Treading type recycling cabinet of paper express box

A kind of express box, step-on technology, applied in the field of express delivery box, can solve the problems of low efficiency, high cost, inconvenience for users and recycling personnel, etc., to achieve the effect of convenient recycling and transportation, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

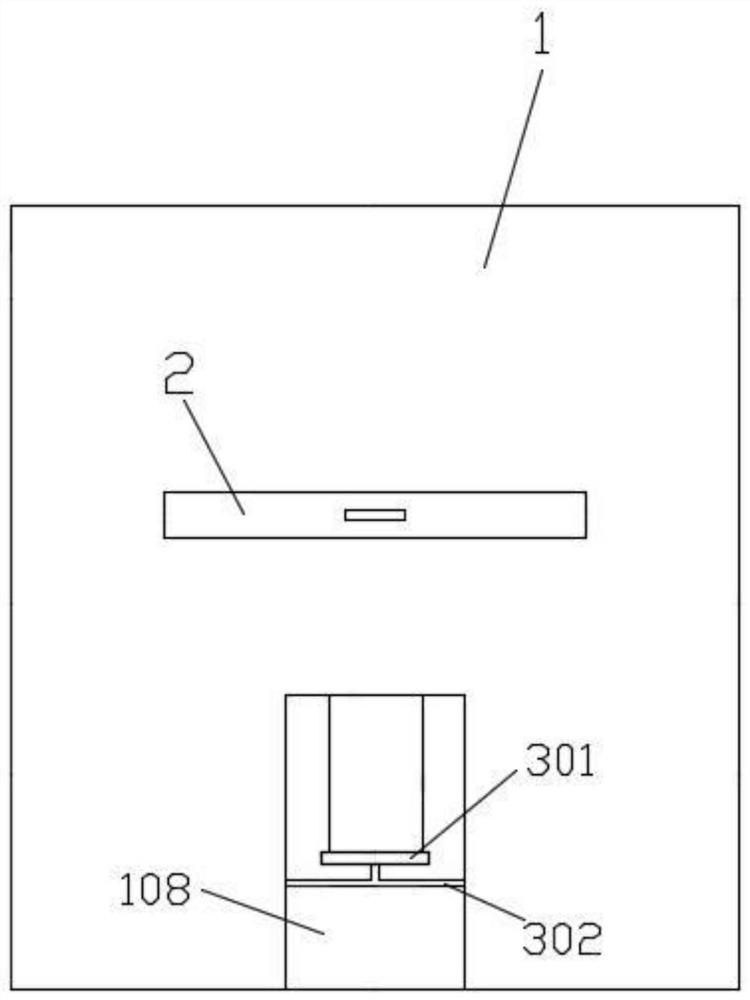

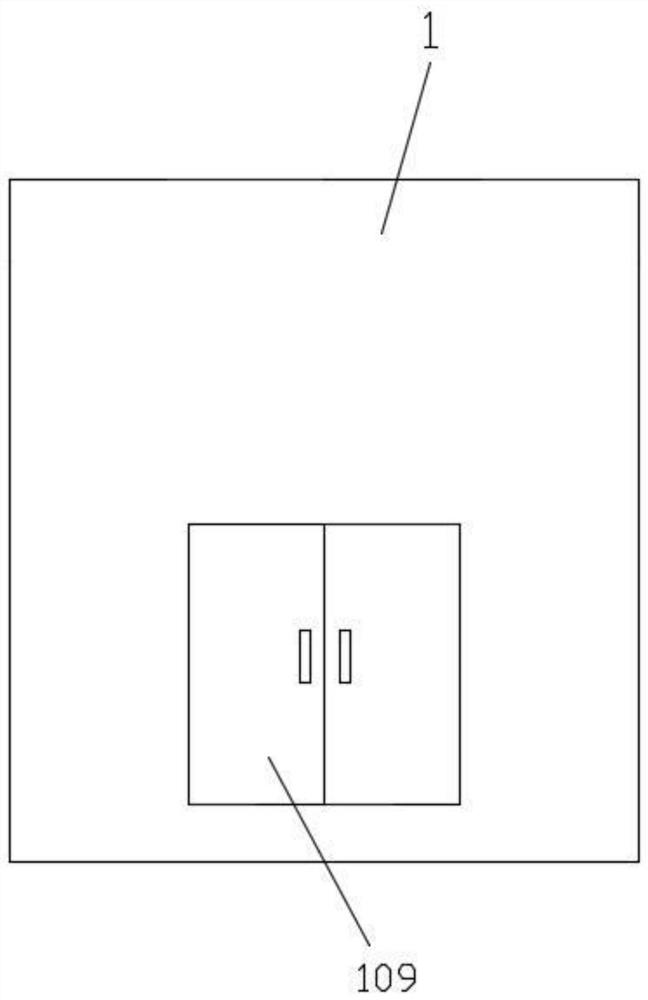

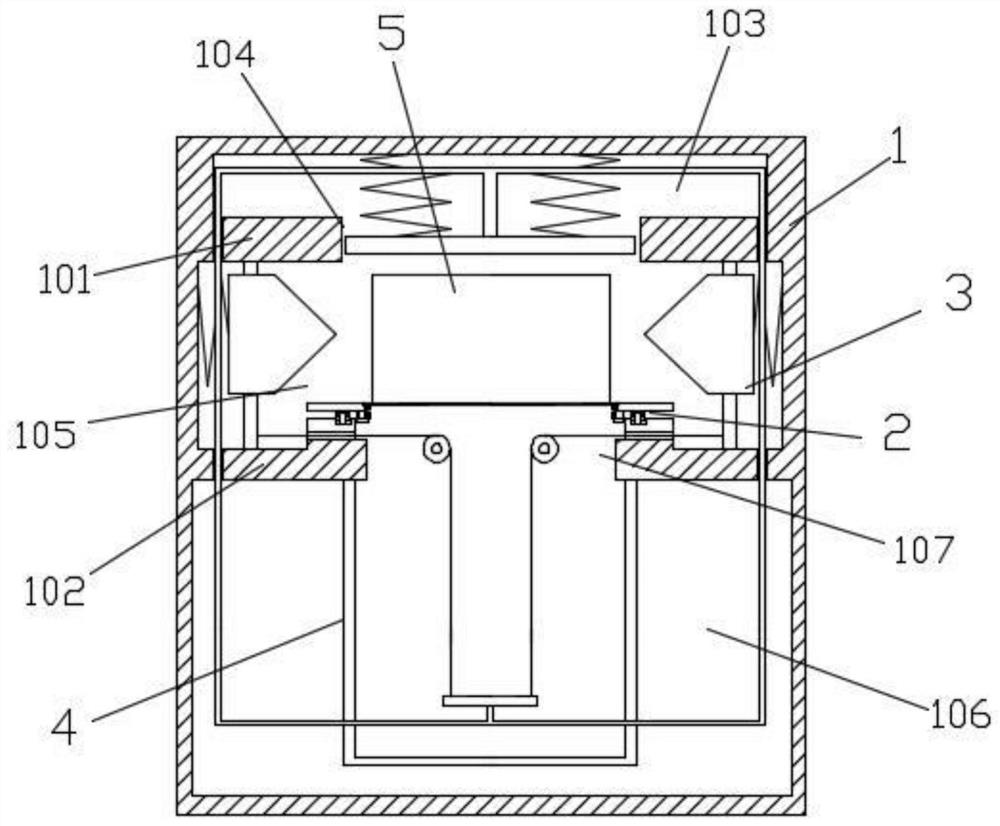

[0025] Such as Figure 1-7As shown, a stepping recycling cabinet for a paper express box includes a recycling cabinet body 1 and a recyclable paper express box 5 matching it. The recyclable paper express box 5 has two symmetrical end faces 501, two A rectangular corrugated box surrounded by two sides 502, a bottom surface and a top surface, wherein, the two end surfaces 501 and one bottom surface are all solid cardboards, and the middle parts of the two sides 502 have a folding line I 503 along the length direction thereof. The two ends of the line I503 are respectively connected to the two corners at the two ends of the side surface 502 through two folding lines II504, so that a triangular folding area I505 is formed at the two ends of the two sides 502, and the length of the top surface of the recyclable paper express box 5 is Two folding lines III 507 are arranged on both sides of the direction. These two folding lines III 507 divide the top surface into an opening area 508...

Embodiment 2

[0028] The basic structure of this embodiment is the same as that of Embodiment 1. The point of improvement and optimization is that the connecting assembly is formed by sequentially connecting the horizontal bar I302, the vertical bar I303, the horizontal bar II306 and the vertical bar II307, wherein the vertical bar II307 is free The end is connected with the top of the extrusion plate 308, the cross bar I302 is connected with the bottom or side of the pedal 301, the cross bar II306 and the cross bar I302 are respectively located in the lifting chamber 103 of the pressing plate and the storage chamber 106 at the lower part, and the vertical bar I303 passes through the The rear two ends of the channel on the partition I101 and the partition II102 are respectively connected with the cross bar II306 and the cross bar I302, and the cooperation with the channel is clearance fit.

Embodiment 3

[0030] The basic structure of this embodiment is the same as that of Embodiment 1. The improvement and optimization is that the middle part of the partition plate I101 is provided with a channel I104 communicating with the pressure plate lifting chamber 103 and the carton extrusion chamber 105, and the extrusion plate 308 passes through the channel I104. Passage I 104 enters into the carton extrusion chamber 105 to extrude the top surface of the recyclable paper express box 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com