A method for checking the parallelism of pipeline installation

A pipeline installation and inspection method technology, applied in the direction of reducing greenhouse gases, climate sustainability, reactors, etc., can solve problems such as easy to touch, troublesome steel bar binding, and large structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The invention will now be described in further detail with reference to the drawings.

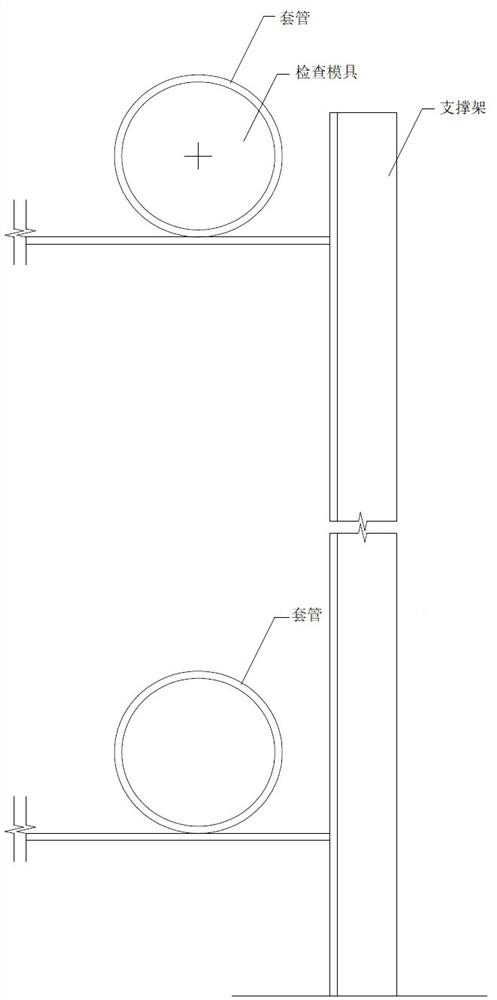

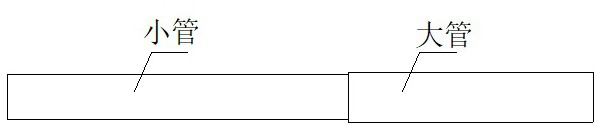

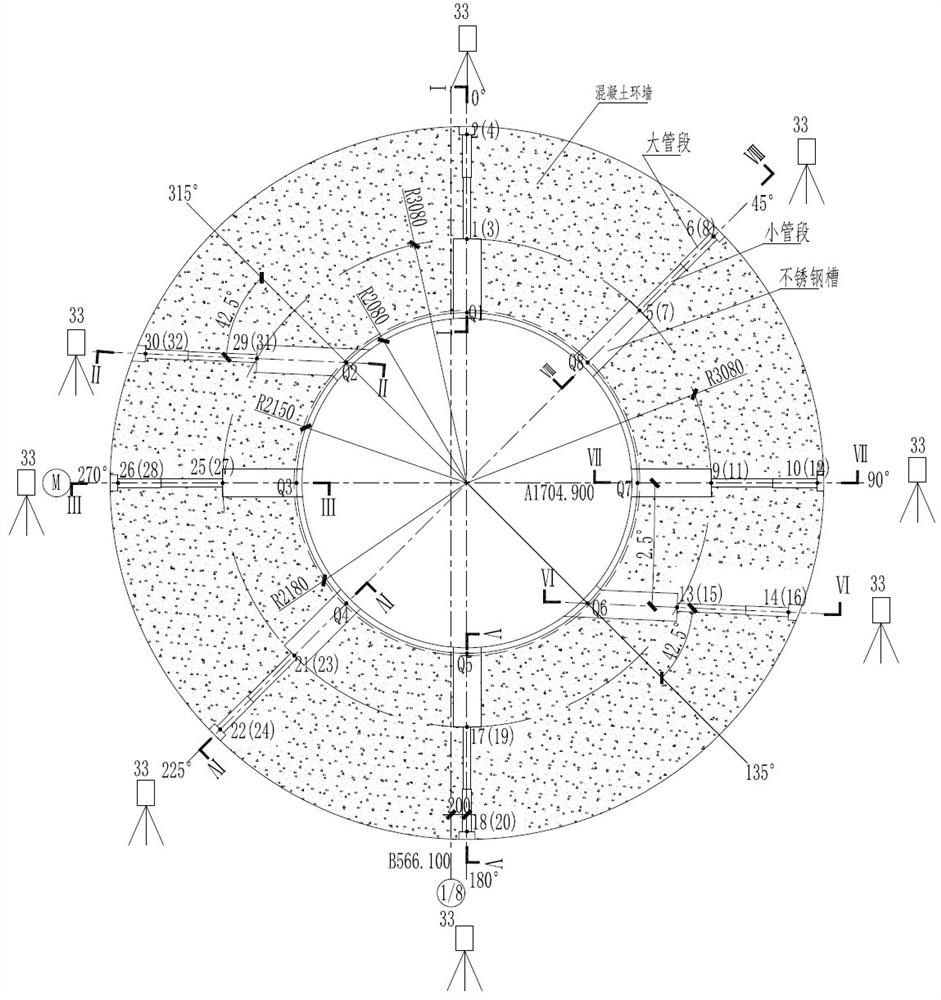

[0037]In an embodiment, the cavity ring wall of a nuclear power plant nuclear reactor plant has eight sets of thrust slots. Each set of push-pull grooves has a pipe, each pipeline consists of different pipe diameters, and the pipeline is large. The tube is located outside the ring wall. It is high for its concentricity and parallelism. It is required to deviate within 1mm. The paralleter requirement is within 1 mm, and the eight sets of push slots are 16 pipes, divided into two specifications, tubes Long 1320mm (image 3 , I, III, IV, V, VII, VIII tube) and 1488mm (image 3 , II, VI tube).

[0038]AppendFigure 1-4Distanceimage 3 In the middle, Q1 ~ Q8 is the starting point in the pipeline direction, and the coordinate can be calculated by the center and radius; 1 to 32 is the pipeline checkpoint, 33 is a full station.Figure 4 The middle 1 (5, 9, 13, 17, 21, 25, 29) is the inner inspection point in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com