Fault prediction method and system

A fault prediction and fault factor technology, which is applied in the direction of prediction, kernel method, neural learning method, etc., to achieve the effect of easy processing and reducing data complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

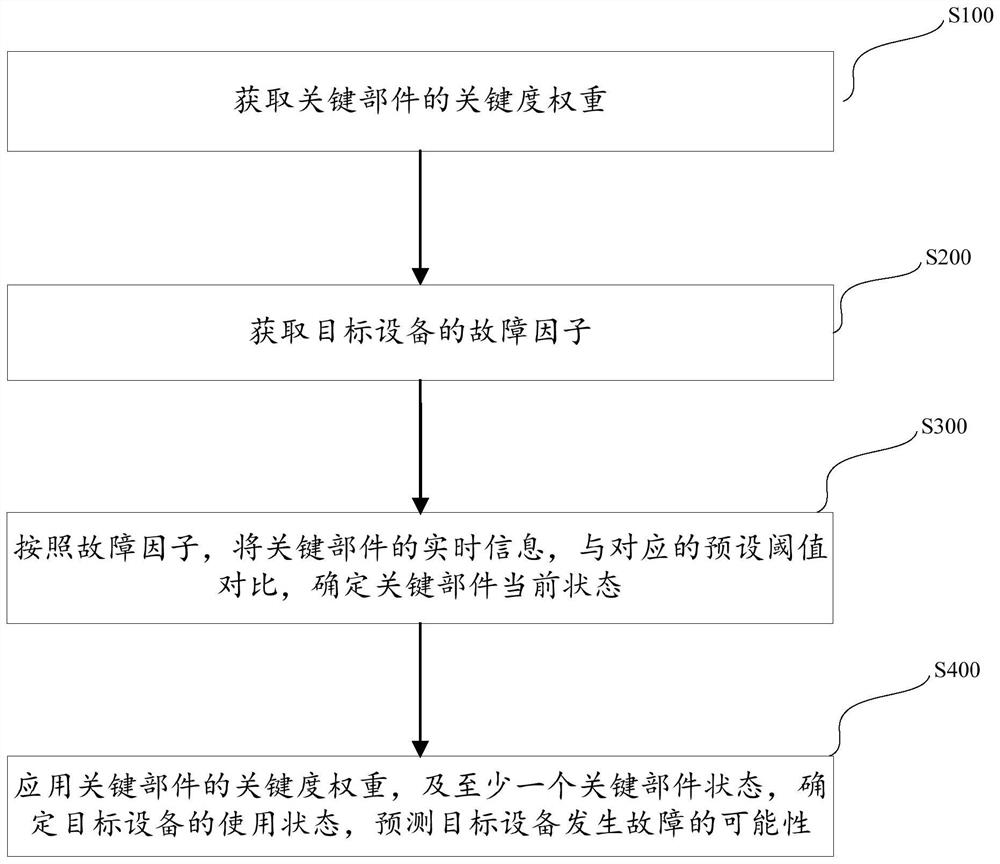

[0062] see figure 1 , figure 1 It is a flowchart of a fault prediction method in an embodiment of the present invention. The present invention provides a fault prediction method, which is applied to a target object, and the target object is equipped with at least one key component, and the method includes the following steps:

[0063] Step S100, obtaining the criticality weight of the key component; wherein, the criticality weight of the key component is used to determine the degree of influence of the key component on the target object;

[0064] Step S200, acquiring the failure factor of the target object; wherein, the key component corresponds to at least one failure factor of the target object;

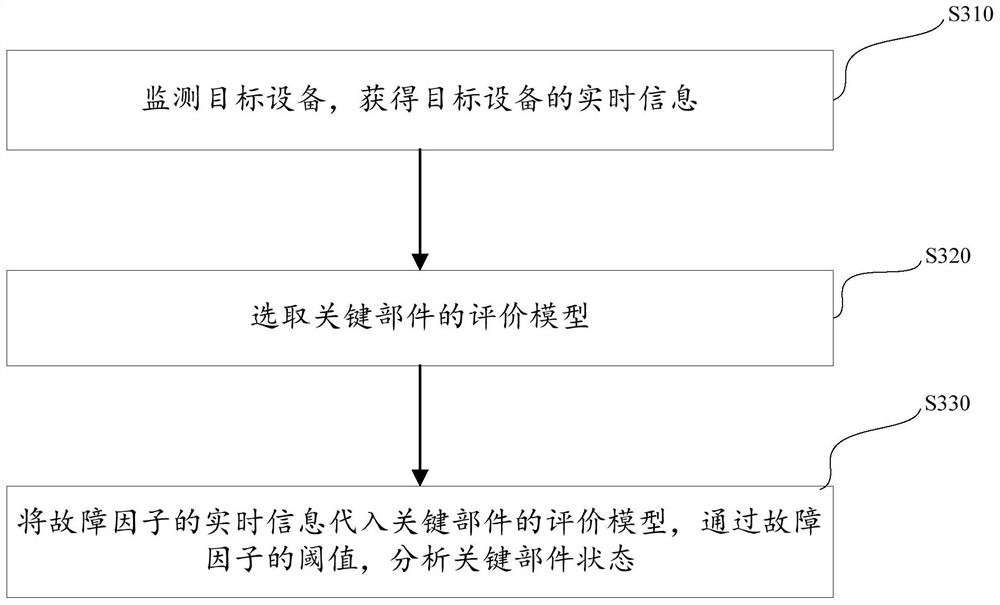

[0065] Step S300, according to the fail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com