Engine preignition endurance test method and device

A durability test, engine technology, applied in the direction of engine testing, measuring devices, machine/structural component testing, etc. The effect of engine assessment, improving reliability capability, and improving development process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

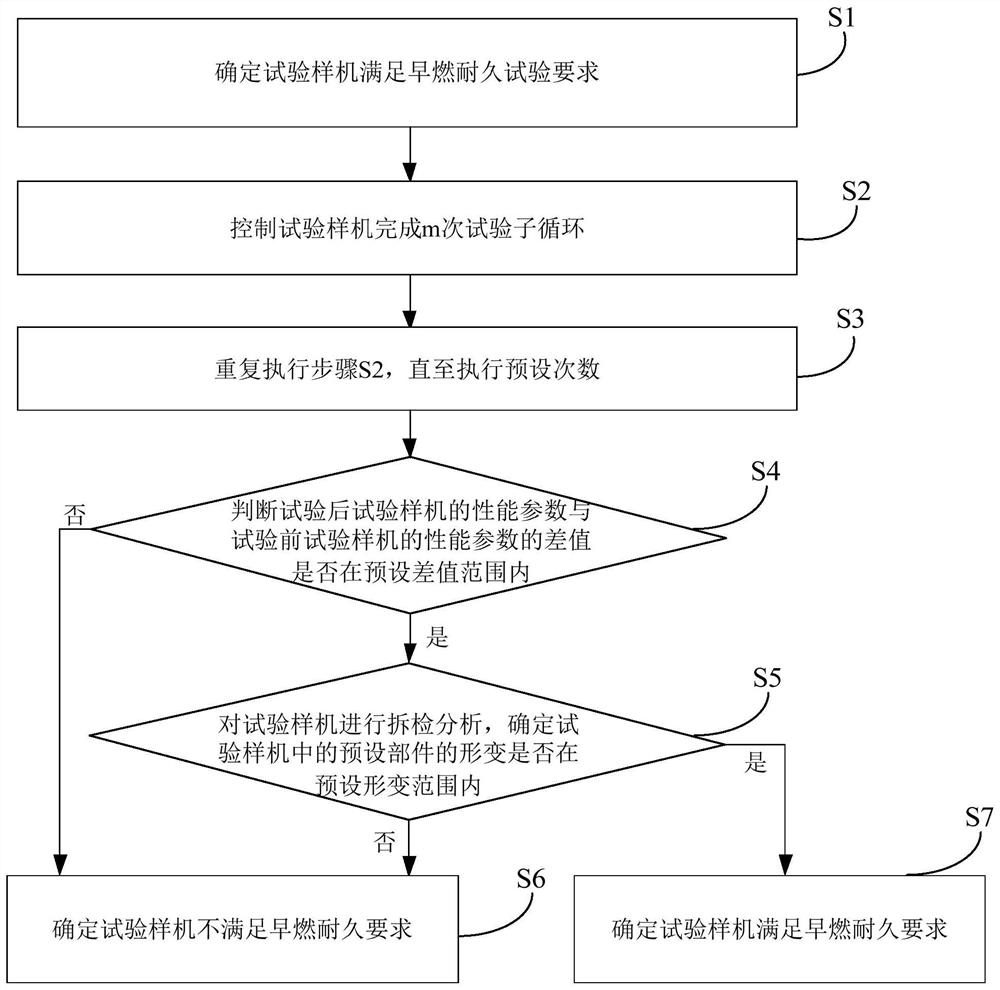

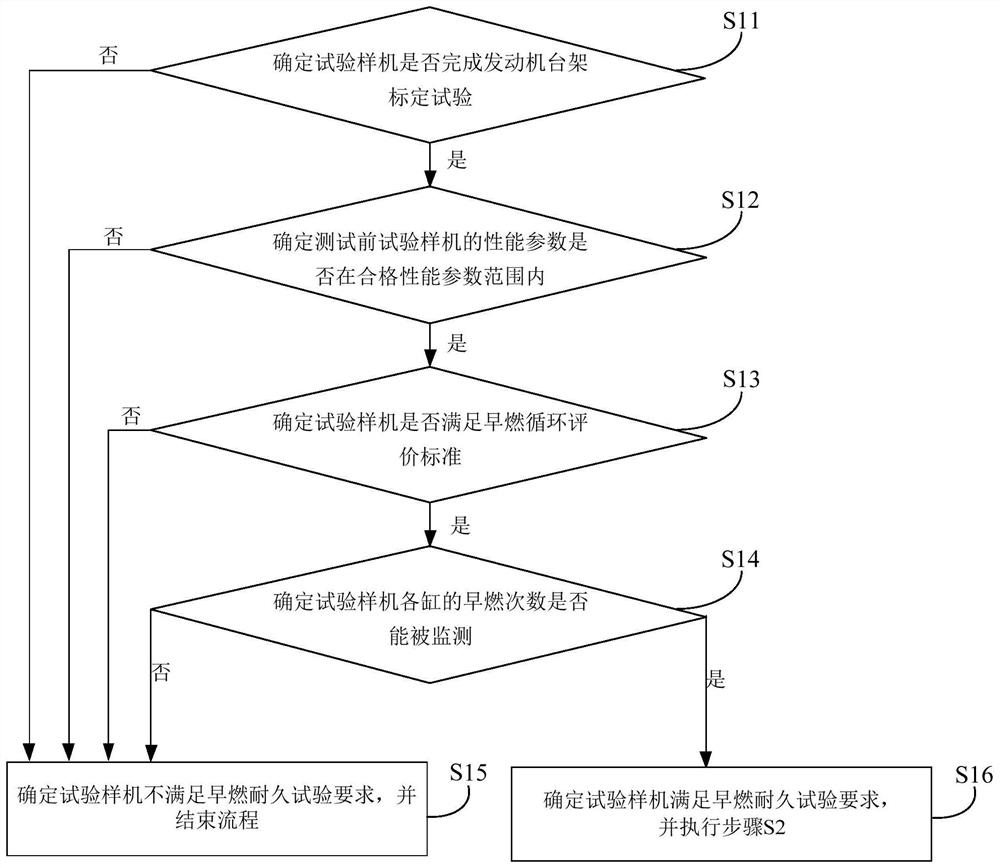

[0051] This embodiment provides an engine pre-ignition durability test method, which can determine whether the test prototype meets the pre-ignition durability requirements, and fills in the vacancy in the engine test about the pre-ignition durability test. Wherein, the engine may be a direct-injection supercharged gasoline engine.

[0052] Moreover, the engine pre-ignition durability test is carried out in the engine bench test room, and the test prototype (that is, the engine to be tested) needs to be normally connected to necessary equipment such as a dynamometer, a fuel consumption meter, a combustion analyzer, a water temperature control system, and a bench operating system. . Through the formulation of the engine pre-ignition durability test method, the ability of the engine to resist the pre-ignition problem can be effectively verified, so that the designer can rationally optimize the design scheme of the engine-related core components according to the test results in t...

