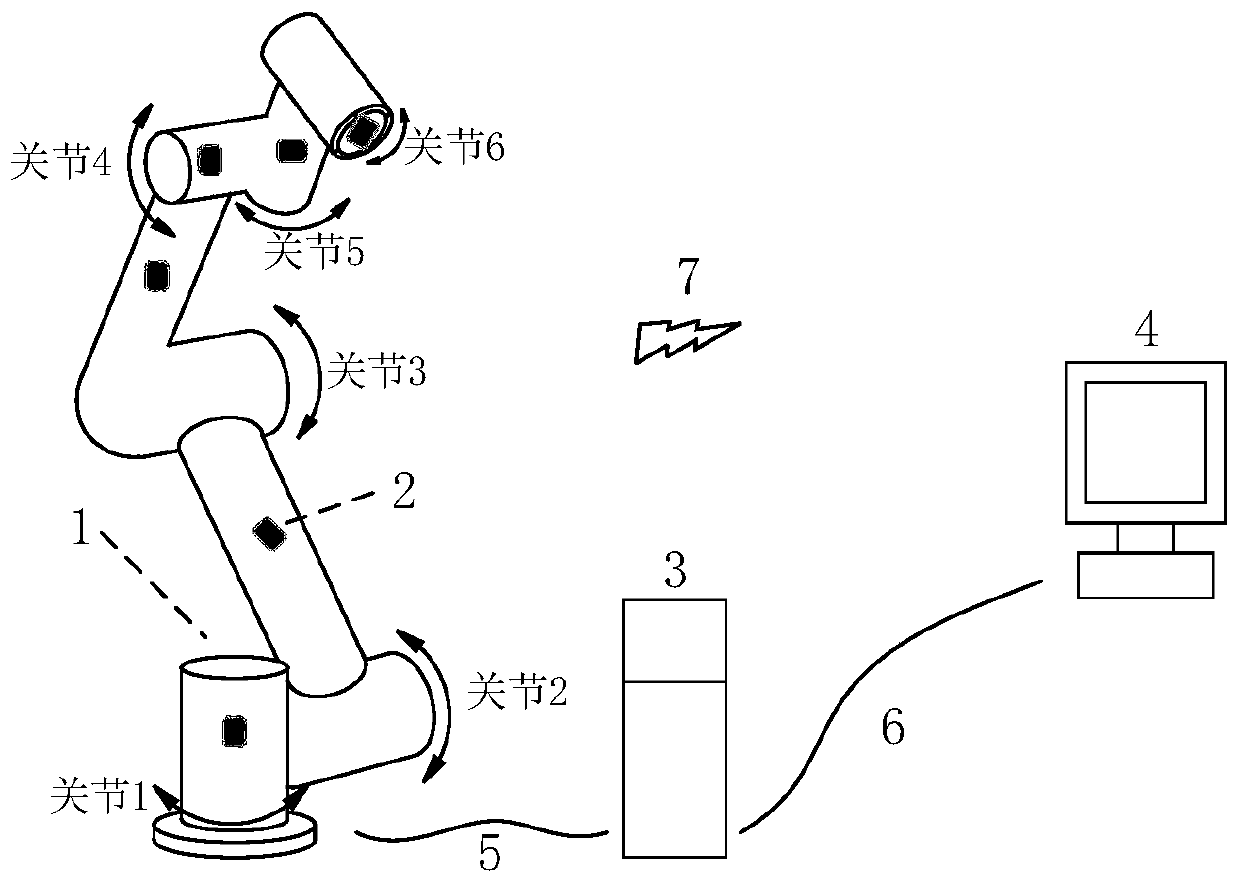

[0054] figure 1 It is a structural schematic diagram of a series rotary joint manipulator joint angle auxiliary measurement system constructed according to a preferred embodiment of the present invention, wherein 1 is a series rotary joint manipulator, 2 is an attitude measurement unit, 3 is a control cabinet of the manipulator, 4 is the computer, 5 is the cable between the robot arm 1 and the control cabinet 3, 6 is the network cable connecting the control cabinet 3 to the computer 4, and 7 is the communication between each attitude measurement unit 2 fixed on the robot arm 1 and the computer 4 Way.

[0055] The mechanical arm 1 can be any multi-degree-of-freedom series rotary joint mechanical arm in practice. For convenience, figure 1 What is shown in is a common six-degree-of-freedom series rotary joint manipulator.

[0056] The number of the attitude measurement units 2 should match the degrees of freedom of the robot arm, and the attitude measurement units 2 can be fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com