Novel rotating shaft sealing device

A technology of sealing device and rotating shaft, applied in the direction of engine seal, transmission parts, belt/chain/gear, etc., can solve the problems of shortening the service life of the rotary seal, affecting the working performance of the transmission device, and reducing the life of the lip seal, etc. Achieve the effect of maintaining continuous sealing ability, improving flexibility and flexibility, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

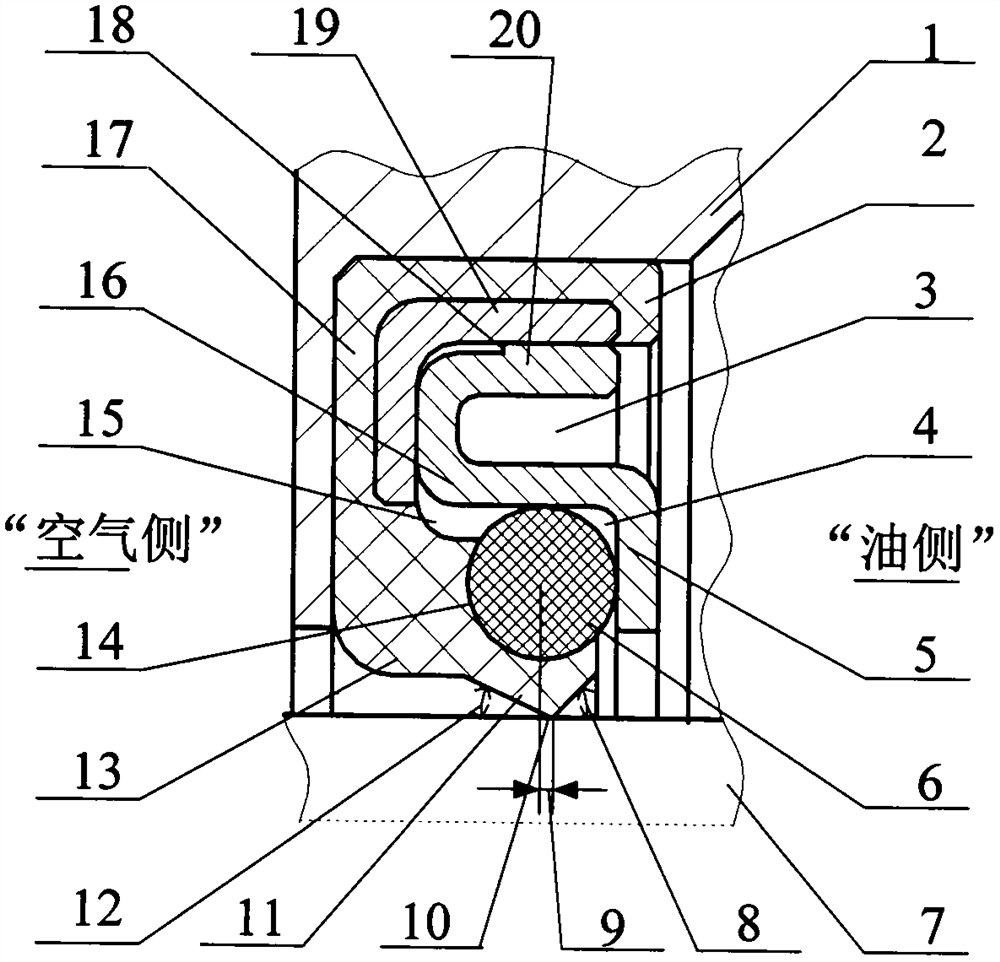

[0021] The implementation of the present invention is further described with reference to the accompanying drawings.

[0022] A new type of rotary shaft sealing device, the sealing device is used to seal the gap between the rotary shaft 7 and the bearing cover 1, including a lip seal 17 sleeved in the bearing cover cavity, an elastic force compensation O-ring 6, an adapter ring 16 , the lip seal 17 is composed of a lip 11, a supporting part 13, an external glue part 2 and an "L-shaped" exposed metal skeleton 19 to form a "C-shaped" cavity 15, and the lip 11 is in contact with the rotating shaft 7. There is a lip tip 10, a semicircular groove 14 is formed on the outer upper edge, the left and right sides of the lip tip 10 are respectively made with an air measuring lip angle 12 and an oil side lip angle 8, the elastic compensation O-ring 6 is made of rubber. The adapter ring 16 is composed of the upper support section 20 and the lower pressure section 5, and the cross-sectional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com