A method for detecting the concentricity of combined pipes with different diameters

A detection method and combined tube technology, which are applied in measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of complex device structure, error, and easy deformation of components, and achieve convenient and flexible measurement, reliable inspection quality, and meet quality requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

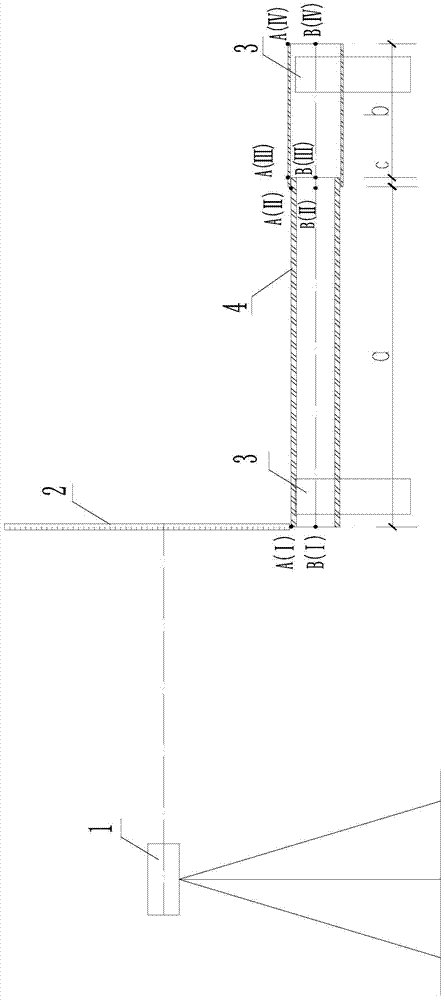

[0030] The method for detecting the concentricity of different-diameter combined pipes in this embodiment is as follows: figure 1 and figure 2 shown, including the following steps:

[0031] 1. A narrow tube and a thick tube are welded end to end to form 4 different-diameter combined tubes. The combined tube 4 is 1320mm long, of which the diameter of the thick tube is 114mm, and the diameter of the thin tube is 102mm.

[0032] 2. Make a concentricity detection device for combined pipes with different diameters. The detection device includes a fixing device, a precision leveling rod 2 and a precision leveling instrument 1. The fixing device includes two V-shaped supports 3 .

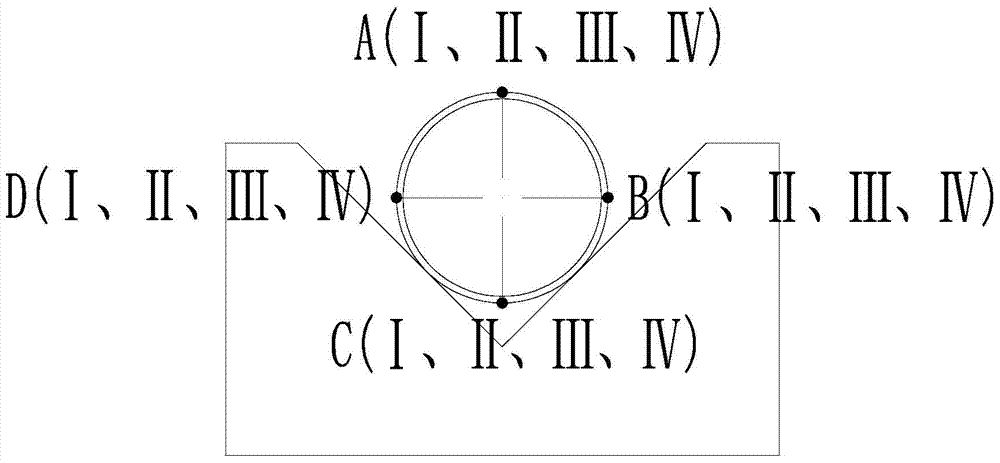

[0033] 3. Place the two ends of the combined pipe with different diameters 4 in the slots of the two V-shaped supports 3 and fix it by the weight of the combined pipe 4 itself, and then mark A, B, C, D on the end faces of the combined pipe with different diameters 4 Four orientations, two adjacent orien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com