Rotary joint

A technology of rotating joints and contact surfaces, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., to achieve the effect of ensuring free rotation, reliable sealing, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

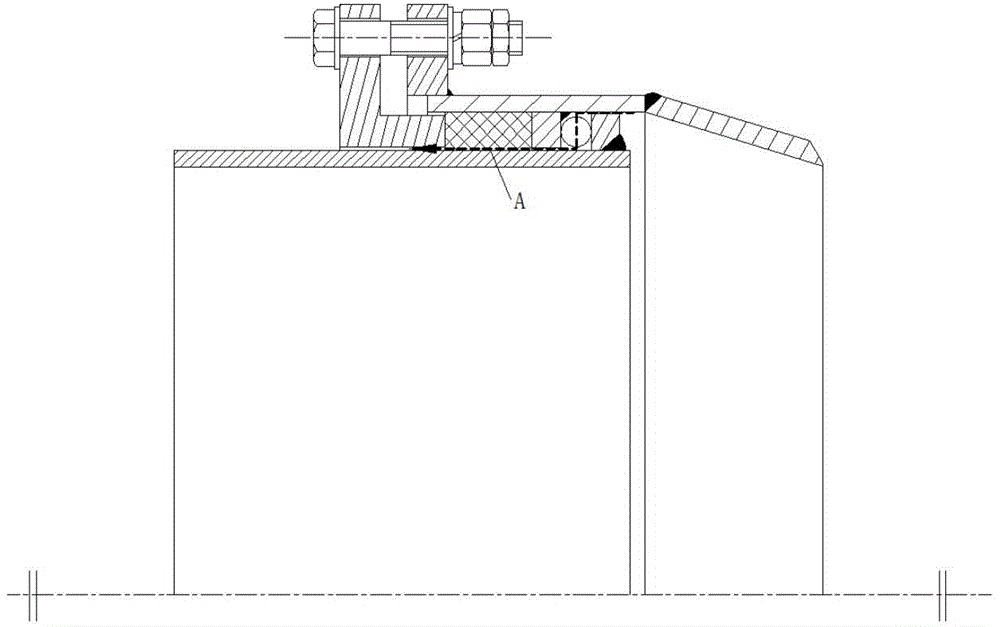

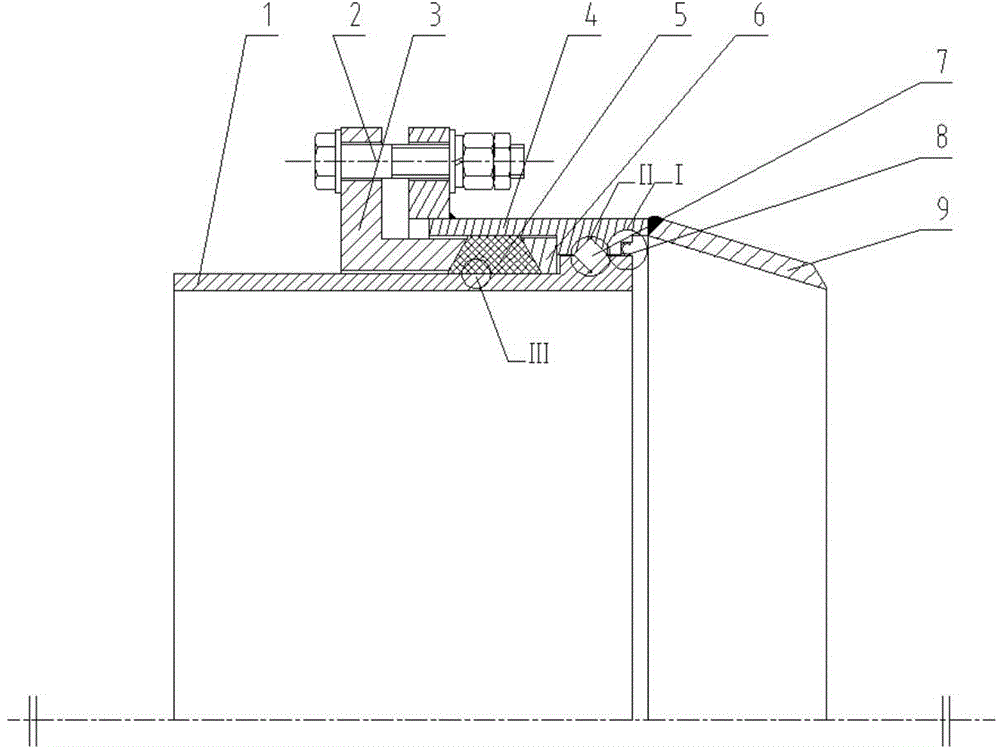

[0019] The present invention will be further described below in conjunction with accompanying drawing.

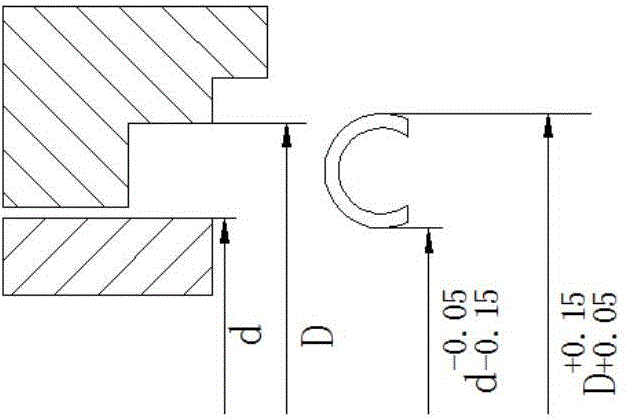

[0020] The high-temperature, high-pressure, low-friction rotary joint of this embodiment is as follows: figure 2 As shown, one end of the outer pipe 4 is welded with a radially extending connecting flange, and the other end is welded with a tapered reducing pipe 9, the inner pipe 1 is inserted into the outer pipe 4 from the end of the connecting flange, and the inner end of the gland 3 is inserted into the outer pipe 4 and Between the inner pipes 1, and its outer end is connected with the connecting flange of the outer pipe through radially extending flanges by means of bolts 2 evenly distributed around the circumference. The outer tube 4 has a radially contracted inner convex ring adjacent to the reducing tube 9, and the inner tube 1 has an outer convex ring corresponding to the position of the inner convex ring. The inner convex ring and the outer convex ring have openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com