debris removal equipment

A technology for cleaning equipment and debris, which is applied to metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of inconvenient recycling and transportation, large space occupied by processing waste iron chips, and inconvenient storage, so as to facilitate recycling Transport, small footprint, easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

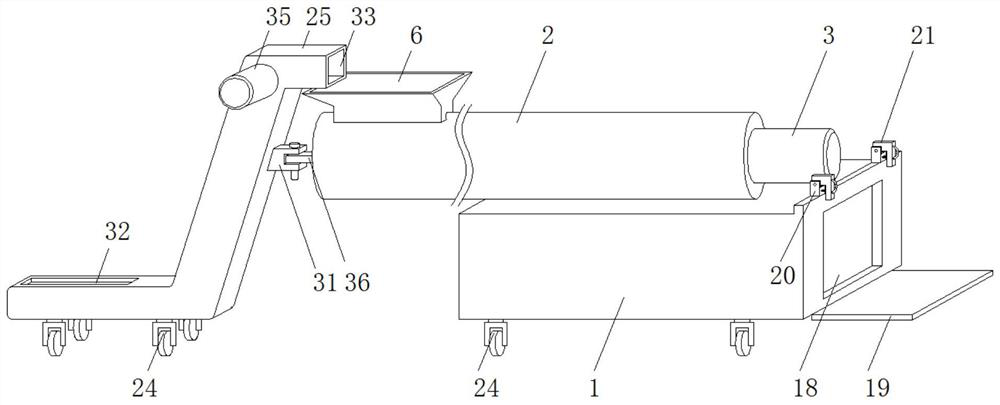

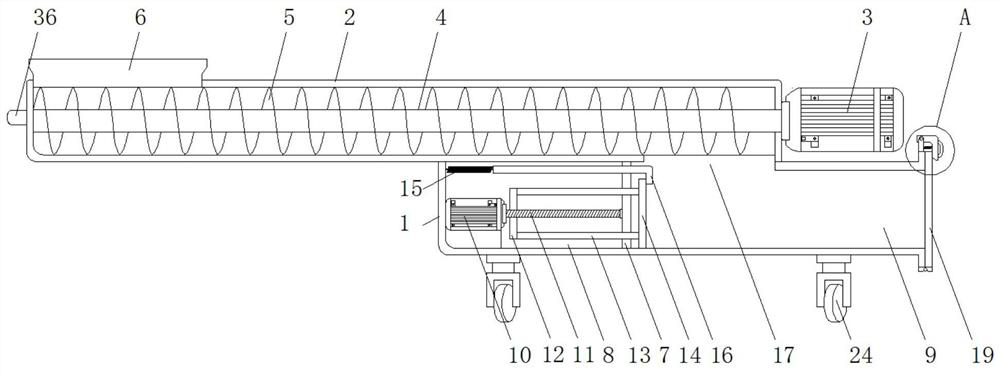

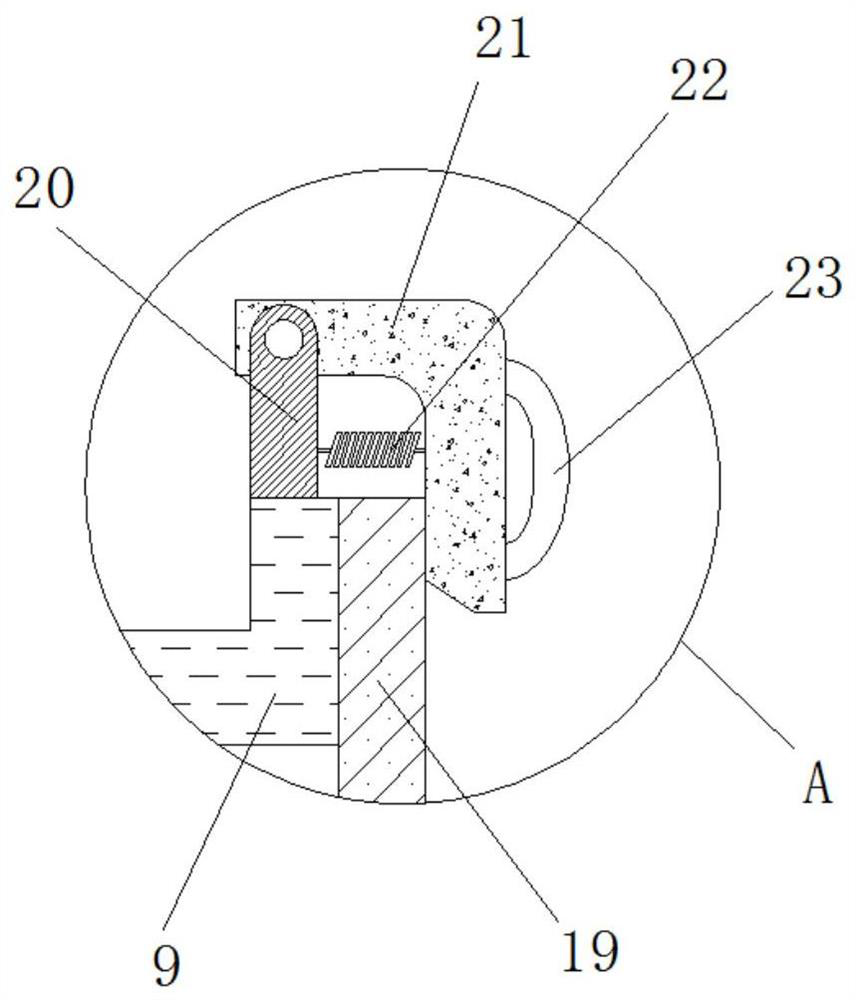

[0024] A debris cleaning device of the present invention, such as figure 1 , as shown in 2 and 4, including a base 1, the upper end surface of the base 1 is horizontally fixedly connected to the material guide cylinder 2, and the inside of the material guide cylinder 2 is fixedly connected with the feeding device, and one end of the material guide cylinder 2 is fixedly provided with the first motor 3, the second The output end of a motor 3 is connected to the feeding device; the outer wall of the end of the material guide cylinder 2 away from the first motor 3 is vertically opened with a first blanking opening 6, and the end of the material guide cylinder 2 close to the first motor 3 is joined to the base 1 There is a collecting port 17 vertically downward at the place; the inner wall of the base 1 is provided with a separating plate 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com