Embodiment 2

[0099] This implementation also provides an engine pre-ignition durability test device, which is used to implement the engine pre-ignition durability test method in the above embodiment. The engine pre-ignition durability test device includes:

[0100] The first determination module is used to determine that the test prototype meets the requirements of the early ignition durability test.

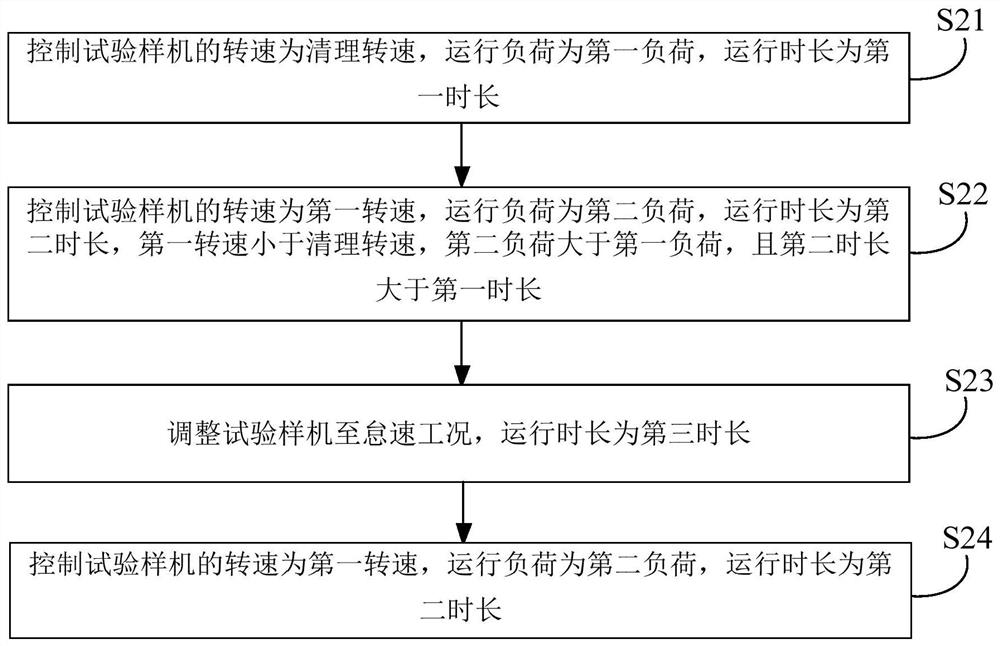

[0101] The control module is used to control the test prototype to complete m test sub-cycles. The test sub-cycle includes controlling the speed of the test prototype to be the cleaning speed, the operating load to be the first load, and the running time to be the first duration; controlling the speed of the test prototype to be the first Speed, the running load is the second load, the running time is the second time, the second load is greater than the first load, and the second time is longer than the first time; adjust the test prototype to the idling condition, and the running time is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com