Method for determining position and polishing amount of variable-pitch bearing soft belt of wind turbine generator

A technology for pitch bearings and wind turbines, applied in electrical digital data processing, computer-aided design, special data processing applications, etc., can solve complex forces, different deformation of pitch bearings, and unreasonable determination of the amount of soft belt grinding, etc. problems, to achieve reasonable and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

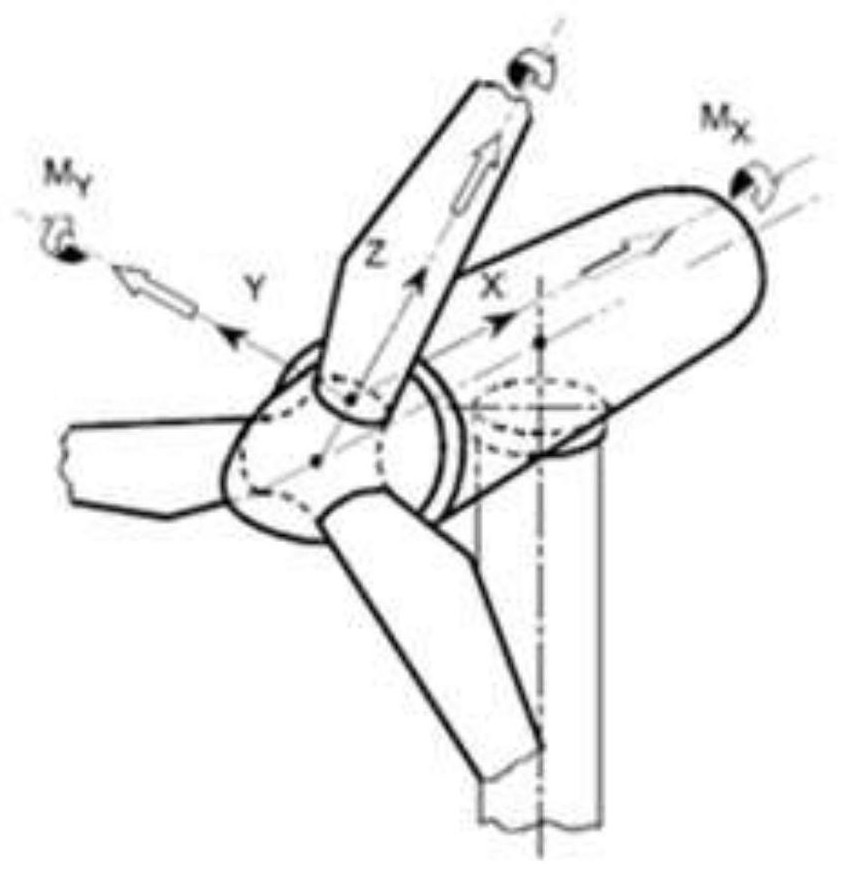

[0025] A method for determining the position and grinding amount of the soft belt of the pitch bearing of a wind turbine. The blade, the hub and the pitch bearing are connected by bolts to form a finite element model of the pitch bearing connection system. The center of the blade root is tied to the upper end surface of the blade prosthesis. Fixed, the blade root load is applied to the center of the blade root, constraining the z-direction freedom of the main shaft end face and the blade heel center point, while using rotational symmetry to constrain the 1 / 3 end face of the hub body.

