Diaphragm type pilot control solenoid valve

A pilot control and solenoid valve technology, applied in the field of solenoid valves, can solve the problems of large movement stroke of the pilot valve core iron, increase the diameter of the valve port, and difficult processing, achieve the maximum allowable working pressure difference, and reduce the coil power. requirements and achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

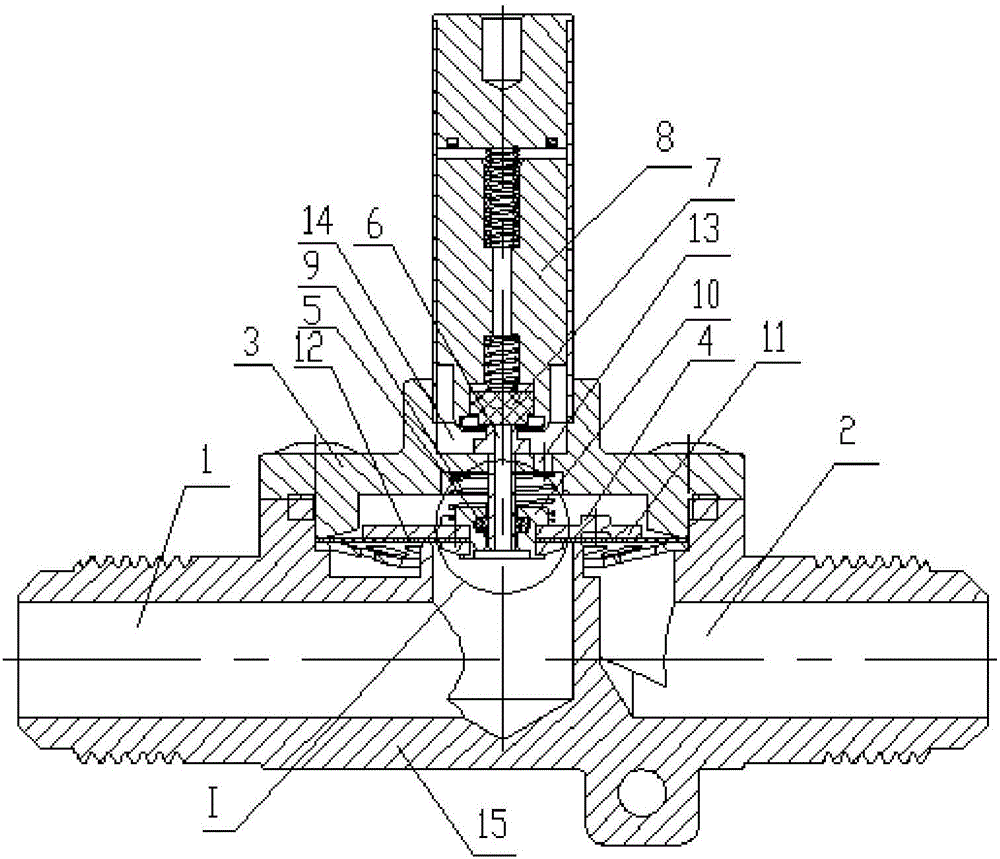

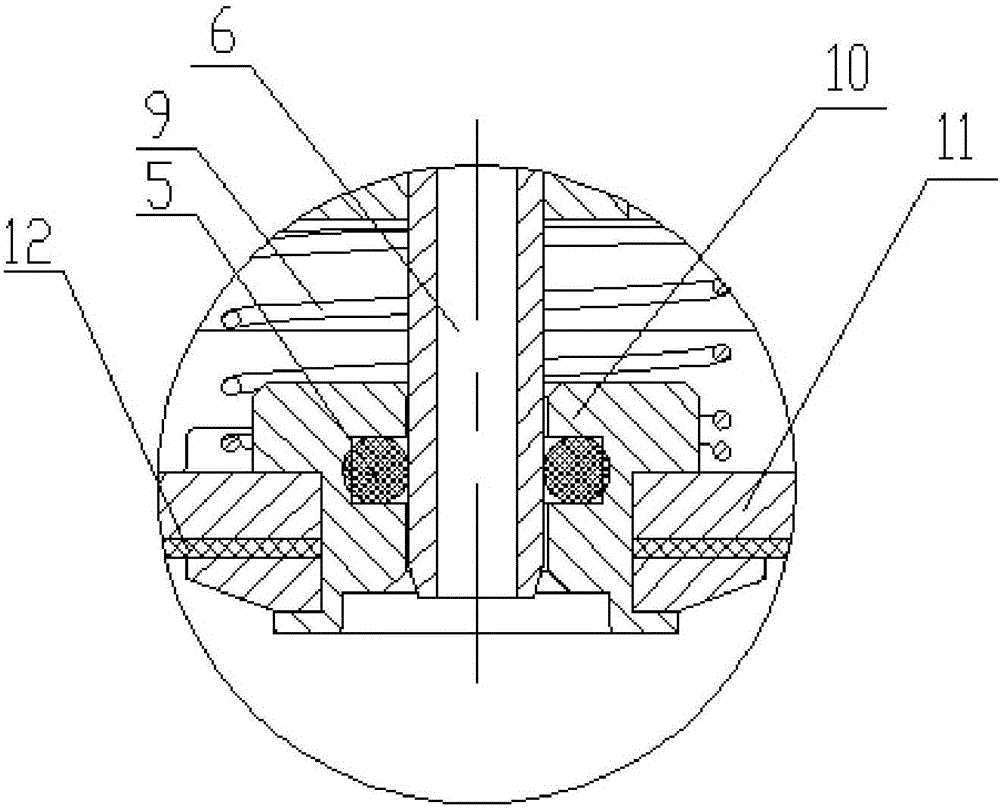

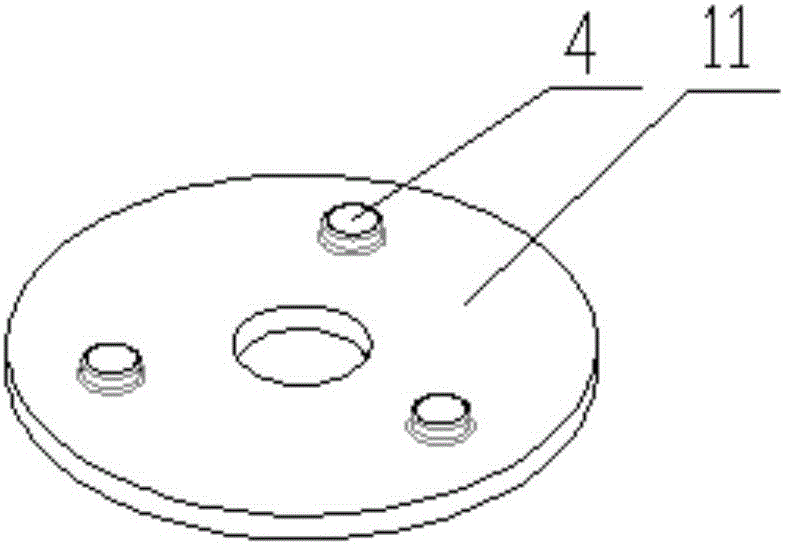

[0027] like figure 1 , figure 2 and image 3 The diaphragm type pilot control solenoid valve shown includes a valve seat 15, and a valve cover 3 is arranged on the upper part of the valve seat 15; The valve seal 7; the middle part of the valve cover 3 is provided with a conduction piece 6; the side of the lower part of the conduction piece 6 is provided with a mandrel sleeve 10, and the outer side of the mandrel sleeve 10 is provided with a movement limiter 11; the lower part of the movement limiter 11 is set There is a seal A12; a seal B5 is provided between the lower part of the movement limiter 11 and the conduction member 6; a return spring 9 is provided between the outside of the conduction member 6 and the movement limiter 11; Hole 13; valve cover 9 upper part is provided with pilot valve chamber 14. A plurality of protrusions 4 are arranged on the upper part of the movement limiting member 11 . The left and right sides of the valve seat 15 are respectively provided...

Embodiment 2

