A marking number roll material feeding device

A technology of feeding device and marking number, which is applied in the direction of thin material processing, winding strip, transportation and packaging, etc., which can solve the problems of inaccurate transmission position, deviation, and unable to achieve stable transmission and operation of marked coil materials, etc. Achieve the effect of accurate transmission position and controllable transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

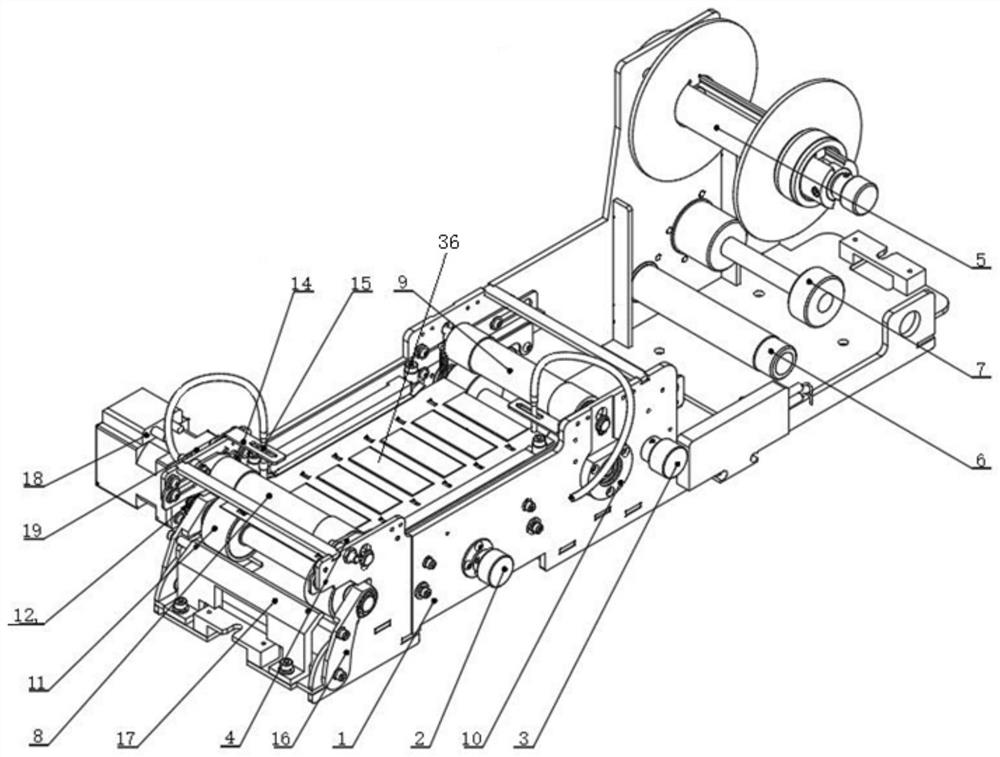

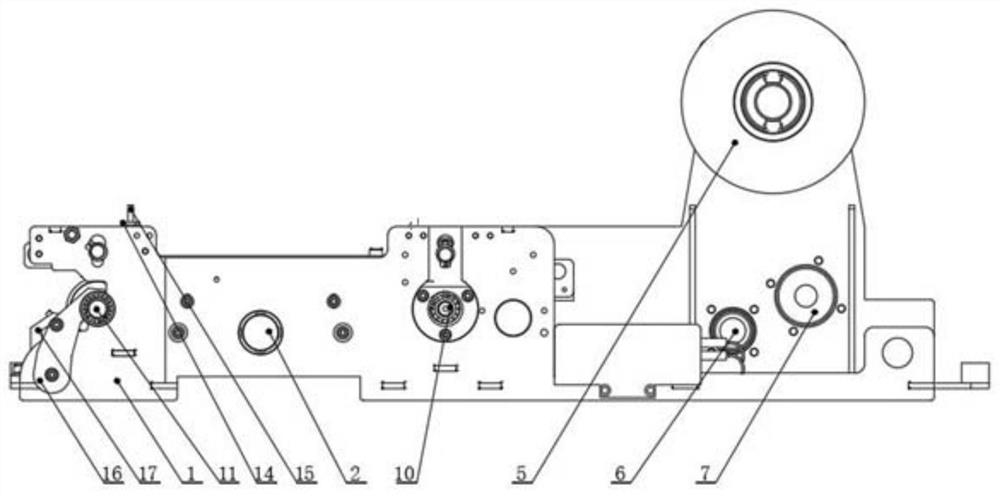

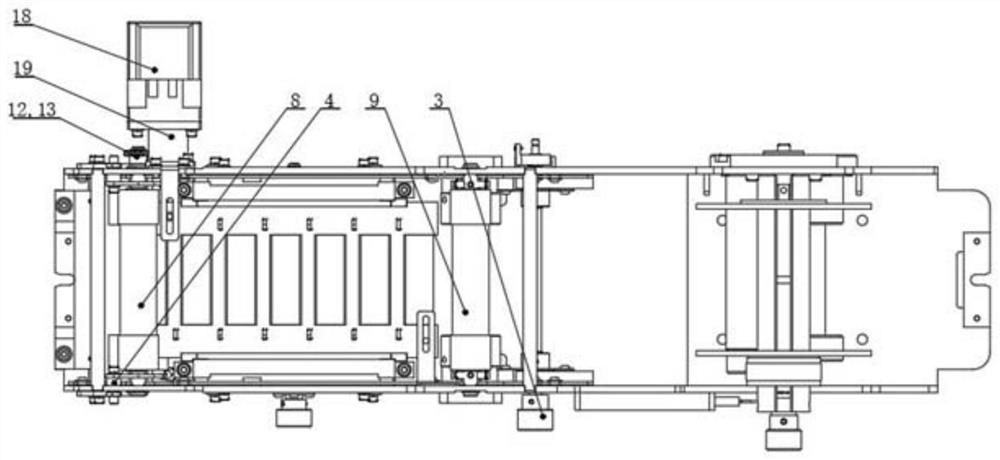

[0024] see figure 1 - Figure 9 , a kind of marking coil material feeding device of the present invention, comprises main frame 1, guide centering device 2, jacking mechanism 3, front roller pressing device 4, material coil main shaft 5, guide shaft 6, guide shaft C 7, Driving wheel shaft 8, driven wheel 9, driving wheel shaft C10, main drive shaft 11, drive shaft gear 12, feeding motor gear, lateral sensor fixing plate 14, positioning sensor 15, main shaft pressing device 16, moving plate pressing block 17, feeding Motor 18, motor base 19, wherein, the guide centering device 2 is installed under the marked number coil material, the guide centering device 2 is used for guide centering adjustment before the marker number coil material is transmitted, and the jacking mechanism 3 is installed on the machine In the middle of the frame, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com