Open-end spinning machine

A free-end, rotor technology, which is applied in the directions of free-end spinning machines, spinning machines, and continuously wound spinning machines, can solve the problems of expensive production and production cost defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

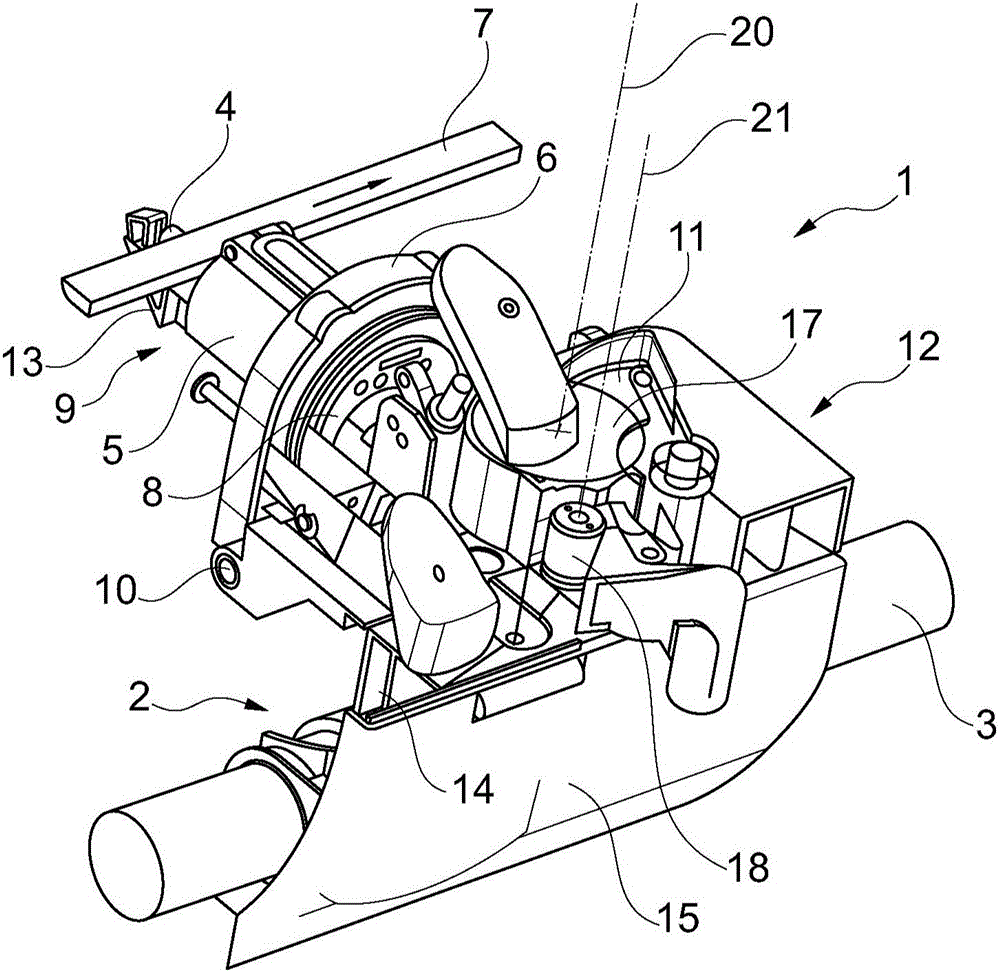

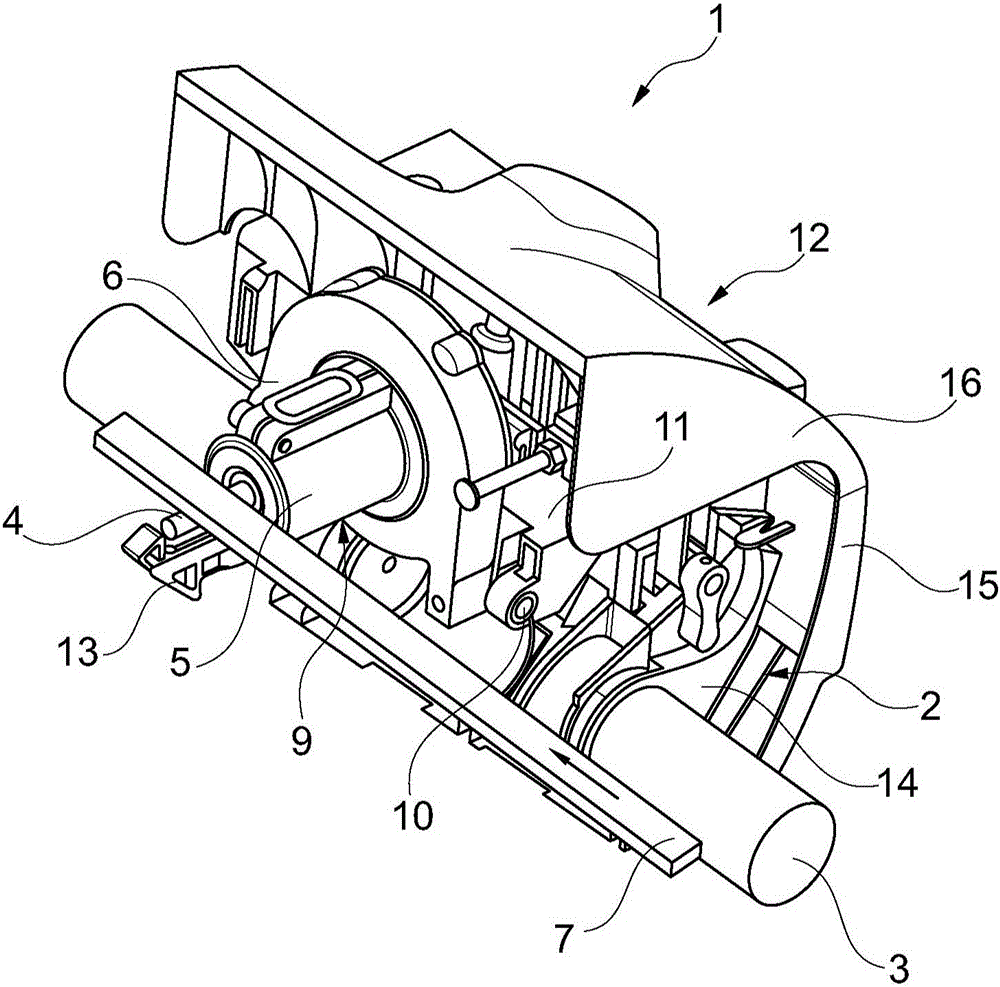

[0029] figure 1 A perspective front view of an open-end spinning device 1 is shown, which is arranged in each case in the region of a workstation of an open-end rotor spinning machine. The open-end spinning device 1 is pivotally mounted via its support mechanism 2 on a stationary support shaft 3 substantially along the length of the