[0034] like Figure 4 and Figure 5 The diaphragm type pilot control solenoid valve shown includes a valve seat 15, and a valve cover 3 is arranged on the upper part of the valve seat 15; The valve seal 7; the middle part of the valve cover 3 is provided with a conduction piece 6; the side of the lower part of the conduction piece 6 is provided with a mandrel sleeve 10, and the outer side of the mandrel sleeve 10 is provided with a movement limiter 11; the lower part of the movement limiter 11 is set There is a seal A12; a seal B5 is provided between the lower part of the movement limiter 11 and the conduction member 6; a return spring 9 is provided between the outside of the conduction member 6 and the movement limiter 11; Hole 13; valve cover 9 upper part is provided with pilot valve chamber 14. A plurality of protrusions 4 are arranged on the upper part of the movement limiting member 11 . The left and right sides of the valve seat 15 are respectively provided with a val...

Embodiment 3

[0042] like Image 6 and Figure 7 The diaphragm type pilot control solenoid valve shown includes a valve seat 15, and a valve cover 3 is arranged on the upper part of the valve seat 15; The valve seal 7; the middle part of the valve cover 3 is provided with a conduction piece 6; the side of the lower part of the conduction piece 6 is provided with a mandrel sleeve 10, and the outer side of the mandrel sleeve 10 is provided with a movement limiter 11; the lower part of the movement limiter 11 is set There is a seal A12; a seal B5 is provided between the lower part of the movement limiter 11 and the conduction member 6; a return spring 9 is provided between the outside of the conduction member 6 and the movement limiter 11; Hole 13; valve cover 9 upper part is provided with pilot valve cavity 14. A plurality of protrusions 4 are arranged on the upper part of the movement limiting member 11 . The left and right sides of the valve seat 15 are respectively provided with a valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com