Double-gate-plate wedge gate valve

A double ram and wedge technology, applied in sliding valves, valve details, valve devices, etc., can solve problems such as unreliable sealing and failure to meet the requirements of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

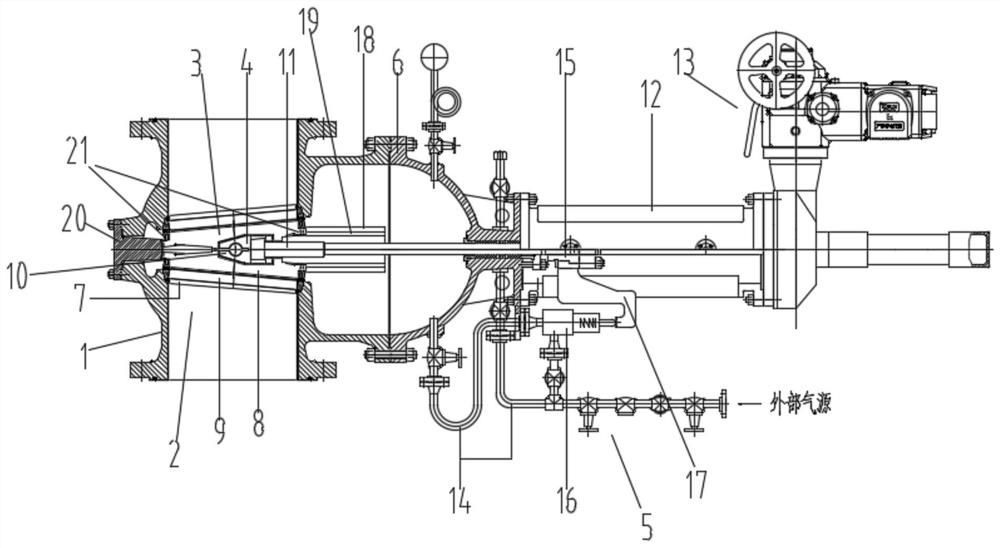

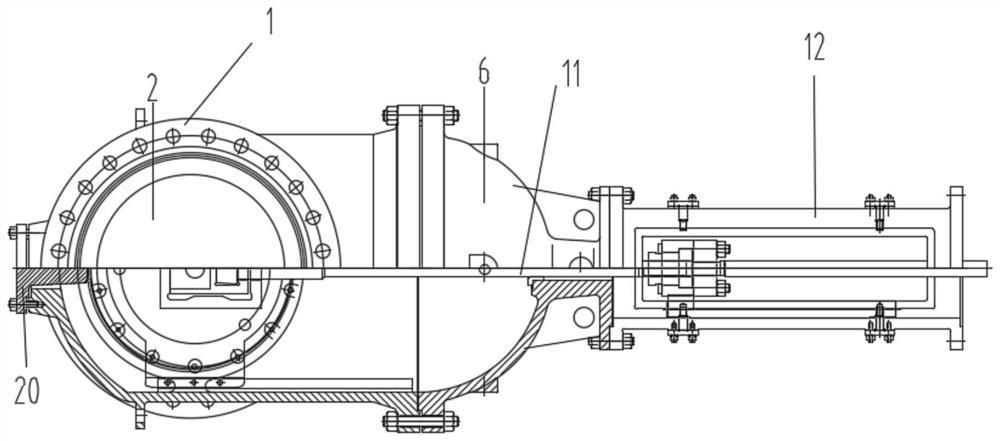

[0047] see Figure 1-2 , an embodiment provided by the present invention: a double gate wedge gate valve, characterized in that it includes: a valve body 1, a flow channel 2, a closing member 3, a driving member 4, a bypass assembly 5, and a valve cover 6;

[0048] The flow channel 2 is arranged inside the valve body 1, the closing member 3 is used to control the opening and closing of the flow channel 2, and the driving member 4 is used to provide driving power for the action of the closing member 3, The right end of the valve body 1 is provided with the valve cover 6, the bypass assembly 5 is arranged outside the valve cover 6 and connected with the valve cover 6, the bypass assembly 5 is used to control the external air source The low-pressure inert gas is input into the valve cover 6 , and then linked with the driver 4 to control the closing of the flow channel 2 in the valve body 1 .

