Wind power air compressor system

An air compressor and wind power technology, applied in the direction of mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of difficulty in finding the wind direction of the wind blades, low utilization rate of wind energy, loss of wind power utilization, etc., and reach the service life Long-term, avoid delays in work and maintenance costs, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

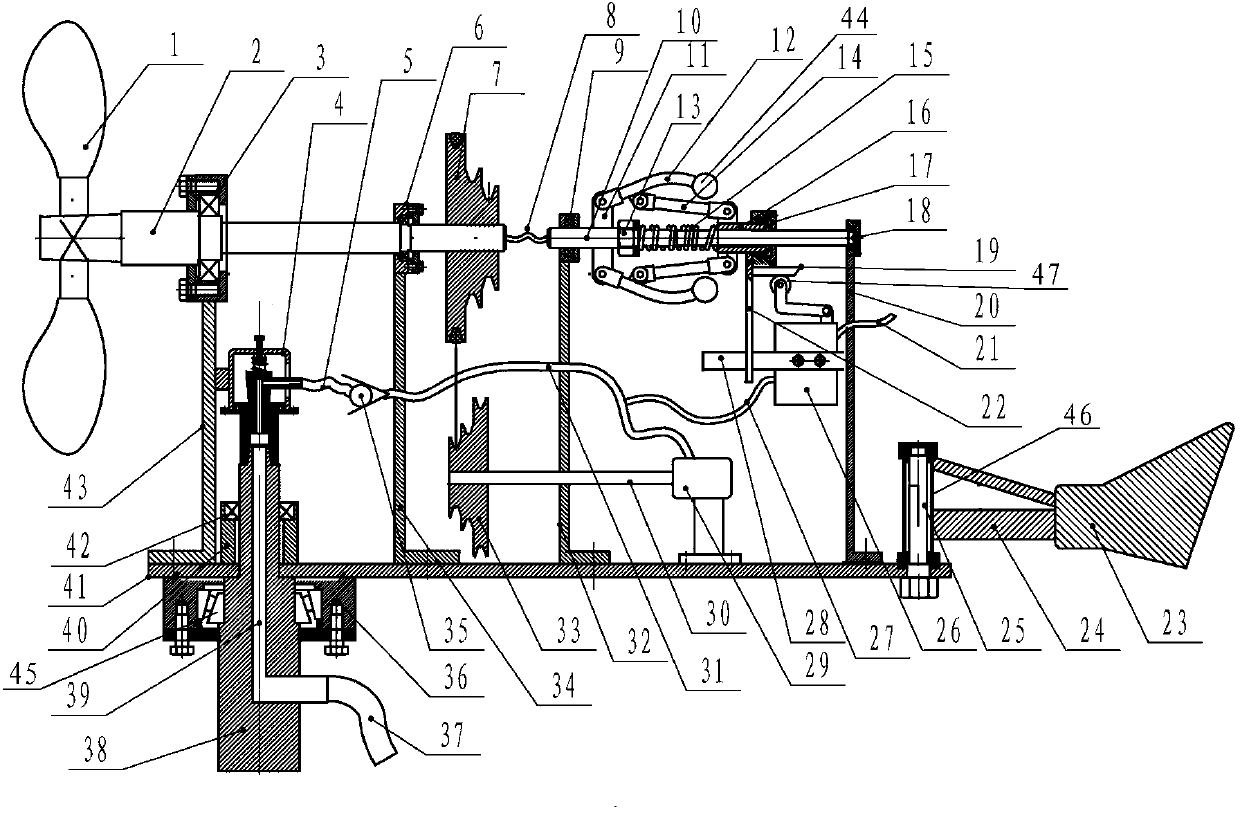

[0034] Depend on Figure 1-2 As can be seen from the illustrated embodiment, it includes a column 38 provided with an air passage 39, a wind mechanism, an air compressor subsystem and a no-load centrifugal start control mechanism;

[0035] Described wind mechanism comprises fan blade 1, main shaft 2, driving pulley 7, rotating chassis 41 and empennage 23; Extend the bearing sleeve 40 of the auxiliary bearing 42, the main shaft 2 is mounted on the first and second supports 43, 34 fixed on the rotating chassis 41 through the bearing, and the fan blade 1 is installed on the left end of the main shaft 2, so The driving pulley 7 is installed on the right end of the main shaft 2, and the empennage 23 is installed on the right end middle part of the rotating chassis 41;

