Sheet separating method and device

A sheet material and conveying device technology, applied in transportation and packaging, thin material processing, printing, etc., can solve the problems of increasing equipment cost, complexity, and overall enlargement, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

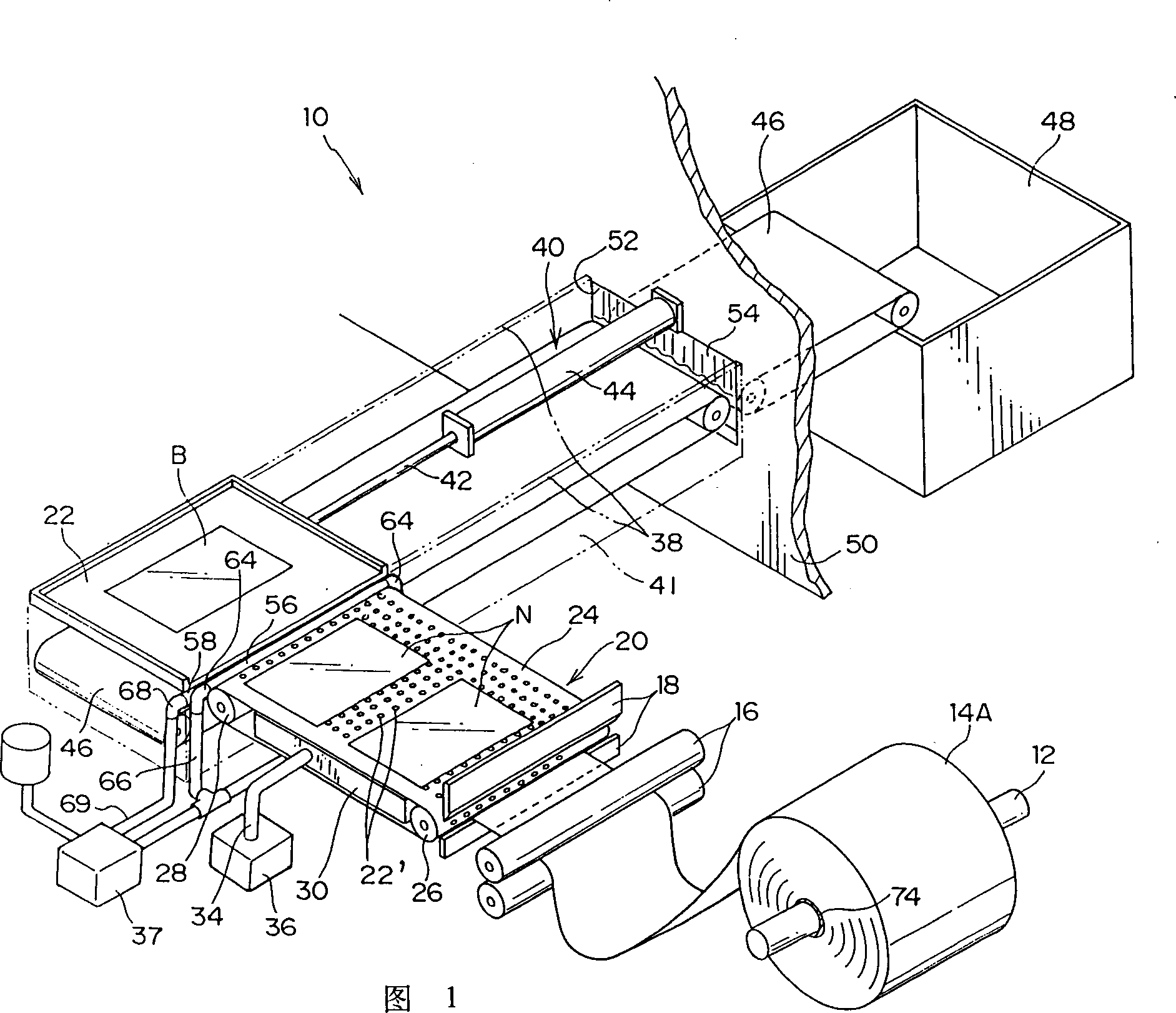

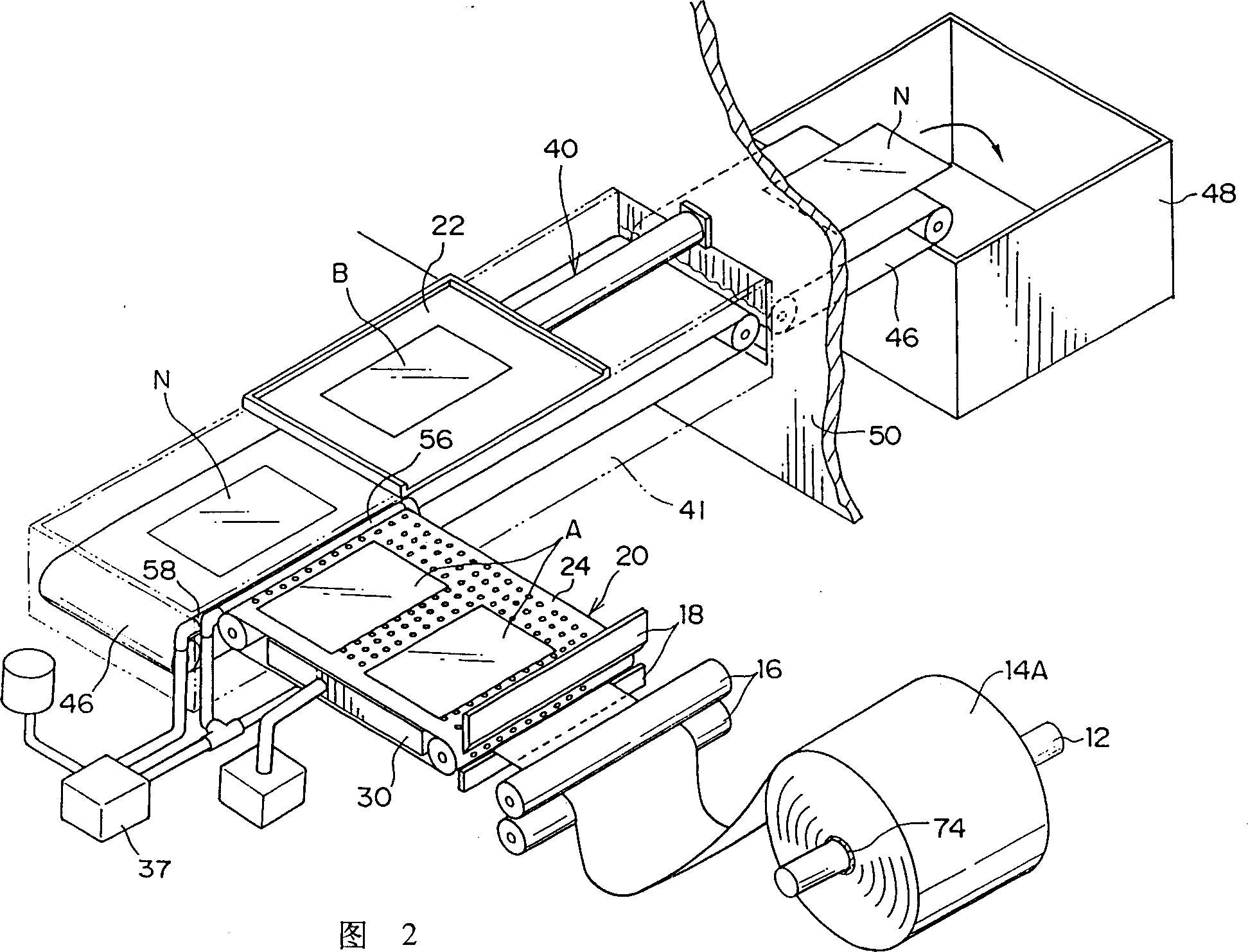

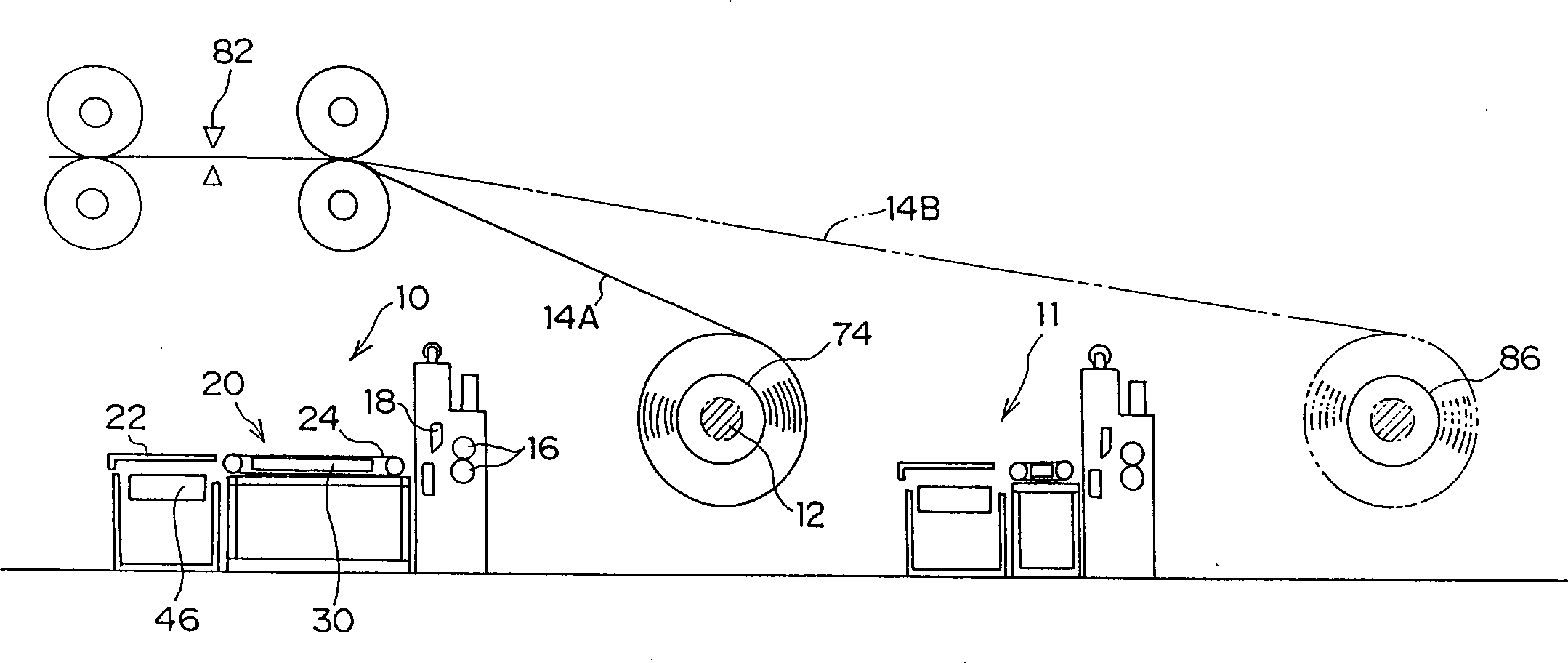

[0032] Hereinafter, an embodiment of the sheet separating device of the present invention will be described in detail with reference to the drawings.

[0033] Such as image 3 As shown, two separating devices 10 and 11 are set in one production line, and the plates 14A and 14B are continuously rolled up and can be sampled. Since the separating devices 10 and 11 basically have the same structure, the left separating device 10 will be described here.

[0034] As shown in FIGS. 1 and 2, the plate 14A is wound on the reel 12 to form a roll 74, and the sample A, the NG slice NG, and the sample B are being cut out.

[0035] First, the plate is unrolled, nipped and conveyed by the feed roller 16, and conveyed to the cutter 18. A suction conveyor belt 20 is arranged downstream of the cutter 18, and the sheets A, NG, and B cut to a predetermined length by the cutter 18 are conveyed to the gathering table 22 by the suction conveyor belt 20.

[0036] The suction conveyor belt 20 has an endle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com