[0049] Preferably, the upper and lower ends of the valve body 1 are respectively an in...

Embodiment 2

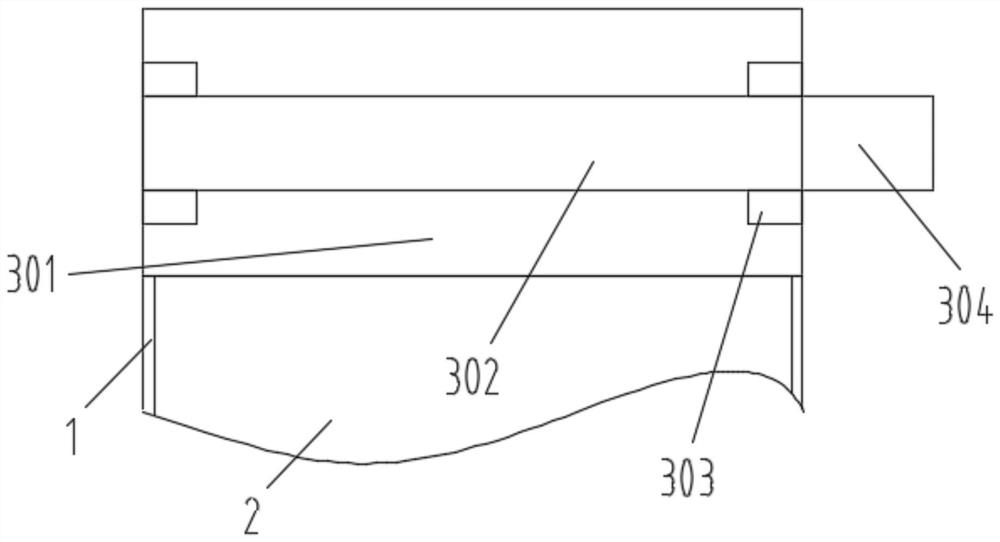

[0063] refer to Figure 3-4 , On the basis of the above-mentioned embodiment 1, a filter device is also provided at the inlet end of the upper end of the valve body 1, and the filter device is fixed with the valve body 1, and the filter device includes: a filter device housing 301, filter assembly 302, limit chute 303, filter replacement device 304;

[0064] The filtering device housing 301 is fixed to the inlet end of the valve body 1, the inner side wall of the filtering device housing 301 is fixed with the limiting chute 303, and the filter screen assembly 302 is slidably connected to the limiting In the chute 303 , the filter housing 301 is provided with a filter replacement device 304 , and the filter replacement device 304 is connected to the filter assembly 302 .

[0065] Preferably, the filter replacement device 304 includes:

[0066] Guide plate 30401, first slider 30402, first chute 30403, rebound power arm 30404, spring connection hole 30405, first linkage plate 3...

Embodiment 3

[0078] refer to Figure 5-7 , On the basis of the above-mentioned embodiment 1, a flow channel change detection device is also provided at the outlet end of the lower end of the valve body 1, and the flow channel change detection device includes:

[0079] Circulation cavity 401, power chamber 402, rotating force arm 403, motor 404, transmission shaft 405, driving gear 406, ring gear 407, fifth fixed shaft 408, seventh hinged shaft 409, detection board 410, fixed bottom plate 411, Limiting tube 412, second chute 413;

[0080] One side of the circulation cavity 401 is fixed to the outlet end of the lower end of the valve body 1, the power compartment 402 is in a ring structure, the circulation cavity 401 is between the power compartments 402, and the power compartment 402 The motor 404 is fixed on the inner wall of 402, and the motor 404 is electrically connected to the power controller. The seven articulated shafts 409 are rotating, while the motor 404 is still running, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com