machine. In this embodiment, the spinning rotor, which is not shown in more detail for reasons of clarity, is mounted rotatably with its rotor shaft 4 in the direct bearing 5 and is tangentially rotated along the length of the machine. Driven by the belt 7, the rotor shaft 4 rests against the rotary tangential belt 7 from below. from figure 1 It can also be seen that the rotor housing 6 is closed by the cover element 8 or by a seal integrated in the cover element 8 , the spinning rotor of the spinning rotor being in the rotor housing 6 during the spinning process with High speed rotation.

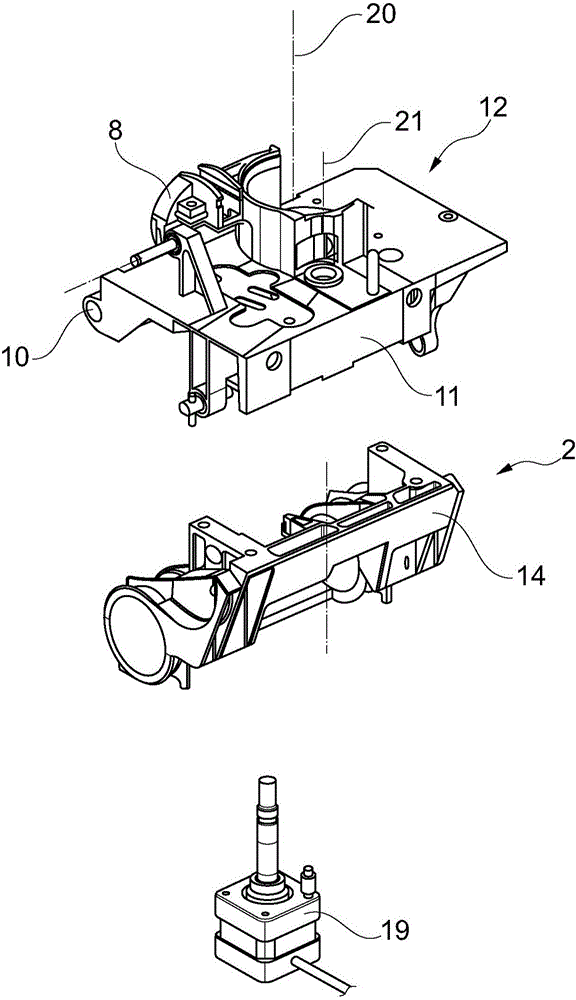

[0030] In this embodiment, the direct bearing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com