A method and device for measuring the flatness of a rail transit locomotive bogie without a platform

A locomotive bogie and rail transit technology, which is applied in the field of platform-less flatness measurement of rail transit locomotive bogies, can solve the problem of high cost, and achieve the effects of simple tooling, reduced damage, and reduced number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

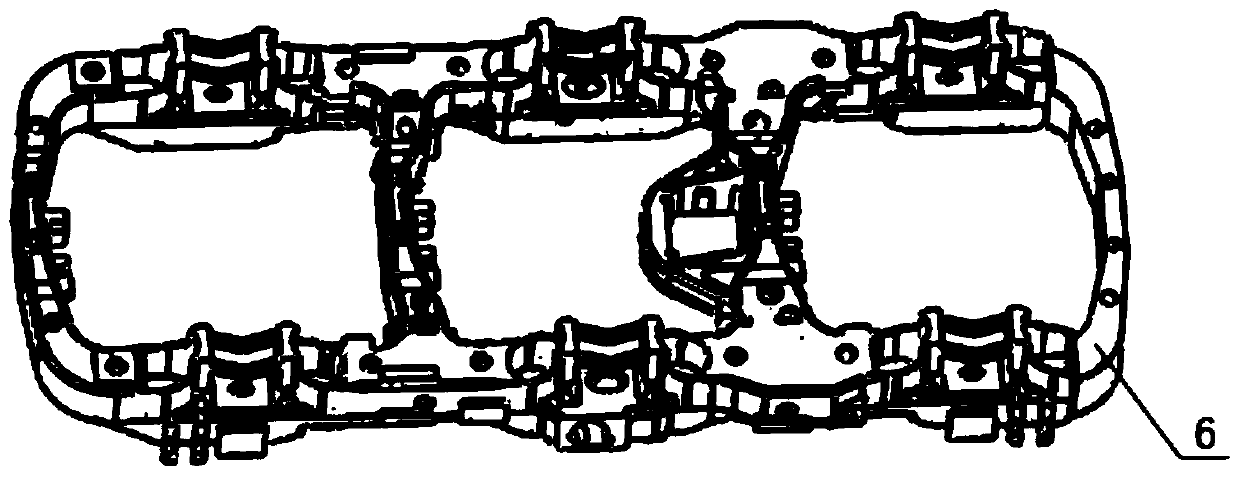

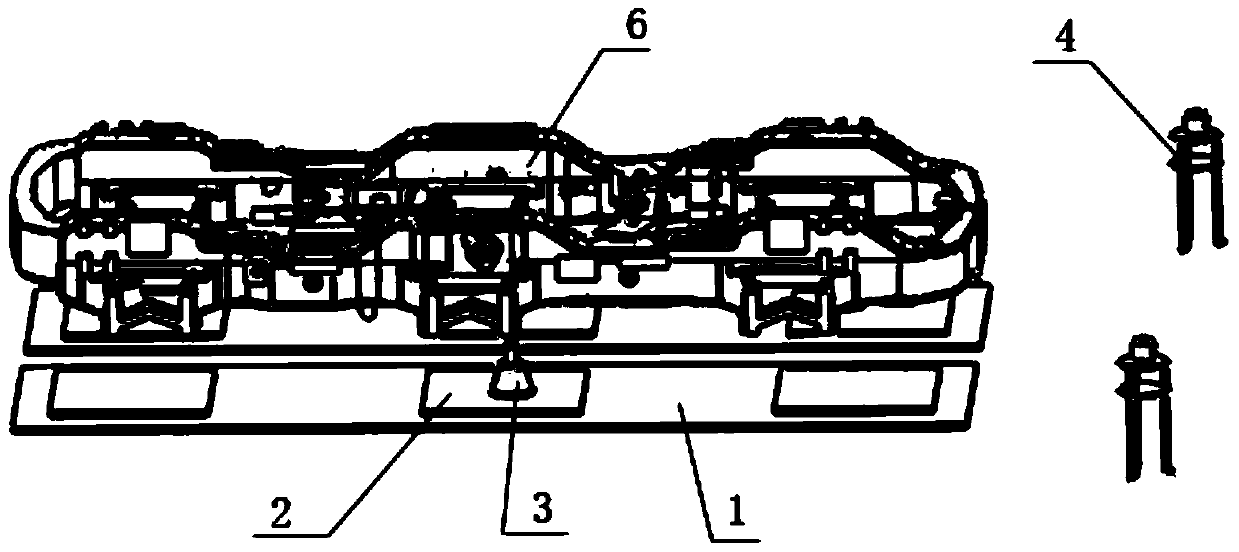

[0027] See Figure 1-Figure 6 , a method for measuring the flatness of a rail transit locomotive bogie without a platform, comprising the following steps:

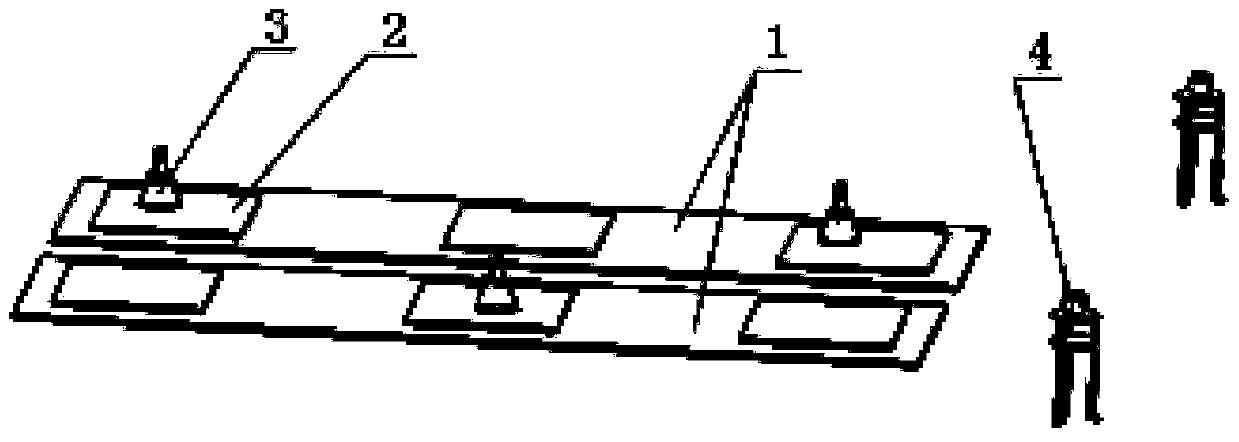

[0028] 1) Laying rubber pads 1 for shock absorption on the field; reducing the degree of damage to the ground;

[0029] 2) place the supporting plate 2 on the rubber pad 1 in the shape of a finished product, so that the rubber pad 1 is partially flat on the supporting plate 2;

[0030] 3) Place thimbles 3 on the supporting plate 2, generally 3 thimbles, which are used together with the supporting plate 2;

[0031] 4) Set two or more laser marking instruments 4 at appropriate positions outside the rubber pad 1, adjust the adjustable bracket 5 of the laser marking instrument 4 to make it hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com