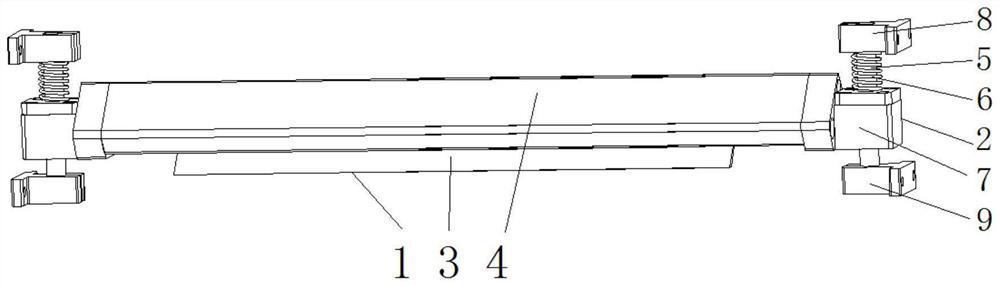

Automatic scraper knife device for FDM type 3D printer

A technology of 3D printers and spatulas, applied in manufacturing auxiliary devices, 3D object support structures, additive manufacturing, etc., can solve the problems of increasing labor costs and achieve the effect of continuous printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

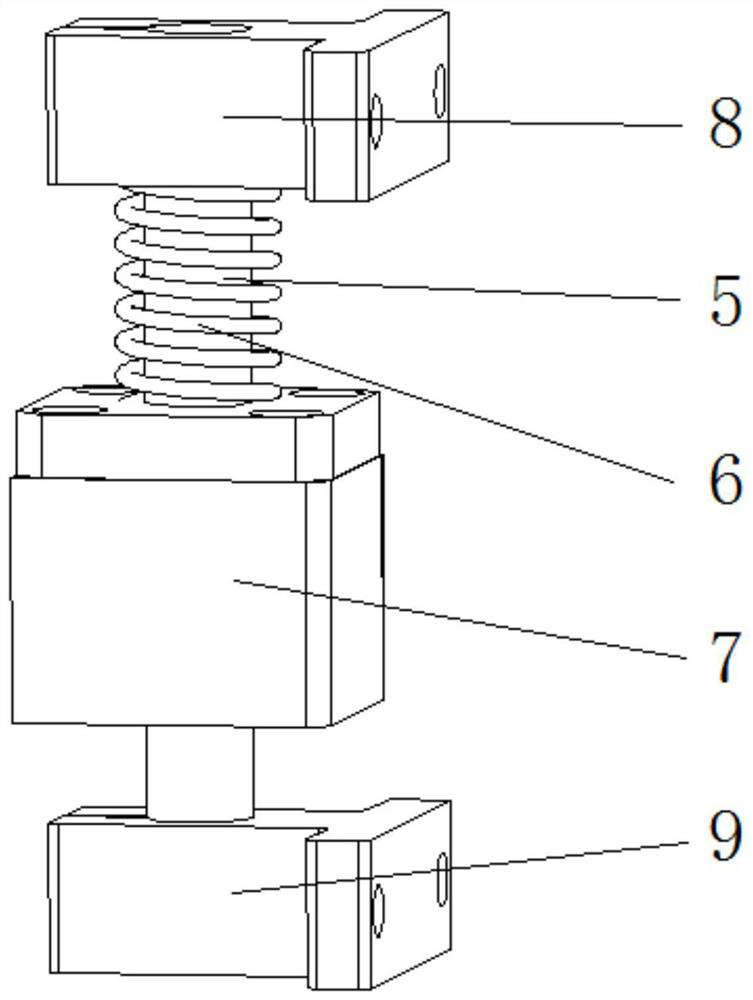

Method used

Image

Examples

Embodiment

[0021] Embodiment: The worker installs the automatic blade device on the gantry of the FDM 3D printer through the fixing part a7 and the fixing part b8, and the installation height of the automatic blade device is higher than the height of the platform. After the device is fixed on the gantry, it can move along the Z-axis direction and the Y-axis direction along with the gantry. When it is necessary to shovel out the forming mold, the shovel device 1 first reduces the distance from the platform in the Z-axis direction until it contacts the shovel 3 with the platform. Continue to reduce the height of the automatic shovel device afterwards, the spring 6 is compressed, and the spring 6 indirectly applies a downward force to the shovel 6, so that the shovel 6 is closely attached to the platform. The gantry then moves in the direction of the Y axis, and relative displacement occurs with the forming model on the platform, and the model is removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com