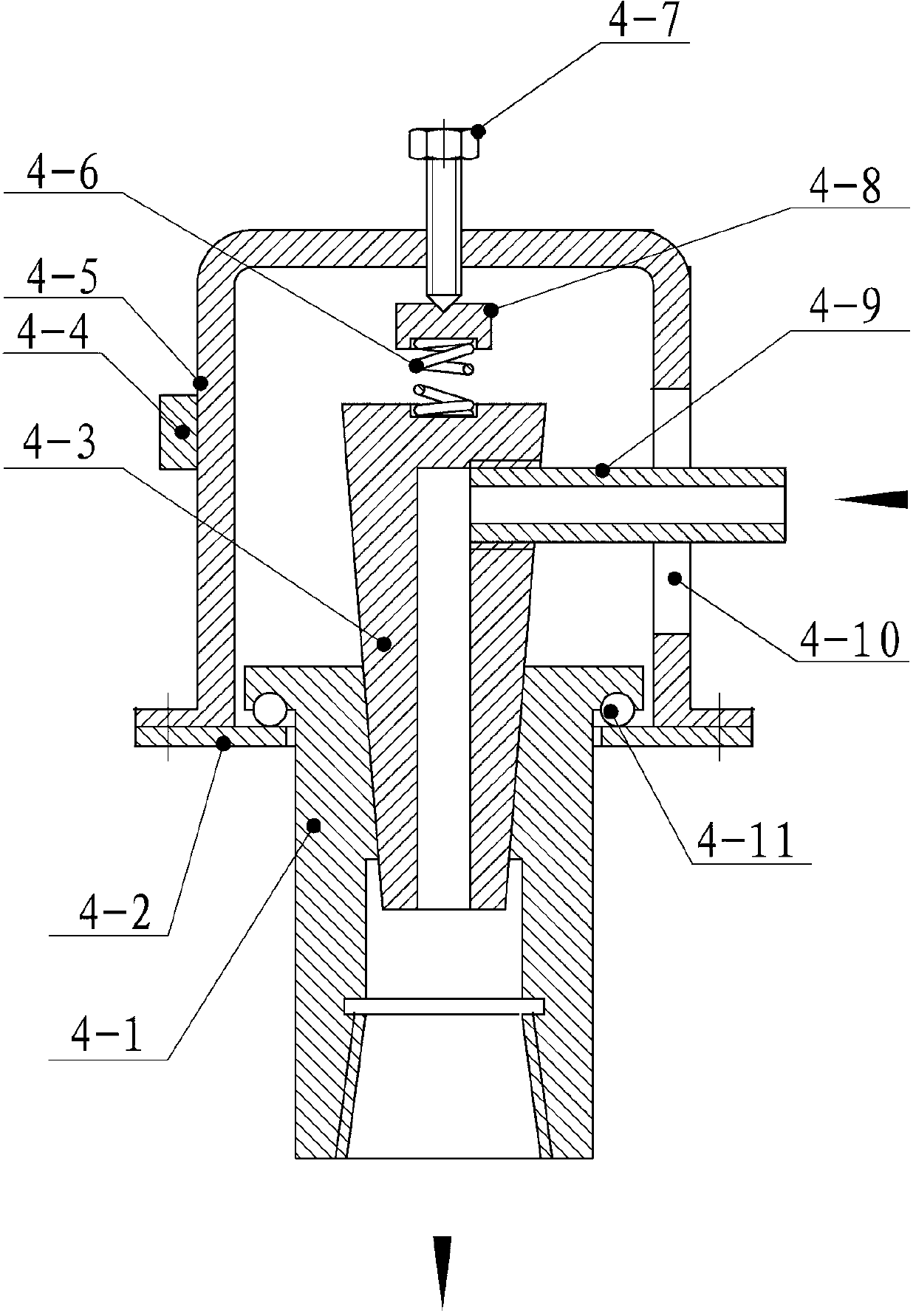

[0036] The air compressor subsystem includes an air compressor 29, a driven pulley 33 installed on the power shaft 30 of the air compressor, a normally closed button valve 26 and a rotary joint 4; the air compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com