A sealing mechanism against gas exchange

A sealing mechanism and gas exchange technology, which is applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve problems such as explosions, safety hazards, and impacts on the sludge pyrolysis and carbonization process, and achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

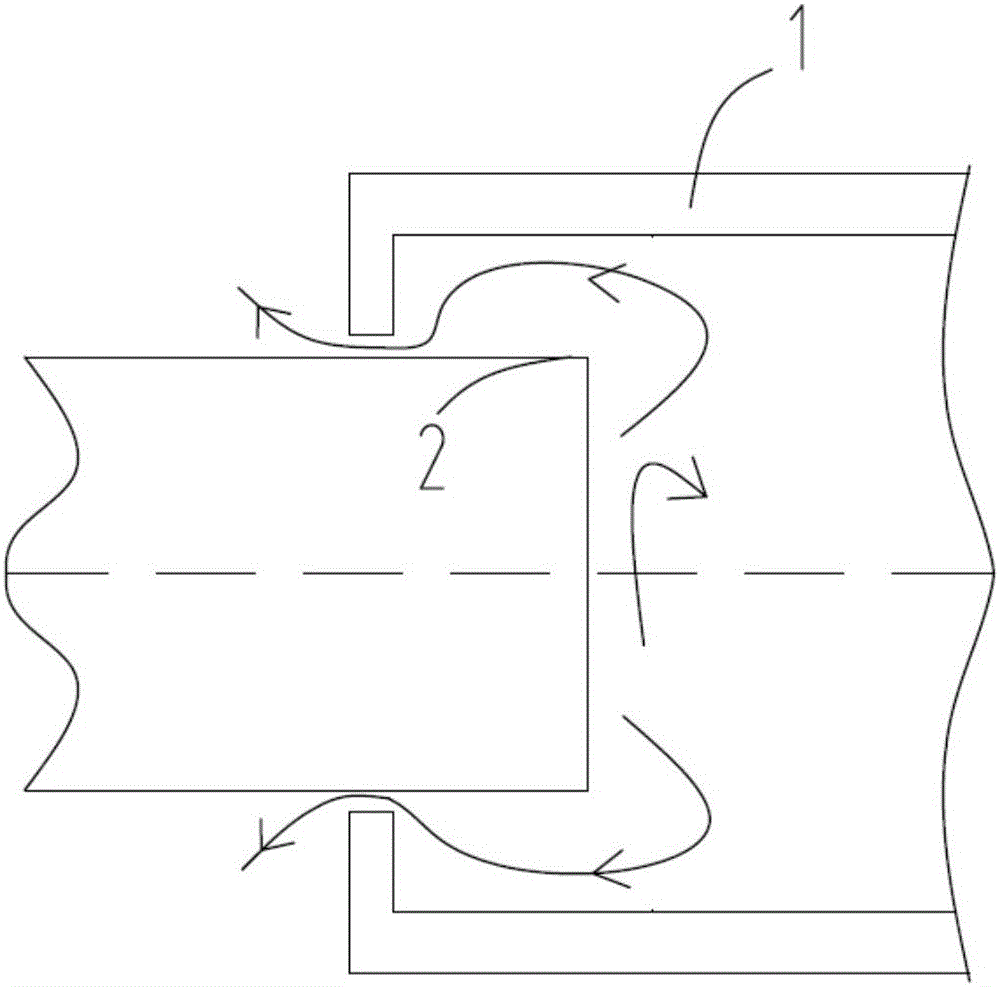

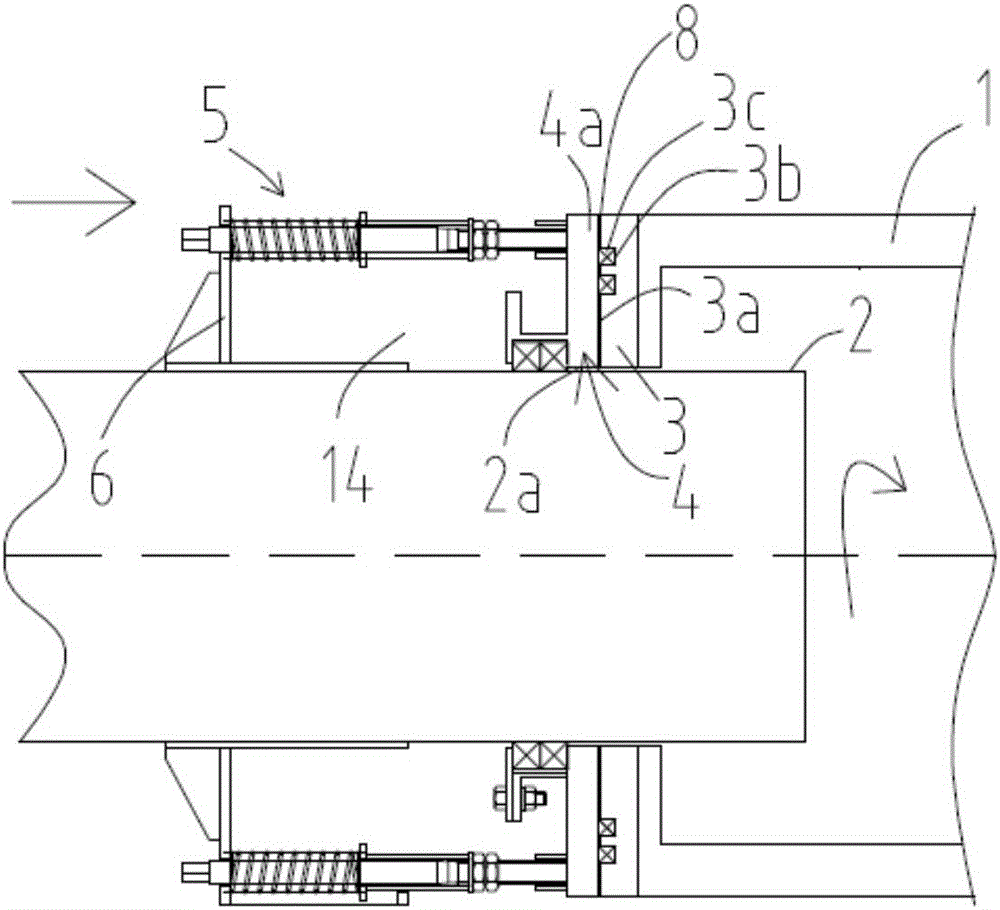

[0033] figure 1 Schematic diagram showing the structure of the rotating part and the fixed part; figure 2 For the structural representation of embodiment one of the sealing mechanism of anti-gas exchange; figure 2 As shown, a sealing mechanism for preventing gas exchange includes a receiving block 3 that is connected with the fixed part 1 and has a clearance fit with the rotating part 2, a pressure block 4 that is rotationally fitted with the rotating part 2 and is fixedly connected with the rotating part 2. The pressing mechanism 5, the pressing block 4 is tested to the receiving block 3 through the pressing mechanism 5; the receiving block 3 has a first plane 3a for pressing, and the first plane 3a is provided with two annular grooves 3b, the annular A first sealing strip 3c is arranged in the groove 3b;

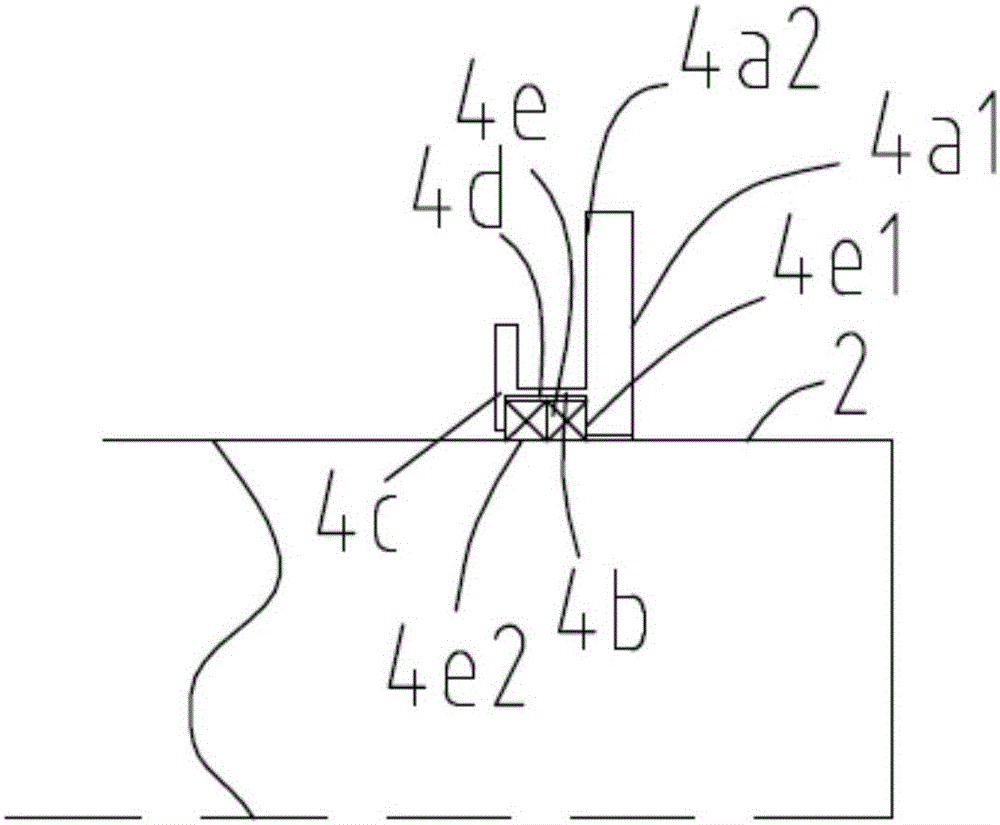

[0034] image 3 It is a schematic structural view of the briquetting block in the sealing mechanism for preventing gas exchange according to Embodiment 1; as image ...

Embodiment 2

[0038] Figure 6 Schematic diagram of the second embodiment of the sealing mechanism for preventing gas exchange. Figure 6 It is a schematic structural diagram of Embodiment 2 of the flue gas treatment system. Such as figure 2 As shown, the pressing surface 4a1 of the present invention also includes a second surface, which is laterally away from the first pressing surface, and the second surface forms a first channel 9 with the first plane 3a of the receiving block 3 and the outer wall of the rotating member 2, It also includes a second fixing plate 14 . The second fixing plate 14 is fixed on the outer wall of the rotating member 2 and arranged flush with the first fixing plate 6 . The screw rod 7 a passes through the second fixing plate 14 .

[0039] It should be noted that, except for this, other structures of this embodiment may be the same as those of Embodiment 1, which need not be repeated here.

Embodiment 3

[0041] Figure 7 Schematic diagram of the third embodiment of the sealing mechanism for preventing gas exchange. Such as Figure 7 As shown, the first baffle 11 and the second baffle 12 are staggered in the first channel 9 of the present invention to form an "S" shaped channel. Insulation cotton 13 is arranged in the "S" shaped channel. It should be noted that, except for this, other structures of this embodiment may be the same as those of Embodiment 1, which need not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com