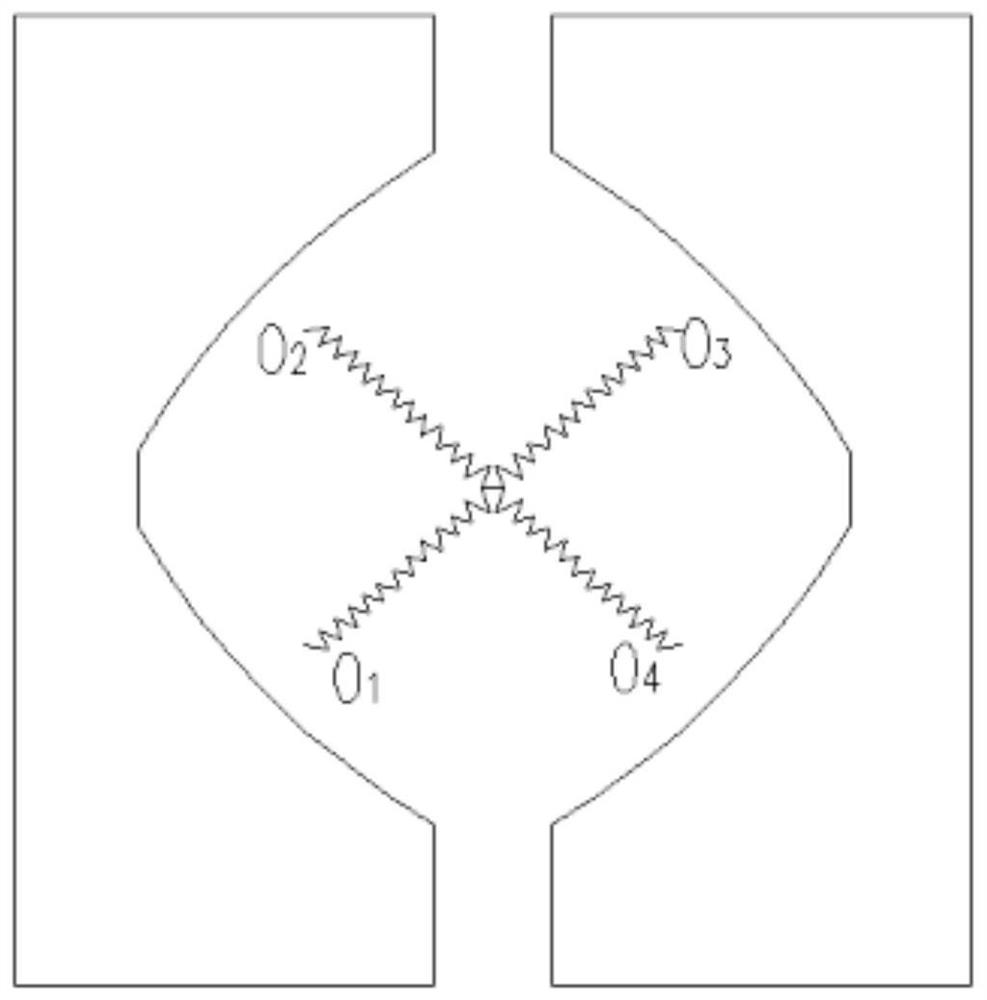

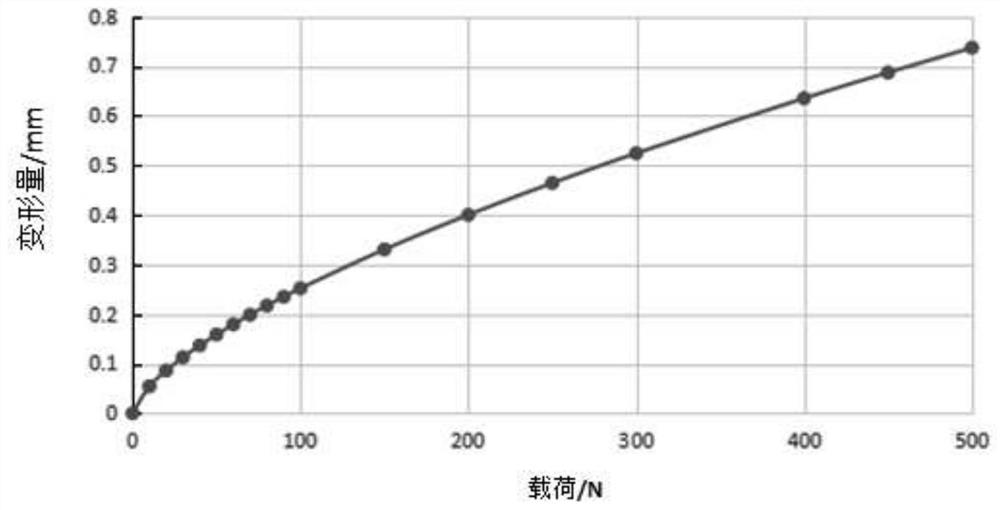

[0026] Using the finite element model analysis and calculation of the pitch bearing connection system, the deformation of the bearing under various load conditions is obtained. In this embodiment, a nonlinear spring unit is used to simulate the load-deformation relationship between the bearing ball and the raceway, as shown in figure 1 As shown, the four points O where the ball contacts the racew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com