An automatic installation mechanism for shaft opening retaining ring

An open retaining ring, automatic installation technology, applied in metal processing equipment, metal processing, manufacturing tools and other directions, can solve the problem of installation trouble, achieve the effect of convenient and fast installation and wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

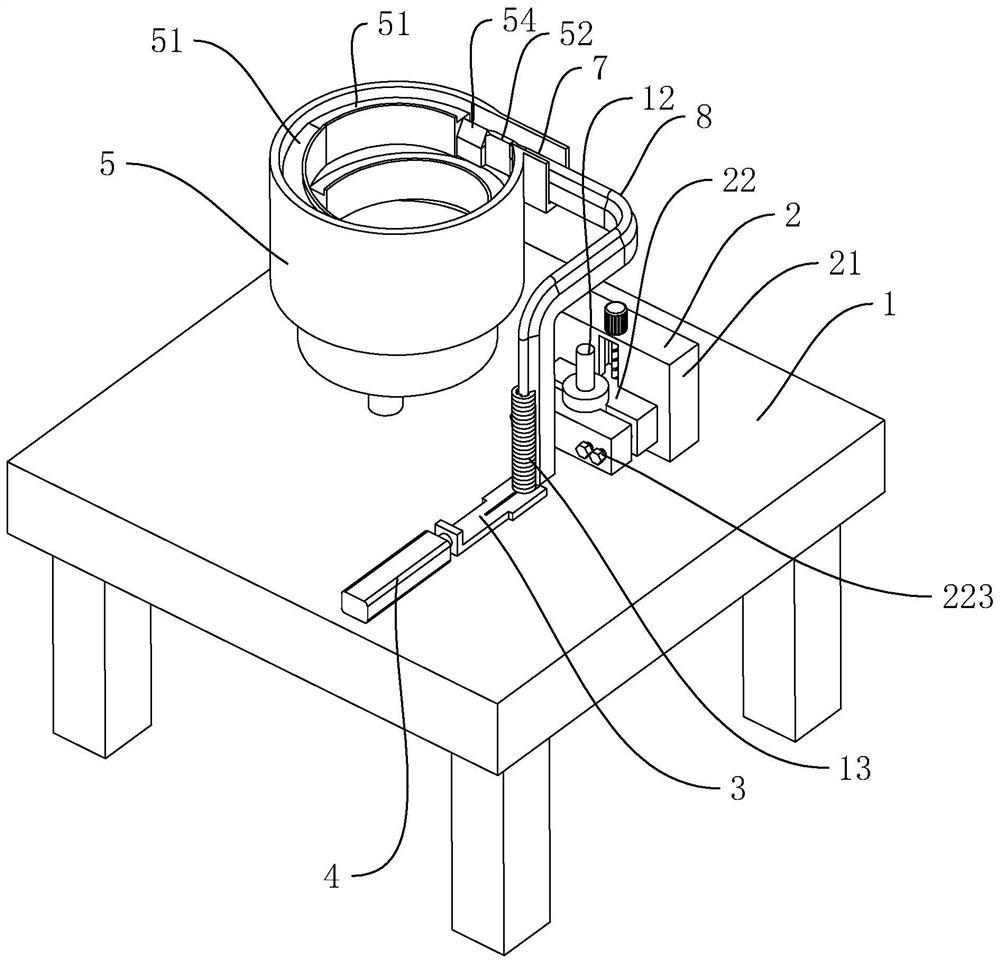

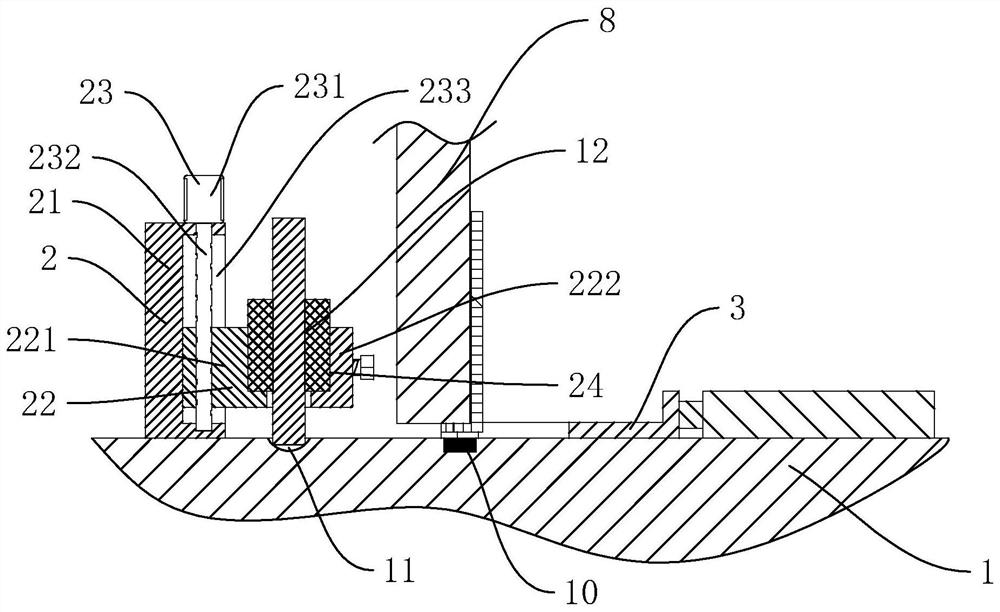

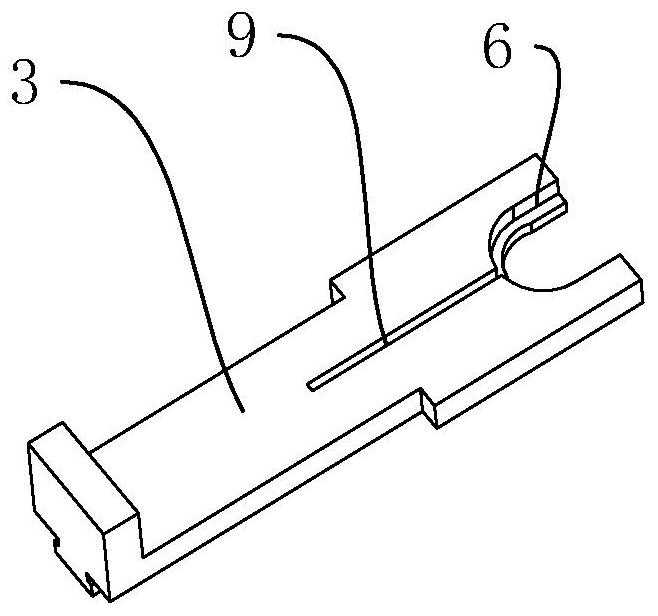

[0029] The following is attached Figure 1-6 The application is described in further detail.

[0030] The embodiment of the present application discloses an automatic installation mechanism for a shaft opening retaining ring. refer to figure 1 , the automatic installation mechanism for the shaft opening retaining ring includes a frame 1, a vibrating plate 5 installed on the frame 1, a rotor positioning seat 2, a press-fit push block 3 and a drive press-fit push block connected to the frame 1 by sliding 3. The driving part 4 that reciprocates back and forth is provided with a discharge port 7 on the vibrating plate 5, and a guide rail 8 connected with the discharge port 7 is also provided on the frame 1, and the other end of the guide rail 8 leads to a press-fit push block 3. The driving part 4 is a cylinder, which is connected to the air pump. The air pump provides the source for the cylinder. At the same time, the cylinder is also connected to a switch that controls its op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com