Automatic batten splicing equipment

An automatic splicing and wood square technology, applied in wood processing equipment, manufacturing tools, etc., can solve problems such as difficult to ensure high-precision work, difficult to meet architectural needs, single splicing method, etc., and achieve the effect of multi-angle free splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

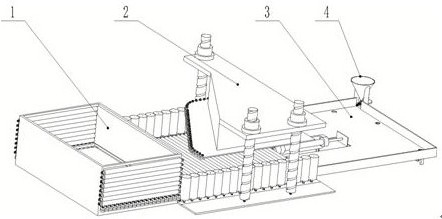

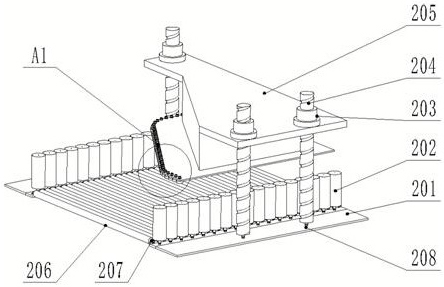

[0028] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 The automatic splicing equipment for wooden cubes shown includes a wooden cube storage module 1 , a wooden cube transfer module 2 , a wooden cube processing area 3 , and a nail arranging mechanism 4 .

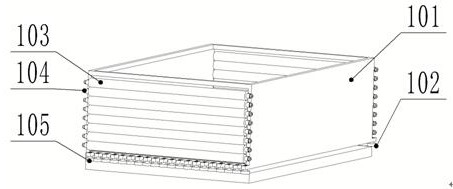

[0029] The wooden storage module 1 is a wooden storage device, comprising: a wooden storage frame 101, a wooden launch friction wheel 102, a wooden storage module sideways lifting friction wheel 103, a wooden storage module sideways lifting friction wheel motor 104, a wooden storage module The lateral lift friction wheel motor 105 of the square storage module, the wooden storage frame 101 and the lateral lift friction wheel motor 104 of the wooden storage module are fixedly installed, and the lateral lift friction wheel motor 104 of the wooden storage module rubs against the lateral lift of the wooden storage module The wheel 103 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com